- DL manuals

- Bard

- Furnace

- W24G1-A

- Installation Instructions Manual

Bard W24G1-A Installation Instructions Manual

WG - SERIES

COMBINATION GAS/ELECTRIC

WALL-MOUNT

MODELS:

W24G1-A

W24G1-B

W24G1-C

W30G1-A

W30G1-B

W30G1-C

W36G1-A

W36G1-B

W36G1-C

W42G1-A

W42G1-B

W42G1-C

W48G1-A

W48G1-B

W48G1-C

W60G1-A

W60G1-B

W60G1-C

Manual No.:

2100-525

Supersedes:

NEW

File:

Volume III, Tab 20

Date:

02-24-10

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead just as planned.

© Copyright 2010

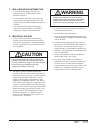

WARNING

READ ALL INSTRUCTIONS CAREFULLY BEFORE

BEGINNING THE INSTALLATION.

THE INSTALLATION MUST COMPLY WITH THESE

INSTRUCTIONS AND THE REQUIREMENTS OF ALL

GOVERNING CODES AND ORDINANCES FOR THE

INSTALLATION LOCATION.

IT IS THE RESPONSIBILITY OF INSTALLER TO KNOW

AND UNDERSTAND ALL OF THESE REQUIREMENTS.

FAILURE TO DO SO COULD CREATE A HAZARD

RESULTING IN PROPERTY DAMAGE, BODILY INJURY,

OR DEATH.

INSTALLATION

INSTRUCTIONS

Summary of W24G1-A

Page 1

Wg - series combination gas/electric wall-mount models: w24g1-a w24g1-b w24g1-c w30g1-a w30g1-b w30g1-c w36g1-a w36g1-b w36g1-c w42g1-a w42g1-b w42g1-c w48g1-a w48g1-b w48g1-c w60g1-a w60g1-b w60g1-c manual no.: 2100-525 supersedes: new file: volume iii, tab 20 date: 02-24-10 bard manufacturing comp...

Page 2

Manual 2100-525 page 2 of 73 contents getting other information and publications .............. 4 w**g series model nomenclature ............................ 5 ventilation options .................................................... 5 air conditioning module options ............................... 6...

Page 3

Manual 2100-525 page 3 of 73 contents figures figure 1 unit dimensions ..................................... 9 figure 2 mounting instructions – w24-36g ....... 12 figure 2a mounting instructions – w42-60g ....... 13 figure 3 combustible clearance – w24-36g .... 14 figure 3a combustible clearance – w...

Page 4

Manual 2100-525 page 4 of 73 getting other information and publications for more information, contact these publishers: acca air conditioning contractors of america 1712 new hampshire avenue, nw washington, dc 20009 telephone: (202) 483-9370 ansi american national standards institute 11 west street,...

Page 5

Manual 2100-525 page 5 of 73 w 42 g 1 – a x c x x x x x x wall mount gas/electric general model number nomenclature 1 low ambient control is required with economizer for low temperature compressor operation. Ventilation options s l e d o m g 6 3 w , g 0 3 w , g 4 2 w g 0 6 w , g 8 4 w , g 2 4 w n o ...

Page 6

Manual 2100-525 page 6 of 73 1. Important the equipment covered in this manual is to be installed by trained, experienced service and installation technicians. All duct work or portions thereof not in the conditioned space should be properly insulated in order to both conserve energy and prevent con...

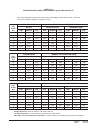

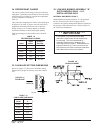

Page 7

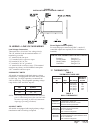

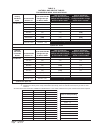

Manual 2100-525 page 7 of 73 table 1 specifications w24g, w30g and w36g models * 75 degree c copper wire size ** maximum time delay fuse or hacr type circuit breaker l e d o ma - 1 g 4 2 wb - 1 g 4 2 wc - 1 g 4 2 wa - 1 g 0 3 wb - 1 g 0 3 wc - 1 g 0 3 wa - 1 g 6 3 wb - 1 g 6 3 wc - 1 g 6 3 w z h 0 6...

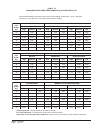

Page 8

Manual 2100-525 page 8 of 73 * 75 degree c copper wire size ** maximum time delay fuse or hacr type circuit breaker table 1a specifications w42g, w48g and w60g models l e d o ma - 1 g 2 4 wb - 1 g 2 4 wc - 1 g 2 4 wa - 1 g 8 4 wb - 1 g 8 4 wc - 1 g 8 4 wa - 1 g 0 6 wb - 1 g 0 6 wc - 1 g 0 6 w z h 0 ...

