- DL manuals

- Bard

- Heat Pump

- QH242

- Installation instructions manual

Bard QH242 Installation instructions manual

Summary of QH242

Page 1

Bard manufacturing company bryan, ohio 43506 since 1914 . . . Moving ahead, just as planned. Manual: 2100-379 supersedes: file: vol ii tab 14 date: 12-01-00 © copyright 2000 models: qh242 qh302 qh362 qh422 qh482 qh602 qtec series packaged heat pump installation instructions mis-1554.

Page 2: Contents

Contents i getting other information and publications for more information, contact these publishers: .......... 1 qt ec general information qt ec model nomenclature .......................................... 2 shipping damage ......................................................... 6 unit removal ...

Page 3

Manual 2100-379 page 1 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. National ele...

Page 4: Series General Information

Manual 2100-379 page 2 table 1 factory built-in electric heat table s l e d o m a - 2 4 2 h q a - 2 0 3 h q b - 2 4 2 h q b - 2 0 3 h q c - 2 4 2 h q c - 2 0 3 h q a - 2 6 3 h q a - 2 2 4 h q a - 2 8 4 h q b - 2 6 3 h q b - 2 2 4 h q b - 2 8 4 h q c - 2 6 3 h q c - 2 2 4 h q c - 2 8 4 h q 1 - v 0 4 ...

Page 5

Manual 2100-379 page 3 electrical specifications continued on page 4 table 2a q r s t u maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. Based on 75° c copper wire. All wiring must conform to the national electrical code and all local codes....

Page 6

Manual 2100-379 page 4 table 2a electrical specifications (continued from page 3) maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. Based on 75° c copper wire. All wiring must conform to the national electrical code and all local codes. These...

Page 7

Manual 2100-379 page 5 figure 1 unit dimensions mis-1572.

Page 8: Warning

Manual 2100-379 page 6 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. The skid must remain attached to the unit until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immediately,...

Page 9: Warning

Manual 2100-379 page 7 handling unit after removal from skid the unit will have to be turned sideways and removed from the skid to fit through a 36” doorway. If the door height allows, the unit can be slid sideways through the door. If the unit can not be slid through the door, then the unit will ha...

Page 10

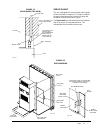

Manual 2100-379 page 8 figure 6 ducted application mis-1574 figure 5 installation with free blow plenum ceiling 8 ft. - 6 in. Minimum recommended ceiling height 8 ft. - 4 in. Floor mis-1573 suspended ceiling fixed ceiling duct duct flange 8 ft. - 7 in. Minimum recommended ceiling height 7 ft. - 2 in...

Page 11

Manual 2100-379 page 9 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design air flow requirement of the equipment. Air conditioning contractors of america (acca) is a...

Page 12

Manual 2100-379 page 10 fresh air intake this unit is equipped with a fresh air damper assembly. The damper blade is locked in the closed position when the unit is shipped from the factory. To allow the damper to operate remove the two plastic locking pins, one on each end of the blade. This will al...

Page 13

Manual 2100-379 page 11 mis-1061 service light the unit is equipped with a service light which signals the user that service is required. The light is located in the upper control panel and is visible only when the hinged service/filter access door is open. The service unit light indicates that the ...

Page 14: Installation Instructions

Manual 2100-379 page 12 installation instructions mounting the unit when installing a qt ec unit near an interior wall on the left side, a minimum of 8 inches is required; 12 inches is preferred. When installing a qt ec unit near an interior wall on the right side, a minimum of 18 inches is required...

Page 15

Manual 2100-379 page 13 the standard climate control option is a remote thermostat connection terminal block. See figure 17 for wiring diagram. Compatible thermostats are listed in table 4. The climate control option a is an electronic, non- programmable manual or auto changeover thermostat. The sub...

Page 16

Manual 2100-379 page 14 table 4 wall thermostats and subbase combinations t a t s o m r e h t e s a b b u s s e r u t a e f t n a n i m o d e r p 7 1 0 - 7 0 4 8 ) 9 2 1 1 r 4 7 8 t ( 9 0 0 - 4 0 4 8 ) 1 8 1 1 l 4 7 6 q ( l o o c r o t a e h o t u a o n 8 1 0 - 3 0 4 8 ) 4 2 0 2 n 4 7 8 t ( 0 1 0 - ...

