- DL manuals

- Bard

- Air Conditioner

- W38A1

- Installation Instructions Manual

Bard W38A1 Installation Instructions Manual

Summary of W38A1

Page 1

Manual 2100-530a page 1 of 22 installation instructions wall mounted package air conditioners models w38a1 w49a1 w61a1 manual : 2100-530a supersedes: 2100-530 file: volume iii tab 16 date: 12-15-11 bard manufacturing company, inc. Bryan, ohio 43506 since 1914...Moving ahead just as planned..

Page 2

Manual 2100-530a page 2 of 22 contents figures figure 1 unit dimensions ...................................... 5 figure 2 fresh air damper assembly ................... 8 figure 3 mounting instructions ............................ 10 figure 4 electric heat clearance ......................... 11 figur...

Page 3

Manual 2100-530a page 3 of 22 getting other information and publications these publications can help you install the air conditioner or heat pump. You can usually find these at your local library or purchase them directly from the publisher. Be sure to consult current edition of each standard. Natio...

Page 4

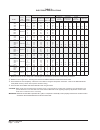

Manual 2100-530a page 4 of 22 wall mount general information air conditioner wall mount model nomenclature table 1 electric heat table s l e d o m a - 1 a 8 3 w a - 1 a 9 4 w a - 1 a 1 6 w b - 1 a 8 3 w b - 1 a 9 4 w b - 1 a 1 6 w c - 1 a 8 3 w c - 1 a 9 4 w c - 1 a 1 6 w 1 - 0 3 2 1 - 8 0 2 3 - 0 3...

Page 5

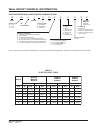

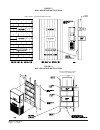

Manual 2100-530a page 5 of 22 figure 1 unit dimensions vent option condenser filter access door panel air outlet ventilation air front view w 5.75 f g heater access panel electric heat cond. Electrical entrance (lockable) 4° pitch entrance disconnect rain hood air built in inlet access panel low vol...

Page 6

Manual 2100-530a page 6 of 22 1 maximum size of the time delay fuse or hacr type circuit breaker for protection of field wiring conductors. 2 based on 75°c copper wire. All wiring must conform to national electrical code and all local codes. 3 these “minimum circuit ampacity” values are to be used f...

Page 7

Manual 2100-530a page 7 of 22 shipping damage upon receipt of equipment, the carton should be checked for external signs of shipping damage. If damage is found, the receiving party must contact the last carrier immediately, preferably in writing, requesting inspection by the carrier’s agent. General...

Page 8

Manual 2100-530a page 8 of 22 filters a 1-inch throwaway filter is supplied with each unit. The filter slides into position making it easy to service. This filter can be serviced from the outside by removing the service door. A 1-inch washable filter and 2-inch pleated filter are also available as o...

Page 9

Manual 2100-530a page 9 of 22 installation instructions warning failure to provide the 1/4 inch clearance between the supply duct and a combustible surface for the first 3 feet of duct can result in fire causing damage, injury or death. Wall mounting information 1. Two holes for the supply and retur...

Page 10

Manual 2100-530a page 10 of 22 b 16" 16" 16" 16" 16" 1 7 8 " 6 1 2 " 6 1 2 " 2 1 8 " 7 8 " 1" 3" 4" ty p. 4" ty p. 6 1 2 " 30" e 16" a c c 3 1 8 " d 1 ra in f l a s hi ng 1 1 duct r e qu ir e d d im e n s ion s t o m a in t a in 1 /4 " m in. Cl e a ra nce f ro m co m b us t ib l e m a t e ri a l s r...

Page 11

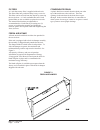

Manual 2100-530a page 11 of 22 figure 4 electric heat clearance warning a minimum of 1/4 inch clearance must be maintained between the supply air duct and combustible materials. This is required for the first 3 feet of ducting. It is important to insure that the 1/4 inch minimum spacing is maintaine...

Page 12

Manual 2100-530a page 12 of 22 figure 5 wall mounting instructions figure 6 wall mounting instructions see figure 3 – mounting instructions see unit dimensions, figure 1, for actual dimensions.

Page 13

Manual 2100-530a page 13 of 22 figure 7 common wall mounting installations.

Page 14

Manual 2100-530a page 14 of 22 wiring – main power refer to the unit rating plate for wire sizing information and maximum fuse or “hacr” type circuit breaker size. Each outdoor unit is marked with a “minimum circuit ampacity”. This means that the field wiring used must be sized to carry that amount ...

Page 15

Manual 2100-530a page 15 of 22 start up these units require r-410a refrigerant and polyol ester oil. General: 1. Use separate service equipment to avoid cross contamination of oil and refrigerants. 2. Use recovery equipment rated for r-410a refrigerant. 3. Use manifold gauges rated for r-410a (800 p...

Page 16

Manual 2100-530a page 16 of 22 start up important installer note for improved start up performance wash the indoor coil with a dish washing detergent. High pressure switch the w38a1, w49a1 and w61a1 models are supplied with a remote reset high pressure switch. If tripped, this pressure switch may be...

Page 17

Manual 2100-530a page 17 of 22 sequence of operation cooling – circuit r-y makes at thermostat pulling in compressor contactor, starting the compressor and outdoor motor. The g (indoor motor) circuit is automatically completed on any call for cooling operation or can be energized by manual fan switc...

Page 18

Manual 2100-530a page 18 of 22 removal of fan shroud 1. Disconnect all power to the unit. 2. Remove the screws holding both grilles, one on each side of unit, and remove grilles. 3. Remove screws holding fan shroud to condenser and bottom. Nine (9) screws. 4. Unwire condenser fan motor. 5. Slide com...

Page 19

Manual 2100-530a page 19 of 22 table 5 indoor blower performance cfm (0.00" – 0.50" h 2 o) 1 l e d o m d e t a r p s e 1 x a m p s e 2 r e w o l b y l n o 3 g n i l o o c 4 c i r t c e l e t a e h a 8 3 w 5 1 . 0 5 . 0 0 1 1 0 0 1 1 0 0 1 1 a 9 4 w 0 2 . 0 5 . 0 0 4 1 0 0 4 1 0 0 4 1 a 1 6 w 0 2 . 0...

Page 20

Manual 2100-530a page 20 of 22 table 7 optional accessories w38a1-a w38a1-b w38a1-c w49a1-a w49a1-b w49a1-c w61a1-a w61a1-b w61a1-c t r a p r e b m u n n o i t p i r c s e d 5 - p o b 5 - d a f b 5 - d a f m e t a l p f f o k n a l b r e p m a d r i a h s e r f c i r t e m o r a b r e p m a d r i a ...

Page 21

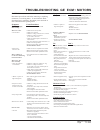

Manual 2100-530a page 21 of 22 troubleshooting ge ecm ™ motors caution: disconnect power from unit before removing or replacing connectors, or servicing motor. To avoid electric shock from the motor’s capacitors, disconnect power and wait at least 5 minutes before opening motor. Symptom cause/proced...

Page 22

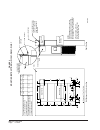

Manual 2100-530a page 22 of 22 troubleshooting ge ecm ™ motors cont’d. Motor motor ok when r > 100k ohm ecm 2.0 only remove hex head bolts connector orientation between 4 and 8 o'clock drip loop back of control figure 5 winding test figure 4 note: use the shorter bolts and alignment pin supplied whe...