Agb meat/cheese 04/16 multi-deck merchandiser i n sta l l at i o n & o p e r at i o n s m a n ua l energy data & case dimensions .......................2-4 general information ............................................... 5 installation ..........................................................6-7...

Ii.

R-744 (co 2 ) notice for systems utilizing r-744 (co 2 ) refrigerant for refrigeration units that utilize r-744 (co 2 ), pressure relief and pressure-regulating relief valves may need to be installed based on the system capacity. The valves need to be located such that no stop valve is posi- tioned ...

Important d a n g e r ▲ indicates an immediate threat of death or seri- ous injury if all instructions are not followed carefully. A t hillphoenix ® , the safety of our customers and employees, as well as the ongo- ing performance of our products, are top priorities. To that end, we include impor- t...

Revision history • new manual format_08/12 • parts list_09/12 • energy data and parts list_01/13 • endviews_03/13 • text update and airfl ow diagram_06/13 • energy data_07/13 • energy data_02/14 • endviews and energy data_09/14 • support diagram and parts page_02/15 • energy data and warranty_04/16 v.

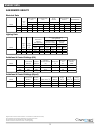

Agb remote gravity energy data numbers are based on standard case sizes. Consult engineering. All measurements are taken per ari 1200 - 2002 specifications. Engineered for stores with ambient conditions not to exceed 75 o and 55% relative humidity. Due to engineering improvements specifications may ...

Energy data numbers are based on standard case sizes. Consult engineering. All measurements are taken per ari 1200 - 2002 specifications. Engineered for stores with ambient conditions not to exceed 75 o and 55% relative humidity. Due to engineering improvements specifications may change without noti...

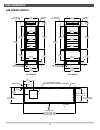

Case dimensions agb remote gravity t8 vertical lighting t8 vertical lighting 2 in [5.1 cm] 28 in [71.1 cm] 30 in [76.2 cm] 6 in [15.2 cm] 32 in [81.3 cm] 19 7/8 in [50.5 cm] 19 7/8 in [50.5 cm] 20 13/16 in [52.8 cm] 11 11/16 in [29.7 cm] 49 13/16 in [126.5 cm] 30 in [76.2 cm] 25 13/16 in [65.6 cm] 2...

Hillphoenix barker specialty products 703 franklin street, po box 478 keosauqua, ia 52565 tel: (319) 293-3777/fax: (319) 293-3776 web site: www.Hillphoenix.Com general information t hank you for choosing hillphoenix for your food merchandising needs. This handbook contains important technical inform...

Case installation floor prep 1. Ask the general contractor if your current copy of the build- ing dimensions are the most recently issued. Also, ask for the points of reference from which you should take dimen- sions to locate the cases. 2. Using chalk lines or a laser transit, mark the fl oor where ...

Case installation fig. 2 horizontal base bracket fig. 3 domino bracket bolt domino track and snap into place. 6. After suffi cient time has passed to allow for bumper shrinkage, cut away the excess bumper for fi nal fi t and fi n- ish. Be certain to use an appropriate cutting tool (tubing- or pvc-cutter...

Case connections refrigeration refrigeration connections will be made through the refrigera- tion stub up location on the customer left side of the case. Refrigeration lines may be headed together for all cases in a line-up, if necessary, by lines through the access holes with a high grade silicon t...

Case connections 48 in 72 in 96 in [121.9 cm] {4’ case} [182.9 cm] {6’ case} [243.8 cm] {8’ case} 18 in [45.7 cm] 14 in [35.6 cm] 28 in [71.1 cm] (30") 34 in [86.4 cm] (36") 30 in [76.2 cm] 36 in [91.4 cm] 26 in [66.0 cm] (30") 32 in [81.3 cm] (36") toekick 15" x 15" mechanical access for elect. ,re...

Lighting & power supplies ballast/power supply access to gain access to the ballasts or power supplies remove the panel located above the rear toe kick. Fig. 7 positive engagement general lighting information hillphoenix cases are equipped with either t-8 lights or led luminaires and feature special...

Lighting & power supplies replacing led lights once store power is connected and the light circuit is ener- gized, the clearvoyant led system should operate without the need for any signifi cant maintenance for several years. Should a power supply need to be removed and/or replaced, turn off the powe...

Pre-power checklist have you thoroughly examined the case for shipping damage? (see pg. 5) have you checked the vertical plumb of the case? The horizontal level? (see pg. 6) have you installed the toekick? (see pg. 7) have you removed the shipping blocks from the refrigeration and plumbing lines? (s...

Airflow & defrost airflow & product load h illphoenix cases provide maximum product capacity within the refrigerated air envelope. Please keep products within the ap- propriate load limit. It is important that you do not overload the food product display so that it impinges on the airfl ow pattern (f...

Case cleaning case cleaning a periodic cleaning schedule should be established to maintain proper sanitation, insure maximum operating efficiency, and avoid the corrosive action of food fluids on metal parts that are left on for long periods of time. We recommend cleaning once a week. Further sugges...

Sovis ultravision ® tempered glass specialized anti-reflective coatings on each surface of the glass. These coatings reduce the glare from lighting so that the products on display are more visible to your customers. While the anti-reflective coatings are durable, they are susceptible to scratching i...

Parts ordering contact the service parts department at: 319-293-3777 provide the following information about the part you are ordering: • model number and serial number* of the case for which the part is intended. • length of the part (if applicable). • color of part (if painted) or color of polymer...

A1-a2 .............................................................................................. Wiring information b1-b4 .............................................................................. Dixell operating instructions c1 .................................................................

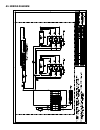

A1: wiring diagram.

A2: wiring dia gram black to chiller switch ( 78 ) wire information wire information black to block 4 - f 1 black to light power white to block 4 - h 1 white to light power wire information wire information black to block 4 - a 1 black refr power white to block 4 - e 1 white refr power wire informat...

B1: dixell operating instructions dixel operating instructions 1592002701 1592002701 xh240l-v gb r1.0 12.01.2004 * xh240l - xh240v 1/4 xh240l – xh240v temperature and humidity controller 1. General warning 1.1 please read before using this manual x this manual is part of the product and should be ke...

B2: dixell operating instructions dixel operating instructions 1592002701 1592002701 xh240l-v gb r1.0 12.01.2004 * xh240l - xh240v 2/4 led mode function on °c °f on °c on the compressor is running flashing - anti-short cycle delay enabled led 3 on the defrost is enabled led 3 flashing drip time in p...

B3: dixell operating instructions dixel operating instructions 1592002701 1592002701 xh240l-v gb r1.0 12.01.2004 * xh240l - xh240v 3/4 when this humidity is reached and after the ahd delay time the hha alarm is enabled. Ahh humidity alarm recovery differential: (0.5÷20.0) intervention differential f...

B4: dixell operating instructions dixel operating instructions 1592002701 1592002701 xh240l-v gb r1.0 12.01.2004 * xh240l - xh240v 4/4 3. Automatically the parameter list of the “hot key” is downloaded into the controller memory, the “dol” message is blinking followed a by flashing “end”. 4. After 1...

C1: sporlan pressure-temperature chart temperature pressure chart - at sea level t o d e te rm in e s u b co o lin g f o r r -4 0 4 a u se b u b b le p o in t v a lu e s (t e m p e ra tu re s a b o v e 5 0 °f — g ra y b a ck g ro u n d ); t o d e te rm in e s u p e rh e a t fo r r -4 0 4 a , u se d ...

A cornice b fixed front glass c adjustable shelf bracket d stainless steel wire shelf e bottom deck ss wire riser f front toekick g outside front h end toekick i dry or refrigerated lower storage j end panel k fixed end glass l shelf standard m outside back n rear load doors o light guard p upper-in...

4844-3514-3187.2 hill phoenix, inc. Hereinafter referred to as manufacturer limited warranty general warranty manufacturer’s products are warranted to be free from defects in materials and workmanship under normal use and maintenance for fourteen months from date of shipment from manufacturer (the “...

Warning maintenance & case care when cleaning cases the following must be performed prior to cleaning: to avoid electrical shock, be sure all electric power is turned off before cleaning. In some installations, more than one switch may have to be turned off to completely de-energize the case. Do not...