- DL manuals

- Bard

- Air Conditioner

- W12AAA

- Installation Instructions Manual

Bard W12AAA Installation Instructions Manual

Summary of W12AAA

Page 1

Page 1 of 21 wall mounted package air conditioners model: w12aaa installation instructions manual: 2100-618 supersedes: new file: tab 16 date: 06-04-14 bard manufacturing company, inc. Bryan, ohio 43506 since 1914....Moving ahead just as planned..

Page 2: Contents

Manual 2100-618 page 2 of 21 contents getting other informations and publications ......... 3 wall mount general information air conditioner wall mount model nomenclature ..... 4 shipping damage ..................................................... 6 general ............................................

Page 3

Manual 2100-618 page 3 of 21 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Nation...

Page 4

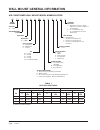

Manual 2100-618 page 4 of 21 table 1 electric heat table models kw w12aaaa w12aaak w12aaad 240v 208v 120v 240v 220v a j btu a j btu a j btu a j btu a j btu 02 18.3 7,985 03 15.0 12,760 13.0 9,705 15.0 12,760 13.8 10,735 05 20.8 17,540 18.1 13,275 j with blower watts included wall mount general infor...

Page 5

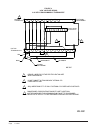

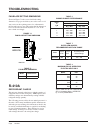

Manual 2100-618 page 5 of 21 figure 1 unit dimensions entrance low voltage entrance electrical built-in rain hood 2° pitch 21.88 1.50 48.00 14.63 access heater & filter ventilation air condenser airflow is blow thru 19.72 19.72 3.88 31.06 20.43 electrical entrance shipping location optional top rain...

Page 6

Manual 2100-618 page 6 of 21 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. General ...

Page 7

Manual 2100-618 page 7 of 21 duct work all duct work, supply and return must be properly sized for the design air flow requirement of the equipment. Air conditioning contractors of america (acca) is an excellent guide to proper sizing. All duct work or portions thereof not in the conditioned space s...

Page 8: Installation Instructions

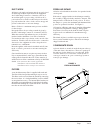

Manual 2100-618 page 8 of 21 installation instructions wall mounting information 1. These units are secured by wall mounting brackets which secure the unit to the outside wall surface at both sides. 2. On wood frame walls, the wall construction must be strong and rigid enough to carry the weight of ...

Page 9

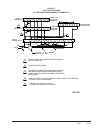

Manual 2100-618 page 9 of 21 figure 3 mounting instructions seal with bead of caulking along entire length of top. Top rain flashing supplied foam air seal wall wall structure mis-3600 flanges and under top flashing at time of installation. Supply air duct return air note: it is recommended that a b...

Page 10

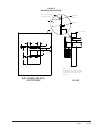

Manual 2100-618 page 10 of 21 figure 5 wall mounting instructions figure 4 wall mounting instructions see figure 3 - mounting instructions see unit dimensions, figure 1, for actual dimensions.

Page 11

Manual 2100-618 page 11 of 21 figure 6 common wall mounting installations.

Page 12

Manual 2100-618 page 12 of 21 wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse or “hacr” type circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount o...

Page 13

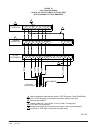

Manual 2100-618 page 13 of 21 low voltage connection these units use a 24-volt ac low voltage circuit. The “ r ” terminal is the hot terminal and the “ c ” terminal is grounded . “ g ” terminal is the fan input . “ y ” terminal is the compressor input for cooling 1-stage units only or 2-stage units ...

Page 14

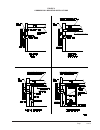

Manual 2100-618 page 14 of 21 yellow/red ac with programmable thermostat mis-3597 remove jumper for 2 stage electric heat on units with 15 or more kw do not connect "a" from 8403-060 if optional co2 controller is used add jumper from "g" to "e" only if optional co2 controller is installed change mod...

Page 15

Manual 2100-618 page 15 of 21 5 c rc r g y w o b crv r g y w1 w2 y1 y2 1 2 3 e f a c c rc r g y w w2 y2 1 2 3 4 5 6 1 2 3 4 mis-3598 optional vent package 3 1 unit 24v terminal block 2 stage cool 2 stage heat thermostat 1 stage cool 1 stage heat thermostat 8403-057 (th3110d1040) 8403-058 (th5220d115...

Page 16

Manual 2100-618 page 16 of 21 figure 10 low voltage wiring 1-stage a/c with optional electric heat with econwm style economizer pur ple bl ue ye llow /r ed bla ck red ye llow pi nk brown/white is 10v (100%). Depending upon application may require setting to lower value. W2 5 y2 c g r 1 2 y wiring ha...

Page 17: Start Up

Manual 2100-618 page 17 of 21 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 ps...

Page 18: Start Up

Manual 2100-618 page 18 of 21 start up important installer note for improved start up performance, wash the indoor coil with a dishwasher detergent. Service hints 1. Caution owner to maintain clean air filters at all times. Also not to needlessly close off supply and return air registers. This reduc...

Page 19

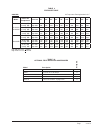

Manual 2100-618 page 19 of 21 adjustments adjustable delay on make and delay on break timer the potentiometer is used to select delay on break time from 30 seconds to 5 minutes. Delay of make (dom) timing on power up and after power interruptions is equal to 2 minutes plus 10% of delay of break (dob...

Page 20: Troubleshooting

Manual 2100-618 page 20 of 21 troubleshooting fan blade setting dimensions shown in figure 7 is the correct fan blade setting dimension for proper air delivery across the outdoor coil. Any service work requiring removal or adjustment in the fan and/or motor area will require that the dimension below...

Page 21

Manual 2100-618 page 21 of 21 table 9 pressure table cooling air temperature entering outdoor coil °f w12aaa table 10 optional field installed accessories model return air temperature pressure 75° 80° 85° 90° 95° 100° 105° 100° 115° 120° w12aaaa w12aaak 75 deg. Db 62 deg. Wb low side high side 125 2...