- DL manuals

- Bard

- Heat Pump

- SH611D

- Installation Instructions Manual

Bard SH611D Installation Instructions Manual

Summary of SH611D

Page 1

Installation instructions wall mounted package heat pumps model sh611d manual : 2100-414c supersedes: 2100-414b file: volume iii tab 17 date: 05-06-05 bard manufacturing company bryan, ohio 43506 since 1914...Moving ahead just as planned. © copyright 2004.

Page 2: Contents

Contents figures figure 1 unit dimensions .................................. 3 figure 2 fresh air damper assembly ................ 5 figure 3 mounting instructions .......................... 7 figure 4 electric heat clearance ....................... 8 figure 5 wall mounting instructions ...............

Page 3

Manual 2100-414c page 1 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. National el...

Page 4

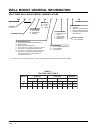

Manual 2100-414c page 2 wall mount general information heat pump wall mount model nomenclature table 1 electric heat table s l e d o m a d 1 1 6 h s b d 1 1 6 h s c d 1 1 6 h s 1 - 0 4 2 1 - 8 0 2 3 - 0 4 2 3 - 8 0 2 3 - 0 6 4 w k a u t b a u t b a u t b a u t b a u t b 9 7 . 1 2 0 0 6 0 3 7 . 8 1 0...

Page 5

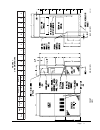

Manual 2100-414c page 3 mis-1261 figure 1 unit dimensions ti n u ht di w w ht p e d d t h gi e h h yl p p u sn r ut e r ef g i j k l m n o p q a bcb d 11 6 h s2 44 / 1- 2 28 / 7- 4 98 / 7- 98 / 7- 9 28 / 7- 5 18 / 7- 9 28 / 7- 3 49 18 / 5- 1 40 36 1/ 11 - 2 47 34 / 3- 4 42 / 1- 2 44 / 1- 33 48 / 7- ...

Page 6

Manual 2100-414c page 4 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. General the e...

Page 7

Manual 2100-414c page 5 figure 2 fresh air damper design the duct work according to methods given by the air conditioning contractors of america (acca). When duct runs through unheated spaces, it should be insulated with a minimum of one inch of insulation. Use insulation with a vapor barrier on the...

Page 8: Installation Instructions

Manual 2100-414c page 6 installation instructions wall mounting information 1. Two holes for the supply and return air openings must be cut through the wall as shown in figure 3. 2. On wood frame walls, the wall construction must be strong and rigid enough to carry the weight of the unit without tra...

Page 9

Manual 2100-414c page 7 figure 3 mounting instructions.

Page 10: Warning

Manual 2100-414c page 8 figure 4 electric heat clearance side section view of supply air duct for wall mounted unit showing 1/4 inch clearance to combustible surfaces. Warning a minimum of 1/4 inch clearance must be maintained between the supply air duct and combustible materials. This is required f...

Page 11

Manual 2100-414c page 9 figure 5 wall mounting instructions figure 6 wall mounting instructions mis-548 see figure 4 – mounting instructions see unit dimensions, figure 1, for actual dimensions.

Page 12

Manual 2100-414c page 10 figure 7 common wall mounting installations mis-550 free air flow no duct ducted supply return at unit false wall installation closet installation.

Page 13: Important

Manual 2100-414c page 11 wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse or “hacr” type circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount of cur...

Page 14

Manual 2100-414c page 12 important note: only the thermostat and subbase combinations as shown above and in table 4 will work with this equipment. The thermostat and subbase must be matched and the correct operation can be assured only by proper selection and application of these parts. Figure 8 shx...

Page 15

Manual 2100-414c page 13 figure 9 shxxxdx – hot gas reheat during dehumidification with programmable thermostat full time dehumidification important note: only the thermostat and subbase combinations as shown in table 4 will work with this equipment. The thermostat and subbase must be matched, and t...

Page 16

Manual 2100-414c page 14 compressor cut off thermostat and outdoor thermostats heat pump compressor operation at outdoor temperatures below 0° f are neither desirable nor advantageous in terms of efficiency. Since most equipment at time of manufacture is not designated for any specific destination o...

Page 17

Manual 2100-414c page 15 note: for total and proper control using ddc, a total of 7 controlled outputs are required (6 if no ventilation system is installed). For proper system operation under emergency heat conditions where the compressor needs to be deactivated, the b-w2-e outputs need to be energ...

Page 18: Start Up

Manual 2100-414c page 16 start up important installer note for improved start up performance wash the indoor coil with a dish washing detergent. Crankcase heaters sh611-b and -c are provided with compressor crankcase heat. All other models are not provided with crankcase heat. They are either single...

Page 19

Manual 2100-414c page 17 phase monitor all units with three phase compressors are equipped with a 3 phase line monitor to prevent compressor damage due to phase reversal. The phase monitor in this unit is equipped with two leds. If the y signal is present at the phase monitor and phases are correct,...

Page 20

Manual 2100-414c page 18 defrost cycle the defrost cycle is controlled by temperature and time on the solid state heat pump control. See figure 12. When the outdoor temperature is in the lower 40° f temperature range or colder, the outdoor coil temperature is 32° f or below. This coil temperature is...

Page 21: Troubleshooting

Manual 2100-414c page 19 troubleshooting solid state heat pump control troubleshooting procedure 1. Turn on ac power supply to indoor and outdoor units. 2. Turn thermostat blower switch to fan on. The indoor blower should start. (if it doesn’t, troubleshoot indoor unit and correct problem.) 3. Turn ...

Page 22

Manual 2100-414c page 20 checking temperature sensor outside unit circuit 1. Disconnect temperature sensor from board and from outdoor coil. 2. Use an ohmmeter and measure the resistance of the sensor. Also use ohmmeter to check for short or open. 3. Check resistance reading to chart of resistance u...

Page 23

Manual 2100-414c page 21 removal of fan shroud 1. Disconnect all power to the unit. 2. Remove the screws holding both grilles, one on each side of unit, and remove grilles. 3. Remove screws holding fan shroud to condenser and bottom. Nine (9) screws. 4. Unwire condenser fan motor. 5. Slide complete ...

Page 24

Manual 2100-414c page 22 low side pressure ± 2 psig high side pressure ± 5 psig tables are based upon rated cfm (airflow) across the evaporator coil. If there is any doubt as to correct operating charge being in the system, the charge should be removed, system evacuated and recharged to serial plate...

Page 25

Manual 2100-414c page 23 figure 14 bard heat pump cooling mode circuit diagram figure 15 bard heat pump dehumidification mode circuit diagram.