Page 9

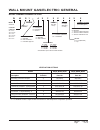

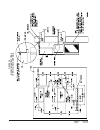

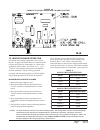

Manual 2100-525 page 9 of 73 f g n p d dd ff gg hh a m i c k j l h r s s s s s t v y aa x u z cc bb b ee o e w ii q b di s co nne ct a cce s s right side re t urn op e n in g en t r an c es pan el pan el ( lo c kabl e) pan el d o o r su ppl y o pen in g ba ck m is -2773 en t r an c es ga s co m b us...

Page 10

Manual 2100-525 page 10 of 73 see figure 3 and clearance information in section 9 and table 2 for additional information. Design the duct work according to methods given by the air conditioning contractors of america (acca). When duct runs through unheated spaces, it should be insulated with a minim...

Page 11

Manual 2100-525 page 11 of 73 7. Wall mounting information 1. Two holes for the supply and return air openings must be cut through the wall as detailed in figure 4. 2. On wood-frame walls, the wall construction must be strong and rigid enough to carry the weight of the unit without transmitting any ...

Page 12

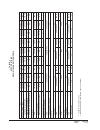

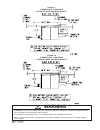

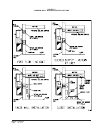

Manual 2100-525 page 12 of 73 figure 2 mounting instructions for w24g, w30g and w36g 39 3/16" 29 3/4" 4 11/16" 12" 12" 12" 12" 12" 12" 2" 2 1/4" 10" 28 5/16" 15" 27" 17 15/16" 11 5/16" 8 5/8" 2 15/16" 2 1/4" 30" 29" 5 1/16" 7/16" 5 9/16" 4 9/16" 4 1/2" 2 15/16" 18 15/16" 4 9/16" supply air duct retu...

Page 13

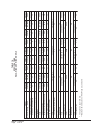

Manual 2100-525 page 13 of 73 figure 2a mounting instructions for w42g, w48g and w60g.

Page 14

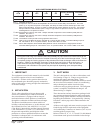

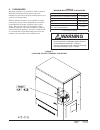

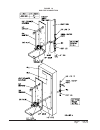

Manual 2100-525 page 14 of 73 figure 3 combustible clearance for w24g, w30g and w36g models figure 3a combustible clearance for w42g, w48g and w60g models warning a minimum of one (1) inch clearance must be maintained between the supply air duct and combustible materials. This is required for the fi...

Page 15

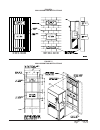

Manual 2100-525 page 15 of 73 figure 4 wall mounting instructions figure 5 wall mounting instructions.

Page 16

Manual 2100-525 page 16 of 73 figure 6 common wall mounting installations.

Page 17

Manual 2100-525 page 17 of 73 9. Clearances minimum clearances, as specified in table 2, must be maintained from adjacent structures to provide adequate fire protection, adequate combustion air, and room for service personnel. While minimum clearances are acceptable for safety reasons, they may not ...

Page 18

Manual 2100-525 page 18 of 73 10. Vent terminal and combustion air inlet hood the vent terminal is shipped in the burner compartment. See figure 7. Remove the two shipping screws and separate the two-piece assembly. Install the vent terminal by using the four screws provided. Do not cut or trim gask...

Page 19

Manual 2100-525 page 19 of 73 12. Vent resizing instructions when an existing furnace is removed from a venting system servicing other appliances, the venting system is likely to be too large to properly vent the remaining attached appliances. The following steps shall be followed with each of the a...

Page 20

Manual 2100-525 page 20 of 73 electrical grounding when installed, the furnace must be electrically grounded in accordance with local codes or in the absence of local codes, with the national electrical code, ansi/nfpa 70, or canadian electrical code, csa22.1, latest edition. Use a copper wire from ...

Page 21

Manual 2100-525 page 21 of 73 note: the voltage should be measured at the field power connection point in the unit and while the unit is operating at full load (maximum amperage operating condition). P a t e g n a r 0 4 2 6 0 2 – 3 5 2 8 0 2 7 8 1 – 0 2 2 17. Thermostats 16. Wiring – low voltage wir...

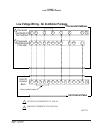

Page 22: Unit Control Panel

Manual 2100-525 page 22 of 73 r y2 y l y1 rc d/yo 3 2 w r a factory installed jumper terminal y1 b unit 24v c mis-2774 low voltage wiring - no ventilation package 1 g y unit control panel g block w1/e g w1 1 c a w2 e y2 o f c o/b r w2 thermostat subbase 2 1 2 set switch on thermostat to "gas-oil" co...

