- DL manuals

- Barnstead

- Cooktop

- SUPER-NUOVA HP133420-33

- Operation Manual And Parts List

Barnstead SUPER-NUOVA HP133420-33 Operation Manual And Parts List

SUPER-NUOVA

™

Digital Plates

OPERATION MANUAL

AND PARTS LIST

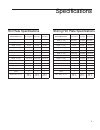

Model #

Voltage

Description

HP133425

120

7X7 Hot Plate

HP133420-33

220-240

7X7 Hot Plate

HP133424

100

7X7 Hot Plate

SP133525

120

7X7 Stirring Hot Plate

SP133520-33

220-240

7X7 Stirring Hot Plate

SP133524

100

7X7 Stirring Hot Plate

LT1335X1 • 7/20/05

Summary of SUPER-NUOVA HP133420-33

Page 1

Super-nuova ™ digital plates operation manual and parts list model # voltage description hp133425 120 7x7 hot plate hp133420-33 220-240 7x7 hot plate hp133424 100 7x7 hot plate sp133525 120 7x7 stirring hot plate sp133520-33 220-240 7x7 stirring hot plate sp133524 100 7x7 stirring hot plate lt1335x1...

Page 2

Safety information ........................................................................................................................................................3 alert boxes ......................................................................................................................

Page 4

6. Use appropriate hand and eye protection when handling hazardous chemicals. 7. Gross weight of items placed on top of units should not exceed 25 lbs. (11.3 kg). 8. “caution: hot top. Avoid contact.” the top plate of the unit can remain hot for some time after use. A “caution - hot top” light will ...

Page 5

5 s n o i s n e m i d l l a r e v o 3 3 - 0 2 4 3 3 1 p h 4 2 4 3 3 1 p h 5 2 4 3 3 1 p h ) m c ( . N i - h t d i w ) 8 . 0 2 ( 2 . 8 ) 8 . 0 2 ( 2 . 8 ) 8 . 0 2 ( 2 . 8 ) m c ( . N i - t h g i e h ) 7 . 9 ( 8 . 3 ) 7 . 9 ( 8 . 3 ) 7 . 9 ( 8 . 3 ) m c ( . N i - h t p e d ) 3 3 ( 3 1 ) 3 3 ( 3 1 ) 3 ...

Page 6

6 g eneral s pecifications heating specifications top plate surface - solid aluminum temperature range: 1°c - 300°c (34°f - 572°f)* * these plates do not cool. The minimum temperature is 1°c if used in a cold room below 1°c. Heat-up time to within 5°c of maximum temperature (unloaded top plate). 5 m...

Page 7

7 g eneral s pecifications environmental conditions operating: 0°c to 27°c; 20% to 80% relative humidity, non-condensing. Installation category ii (overvoltage) in accordance with iec 664. Pollution degree 2 in accordance with iec 664. Altitude limit: 2,000 meters. Storage: -25°c to 65°c 10% to 85% ...

Page 9

9 unpacking remove your super-nuova plate from the carton. Inspect to ensure that the unit has not been damaged during shipment. If the unit appears to have sustained shipping damage contact the distributor from whom you purchased this product or barnstead international customer service at 800-553-0...

Page 10

10 u npacking and i nstallation rpm rpm stir stir presets presets power power super-nuova ™ super-nuova ™ c c heat heat 1 2 3 4 set external probe external probe set pause timer timer 12 8 4 2 1 (hours) adjust ca caution! Ution! Hot top hot top 1 2 4 13 7 8 9 6 3 12 14 10 16 15 11 5* *use only a no....

Page 11

11 u npacking and i nstallation control panel key description 1 caution! Hot top indicator 2 temperature display 3 temperature set button 4 power button 5 writable preset surface 6 preset buttons 7 external probe indicator light 8 set indicator light 9 knob 10 timer 11 timer indicator lights 12 spee...

Page 12

Each super-nuova unit utilizes the latest microproces- sor technology to deliver the most reliable, accurately controlled, aluminum top digital plate on the market. Your super-nuova plate has an electronic, closed-loop feedback control which will accurately maintain tempera- ture setpoints from 1°c ...

Page 13

Power button the super-nuova unit has a power button located on the front control panel. The unit may be powered on by pressing the power button or any button on the control panel. When the unit is turned on, there will be three beeps, the unit will initialize and then “off” will be dis- played on b...

