- DL manuals

- Barnstead

- Laboratory Equipment

- Harvey EC5500

- Owner's/operator's Manual

Barnstead Harvey EC5500 Owner's/operator's Manual

Summary of Harvey EC5500

Page 1

1 harvey ® chemiclave ec5500/ec6000 sterilizers owner/operator manual ec5500 series 1121 ec6000 series 1122 lt1121x1 • 1/9/03.

Page 2

2 table of contents safety information ..................................................................................................................................................................3 alert signals.......................................................................................

Page 3

3 safety information your harvey ® chemiclave ec5500/ec6000 sterilizer has been designed with function, reliability and safety in mind. It is your responsibility to install it in conformance with local electrical codes. This manual contains impor- tant safety information. You must carefully read and...

Page 4

4 the harvey ® chemiclave sterilizer is a safe, fast and effective sterilizer for use in medical and dental offices, hospitals, clin- ics and other health care facilities. To sterilize goods, chemiclave sterilizers use an unsaturated chemical vapor process. This method is proven for sterilizing inst...

Page 5

5 controls and features power switch the power switch on the front of the sterilizer turns power to the sterilizer on (i) or off (o). See figure 1. Control panel pressure gauge displays the chamber pressure. See figure 2. Timer times the 20 minute exposure phase and the purge phase. During the count...

Page 6

6 chemi-filter ® the chemi-filter is a cylindrical filter that is placed in the top of the sterilizer, directly behind the fill funnel. It removes form- aldehyde and potentially objectionable odors from the chemiclave exhaust. Door latch the door latch secures the door. It is opened by the door hand...

Page 7

7 warning do not attempt to open the door until the pressure gauge has returned to 0 psig. Warning do not use this equipment to sterilize volatile substances or for any purpose other than its intended design. Warning do not operate the chemiclave without a chemi-filter in place. Operation with- out ...

Page 8

8 preparing items for sterilization 1. Thoroughly clean, rinse and dry the items before placing them in the sterilizer, an ultrasonic cleaner is suggested for removal of debris. 2. Clean and lubricate instruments according to the manufacturer’s instructions. 3. If processed instruments will be store...

Page 9

11 draining the waste tank 1. Insert the open end of the tubing into a contain- er. 2. Lock the drain fitting into the drain port. Waste will begin to exit the drain (see figure 4). 3. To release the drain fitting, press the release tab. 4. Store the tubing with the drain fitting attached. 5. Dispos...

Page 10

12 filling the reservoir 1. Locate the fill funnel (see figure 5). Remove cap from the fill funnel. 2. Remove the cap from a bottle of vapo-steril solution, and attach the fill spout. 3. Invert the bottle. Insert the fill spout completely into the fill funnel. 4. Empty the bottle into the reservoir....

Page 11

13 o peration figure 6: controls and features.

Page 12

14 warning do not use this equipment to sterilize volatile substances or for any other purpose than its intended design. Warning do not use this equipment to sterilize liquids or solutions. Attempts to process liquids or solutions in the ster- ilizer could result in (1) the liquids boil- ing over an...

Page 13

15 unwrapped goods • use harvey chemi-test tray liners. • be sure instruments are clean and dry. • do not overload. Maximum loads: ec5500—3.1 lb. (1400 g); ec6000— 6.2 lb. (2800g). Wrapped goods • package loads loosely—single wrapped, paper bags or pouches. This permits chemical vapor penetration. •...

Page 14

16 if the door will not open 1. Swing the door handle 180°. 2. Hook the fingers of your left hand around the door handle and brace your left thumb against the right side of the sterilizer. 3. Squeeze so the handle pulls directly to the right (see figure 10). This will release the door latch. The doo...

Page 15

17 starting the cycle 1. Turn the control knob to pressurize. • this starts the exposure phase of the cycle (see figure 11). • the timer will display “20.” • chamber pressure will increase. Timed exposure begins • when chamber pressure reaches 20 psi, the timer starts automatically (see figure 12). ...

Page 16

18 completing the cycle 1. After the tone sounds, turn the control knob to depressurize (see figure 13). After 1 minute, the automatic purge phase begins (see figure 14). • the purge indicator lights. • the complete indicator goes out. • the timer displays “07” (ec5500) or “09” (ec6000). • the decim...

Page 17

19 • squeeze so the handle pulls directly to the right (see figure 15 ). This will release the door latch. The door will now open. 2. Open door fully. 3. Use the tray handle to remove the tray from the sterilizer (see figure 16). When the unit is not in use, leave the door closed but unlatched. This...

Page 18

20 stopping a cycle if you must stop a cycle before it is complete, follow the procedure below: 1. Turn the control knob to depressurize. 2. Observe the sterilizer. A. The timer displays “00.” b. The tone sounds. C. The purge indicator flashes during the tone. D. The purge phase will run (refer to “...

Page 19

21 3. Leave the control knob at pressurize. This keeps the chamber sealed. 4. Do not remove the load yet. Wait for the power to be restored. Power restored when the power is restored, the sterilizer responds dif- ferently depending on (1) the model and (2) where in the cycle it was interrupted. (see...

Page 20

22 troubleshooting m e l b o r p e s u a c e l b a b o r p y d e m e r g n i r u d s p o t s r e m i t . E s a h p e r u s o p x e d e p p o r d s a h e r u s s e r p . I s p 0 2 w o l e b f i . E m u s e r ll i w r e m i t , i s p 0 2 o t s n r u t e r e r u s s e r p n e h w s e s o l t i n u " e ...

Page 21

23 daily cleaning the door gasket wipe the door gasket and mating surface each day with a clean, damp cloth (see figure 19 ) do not use abrasive cleaners. Examine the door gasket for cracks or damage, which could result in a poor pressure seal. If replacement is required, refer to “door gasket repla...

Page 22

24 draining the waste tank drain the waste tank when the vapo indicator lights on the control panel (see figure 20). If preferred, drain the waste tank daily – but also when the vapo indicator lights. Store the tubing with the drain fitting attached. Warning vapo-steril solution causes eye dam- age ...

Page 23

25 weekly cleaning the chamber and trays 1. Close the door. 2. Turn on the power switch. Wait 2 minutes. 3. Turn off the power switch. 4. Open the door. The chamber should be warm, not hot. 5. Clean the chamber and trays with harvey chamber cleaner. Follow the instructions on the container. Monthly ...

Page 24

26 when required replacing the chemi-filter 1. Be sure the power switch is off. (see figure.) 2. Grasp the pull strap at the top of the used chemi-filter. Remove the filter from the filter opening. Dispose of it properly. 3. Remove the new chemi-filter from its package. 4. Mark the replacement date ...

Page 25

27 months until replacement calculation values needed: 1. Assign proper values to c, d and t. C = no. Of cycles/workday (operator defined) d = no. Of workdays/week (operator defined) t = total no. Of cycles before filter needs re- placement (see chart ) calculation: 2. Insert the values for c, d and...

Page 26

28 door adjustment if chamber pressure is not retained during a cycle, door adjustment may be necessary. 1. Clean or replace the door gasket if necessary. 2. Turn the sterilizer on. Run a “no load” cycle to heat it to operating temperature. When the cycle is complete and chamber pressure is below 2 ...

Page 27

29 installation to install the sterilizer, complete these steps: • position the sterilizer. • make the electrical connection. • install the chemi-filter. • perform an operational checkout. Positioning the sterilizer area of operation operate the system only in a well ventilated area. Support surface...

Page 28

30 figure 26: positioning the unit m aintenance figure 27: electrical connection.

Page 29

31 electrical requirements a separate electrical circuit is recommended for the electri- cal power source for the chemiclave (see figure 27). Chemi-filter installation 1. Remove the new chemi-filter from its package. 2. Mark the replacement date in the “replace by” box on the chemi-filter label or r...

Page 30

32 a t a d l a c i n h c e t 0 0 5 5 c e l e d o m e z i s t e n i b a c d " 5 . 8 1 x h " 3 1 x w " 5 7 . 6 1 ) m m 0 7 4 x m m 0 3 3 x m m 5 2 4 ( e z i s r e b m a h c p e e d " 5 2 . 3 1 x r e t e m a i d " 8 ) m m 7 3 3 x m m 3 0 2 ( t h g i e w ) g k 8 . 6 2 ( . S b l 9 5 e g a t t a w r e t a...

Page 31

33 t echnical s pecifications declaration of conformity barnstead international hereby declares under its sole responsibility that this product conforms with the technical requirements of the following standards (230 volt models only): emc: en 61326-1 safety: en 61010-1 en 61010-2-010 and meet(s) th...

Page 32

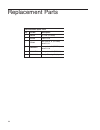

34 replacement parts s t r a p e r a p s d e d n e m m o c e r . Y t q . O n t r a p n o i t p i r c s e d 1 0 6 5 0 6 2 ) 0 0 5 5 c e ( r e t li f r i a 1 9 6 5 1 6 2 r e t li f - i m e h c 1 0 6 x s g ) 0 0 5 5 c e ( " 8 , t e k s a g r o o d 1 2 1 1 s e i r e s 1 1 0 3 0 0 0 0 8 2 ) 0 0 5 5 c e (...

Page 33

35 ordering procedures please refer to the specification plate for the complete model number, serial number and series number when requesting service, replacement parts or in any correspondence concerning this unit. All parts listed herein may be ordered from the barnstead international dealer from ...

Page 34

36 agar: semisolid growth medium used in growing microorganisms. Biological indicator: a calibrated population of bacterial spores (of high resistance to the mode of steriliza- tion being monitored) in or on a carrier, put up in a package which maintains the integrity of the inoculated car- rier and...

Page 35

37 g lossary psi: (pounds per square inch) english unit of pressure. Purge: phase of the cycle when vapors are removed from the chamber. B/t sure biological indicator: a biological indicator strip for monitoring steam and chemical vapor steriliza- tion, available from harvey. Sterilant: chemical sol...