- DL manuals

- Bard

- Heat pumps

- QW242

- Installation Instructions Manual

Bard QW242 Installation Instructions Manual

Manual

2100-532B

Page

1 of 46

QW SERIES

GEOTHERMAL R-410A

STAGED CAPACITY

PACKAGED HEAT PUMP

INSTALLATION

INSTRUCTIONS

Models:

QW2S1

QW3S1

QW4S1

QW5S1

Manual No.:

2100-532B

Supersedes:

2100-532A

File:

Vol II Tab 14

Date:

07-19-10

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

MIS-2736

Earth Loop Fluid

Temperatures 25 – 110

Ground Water Temperature 45 – 75

Summary of QW242

Page 1

Manual 2100-532b page 1 of 46 qw series geothermal r-410a staged capacity packaged heat pump installation instructions models: qw2s1 qw3s1 qw4s1 qw5s1 manual no.: 2100-532b supersedes: 2100-532a file: vol ii tab 14 date: 07-19-10 bard manufacturing company, inc. Bryan, ohio 43506 since 1914...Moving...

Page 2

Manual 2100-532b page 2 of 46 contents getting other information and publications for more information, contact these publishers: ...... 4 qw general information qw model nomenclature ........................................ 5 shipping damage .................................................... 7 un...

Page 3

Manual 2100-532b page 3 of 46 figures figure 1 unit dimensions ..................................... 6 figure 2 removal of unit from skid .................... 7 figure 3 proper handling of unit after removal from skid ................................................ 8 figure 4 installation of unit w...

Page 4

Manual 2100-532b page 4 of 46 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

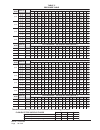

Page 6

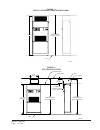

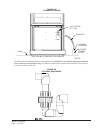

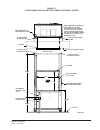

Manual 2100-532b page 6 of 46 figure 1 unit dimensions 36 1/16" 36 7/8" 68 3/4" unit dim. "a" dim. "b" dim. "c" dim. "d" qw2s, qw3s 8 5/8" 42 " 30 " 43 " qw4s, qw5s 8 3/4" 48 " 40 " 49 " mis-2737 b (optional) filter access door supply air thermostat return air co2 sensor grille grille (optional) doo...

Page 7

Manual 2100-532b page 7 of 46 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. The skid must remain attached to the unit until the unit is ready for installation. If damage is found, the receiving party must contact the last carrier immed...

Page 8

Manual 2100-532b page 8 of 46 removal of wall bracket from shipping location (units with blank off plate only) the wall brackets are attached to the back of the unit. Remove and retain the wall brackets for use when attaching the unit to the wall. In units equipped with a ventilator a wall sleeve is...

Page 9

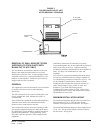

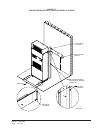

Manual 2100-532b page 9 of 46 mis-2739 a air divider eliminator 5" wall sleeve mist trim piece supply air rollers bottom return air circuit breaker, rotary, or toggle disconnect electrical access blow plenum box (top-side) and locking cover low voltage optional free electrical entrance (top-rear-sid...

Page 10

Manual 2100-532b page 10 of 46 figure 6 ducted application installation height 8 ft. - 9 in. Minimum required mis-2740 floor 8 ft. - 8 in. Installation height 9 ft. Minimum required unit height 7 ft. - 6 in. Minimum 25 in. To duct bottom 2 in. Minimum from duct flange installation height 8 ft. - 9 i...

Page 11

Manual 2100-532b page 11 of 46 duct work any heat pump is more critical of proper operating charge and an adequate duct system than a straight air conditioning unit. All duct work must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acc...

Page 12

Manual 2100-532b page 12 of 46 figure 8a condensate drain figure 8b optional rear drain the drain can be routed through the floor or through the wall. If the drain is to be routed through an unconditioned space, it must be protected from freezing. The drain line must be able to be removed from the u...

Page 13

Manual 2100-532b page 13 of 46 the rear drain can be used with wall thickness of up to 10 inches where a water trap can be installed between the unit and the interior wall. See figure 8b. The trap cannot extend beyond the edge of the unit or it will interfere with the wall mounting bracket. The drai...

Page 14

Manual 2100-532b page 14 of 46 q-tec energy recovery ventilator option before starting the removal make sure that the power has been turned off. The hinged return air grille panel must be opened. The energy recovery ventilator (qerv) can be seen after the panel is opened. To gain access to the mist ...

Page 15

Manual 2100-532b page 15 of 46 installation instructions mounting the unit when installing a qw unit near an interior wall on the left side, a minimum of 8 inches is required; 12 inches is preferred. When installing a qw unit near an interior wall on the right side, a minimum of 12 inches is require...

