A crane co. Company barnes ® installation manual submersible grinder pump important! Read all instructions in this manual before operating pump. As a result of crane pumps & systems, inc., constant product improvement program, product changes may occur. As such crane pumps & systems reserves the rig...

2 please read this before installing or operating pump. This information is provided for safety and to prevent equipment problems. To help recognize this information, observe the following symbols: important! Warns about hazards that can result in personal injury orindicates factors concerned with a...

3 user guide congratulations on your purchase of a barnes ultragrind™ grinder pump system. With proper care and by following a few simple guidelines your grinder pump will give you many years of dependable service. Use and care the ultragrind grinder pump station is designed to handle routine, domes...

4 discharge ....................... 1¼” npt, female, vertical, bolt-on flange liquid temperature .... 160°f (71°c) intermittent motor housing ............. Cast iron astm a-48, class 30 volute .............................. Cast iron astm a-48, class 30 seal plate ...................... Cast iron as...

5 model no hp volt ph/hz rpm (nom) nema start code full load amps locked rotor amps cord size code type cord o.D. ± .02 (.5) in (mm) winding resistance main -- start pgpp2022 2 240 1 / 60 3450 h 15.0 53.8 14/3 sow .61 (15.5) 1.5 -- 5.1 pgpp2022a 2 240 1 / 60 3450 h 15.0 53.8 14/3 sow .61 (15.5) 1.5 ...

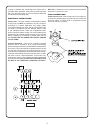

6 if pump is installed with a discharge hose rather than a moveable fi tting assembly, make sure the discharge pipe has a 1/8” dia. Hole approx. 5” from end nearest volute and oriented towards the pump body. Electrical connections: pump cords - the quick connect cord assembly mounted to the pump must...

7 trouble shooting caution ! Always disconnect the pump from the electrical power source before handling. If the system fails to operate properly, carefully read instructions and perform maintenance recommendations. If operating problems persist, the following chart may be of assistance in identifyi...

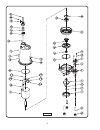

8 figure 5.

9 parts kits seal repair kit ...........P/n: 108302 item #’s 6,7,13,14,15,19,20,21,25,26,27,32,35,47 cutter kit ..................P/n: 108321 item #’s 5,6,7,9,15,19,23 parts list item qty part no. Descrition 1 1 108344 volute 3 1 108343 seal plate 4 1 108342 motor housing 5 1 082085a shredding ring ...

A crane co. Company 420 third street 83 west drive, brampton piqua, ohio 45356 ontario, canada l6t 2j6 phone: (937) 778-8947 phone: (905) 457-6223 fax: (937) 773-7157 fax: (905) 457-2650 www.Cranepumps.Com limited 24 month warranty crane pumps & systems warrants that products of our manufacture will...

Returned goods return of merchandise requires a “returned goods authorization”. Contact your local crane pumps & systems, inc. Distributor. Products returned must be cleaned, sanitized, or decontaminated as necessary prior to shipment, to insure that employees will not be exposed to health hazards i...

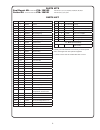

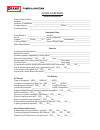

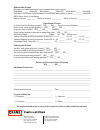

Start-up report general information pump owner’s name: __________________________________________________________ address: ____________________________________________________________________ location of installation: _________________________________________________________ contact person: ________...

Submersible pumps resistance of cable and pump motor (measured at pump control): red-black:_______ohms( ) red-white:_______ohms( ) white-black:_______ohms( ) resistance of ground circuit between control panel and outside of pump: __________ohms( ) meg ohms check of insulation: red to ground: _______...

Notes.