Page 17

Manual 2100-379 page 15 figure 16 remote thermostat wiring diagram “x” thermostat option t8511 1f94-80 t874n1024 q674f1261 t874r1129 q674l1181 lvtb p2 mis-1284 24vac hot 1st stage heat (comp) check system light reversing valve 2nd stage heat emergency heat 24vac com 1st stage cool (comp or econ) blo...

Page 18

Manual 2100-379 page 16 figure 17 remote thermostat wiring diagram “a” thermostat option mis-1293 p2 p2 t8511.

Page 19

Manual 2100-379 page 17 figure 18 remote thermostat wiring diagram “d” thermostat option mis-1292 1f94-80 p2 p2.

Page 20: Start Up

Manual 2100-379 page 18 start up description of standard equipment solid state electronic heat pump control provides efficient 30 minute defrost cycle. A thermistor sensor and speed up terminal for service along with a 10 minute defrost override are standard on the electronic heat pump control. High...

Page 21

Manual 2100-379 page 19 all three phase scroll compressors used in the qt ec series are wired identically internally. As a result, once the correct phasing is determined for a specific system or installation, connecting properly phased power leads to the same fusite terminal should maintain proper r...

Page 22

Manual 2100-379 page 20 vent options barometric fresh air damper (standard) before starting, make sure the power has been turned off. The return air grille panel must be removed. The fresh air damper assembly can be seen on the back of the unit. See figure 19. 1. The fresh air damper is attached to ...

Page 23

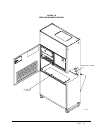

Manual 2100-379 page 21 figure 19 fresh air damper removal mis-1578 mounting screw blank off plate.

Page 24

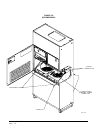

Manual 2100-379 page 22 figure 20 qerv removal mis-1039 mounting screws front fill lower blower assembly power connector power connectors.

Page 25

Manual 2100-379 page 23 optional climate controls sequence of operation the climate control option a is an electronic, non- programmable manual or auto changeover thermostat. The thermostat may be manually set to heat or cool mode. The thermostat will maintain the temperature set on the thermostat i...

Page 26

Manual 2100-379 page 24 if some abnormal or temporary condition such as a high wind causes the heat pump to have a prolonged defrost cycle, the heat pump control will restore the system to heating operation automatically after 10 minutes. There are three settings on the heat pump control – 30 minute...

Page 27: Troubleshooting

Manual 2100-379 page 25 troubleshooting table 5 troubleshooting n o t p m y s e s u a c e l b i s s o p k c e h c o t t a h w r i a p e r r o k c e h c o t w o h r o s s e r p m o c t o n s e o d r o t c a t n o c e z i g r e n e ) g n i t a e h r o g n il o o c ( g n i r i w t i u c r i c l o r t n...

Page 28

Manual 2100-379 page 26 checking temperature sensor 1. Disconnect temperature sensor from board and from outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance use sensor ambient temp...

Page 29

Manual 2100-379 page 27 fan blade setting dimensions any service work requiring removal or adjustment in the fan and/or motor area will require that the dimensions in table 7 be checked and blade adjusted in or out of the motor shaft accordingly. Note: these units are equipped with a variable speed ...

Page 30

Manual 2100-379 page 28 low side pressure ± 2 psig high side pressure ± 5 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the charge should be removed, system evacuated and recharged to serial plate ...

Page 31

Manual 2100-379 page 29 refer to notes following table 10 table 11 heating pressure (all temperatures in degrees f) l e d o m n r u t e r r i a . P m e t e r u s s e r p l i o c r o o d t u o g n i r e t n e e r u t a r e p m e t r i a 0 5 0 1 5 1 7 1 0 2 5 2 0 3 5 3 0 4 7 4 0 5 5 5 0 6 2 4 2 h q 0 ...

Page 32

Manual 2100-379 page 30 table 12 optional accessories : s e l l i r g r e v u o l r o o d t u o ) s l e d o m n o t 2 / 1 - 3 - 2 r o f ( 0 1 - g l q ) s l e d o m n o t 2 / 1 - 3 - 2 r o f ( 0 2 - g l q ) s l e d o m n o t 2 / 1 - 3 - 2 r o f ( 0 3 - g l q ) s l e d o m n o t 5 - 4 r o f ( 5 1 - g ...