- DL manuals

- Barnstead

- Water System

- D14031

- Operation Manual

Barnstead D14031 Operation Manual

Summary of D14031

Page 1

Diamond ™ tii type ii water system operation manual model no. Description voltage d14031 12 lph 100v - 240v d14041 24 lph 100v - 240v lt1403x8 • 10/05/06.

Page 2

Safety information ..................................................................................................................................................................4 alert signals ..........................................................................................................

Page 3

Flush mode ............................................................................................................................................................30 automatic flush (ro membrane) .......................................................................................................

Page 4

Your barnstead international diamond tii type ii water system has been designed with function, reliability, and safety in mind. It is your responsibility to install it in con- formance with local electrical codes. This manual con- tains important safety information. You must carefully read and under...

Page 5

2. Do not use in the presence of highly corrosive substances such as bleach or acid baths; fire may result. 3. This device is to be used with water feeds only. Sanitizing agents must be used in compliance with instructions in this manual. Failure to com- ply with the above could result in explosion ...

Page 6

6 introduction product overview the barnstead diamond tii is a tap-fed water purification system designed to be simple to use and to provide reagent grade water that exceeds astm type ii, and nccls/cap type i standards. It uses a thin film compos- ite reverse osmosis membrane with pretreatment to pr...

Page 7

7 dimensions and clearance requirements diamond tii dimensions - 13.5" w x 18.5" d x 19.5" h (34.3 cm x 47.0 cm x 49.5 cm) clearances: sides - 9" (22.9 cm) minimum to allow for servicing above - 3" (7.6 cm) minimum for removal of top cover front - 4.75" (12.1 cm) minimum for opening front door elect...

Page 8

8 ro system model ro product flow rate recovery d14031 12 lph ±15% (3.2 gph) 10-20% d14041 24 lph ±15% (6.3 gph) 20-40% ro membrane performance 1 rejection inorganic (minimum) >90% inorganic (typical) >95% particles >99% bacteria >99% organics (>300 mw) >99% 1 500 ppm nacl feedwater solution @ 25°c ...

Page 9

9 environmental conditions operating: 15°c - 30°c; 20% - 80% relative humidity, non-condensing. Installation category ii (overvoltage) in accordance with iec 664. Pollution degree 2 in accordance with iec 664. Altitude limit: 2,000 meters. Storage: -25°c - 65°c; 10% to 85% relative humidity. Declara...

Page 10

10 unpacking remove the unit from its shipping container and ensure that the following items are removed from the packaging materials before discarding: 1) diamond tii unit 2) approximately 6 ft. (1.83 m) of 1/4” (0.64 cm) o.D. Drain tubing (tu1190x12) with a 1/4” npt fitting at one end 3) approxima...

Page 11: ********************

11 locating unit locate storage reservoir approximately 5 ft. (1.52 m) from the diamond tii for electrical connections. See diamond tii storage reservoir manual or customer-supplied reser- voir manual for mounting instructions. The outlet of diamond tii storage reservoir must be above or at the same...

Page 12

12 installing the control panel in a remote location (see fig. 1) for your convenience, the control panel can be removed from the unit and mounted at a convenient location within 10 ft. (3.1 m.) of the unit. To remove the control panel from the unit: 1. Turn the unit off and disconnect it from the p...

Page 13

13 component installation uv lamp installation (see fig. 7) locate the uv chamber inside the left door of the diamond tii. Install the uv lamp as follows: 1. Disconnect the power cord from the unit. 2. Access the left side of the unit by unlatching the screw securing the door with a flathead screw- ...

Page 14

14 water connection details push-to-connect fitting tubing installation (refer to fig. 2) the following instructions will apply when you need to attach a piece of tubing to your diamond tii during instal- lation, unless otherwise noted in the installation instruc- tions. To make tubing connections: ...

Page 15

15 tubing adapter fittings 1. Completely disassemble the fitting. Refer to figure 4 to familiarize yourself with the names of the component parts. 2. Make sure the tubing is cut off reasonably square and that no plastic burrs or ridges are present. 3. Place the grab ring and back-up ring in the hex ...

Page 16

16 quick disconnect fittings these fittings are found on the water inlet. (see fig. 5) to insert the inlet tubing: 1. Press on the metal thumbpad on the coupling body to ensure the fitting is open. 2. Wet the o-ring on the coupling insert and push into the coupling body until you hear a click. Gentl...

Page 17

17 cartridge and membrane installation (see fig. 6) your diamond tii has been shipped with one membrane (for 12 lph unit) or two membranes (for 24 lph unit), that you will install. The startup kit (d502138) includes a pre- filter, mps cartridge and carbon filter, and must be pur- chased separately. ...

Page 18

Carbon filter installation chlorine can also damage your membranes, resulting in premature membrane failure. Therefore, your diamond tii uses an extruded carbon filter to remove chlorine from your feed water. Install the carbon filter as follows: 1. Remove the carbon filter (part number d502115) fro...

Page 19

7. The door can remain open until the unit has been operating and you have checked for possi- ble water leaks at the membrane connections. 8. Rinse membrane per the instructions in the “initial operation” section of this manual. 24 liter per hour units (2 membranes) 1. Remove the ro membranes from t...

Page 20

20 8. Make the product (e) and reject 2 (f) connections on left most membrane by first wet- ting the tube stem of the elbow with water and pushing it firmly into the connector. See figure 9. 9. The door can remain open until the unit has been operating and you have checked for possi- ble water leaks...

Page 21

21 i nstallation caution do not connect feed water until direct- ed to do so during “initial operation.” note to prevent leaking, push the tubing into the atmospheric drain connection until it bottoms out. 100 psi max 120°f max drain feedwater inlet rs232 remote 1 tank floats pump interlock accu. Di...

Page 22

22 power connections 1. The power cord connection is located on the upper right corner on the right side of the unit (see fig. 15). 2. Determine which power cord you need (this will be based on your country and outlets available in your lab). Both north american and european power cords are provided...

Page 23

Dispense overflow cutoff float accessory ay1367x1 (overflow float with 6 ft. [1.83 meter] cable) is designed as a user option to ensure automatic dispensers (time or volumetric) do not overflow carboy style containers. This accessory can be especially helpful if the actual volume of a container is u...

Page 24

Performing an electronic calibration using the optional n.I.S.T. Calibration module if you purchased the optional n.I.S.T. Calibration module (catalog no. E1403x5) you can perform a calibration of the diamond tii product purity sensing electronics trace- able to n.I.S.T. Standards. 1. Press menu. Sc...

Page 25

25 control panel the diamond tii is controlled through a panel which incorporates buttons to control its functions. This control panel utilizes a graphical display to show system informa- tion and the purity of the product water. The intensity of the display may be adjusted according to user prefere...

Page 26

26 auto dispense modes, pressing the start/stop switch will return the unit to the mode it was in prior to initiating a flush. 2. Dispense allows you to automatically deliver water from the unit. Please refer to “automatic dispensing” in the “user settings” section of this manual for more informatio...

Page 27

All the ro prefilters and ro membranes should already be installed at this point. If they have not, refer to “cartridge and membrane installation” earlier in this man- ual. Ro membrane rinse when new ro membranes are installed in the diamond tii, the membranes should be rinsed to remove all traces o...

Page 28

28 2. Follow the prompts on the screen. These will guide you through the process. It is very impor- tant that the steps are followed in order for the sanitization to be successful. Be sure to con- nect the tubing supplied with the sanitization block and route securely to an atmospheric drain to prev...

Page 29

Cartridge pack rinse up 1. If not already installed, install the hose barb into the fitting in the dispense valve. 2. Turn unit on and from standby press the start/stop button to begin unit operation. 3. Rinse approximately 3 liters of water through the dispense valve to drain. 4. Close the dispense...

Page 30

30 note each time the ro system automati- cally turns on, in run or standby mode, the ro membrane will flush water to the drain for 30 seconds prior to filling the reservoir. 2. Allow the water’s resistivity to rise to the desired purity before dispensing water. Also in the run mode, the ro operatio...

Page 31

31 the mode (idle, run or stby) it was in when you initiat- ed the flush. To initiate a flush: 1. Choose menu and scroll to ro options. Press ok. 2. Choose manual flush and press ok. Normal operation 1. Turn the system power on by depressing the main power switch to the “i” position. 2. The system e...

Page 32

32 note when the ro operation is automati- cally turned on, ro water will be put into the reservoir. Anytime the ro purity falls below the user-selected % rejection setting the system alarm led will illuminate. Note volumetric dispensing is based upon total fluid volume entering the diamond tii. Poi...

Page 33

33 user settings setting the displayed language 1. Upon power up, press any of the four buttons below the display when the display shows “lan- guage.” or, if the unit’s power is already on: 1. Press menu and scroll to the language screen and press ok. 2. Press the up or down arrow to select the lan-...

Page 34

34 i nitial o peration setting the ro % reject alarm the ro % reject alarm monitors ro membrane perform- ance and can be set between 65% and 90% reject. Factory default is 75%. To adjust the alarm: 1. Press menu. Scroll to ro options and choose low reject alarm. Use the up and down arrows to set the...

Page 35

Setting system options see procedures in the table below to choose system options. Auto standby timer the auto standby timer can be set so that the unit will automatically be placed in standby and come back out of standby and be placed into run mode at a set time each day. Unit under counter (factor...

Page 36

Display contrast the diamond tii display can be adjusted based on the user’s preference. Set units the diamond tii can display readings in a variety of units. Use this option to set desired units. Printer attached the diamond tii can print readings to an optional printer accessory (ay1137x1). Reserv...

Page 37

Connecting diamond tii to computer and communicating through the rs-232 port using hyperterminal or procomm hyperterminal rs-232 capture instructions 1. Connect the 9 pin serial cable (part no. Whx18) from the diamond tii rs-232 port on the back left side of the unit to (com2:) port or (com1:) port ...

Page 38

11. You should see the data on the computer screen. 12. When you are finished storing data from the diamond tii, save your file. You can exit hyperterminal or set up a new experiment. 13. Hyperterminal data can be manipulated and graphed in excel ® . Procomm 1. Connect the 9 pin serial cable from th...

Page 39

13. Type in 24 , saves settings. 14. Press esc to exit setup menu. 15. Procomm is now ready to accept input from the diamond tii. 16. To begin downloading a file, type alt-f1, and give the file an appropriate name when prompted. The optional printer (part no. Ay1137x1) provides a paper tape record f...

Page 40

40 system sanitization frequency of sanitization will vary, depending on quality of feedwater and usage. Sanitization is necessary if residual deposits are evident inside the reservoir, or if a new 0.2 micron final filter clogs rapidly. For sanitization procedure, see “system sanitization procedure”...

Page 41

41 2. Remove the mps cartridge by pulling the car- tridge straight out. 3. Replace the mps cartridge by following the instructions located in the “mps cartridge installation” section of this manual. Carbon replacement the carbon filter incorporated in your diamond tii pro- vides a combination of fil...

Page 42

42 the simple-to-use sanitization block is available from barnstead international (catalog number bk1403x2). This is used to effect a complete cleaning. 1. Turn off the diamond tii and disconnect it from the power supply. 2. Disconnect the quick connect fitting in the tubing connected to the “from t...

Page 43

43 access door. And carefully unhook the velcro ® strap(s) that secure it (them). 4. Remove the old membrane(s) by disconnecting the reject and product tubing from the top of the membrane and the feed water connection from the bottom. See “water connection details” for tubing removal instructions. 5...

Page 44

44 note when the lamp is burned out or dis- connected, the system alarm led will illuminate. Press menu and scroll to system alarm for details. Fuse replacement 1. Turn off the diamond tii and disconnect it from the power supply. 2. Pull out the fuse drawer located in the power entry module. 3. Remo...

Page 45

45 m aintenance and s ervicing timer procedure prefilter timer menu timers prefilter [display shows time remaining in days] reset are you sure? Yes/no mps timer menu timers mps [display shows time remaining in days] reset are you sure? Yes/no carbon timer menu timers carbon [display shows time remai...

Page 46

46 system uv timer the user must reset the system uv timer each time the uv lamp in the diamond tii is replaced. This will reset the uv timer for approximately six months calendar time. Reservoir uv timer the user must reset the uv timer each time the uv lamp in the diamond tii storage reservoir is ...

Page 47

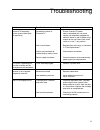

47 problem possible causes solutions diamond tii completely no electrical power to ensure diamond tii power inactive (pump and display diamond tii. Cord is connected to a live power not operating.) source and completely plugged into electrical outlet as well as power entry module on the unit. Make s...

Page 48

48 problem possible causes solutions water is leaking between the wing head screw is not hand tighten wing head screw on unit manifold and the cartridge tight enough. Manifold. Pack. New cartridge pack: o-ring turn off power to system. Disconnect missing from post (each of the quick connect fitting ...

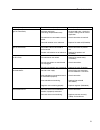

Page 49

Message possible causes action res interface error reservoir interface cable not attached check cable connections. At both ends. Interface board not connected. Check cable connection to control board. Interface board, control board, or replace board (pc1403x2, reservoir board out of tolerance. Pc140...

Page 50

50 t roubleshooting problem (cont.) possible causes (cont.) action (cont.) di temp error resistivity cell not connected to board. Check resistivity cell lead connection on board. Resistivity cell temperature sensor replace resistivity cell out of tolerance. (e1403x1a). Reservoir water temperature ou...

Page 51

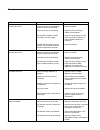

51 t roubleshooting problem (cont.) possible causes (cont.) action (cont.) high ro feed purity improper feed water analyze feed water - check that (unit being fed pretreated water). System is being used for correct application. Ro feed cell not connected to control check connection of feed cell. Boa...

Page 52

T roubleshooting problem (cont.) possible causes (cont.) action (cont.) pressure sensor er2 pressure sensor not connected to check connection. Board or improperly connected. Pressure sensor not functioning. Replace pressure sensor(s) (tdx8) and recalibrate. Possible leak, prefilter installed check f...

Page 53

53 t roubleshooting problem (cont.) possible causes (cont.) action (cont.) check res uv reservoir uv lamp cable not plug reservoir uv lamp cable into plugged in. Control board. Reservoir uv lamp burnt out or replace reservoir uv lamp inadequate uv output. (lmx31) and reset timer. Reservoir uv lamp n...

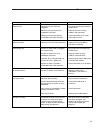

Page 54

54 t roubleshooting routine care message possible causes action replace carbon chlorine capacity of the carbon replace carbon prefilter prefilter has been reached, or 1 year (d502115) and reset the carbon service life has expired. Prefilter timer. Check prefilter system has sensed that the prefilter...

Page 55

55 replacement parts consumables consumable parts are those required to support the day-to-day operation of this equipment. Barnstead international establishes two types of consumables; those items that must periodically be replaced to maintain performance (filters, resin cartridges, etc.) and other...

Page 56

56 r eplacement p arts general maintenance general maintenance parts are defined as laboratory level repair parts which do not require great expertise or special tools for installation. Barnstead international recommends that you stock the general maintenance parts as an aid to ensuring the continue...

Page 57

57 wiring diagrams red blk +24 v dc gnd -12 v dc n/c gnd +5 vdc gnd +12 v dc interfa ce p.C. Board (interface ) pressure (prefilter ) pressure (membrane ) fl o w s en sor pump (ro system ) p.C. Board (main ) pump (di system ) pressure (inlet ) p 3 p4 p2 p1 m 4 m1 m2 m 3 p c 14 03 x 3 p u 11 90 x 1 t...

Page 58

58 w iring d iagrams h j j h g n d g r n re d b lk yel g r n grn , wht b l k re d 1 jmp 1 jmp 2 1 jmp 3 1 (neutral ) (line ) left s id e co nne c ti on d etai l ref . A1 de sc ripti on a ccu -di s pen s e a ss embl y d14031 / d14 0 4 1 d1 3661 - d14 061 - d14 062 - d14 063 - d14 064 - d14 0 7 1 - d1...

Page 59

59 ordering information please refer to the specification plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any corre- spondence concerning this unit. All parts listed herein may be ordered from the barnstead international dealer f...

Page 60

60 two year limited warranty barnstead international (“barnstead”) warrants that a product manufactured by barnstead shall be free of defects in materials and workmanship for two (2) year from the first to occur of (i) the date the product is sold by barnstead or (ii) the date the product is purchas...