Page 23: Low Voltage Wiring -

Manual 2100-525 page 23 of 73 2 d/yo a low voltage wiring - r y1 w have occupancy output. Y g l w1/e black/white c w1 a factory installed 4 r terminal y1 part #8403-057 (th311dd1040) y2 1 thermostat unit control panel (1120-445) thermostat subbase jumper g rc vent package g part #8403-060 thermostat...

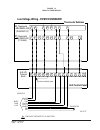

Page 24: Unit Control Panel

Manual 2100-525 page 24 of 73 c rc w2 terminal w1/e unit control panel y low voltage wiring - eifm economizer 1 y g l y1 unit 24v plug y2 r thermostat subbase factory installed jumper w2 o/b g red wires block r c w1 a w2 e y2 y1 from c 2 3 r purple a w g thermistor d/yo orange y2 wgseifm-5 red 1 bla...

Page 25

Manual 2100-525 page 25 of 73 figure 14 gas pipe connection w24g - w36g w42g - w60g.

Page 26

Manual 2100-525 page 26 of 73 18. Gas supply and piping general recommendations 1. Be sure the gas line complies with the local codes and ordinances, or in their absence with the national fuel gas code, ansi z223.1, or natural gas installation code, can/cga b149.1, or propane installation code b149....

Page 27

Manual 2100-525 page 27 of 73 19. Manifold pressure adjustment you will need a 0 to 15 inch water manometer with 0.1 inch resolution and a 1/8" npt manual shut off valve to measure actual manifold pressure. Depending on your local gas heating value and elevation, you may need to adjust manifold pres...

Page 28

Manual 2100-525 page 28 of 73 natural gas input rate natural gas heating value (btu/cu. Ft.) can vary significantly. Before starting natural gas input check, obtain gas heating value at your location from local supplier. You will need a stopwatch to measure actual gas input. 1. Gas supply pressure m...

Page 29

Manual 2100-525 page 29 of 73 21. Standard orifice sizing and high altitude derate this furnace is shipped with fixed gas orifices for use with natural gas and sized for 1000 btu/cubic foot gas. Make sure actual gas input does not exceed rating plate input. You may need to change orifices to get cor...

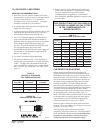

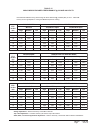

Page 30

Manual 2100-525 page 30 of 73 all other orifice sizes shown are available as individual items. See orifice charts below for part numbers and number required. Table 8 natural gas orifice tables for models w24g, w30g and w36g y r o t c a f d r a d n a t s t u p n i e u l a v * t a e h s a g . T f . U ...

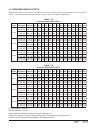

Page 31

Manual 2100-525 page 31 of 73 all other orifice sizes shown are available as individual items. See orifice charts on page 28 for part numbers and number required. Table 8a natural gas orifice tables for models w42g, w48g and w60g y r o t c a f d r a d n a t s t u p n i * t a e h s a g e u l a v . T ...

Page 32

Manual 2100-525 page 32 of 73 23. Measuring air temperature rise air temperature rise (supply air temperature minus return air temperature) must be within allowable air temperature rise range specified on furnace rating plate. You will need 2 thermometers with 1 degree resolution capable of reading ...

Page 33

Manual 2100-525 page 33 of 73 24. Filters a 2" thick throwaway filter is supplied with each unit. This filter is installed by opening the main service door. (see figure 16.) replacement filters are available through your dealer. 25. Compressor control module the compressor control is an anti-short c...

Page 34

Manual 2100-525 page 34 of 73 alarm output alarm terminal is output connection for applications where alarm signal is desired. This terminal is powered whenever compressor is locked out due to hpc or lpc sequences as described. Note: both high and low pressure switch controls are inherently automati...

Page 35

Manual 2100-525 page 35 of 73 26. Lighting and shutdown instructions figure 17 instruction label.

Page 36

Manual 2100-525 page 36 of 73 27. Service agency procedures main burner observe the main burners in operation. The flame should be mostly “blue” with possibly a little orange (not yellow) at the tips of the flame. The flames should be in the center of the heat exchanger tubes and not impinging on th...

Page 37

Manual 2100-525 page 37 of 73 routine maintenance 1. Air filters – check the condition at least monthly when the unit is in use, and replace as necessary. 2. Lubrication requirements – the indoor circulating air blower motor and outdoor circulating air fan motor are permanently lubricated and requir...

Page 38

Manual 2100-525 page 38 of 73 30. Sequence of operation – heating on a call for heat from the thermostat, the induced draft blower is energized. Once sufficient draft is established, the pressure switch contacts close and the ignition system is energized. The direct spark ignitor will be energized a...