Page 16

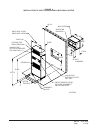

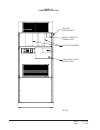

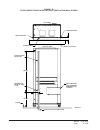

Manual 2100-532b page 16 of 46 figure 11 unit mounting without ventilation wall sleeve bracket wall mounting base trim side trim cut to length 41" adjustable side trim extension kit -ordered separately side trim extension mis-2744 a base trim extension.

Page 17

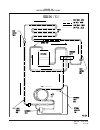

Manual 2100-532b page 17 of 46 figure 12 component location wire entrance side field terminal block remote thermostat indoor dual blowers control box/ circuit breaker panel mis-2745.

Page 18

Manual 2100-532b page 18 of 46 wiring – main power refer to the unit rating plate and/or table 2 for wire sizing information and maximum fuse or “hacr type” circuit breaker size. Each unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that ...

Page 19

Manual 2100-532b page 19 of 46 low voltage connections the “r” terminal is the 24 vac hot terminal and is supplied through pin #10 of plug p2. The “c” terminal is the 24 vac common/grounded terminal and feeds through pin #11 of plug p2. The “g” terminal is the indoor blower input signal and feeds th...

Page 20

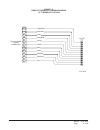

Manual 2100-532b page 20 of 46 10 6 5 4 3 2 1 1 2 3 4 5 6 7 8 9 11 12 blue pink purple purple/white yellow yellow w1/e l g l part #8403-056 4115-102 a co2 controller 24vac o/b out part #8403-060 c y2 a y1 r g analog controller terminal strip e w2 o c y2 a w2 y1 r temp. And humidity low voltage d/yo ...

Page 21

Manual 2100-532b page 21 of 46 figure 15 remote thermostat wiring diagram “d” thermostat option blue pink purple l o/b w1/e y1 part #8403-060 c y2 a w2 g r temp. And humidity controller d/yo orange yellow brown/white brown 9 8 11 10 plug #2 red/yellow red/white 1 2 3 4 5 6 7 12 black/white purple/wh...

Page 22

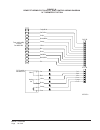

Manual 2100-532b page 22 of 46 10 6 5 4 3 2 1 1 2 3 4 5 6 7 8 9 11 12 blue pink purple yellow yellow r y1 o/b part #8403-056 24vac g w1/e l co2 controller out c y2 a w2 analog temp. And humidity controller part #8403-060 orange orange orange yellow green green brown brown brown/white brown red/white...

Page 23

Manual 2100-532b page 23 of 46 start up description of standard equipment low pressure switch note: this unit is supplied with two low pressure switches installed, a 45 psig and a 60 psig. The 60 psig is wired into the system. This switch is suitable for ground water (pump and dump), and water loop ...

Page 24

Manual 2100-532b page 24 of 46 optional cfm all models covered by this manual are factory set to operate at rated cfm levels as shown in table 4. Rated cfm is required for ducted applications for maximum performance ratings. For free blow applications where full load rated cfm is undesirable due to ...

Page 25

Manual 2100-532b page 25 of 46 1 maximum esp (inches wc) shown is with 2" merv 6 pleated filter. 2 rated cfm for ducted applications – required for maximum performance rating. To obtain full cfm on models qw3s1, qw4s1 and qw5s1, locate pink wire that is secured to purple wire at low voltage terminal...

Page 26

Manual 2100-532b page 26 of 46 figure 17 fluid connections on unit with ventilation wall sleeve 23 1/2" 33" 8 1/2" 66 1/2" to unit spec. Sheet for from ceiling side trim peices fluid access 8" to 14" exterior wall proper color (shipped with unit) ceiling side trim pieces (shipped with unit) if the w...

Page 27

Manual 2100-532b page 27 of 46 figure 18 fluid connections on unit without ventilation wall sleeve 23 1/2" 8 1/2" 66 1/2" 4" (left bracket removed for floor fluid access from floor fluid access from top clarity) wall bracket opening in rear of unit 3" x 8" back of unit mis-2747 water lines wall brac...

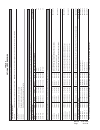

Page 28

Manual 2100-532b page 28 of 46 table 5 pressure table s 2 w q s 3 w q s 4 w q s 6 w q r e t a w h s e r f r o f m p g d e r i u q e r e t a r w o l f 5 6 7 9 l o n a h t e m % 5 1 r o f m p g d e r i u q e r e t a r w o l f 7 8 9 1 1 p o o l r e l i o b / r e w o t g n i l o o c , m p g d e r i u q ...