Page 14

14 note the temperature display will indicate the actual temperature of the top plate (1°-300°c). This plate does not cool. The minimum temperature is 1°c if used in a cold room at 1°c. Note the top plate temperature will be higher than the solution temperature. O peration setting the temperature th...

Page 15

15 controlling solution temperature using external probe to control the solution temperature plug the included probe or an ungrounded type k thermocouple probe into the probe receptacle located on the right side of the unit. Be careful to observe the correct polarity of the probe connector when inse...

Page 16

16 using preset programs the super-nuova plate features the option of presetting 4 setpoints into its memory. To program a preset, adjust the heat and/or stir features to your desired setpoints. Press and hold one of the presets and the unit will beep indicating those setpoints have been stored in m...

Page 17

17 o peration if at any time you wish to reset the timer, press the right or left arrow keys until the indicator light corresponds to your desired time. The unit will beep indicating it has been reset. One minute before shutdown, the unit will beep three times and flash the 1 hour light. The unit wi...

Page 18

18 rs232 output an rs232 port is available on the super-nuova to output elapsed time, speed, and temperature data. The data is print- ed once every second when the unit is powered on (displays on). A comma separates each piece of data so that it may easily be imported into a spreadsheet as csv (comm...

Page 19

19 using hyperterminal w/rs232 with hyperterminal you can store the rs232 output data of a super-nuova on a pc. Note: other terminal programs that capture rs232 data can be used as well. In order to follow this procedure, you must have: • microsoft windows 95‚ or greater with hyperterminal installed...

Page 20

5. Select file, save as, and save this setup wherever you would like it to be located (if you would like it on the desktop, select desktop) and select save. You will be able to run hyperterminal with this setup in the future by just double-clicking the icon if you put it on the desktop. 6. The setup...

Page 21

E r u t a e f y a l p s i d y t i l i b a l i a v a n o i t p i r c s e d f e i r b t n i o p t e s e r u t a r e p m e t - r e v o p s o p s , p h e h t f o g n i t t e s e h t e e s o t r e s u e h t w o ll a . L o r t n o c n o i t c e t o r p e r u t a r e p m e t r e v o e b o r p e r u t a r e...

Page 22

22 over-temperature set point - osp this option is only available for units that have heating functionality. The over-temperature set point is the set point of the independent temperature control. The pur- pose of the control is to limit the top temperature of the element independently of the standa...

Page 23

23 temperature probe calibration - cal this section applies only to the calibration of the temperature probe system. The hot plate surface and the motor speed cannot be calibrated. This method is only applicable to units that have heating functionality. There are two types of calibration available. ...

Page 24

System method of calibration 1. Select an independent temperature probe to be placed in the load, along with the unit tempera- ture probe before continuing with calibration. Select the load to be calibrated, and place on top of the hot plate. Place a stir bar in the mix- ture if stirring is desired ...

Page 25

25 stirring capability then skip to the next step. The set indicator under the stir display will be lit, and the displays will show the stirring control set point. The speed may be adjusted by using the center knob. The adjustable range is 50 – 999, and also off (zero). When the adjustment is comple...

Page 26

26 holding the power key. After about 3 seconds a single beep will be heard and you may remove your finger from the power key. The display will change to osp. 3. Rotate the center knob dial one position clock- wise and the display will read cal. This is the calibration menu. Press the set key under ...

Page 27

Hot top warning system is indicating a hot sur- face), enter the service menu by pressing and holding the power key. After about 3 seconds a single beep will be heard and you may remove your finger from the power key. The display will change to osp. 2. Rotate the center knob until the display reads ...

Page 28

28 accept, and the display will change to h (heating off), h s (heating and stirring off), or s (stirring off). Rotate the center knob to change the display to the method of choice and press the set key under either display again. 3. The unit will return to the previous menu. Select another feature ...

Page 29

Probe response - pr this feature is available for units with heating functionality and is only applicable when using a probe. The purpose of this feature is to select the minimum time required for a temperature change to be detected before signaling a probe out of solution error (e03). A choice betw...

Page 30

Of osp. Selection of ul would allow the set point to be unlimited and would not be affected by osp setting. To modify/view the set point limit follow the instructions given below: 1. Plug the unit into the appropriate power, but do not turn it on (displays should be blank, unless hot top warning sys...

Page 31

2. Rotate the center knob until the display reads err. Press the set key under either display to accept, and the display will change to clr (re- enable all disabled errors). Rotate the center knob to change the display to the error number of choice and press the set key under either display again. 3...

Page 32

3. The unit has now been returned to the factory default settings. The unit will return to the previ- ous menu. Select another feature to change, or press the power key again to return to the off mode. Model selection - sel this feature is available for all units to select the type and size, but sho...

Page 33

Flash upgrade - fls this feature is available for all units and is designed to allow a firmware upgrade via rs232 port to be applied without exchanging controls. Note: special software and an rs232 cable are required to complete this proce- dure. Complete instruction will be included with the firmwa...

Page 34

34 e g a s s e m d e y a l p s i d t c e t e d o t d e d n e t n i e s u a c n o i t u l o s 1 0 e f o t u o e l p u o c o m r e h t l a n r e t n i . E g n a r t o n e l p u o c o m r e h t l a n r e t n i . D e t c e n n o c . N e p o e l p u o c o m r e h t d e t c e n n o c e l p u o c o m r e h...

Page 35

35 t roubleshooting e g a s s e m d e y a l p s i d t c e t e d o t d e d n e t n i e s u a c n o i t u l o s 7 0 e n e e w t e b e c n e r e f f i d e g r a l d n a e l p u o c o m r e h t l a n r e t n i . E l p u o c o m r e h t p t o e l p u o c o m r e h t p t o r o l a n r e t n i . D e t c e ...

Page 36

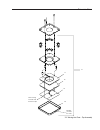

36 exploded views 6 5 7 8 9 10 11 22 13 14 12 16 15 2 1 3 4 7x7 stirring hot plate - exploded view.

Page 37

37 e xploded v iews 21 18 19 20 17 note routing of leads and thermocouple number located this side 7x7 stirring hot plate - top assembly.

Page 38

38 e xploded v iews 7 x 7 hot plate - exploded view 5 6 7 8 10 22 12 13 16 1 2 3 4.

Page 39

39 e xploded v iews 21 17 18 19 20 7 x 7 hot plate - top assembly.

Page 40

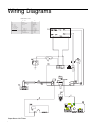

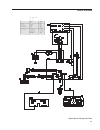

40 wiring diagrams pc2 pc1 (220-240v) el1 (100v) c1 pc1318x1 display pcb component chart cex373 elx51 inlet element control pcb description (7x7) el1 (120v) element elx50 el1 (220-240v) element elx52 pc1 (100-120v) ( ) control pcb c2 ext. Probe cex376 c3 rs232 wh1318x1 f1 (220-240 only) fuse 261575 ...

Page 41

41 w iring d iagrams super-nuova stirring hot plates s1 pc2 pc1 (220-240v) mt1 (220-240v) el1 (100v) c1 pc1318x1 display pcb sc1313x1 speed sensor component chart cex373 elx51 mt1318x2 inlet element motor control pcb description (7x7) el1 (120v) element elx50 el1 (220-240v) element elx52 mt1 (100-12...

Page 42

42 to insure your safety and for proper operation, the aluminum top plates for hot plates and stir plates are only sold as complete assemblies. This assembly includes the aluminum top, element, thermocouple, insulation, baffle plate, and 2 aluminum top holders. Barnstead recommends not replacing ind...

Page 43

43 accessories part no. Description tc732x1 general purpose immersion probe with 6” (15.24 cm) stainless steel sheath tc732x2 general purpose immersion probe with 10” (25.40 cm) stainless steel sheath tc727x2 chemically-resistant immersion probe with 7” (17.78 cm) teflon sheath 711s non-mercury ther...

Page 44

Please refer to the specification plate for the complete model number, serial number, and series number when requesting service, replacement parts or in any corre- spondence concerning this unit. All parts listed herein may be ordered from the barnstead international dealer from whom you purchased t...

Page 45

45.

Page 46

46.

Page 47

47.

Page 48

48 barnstead international (“barnstead”) warrants that if a product manufactured by barnstead shall be free of defects in materials and workmanship for two (2) years from the first to occur of (i) the date the product is sold by barnstead or (ii) the date the product is purchased by the original ret...