Page 39

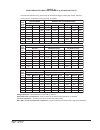

Manual 2100-525 page 39 of 73 32. Indoor blower operation all models have multiple speed direct drive blower motors. If supply and return ducts are connected to the unit, the ducts must be of adequate size. Refer to the appropriate blower tables. See tables 10, 11, 12, 13, 14 and 15 for maximum stat...

Page 40

Manual 2100-525 page 40 of 73 table 10 w24g indoor blower performance @ 230 and 460 volts recommended w24g cooling airflow range at rated 800 cfm @ 0.15 esp (wc) is 680 - 920 cfm factory set on low speed for cooling and high for heating. Voltage adjustment – reduce airflow by 100 cfm for 208 volt de...

Page 41

Manual 2100-525 page 41 of 73 table 11 w30g indoor blower performance @ 230 and 460 volts recommended w30g cooling airflow range at rated 1000 cfm @ 0.35 esp (wc) is 820 - 1150 cfm factory set on medium speed for cooling and for heating. Voltage adjustment – reduce airflow by 100 cfm for 208 volt de...

Page 42

Manual 2100-525 page 42 of 73 table 12 w36g indoor blower performance @ 230 and 460 volts recommended w36g cooling airflow range at rated 1100 cfm @ 0.250 esp (wc) is 935 - 1265 cfm factory set on medium speed for cooling and for heating. Voltage adjustment – reduce airflow by 100 cfm for 208 volt d...

Page 43

Manual 2100-525 page 43 of 73 table 13 w42g indoor blower performance @ 230 and 460 volts recommended w42g cooling airflow range at rated 1300 cfm @ .35 esp (wc) is 1500 - 1030 cfm factory set on medium speed for heating and cooling voltage adjustment – reduce airflow by 130 cfm for 208 volt top out...

Page 44

Manual 2100-525 page 44 of 73 table 14 w48g indoor blower performance @ 230 and 460 volts recommended w48g cooling airflow range at rated 1550 cfm @ .38 esp (wc) is 1750 - 1280 cfm factory set on high speed for cooling and medium speed for heating. Voltage adjustment – reduce airflow by 130 cfm for ...

Page 45

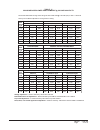

Manual 2100-525 page 45 of 73 table 15 w60g indoor blower performance @ 230 and 460 volts recommended w60g cooling airflow range at rated 1650 cfm @ .30 esp (wc) is 1910 - 1340 cfm factory set on high speed for cooling and medium speed for heating. Voltage adjustment – reduce airflow by 130 cfm for ...

Page 46

Manual 2100-525 page 46 of 73 table 16 integrated furnace and blower control operation l o r t n o c e c n e u q e s n o i t i n g i e c r u o s n o i t i n g i i s d c a v 4 2 g n i s n e s e m a l f e t o m e r s g n i m i t - - - - - - - - - - - - - - e g r u p e r p e g r u p t s o p e g r u p l...

Page 47

Manual 2100-525 page 47 of 73 33. Pressure service ports high and low pressure service ports are installed on all units so that the system operating pressures can be observed. Tables 17a & 17b outlines expected pressures at various indoor and outdoor temperatures. Table 17a cooling pressure table ta...

Page 48

Manual 2100-525 page 48 of 73 "a" airflow mis-1724 34. Refrigerant charge the correct system r-410a charge is shown on the unit rating plate. Optimum unit performance will occur with a refrigerant charge resulting in a suction line temperature (6" from compressor) as shown in table 18. The suction l...

Page 49

Manual 2100-525 page 49 of 73 index wiring diagrams and ladder diagrams t i n u . O n l e d o m c i s a b m a r g a i d g n i r i w l a u n a m . O n e g a p c i s a b m a r g a i d r e d d a l l a u n a m . O n e g a p a - 1 g 4 2 w a 4 4 1 - 5 8 0 4 0 5 5 4 1 - 5 8 0 4 1 5 b - 1 g 4 2 w a 4 4 2 - ...

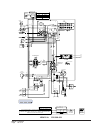

Page 50

Manual 2100-525 page 50 of 73 w24g1-a 230/208-60-1 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange pink pink l2 l1 bl u e blue blue 1 2 3 4 5 6 8 9 7 12 10 bl u e 11 bl u e a bl u e purple purple no c mv mv y e llo w /r e d yellow yellow y e llo w yellow yellow a y e llo w brown brown l2...

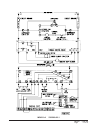

Page 51

Manual 2100-525 page 51 of 73 w24g1-a 230/208-60-1.