Page 29

Manual 2100-532b page 29 of 46 table 6 optional accessories s n oit p o n oit ali t n e v hti w n oit all at s ni h c a e r of d e s u e b t s u m – s ei r o s s e c c a l a n oit p o : s e v e el s ll a w n oit ali t n e v 2 4 s v w q. K ci ht s e h c ni 4 1 ot p u sll a w r of ev e el s ll a w n o...

Page 30

Manual 2100-532b page 30 of 46 circulation system design equipment room piping design is based on years of experience with earth coupled heat pump systems. The design eliminates most causes of system failure. Surprisingly, the heat pump itself is rarely the cause. Most problems occur because designe...

Page 31

Manual 2100-532b page 31 of 46 start up procedure for closed loop system 1. Be sure main power to the unit is off at disconnect. 2. Set thermostat system switch to off, fan switch to auto. 3. Move main power disconnect to on. Except as required for safety while servicing, do not open the unit discon...

Page 32

Manual 2100-532b page 32 of 46 0 10 20 30 40 50 60 70 0 5 10 15 20 25 30 35 flow (gpm) head (feet) figure 22 performance model dorfc-2 loop pump module 0 5 10 15 20 25 30 35 0 5 10 15 20 25 30 35 flow (gpm) head (feet) figure 21 performance model dorfc-1 loop pump module.

Page 33

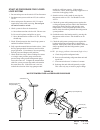

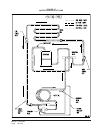

Manual 2100-532b page 33 of 46 6 10 11 8 9 12 7 mis-2749 open loop (well system applications) water connections it is very important that an adequate supply of clean, noncorrosive water at the proper pressure be provided before the installation is made. Insufficient water, in the heating mode for ex...

Page 34

Manual 2100-532b page 34 of 46 well pump sizing strictly speaking, sizing the well pump is the responsibility of the well drilling contractor. It is important, however, that the hvac contractor be familiar with the factors that determine what size pump will be required. Rule of thumb estimates will ...

Page 35

Manual 2100-532b page 35 of 46 water corrosion two concerns will immediately come to light when considering a water source heat pump, whether for ground water or for a closed loop application: will there be enough water? And, how will the water quality affect the system? Water quantity is an importa...

Page 36

Manual 2100-532b page 36 of 46 mis-2750 hose bib (a) hose bib (b) pump isolation valve to water coil from water coil lake and pond installations lakes and ponds can provide a low cost source of water for heating and cooling with a ground water heat pump. Direct usage of the water without some filtra...

Page 37

Manual 2100-532b page 37 of 46 figure 25 water well system 12' to 15' lake or pond w a ter level gra vel fill well cap electrical line pitless adapter t o pressure t ank submersible pump perfora ted plastic casing drop pipe w a ter suppl y line 15' to 20' deep.

Page 38

Manual 2100-532b page 38 of 46 for complete information on water well systems and lake and pond applications, refer to manual 2100-078 available from your distributor. Cooling tower / boiler application the cooling tower and boiler water loop temperature is usually maintained between 50°f to 100°f t...

Page 39

Manual 2100-532b page 39 of 46 figure 26 water source heat pump.

Page 40

Manual 2100-532b page 40 of 46 figure 27 water source heat pump.

Page 41

Manual 2100-532b page 41 of 46 service unbrazing system components if the refrigerant charge is removed from a scroll equipped unit by bleeding the high side only, it is sometimes possible for the scrolls to seal, preventing pressure equalization through the compressor. This may leave low side shell...

Page 42

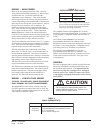

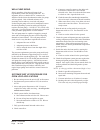

Manual 2100-532b page 42 of 46 troubleshooting ge ecm ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/proced...

Page 43

Manual 2100-532b page 43 of 46 troubleshooting ge ecm ™ motors cont’d. Motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts and alignment pin supplied whe...

Page 44

Manual 2100-532b page 44 of 46 heat gen. Power failure blown fuse or tripped breaker faulty wiring loose terminals low voltage defective contacts in contactor compressor overload potential relay run capacitor start capacitor faulty wiring loose terminals control transformer low voltage thermostat co...

Page 45

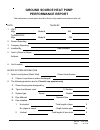

Manual 2100-532b page 45 of 46 ground source heat pump performance report this performance check report should be filled out by installer and retained with unit. Date: taken by: 1. Unit: mfgr model # s/n thermostat: mfgr model # p/n 2. Person reporting 3. Company reporting 4. Installed by date insta...

Page 46

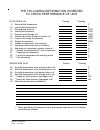

Manual 2100-532b page 46 of 46 the following information is needed to check performance of unit fluid side data cooling ** heating 9. Entering fluid temperature f 10. Leaving fluid temperature f 11. Entering fluid pressure psig 12. Leaving fluid pressure psig 13. Pressure drop through coil psig 14. ...