- DL manuals

- Bard

- Heat Pump

- T24H1

- Installation Instructions Manual

Bard T24H1 Installation Instructions Manual

Manual 2100-541D

Page

1 of 28

INSTALLATION INSTRUCTIONS

WALL MOUNTED

PACKAGE HEAT PUMPS

Standard & Dehumidification

MODELS

T24H1

T24H1D

T30H1

T30H1D

T36H1

T36H1D

T42H1

T42H1D

T48H1

T48H1D

T60H1

T60H1D

Manual: 2100-541D

Supersedes: 2100-541C

File:

Volume III Tab 17

Date: 03-28-14

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

Summary of T24H1

Page 1

Manual 2100-541d page 1 of 28 installation instructions wall mounted package heat pumps standard & dehumidification models t24h1 t24h1d t30h1 t30h1d t36h1 t36h1d t42h1 t42h1d t48h1 t48h1d t60h1 t60h1d manual: 2100-541d supersedes: 2100-541c file: volume iii tab 17 date: 03-28-14 bard manufacturing c...

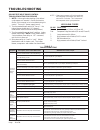

Page 2: Contents

Manual 2100-541d page 2 of 28 contents figures figure 1 fresh air damper assembly ..................... 5 figure 2 unit dimensions ....................................... 7 figure 3a mounting instructions t24 & 30 ............... 8 figure 3b mounting instructions t36, 42, 48 ............ 9 figure 4 ...

Page 3

Manual 2100-541d page 3 of 28 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

Manual 2100-541d page 4 of 28 wall mount general information heat pump wall mount model nomenclature t 36 h 1 – a 10 x x x x x x note: vent options x, b and m are without exhaust capability. May require separate field supplied barometric relief in building. Shipping damage upon receipt of equipment,...

Page 5

Manual 2100-541d page 5 of 28 duct work all duct work, supply and return, must be properly sized for the design airflow requirement of the equipment. Air conditioning contractors of america (acca) is an excellent guide to proper sizing. All duct work or portions thereof not in the conditioned space ...

Page 6: Warning

Manual 2100-541d page 6 of 28 clearances required for service access and adequate condenser airflow models left side right side t24h, t30h 15" 20" t36h, t42h, t48h, t60h 20" 20" minimum clearances required to combustible materials models supply air duct first three feet cabinet t24h, t30h 1/4" 0" t3...

Page 7

Manual 2100-541d page 7 of 28 panel door vent option filter access ventilation air front view 5.75 f w g condenser air outlet 1 1 mis-2729 a electrical low voltage entrance high voltage electrical entrance 4° pitch rain hood built in access panel (lockable) heater electric heat c. Breaker/ disconnec...

Page 8

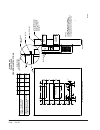

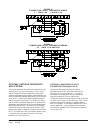

Manual 2100-541d page 8 of 28 figure 3a t24h1, t30h1 mounting instructions d 12" 12" 12" 12" 12" c c a 28" 1" 3" 4" ty p. 4 1 2 " b e 14" 1" 3 1 8 " 4" ty p. 5" 4 1 2 " 7 8 " re turn a ir su pp li ed re tu rn o pe nin g 16 7 /8 4 9/ 16 4 1/2 10 30 17 5 /8 3 13 /1 6 5 1/4 8 1/2 28 1 /2 e d c b a co m...

Page 9

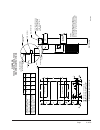

Manual 2100-541d page 9 of 28 figure 3b t36h1, t42h1, t48h1, t60h1 mounting instructions d 16" 16" 16" 16" 16" 1 7 8 " 6 1 2 " 6 1 2 " 2 1 8 " 7 8 " 1" 3" 4" ty p. 4" ty p. 6 1 2 " 30" e 16" a c c 3 1 8 " b w all opening and hole loc ation view re turn air 1 req ui re d di m en sio ns to m ai nt ain...

Page 10: Warning

Manual 2100-541d page 10 of 28 figure 4 electric heat clearance warning a minimum of 1/4 inch clearance must be maintained between the supply air duct and combustible materials. This is required for the first 3 feet of ducting. It is important to insure that the 1/4 inch minimum spacing is maintaine...

Page 11

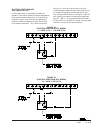

Manual 2100-541d page 11 of 28 figure 5 wall mounting instructions figure 6 wall mounting instructions duct opening return air supply air wood frame wall installation opening wall before mount on unit opening before installation bottom mounting concrete block wall installation bracket. Mount on open...