Page 52

Manual 2100-525 page 52 of 73 w24g1-b 230/208-60-3 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange 37 32 35 valve gas 32 27 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch t3 t1 t2 bard mfg. Co. Bryan, ohio 4085-244 a low voltage high...

Page 53

Manual 2100-525 page 53 of 73 w24g1-b 230/208-60-3.

Page 54

Manual 2100-525 page 54 of 73 w24g1-c 460-60-3 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange l1 or a n g e 55 55 valve gas 53 32 27 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch t3 t1 t2 bard mfg. Co. Bryan, ohio 4085-365 a low vo...

Page 55

Manual 2100-525 page 55 of 73 w24g1-c 460-60-3.

Page 56

Manual 2100-525 page 56 of 73 w30g1-a, w36g1-a 230/208-60-1 32 orange lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 35 pressure 36 switch 35 valve gas 32 32 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary s r c bard mfg. Co. Bryan, ohio 4085-146 a l...

Page 57

Manual 2100-525 page 57 of 73 w30g1-a, w36g1-a 230/208-60-1.

Page 58

Manual 2100-525 page 58 of 73 w30g1-b, w36g1-b 230/208-60-3 32 orange lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 pink pink l1 blue blue 1 2 3 4 5 6 8 9 7 12 10 11 bl u e bl u e l2 bl u e a l3 a bl u e purple purple no c mv mv yellow y e llo w yellow yellow y e llo w yellow yellow/black yellow...

Page 59

Manual 2100-525 page 59 of 73 w30g1-b, w36g1-b 230/208-60-3.

Page 60

Manual 2100-525 page 60 of 73 w30g1-c, w36g1-c 460-60-3 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange l1 or a n g e re d 25 54 valve gas 56 32 27 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch t3 t1 t2 bard mfg. Co. Bryan, ohio 408...

Page 61

Manual 2100-525 page 61 of 73 w30g1-c, w36g1-c 460-60-3.

Page 62

Manual 2100-525 page 62 of 73 w42g1-a 230/208-60-1 32 orange lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 35 pressure 36 switch 35 valve gas 32 32 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary s r c bard mfg. Co. Bryan, ohio 4085-146 a low voltag...

Page 63

Manual 2100-525 page 63 of 73 w42g1-a 230/208-60-1.

Page 64

Manual 2100-525 page 64 of 73 w42g1-b 230/208-60-3 32 orange lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 pink pink l1 blue blue 1 2 3 4 5 6 8 9 7 12 10 11 bl u e bl u e l2 bl u e a l3 a bl u e purple purple no c mv mv yellow y e llo w yellow yellow y e llo w yellow yellow/black yellow/red yell...

Page 65

Manual 2100-525 page 65 of 73 w42g1-b 230/208-60-3.

Page 66

Manual 2100-525 page 66 of 73 w42g1-c 460-60-3 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange l1 or a n g e re d 25 54 valve gas 56 32 27 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch t3 t1 t2 bard mfg. Co. Bryan, ohio 4085-367 a l...

Page 67

Manual 2100-525 page 67 of 73 w42g1-c 460-60-3.

Page 68

Manual 2100-525 page 68 of 73 w48g1-a, w60g1-a 230/208-60-1 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange 38 39 38 42 43 red 39 black 35 37 35 valve gas 32 32 37 35 32 32 32 32 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch s r c bard mfg. Co. Bryan...

Page 69

Manual 2100-525 page 69 of 73 w48g1-a, w60g1-a 230/208-60-1.

Page 70

Manual 2100-525 page 70 of 73 w48g1-b, w60g1-b 230/208-60-3 32 orange lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 37 35 valve gas 32 27 37 35 32 32 32 32 35 limit flame limit primary 59 rollout spark ignitor 32 flame sensor secondary switch t3 t1 t2 bard mfg. Co. Bryan, ohio 4085-248 a low vol...

Page 71

Manual 2100-525 page 71 of 73 w48g1-b, w60g1-b 230/208-60-3.

Page 72

Manual 2100-525 page 72 of 73 w48g1-c, w60g1-c 460-60-3 lp c cc hp c y al r c lp c m inut e s 4 2 3 5 r 1 32 orange pink pi n k blue blue 1 2 3 4 5 6 8 9 7 12 10 11 l3 bl u e bl u e l2 a a bl u e purple purple purple c mv no mv p urp le bl ac k yellow y e llo w yellow yellow/black yellow/red yellow ...

Page 73

Manual 2100-525 page 73 of 73 w48g1-c, w60g1-c 460-60-3.