A crane co. Company barnes barnes ® installation and operation manual diaphragm pumps important! Read all instructions in this manual before operating pump. As a result of crane pumps & systems, inc., constant product improvement program, product changes may occur. As such crane pumps & systems rese...

2 table of contents safety first ............................................................................................... 3 a. Pump specifications ............................................................................... 4 - 5 b. General information ........................................

3 please read this before installing or operating pump. This information is provided for safety and to prevent equipment problems. To help recognize this information, observe the following symbols: important! Warns about hazards that can result in personal injury or indicates factors concerned with ...

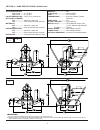

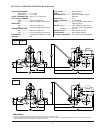

4 suction/discharge: 2ade-2cde ....... 2” x 2" npt 3ade-3cde ........ 3” x 3” npt liquid temperature ... 160°f (71°c) continuous suct/disch chamber ade ..................... Aluminum, class 319 cde ..................... Cast iron astm a-48, class 30 water box ade .................... Aluminum, class...

5 section: a - pump specifications: wheel mounted important ! 1.) do not use for pumping fluids with a flash point of less than 100°f. 2.) make certain that pump and/or motor assembly and controls have the appropriate ratings for the given application area classification. (ie division i, agency list...

6 section b: general information b-1) to the purchaser: congratulations! You are the owner of one of the fi nest pumps on the market today. Barnes® pumps are products engineered and manufactured of high quality components. Over one hundred years of pump building experience along with a continuing qua...

7 section d: maintenance instructions 1. Keep interior of pump and valves clean. When pumping liquids containing foreign materials, fl ush out pump with clear water whenever possible. 2. Keep suction hose air tight and check for leaks and loose lining, as these are major trouble sources when priming....

8.

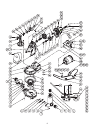

9 parts list 2cde 3cde item qty. Part no. Part no. Description 1 2 p3015 p3041 nipple 2 1 p3354ay-c2 p3309ay-c2 suct. Conn & groove pin assy 3 2 ----- ----- groove pin, type d, 1/8” x 3/8” 4 1 p3322 p3322 plug, 2” 5 1 p3323 p3323 plug gasket, 2” 6 6 a.010.050.0175 a.010.050.0175 hex screw, 1/2”-13 x...

10 55 1 w16-6006llu w16-6006llu ball bearing (sealed) 56 1 w63-5100-118 w63-5100-118 retaining ring, external 57 1 p4859 p4859 o-ring 58 1 p4857 p4857 adaptor, electric motor 59 4 bc070.031.0100 bc070.031.0100 socket hd. Screw, 5/16-18 x 1” 60 4 f635.031z f635.031z int. Tooth lock washer, 5/16” 61 1...

11 2ade 3ade item qty. Part no. Part no. Description 1 2 p3015 p3041 nipple 2 1 p3354ay-a1 p3309ay-a1 suct. Conn & groove pin assy 3 2 ----- ----- groove pin, type d, 1/8” x 3/8” 4 1 p3322 p3322 plug, 2” 5 1 p3323 p3323 plug gasket, 2” 6 6 a.010.050.0175 a.010.050.0175 hex screw, 1/2”-13 x 1-3/4” 7 ...

12 58 1 p4857 p4857 adaptor, electric motor 59 4 bc070.031.0100 bc070.031.0100 socket hd. Screw, 5/16-18 x 1” 60 4 f635.031z f635.031z int. Tooth lock washer, 5/16” 61 1 p5601 p5601 sq. Key, 3/16 x 1” 62 4 a.010.037.0150 a.010.037.0150 hex screw, 3/8-16 x 1-1/2” 63 4 f620.037 f620.037 lock washer, 3...

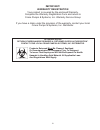

13 returned goods return of merchandise requires a “returned goods authorization”. Contact your local crane pumps & systems, inc. Distributor. Products returned must be cleaned, sanitized, or decontaminated as necessary prior to shipment, to insure that employees will not be exposed to health hazard...

14 a crane co. Company 420 third street 83 west drive, bramton piqua, ohio 45356 ontario, canada l6t 2j6 phone: (937) 778-8947 phone: (905) 457-6223 fax: (937) 773-7157 fax: (905) 457-2650 www.Cranepumps.Com barnes barnes ® limited warranty we warrant to our immediate customer and to the ultimate co...

15 notes.

16 notes.

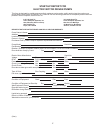

17 start-up report for electric motor driven pumps this form is designed to provide assurance that customer service and a quality product are the number one priority with crane pumps & systems, inc. Please fi ll out the following questions as completely and accurate as possible. When complete, mail t...

18 barnes control panel part no. Number of pumps operated by control panel note: at no time should holes made in top of control panel, unless proper sealing devices are utillzed. Control panel manufactured by others company name model no. Short circuit protection type number and size of short circui...

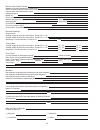

Fold here and tape, do not staple **important!** warranty registration customer’s name date installed address city state zip phone # fax # dealer’s name city state zip model no. Serial no. Part no. Brand important! Warranty registration your product is covered by the enclosed warranty. Complete the ...

Crane pumps & systems, inc. Warranty service group 420 third street piqua, ohio 45356 - u.S.A. Fold here and tape, do not staple place stamp here.