Page 12

Manual 2100-541d page 12 of 28 figure 7 common wall mounting installations lowered raised floor rafters supply air ceiling surface wall sleeve return air closet wall grille flashing return air flashing supply duct maybe located in an attic or below ceiling rafters as shown supply duct may be located...

Page 13

Manual 2100-541d page 13 of 28 wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse or “hacr” type circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount ...

Page 14

Manual 2100-541d page 14 of 28 optional outdoor thermostat applications since most equipment at the time of manufacture is not designated for any specific destination of the country and are installed in areas not approaching the lower outdoor temperature range, outdoor thermostats are not factory in...

Page 15

Manual 2100-541d page 15 of 28 electric heat hold-off (see figures 10 & 11) in other applications, it is desirable to disable the operation of the electric heat until outdoor temperatures have reached a certain design point. This won't allow the electric heat to come on as second stage heating unles...

Page 16: Start Up

Manual 2100-541d page 16 of 28 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 p...

Page 17

Manual 2100-541d page 17 of 28 start up (continued) important installer note for improved start up performance wash the indoor coil with a dish washing detergent. High & low pressure switch all t**h wall mounted air conditioner series models are supplied with a remote reset for the high and low pres...

Page 18

Manual 2100-541d page 18 of 28 sequence of operation cooling – circuit r-y makes at thermostat pulling in compressor contactor, starting the compressor and outdoor motor. The g (indoor motor) circuit is automatically completed on any call for cooling operation or can be energized by manual fan switc...

Page 19

Manual 2100-541d page 19 of 28 120* sw 1 sw 2 time (sec) off off on on off on off on 30 60 180 mis-2668 a off low pressure bypass timer switch *(factory setting 120 seconds) accumulated defrost time timer (factory setting 60 min.) on figure 12 defrost control board.

Page 20: Troubleshooting

Manual 2100-541d page 20 of 28 troubleshooting table 3 troubleshooting sympton description, check & possible causes what & how to check / repair compressor will not start (heating or cooling) 1. Check for led illumination. Is there an led illuminated on the board (flashing)? Yes = go to step #2; no ...

Page 21

Manual 2100-541d page 21 of 28 f r f r f r f r -25.0 196871 13.0 56985 53.0 19374 89.0 7507 -24.0 190099 14.0 55284 52.0 18867 90.0 7334 -23.0 183585 15.0 53640 53.0 18375 91.0 7165 -22.0 177318 16.0 52051 54.0 17989 92.0 7000 -21.0 171289 17.0 50514 55.0 17434 93.0 6840 -20.0 165487 18.0 49028 56.0...

Page 22: R-410A

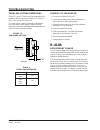

Manual 2100-541d page 22 of 28 troubleshooting figure 13 fan blade setting table 4 fan blade dimension removal of fan shroud 1. Disconnect all power to the unit. 2. Remove the screws holding both grilles, one on each side of unit, and remove grilles. 3. Remove screws holding fan shroud to condenser ...

Page 23

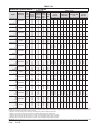

Manual 2100-541d page 23 of 28 model return air temperature pressure 75 80 85 90 95 100 105 110 115 120 t24h 75° db 62° wb low side high side 131 306 133 321 135 337 137 357 138 377 140 400 142 425 143 451 145 480 147 510 80° db 67° wb low side high side 140 314 142 329 144 346 146 366 148 387 150 4...

Page 24

Manual 2100-541d page 24 of 28 table 6a these “minimum circuit ampacity” values are to be used for sizing the field power conductors. Refer to the national electrical code (latest version), article 310 for power conductor sizing. Caution: when more than one field power circuit is run through one con...

Page 25

Manual 2100-541d page 25 of 28 electrical specifications — t**h series dehumidification table 6b these “minimum circuit ampacity” values are to be used for sizing the field power conductors. Refer to the national electrical code (latest version), article 310 for power conductor sizing. Caution: when...

Page 26

Manual 2100-541d page 26 of 28 table 7 t**h indoor blower performance - cfm (0.00" — 0.50" h 2 0) model rated esp max. Esp blower only except for crvmp vent options blower only for crvmp vent options cooling & heat pump electric heat t24h .10 .50 800 650 800 1000 t30h .10 .50 900 700 900 1000 t36h...

Page 27: Troubleshooting Ecm

Manual 2100-541d page 27 of 28 troubleshooting ecm ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/procedure...

Page 28: Troubleshooting Ecm

Manual 2100-541d page 28 of 28 manual 2100-522b page 36 of 38 troubleshooting ge ecm ™ motors cont’d. Motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts...