- DL manuals

- Barnant Company

- Temperature Controller

- 689-0010

- Operating Instructions Manual

Barnant Company 689-0010 Operating Instructions Manual

OPERATING MANUAL

TEMPERATURE

CONTROLLER R/S

(ADVANCED MODEL)

689-0010

689-0015

Barnant Company

28W092 Commercial Avenue

Barrington, Illinois U.S.A. 60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

e-mail: barnant@barnant.com

A-1299-0610

Edition 04

Barnant-cover.p65

10/8/01, 9:42 AM

1

Summary of 689-0010

Page 1

Operating manual temperature controller r/s (advanced model) 689-0010 689-0015 barnant company 28w092 commercial avenue barrington, illinois u.S.A. 60010-2392 (847) 381-7050 (847) 381-7053 (fax) 800-637-3739 www.Barnant.Com e-mail: barnant@barnant.Com a-1299-0610 edition 04 barnant-cover.P65 10/8/01...

Page 2: Eu Declaration of Conformity

Eu declaration of conformity name of apparatus: temperature controller model number: 689-0015 description of apparatus: deluxe process temperature controller, 15a output. Barnant company declares that the above model is in conformity to the following harmonized standards and directives: applicable a...

Page 3: Table of Contents

I table of contents title page warnings and cautions ................................................................ 1 introduction .................................................................................... 2 application data ..................................................................

Page 4: Title

Ii table of contents (continued) title page control action ............................................................................ 22 control mode ............................................................................. 22 control mode on/off ..................................................

Page 5: Safety Precautions

1 safety precautions danger: there are no user-serviceable parts in this instrument. Do not remove cover, as high voltages exist inside the unit. Refer servicing to your dealer. Danger: if thermocouples are at a high voltage, this volt- age will be present at other points inside the unit. Danger: fo...

Page 6: Introduction

2 introduction this manual provides information for installing and operating the tempera- ture controller r/s (advanced model). Refer to figure 1 for a view of the front panel of the temperature controller r/ s. Refer to figures 2 and 3 for a view of the back panels of the 115 v or 230 v versions. F...

Page 7: Application Data

3 figure 3. Temperature controller r/s, back panel (230 v model) application data applications for the temperature controller r/s include heating and cooling of solids, liquids, and gases. For all applications, there are certain set-up operations that should be made carefully to assure optimum and s...

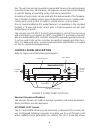

Page 8: Control Panel Description

4 tion. The unit can also be mounted in a panel with the use of an optional panel mount kit. A two-line, 16-character, 14-segment vacuum fluorescent display is used for display of operating, setup, and alarm parameters. A number of accessories can be used with this deluxe model of the tempera- ture ...

Page 9

5 you to change default numeric settings by moving the blinking cursor left to the next most significant digit. When you have reached the most significant digit (furthest left), the left arrow key will move the flashing cursor back to the least significant digit (furthest right). Menu key the menu k...

Page 10

6 heat, cool, tune led annunciators these three indicators will light to indicate temperature controller functions. The green heat light will turn on when power is being applied to the heater output. The green cool light will turn on when the temperature controller is in the cooling mode and power i...

Page 11: Installation

7 installation initial hardware setup 1. Remove controller from packaging. Keep all packing material until proper operation has been verified. 2. Use the "bail" bar (or tilt-stand) at the bottom of the unit to adjust position for easy viewing of front panel. Caution: to avoid electric shock, the pow...

Page 12: 230 V

8 line cord connection heater cord cable connection recorder output isolated 4-20 ma rs-232c serial connector mini-ansi thermocouple jack (500 ohm max load resistance) heater/cooler output fuse thermistor probe jack 3 wire rtd probe jack on/off switch main power fuse 230 v figure 5. 230 v back panel...

Page 13: Setup Procedure

9 8. Recorder output and alarm output devices may be installed on the tem- perature controller (refer to figure 5). The 4/20ma recorder output is designed for a left positive (+) and a right negative (-) connection. Alarm output is designed for a left–no (normally open), center–com (com- mon), and r...

Page 14: Thermocouple

10 2. Press the down arrow key to select one of the three sensor types, which are described as follows: thermocouple 1. To select a thermocouple type, press the menu key (refer to figure 8). 2. The screen will display the last thermocouple selected. To chose an- other thermocouple type, press the do...

Page 15: 100 Ohm Rtd

11 platinum rtd 1. The platinum rtd is the third sensor type that can be selected. Press the menu key at the sensor type - platinum rtd screen and the following screen will appear (refer to figure 10). 2. Select either alpha .003850 or alpha .003916. Select an alpha of 0.003850 (default setting) for...

Page 16: Alarm Setpoints

12 alarm selections 1. Alarms will activate only when the temperature controller is in the run mode. When an alarm occurs, the alarm relay will energize, the alarm led will flash, the audible alarm will sound intermittently and the display will flash the type of alarm. There are three possible alarm...

Page 17: Alarm Setpoints

13 5. To select an automatic alarm reset, press the menu key when the auto reset screen is blinking. 6. To go to the alarms off screen, press the down arrow key. Refer to figure 15. If selected, refer to alarms auto reset procedure, below. Alarm setpoints off figure 15. Alarm setpoint off screen 7. ...

Page 18: Process Alarm

14 2. Select the process - hi screen by pressing the menu key. The follow- ing screen will appear (refer to figure 17). Set the process hi tempera- ture by using the arrow keys. Process alarm hi xxxxx °f figure 17. Process hi settings screen process lo 1. Process lo is a fixed value and will not cha...

Page 19: Alarm Mode

15 process hilo 1. Process hilo is a fixed value (a fixed high and a fixed low alarm setpoint) and will not change if the sp temperature value is changed. The purpose for process hilo is to set the fixed hi and lo value at which to trigger the alarm relay. Refer to figure 20. Refer to the process hi...

Page 20: Alarm Mode

16 deviation lo deviation lo adjusts the alarm value as the sp temperature value is adjusted. Whatever value deviation lo is set at, it will remain the same until changed. Refer to figure 22. Alarm mode deviation lo figure 22. Deviation lo screen for example: if the deviation lo value is set for 10 ...

Page 21: Deviation Alarm

17 for example: if the deviation hi value is set for 10 degrees fahrenheit and the sp temperature is set for 50 degrees fahrenheit, the alarm will trigger at 60 degrees fahrenheit. If the sp temperature value is changed to 55 degrees fahrenheit, the deviation hi will not trigger the alarm until it r...

Page 22: Deviation Alarm

18 2. Select the deviation- hilo screen by pressing the menu key. The following screen will appear (refer to figure 27). Set the deviation tem- perature by using the arrow keys. 3. After selecting values, press the menu key to continue. Deviation alarm hi/lo xxxxx °f figure 27. Deviation hi/lo setti...

Page 23: Alarm Hysteresis

19 alarm hysteresis 1. Alarm hysteresis determines when the alarm is going to be out of the alarm condition. Alarm hysteresis prevents actuation of nuisance, or re- current, alarms. Hysteresis is either added or subtracted to the alarm point, depending on whether a hi or lo alarm has been set. For e...

Page 24: Enter Advanced

20 advanced set-up 1. After pressing the menu button, the enter advanced setup screen will be displayed (refer to figure 32). 2. The flashing message yes will ask if you want to enter the advanced screen. Press the menu key as the word yes blinks. Note: if a change to that selection is not chosen wi...

Page 25: Over Temp. Stop

21 over temp stop 1. Over temp stop temperature, a safety feature, is added to the setpoint (sp) temperature. If the pv temperature exceeds this amount, the tem- perature controller will stop. Over temp stop does not operate if the cool control action is selected. Refer to figure 34. Over temp. Stop...

Page 26: Control Mode

22 control action 1. The control action screen allows selection of the type of process that will be performed; either heat or cool. Refer to figure 36. In the heat mode, the output is on when the actual temperature is below the setpoint temperature (inverse action). In the cool mode, the output is o...

Page 27: On/off Control

23 control mode on/off 1. The control mode on/off turns off the output when the actual tempera- ture exceeds the setpoint (heat control action). The output will turn on when the actual temperature falls below the setpoint temperature minus the hysteresis temperature. Refer to figure 38. On/off contr...

Page 28: Proportional

24 2. Select an option using the arrow keys. 3. If auto tune enabled is selected, press the menu key four times to advance past the pid setup to the run time screen. Note: auto tune disabled is also a safety feature to prevent accidental auto tuning. Proportional band 1. Select the proportional band...

Page 29: Derivative Rate

25 derivative rate 1. The derivative rate reduces or eliminates overshoot. Refer to figure 42. It is measured in seconds and must be tuned to work with the overall system cycle time. Derivative rate xxxx seconds figure 42. Derivative screen 2. Use the arrow keys to enter the correct value and press ...

Page 30: Assured Soak

26 assured soak assured soak applies only to ramp and soak. Refer to figure 44. In select- ing assured soak, each segment is extended until the actual temperature reaches the setup temperature specified in that segment (before moving on to the next segment). If assured soak is not selected, then the...

Page 31: Cycle Time

27 each cp number represents a set of proportional band, integral time, and derivative rate values. This is included for convenience in setting ramp and soak pid values when individual segments have different stability require- ments. Specific cp values are set in control parameters, below. Selectin...

Page 32: Recorder Out At

28 1. Use the down arrow key to increment the time period desired. 2. Press the menu key to enter your selection. Recorder output recorder out consists of two selections: recorder out at 4ma and re- corder out at 20ma screens. Refer to figure 48. This function allows the operator to scale the temper...

Page 33: Power Up Control

29 1. Set the serial baud rate using the arrow keys. 2. Press the menu key to advance to the power up control screen. Power up control this set up option allows you to specify one of two conditions for the tem- perature controller at turn on. Power up control has two options: last state and stopped....

Page 34: Operation

30 operation once installation and setup are complete, press the run/stop key to begin operation. The following screen will appear (refer to figure 51) if a previous run was stopped before it completed. Run option continue/restart figure 51. Run screen select either continue or restart using the arr...

Page 35: Ramp and Soak Mode

31 ramp and soak mode if you selected ramp and soak during the setup, the following screen will appear (refer to figure 53). Xx.X °f seg x xx_xx_xx ramp v figure 53. Temperature/time/segment display for ramp/soak mode during the ramp and soak operation, the temperature, segment number, time remainin...

Page 36: Warning:

32 troubleshooting and maintenance warning: there are no user-serviceable parts in this instrument. Do not remove cover, as high volt- ages exist inside the unit. Refer servicing to your dealer. Warning: if thermocouples are at a high voltage, this voltage will be present at other points inside the ...

Page 37: Specifications

33 specifications display: two lines of 16 characters. Four-digit process value. Four-digit setpoint value. Accuracy: type j,k,t,e and n above − 100°c ( − 148°f): ±0.1% reading, ±0.4°c (±0.7°f) below − 100°c ( − 148°f): ±0.1% reading, ±1°c (±1.8°f) type r,s and b ±0.1% reading, ±1°c (±1.8°f) thermis...

Page 38: Specifications (Continued)

34 specifications (continued) thermistors: ysi 400: − 40 to 100°c ( − 40 to 212°f) ysi 700: − 30 to 100°c ( − 22 to 212°f) platinum rtd 100 ohm: − 200 to 850°c ( − 328 to 1562°f) inputs ac line input 115v model 230v model input: 115v ac ±15%, 49/61 hz 230v ac ±15%, 49/61 hz 15a max 15a max connector...

Page 39: Outputs

35 impedance: 2252 ohm @ 25°c (77°f) (t1) 6,000 ohm @ 25°c (77°f) (t2) 30,000 ohm @ 25°c (77°f) interchangeability: ±0.10°c ±0.15°c lead resistance: 0.45 ohm max 1.2 ohm max power dissipation: 0.5 mw max 1.3 mw max rtd probe input connector: 3-pin circular (mate to switchcraft ta3f plug) pin 1: rtd ...

Page 40: Warranty

36 warranty the manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary within the warranty period, the problem will be corrected at no charge if it is not due to misuse or abuse on your part as determined by the m...

Page 41: Appendix A

A-1 appendix a temperature controller setup mode for advanced model.

Page 42

A-2 temperature controller setup mode for advanced model.

Page 43: Appendix B

B-1 appendix b the following is a list of error messages that may be displayed by the tem- perature controller and a description of corrective action. Upper lower display display action normal over temp stop pv exceeded over temp stop setting in user setup. Normal loop break stop no change in pv wit...

Page 44

Barnant advanced models 689-0010 115v 689-0015 230v catalog # model description 689-0050 all models panel mount kit 689-0098 all models heater sizing software 689-0097 all models alarm/recorder output connector 689-0078 230v only input cord - iec320/nema 6-15p 689-0079 230v only input cord - iec320/...