- DL manuals

- Barnstead

- Water Filtration Systems

- EASYpure LF

- Operation Manual And Parts List

Barnstead EASYpure LF Operation Manual And Parts List

Summary of EASYpure LF

Page 2: Table of Contents

2 important information this manual contains important operating and safety information. You must carefully read and understand the contents of this manual prior to the use of this equipment. Water purification technology employs one or more of the following: chemicals, electrical devices, mercury v...

Page 3: Safety Information

3 safety information your barnstead easypure lf has been designed with function, reliability, and safety in mind. It is your respon- sibility to install it in conformance with local electrical codes. For safe operation, please pay attention to the alert boxes throughout the manual. Alert boxes warni...

Page 4: Warnings

4 warnings warning to avoid electrical shock, always: 1. Use a properly grounded electrical outlet of correct voltage and current handling capacity. 2. Do not locate the easypure lf directly over equipment that requires electrical service. Routine main- tenance of this unit may involve water spillag...

Page 5: Introduction

5 introduction the barnstead easypure lf is a line-fed water purifica- tion system designed to provide type i reagent-grade water with extremely low organic content. It uses a three-stage deionization process combined with a 0.2 micron filter to polish pretreated water (distilled, deion- ized, or re...

Page 6: Specifications

6 specifications dimensions and clearance requirements. Easypure lf dimensions - 12 7/8" w x 19" d x 17 1/8" h (32.7 cm x 48.3 cm x 43.5 cm). Clearances: sides - 4" (10.2 cm) minimum to allow air flow. Above - 12" (30.5 cm) minimum for removal of the top cover. Cartridge replacement requires that yo...

Page 8: Unpackaging and Installation

8 unpackaging and installation 1. Remove the unit from its shipping container. Ensure that the tubing, adapter and power cord are removed from the packaging materials before discarding. Description catalog number easypure high purity/low toc cartridge d50229 pretreatment cartridge di feed d50230 pre...

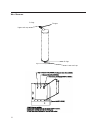

Page 9: Tubing Adapter Installation

9 tubing adapter installation 1. Completely disassemble the fitting. Refer to figure 3 to familiarize yourself with the names of the com- ponent parts. 2. Make sure the tubing is cut off reasonably square and that no plastic burrs or ridges are present. 3. Place the grab ring and back-up ring in the...

Page 10: Wall Mounting

10 wall mounting install the wall bracket on the wall in a location that is ac- cessible to water and convenient to use. A minimum of 4 fasteners must be used. 1. Remove the pump interlock plug from the rear of the unit. 2. Open cartridge access door in the rear of the unit. 3. Remove the cover of t...

Page 11

11 9. Install the four screws removed in step 7 through the bottom of the wall bracket and into the easypure lf. 10. Snake the tubing removed in step 4 through the hole in the easypure lf floor and the wall bracket and attach it to the quick disconnect body installed on the side of the bracket. 11. ...

Page 12

12 figure 5 cartridge installation w all m ounting o-rings upper end cap flanges o-rings lower end cap.

Page 13: Initial Operation

13 initial operation cartridge installation and rinse up 1. Open cartridge access door in the rear of the unit by pushing the door latch down. 2. Remove a new pretreatment cartridge (catalog no. D50230 or d50231) from its plastic bag. 3. Wet the o-rings on both end caps. 4. Press the upper end cap i...

Page 14: Normal Operation

14 normal operation 1. Press the “start” button on the front of the easypure lf. The easypure lf’s pump will begin to run and the purity meter will display the resistivity of the water in megohm- cm. 2. Allow the water’s resistivity to rise to the desired purity before drawing off water. Water draw ...

Page 15: Installing Float Or Pressure

15 installing float or pressure switch accessories d0606 (float switch) and d2706 (pressure switch) are designed to protect the easypure lf pump by alerting the easypure lf of an inadequate feedwater condition so that the pump can be shut down. Use the following instructions for installation. 1. Dis...

Page 16: Maintenance and Servicing

16 maintenance and servicing cartridge replacement the frequency with which you will need to replace cartridg- es is dependent on your feedwater’s characteristics, your purity requirements and your usage. Replace the cartridges when the product water purity drops below acceptable lev- els of resisti...

Page 17

17 0.2 micron filter replacement replace the 0.2 micron filter whenever any of the follow- ing conditions occur: every 30 days, the product water flow rate is reduced or bacteria break through. The 0.2 micron filter is shipped assembled with a bell. To replace the 0.2 micron filter assembly: 1. Remo...

Page 18

18 3. Depressurize system by opening the draw-off valve. 4. Open the cartridge access door in the rear of the unit by sliding the latch down and pulling the door toward you. The door will swing down. 5. Remove exhausted cartridge in the right-hand position by pulling it first up and then out. 6. Rem...

Page 19

19 8. Replace fuse drawer. 9. Replace cover, power cord, and pump interlock plug. 10. Reconnect unit to power supply, and connect in- coming water line at quick disconnect. Printed circuit board replacement 1. Turn system off. 2. Disconnect incoming water line at quick disconnect. Depressurize syste...

Page 20

20 supply (3 wires) from printed circuit board. 14. Reconnect power supply to new printed circuit board and install the new printed circuit board. Refer to elec- trical diagrams. 15. Reconnect the resistivity cell lead and printed circuit board relay plug. 16. Reconnect the membrane switch lead. 17....

Page 21

21 cleaning the resistivity cell 1. Turn unit off. 2. Disconnect incoming water line at quick disconnect. Depressurize system by opening outlet valve. 3. Disconnect the easypure lf from the power sup- ply. 4. Remove the power cord from the power entry mod- ule, and remove the pump interlock plug fro...

Page 22

22 14. Reinstall the cell into the cell well and hand tighten. Reroute the cable up through the housing and recon- nect. 15. Reinstall the screw holding the cell-cable retaining clip. Reinstall membrane switch lead. Replace the front cover. Retape the luer fitting with new teflon tape and reinstall ...

Page 23

23 troubleshooting problem possible causes solutions easypure lf completely no electrical power to ensure that the easypure lf power inactive. (pump not operating, easypure lf. Cord is connected to a live power control panel not lit, etc.). Source and completely plugged into electrical outlet. Make ...

Page 24

24 problem possible causes solutions 0.2 micron final filter clogs easypure lf contaminated sanitize easypure lf according rapidly after replacement. With bacteria. To the instructions in system sanitization. Replace the 0.2 filter assembly as indicated in the 0.2 micron filter replacement section. ...

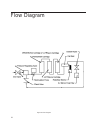

Page 28

28 figure 8 flow diagram flow diagram.

Page 29

29 figure 9 100 volt wiring schematic or float switch. Optional pressure for use with with jumper plug pump interlock fuse draw with switch and power entry module power cord membrane blue and yellow cell 3 black motor pump red orange monitor resistivity pcb's 2 1 4 switch red black transformer 100/1...

Page 30

W iring d iagram 30 or float switch. Optional pressure with jumper plug pump interlock with switch and power entry module power cord optional pressure cat. No. D2706 switch 2 4 3 yellow blue and optional float cat. No. D0603 switch cr 1 orange black motor pump red 2 3 1 4 2 3 4 for use with line fil...

Page 31

31 figure 11 240 volt wiring schematic or float switch. Optional pressure with jumper plug pump interlock with switch and power entry module power cord black optional pressure cat. No. D2706 switch 2 4 3 yellow optional float cat. No. D0606 switch cr 1 orange blue motor pump red 2 3 1 4 2 3 4 for us...

Page 32

32 or float switch. Optional pressure with jumper plug pump interlock with switch and power entry module power cord black optional pressure cat. No. D2706 switch 2 4 3 yellow optional float cat. No. D0606 switch cr 1 orange blue motor pump red 2 3 1 4 2 3 4 for use with line filter 230 v.A.C. Monito...

Page 33

33.

Page 34

34.

Page 36: Barnstead Thermolyne

36 barnstead thermolyne 2555 kerper blvd. P.O. Box 797 dubuque, ia 52004-0797 usa phone: 319-556-2241 • 800-553-0039 fax: 319-589-0516 e-mail: mkt@barnsteadthermolyne.Com a subsidiary of.