- DL manuals

- Baroness

- Lawn Mower

- LM18G

- Service Manual

Baroness LM18G Service Manual

Summary of LM18G

Page 1

Ver.1.3.

Page 2

Introduction this service manual describes the steps to maintain the baroness greens mower lm18g, lm56g and lm66t as well as the resources for diagnosing malfunctions and other issues. The content is organized by categories of representative maintenance methods. Please refer to the appropriate chapt...

Page 3

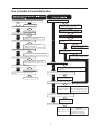

Specifications ......................................................................................................... 1 part names ........................................................................................................... 1 maintenance schedule ......................................

Page 4

1 1 specifications part names head light switch throttle lever handle engine clutch cover blade reel engine switch engine switch cord brake lever drum wheel wheel shaft traveling wheel grass catcher front roller front groome safety lock lever main clutch lever head lamp engine lm56g lm18g model lm66...

Page 5

22 3 locations for greasing maintenance schedule before use every 8hr only after the initial operation every 10hr every 50hr engine main unit every 10hr left frame intermediate shaft (for reel) right & left frame intermediate shaft (for drum) differential gear parts vertical gear case intermediate s...

Page 6

22 3 how to handle a product malfunction is the mowing height on both sides adjusted to be the same? Adjust the mowing height. Is the bedknife cracked? Replace the bedknife. Does the front roller rattle up and down? Replace the bearing on the front roller. Replace the front roller shaft. Does the dr...

Page 7

44 5 yes no no are genuine parts used for the blades? Replace the blades with genuine parts. Does the bedknife & reel have too much contact? Is the blade surface of the bedknife too rough? Have you recently applied topdressing sand to the greens? Engage the blades lightly. Is the grain size of lappi...

Page 8

44 5 is the roller bracket secured? Is the mower adjusted to the correct mowing height? Adjust the mowing height. Does the front roller rattle up and down? Replace the bearing on the front roller. Replace the front roller shaft. Tighten and secure the bracket. Replace the locking screw. Does the dru...

Page 9

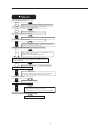

66 7 required tools * tool sizes are indicated in mm. Notes for inspection always refer to this service manual as well as the owner’s manual when inspecting the mower. During the inspection and operation of the mower, always wear gloves. “left” and “right” directions in this manual are based on the ...

Page 10

66 7 change lever travel on drum operation reel cutter stop travel on drum stop drum operation reel cutter stop reel cutter operation reel on * please always wear gloves during this replacement as it could be dangerous. 1) set up the stand first, and then remove the traveling wheels on both sides. 2...

Page 11

88 9 groomer ass'y tall nut square-root bolt right case locking bolt tall nut groomer ass'y lower pull out to the right square-root bolt clutch cover bolt 6) open the clutch cover [5-1,2,50]. 7) remove the bolts [1-25] on both sides that are holding the reel cover. Models equipped with a groomer 8) ...

Page 12

88 9 9) loosen the lock nut [1-21] on the cutter pin on both sides, and then loosen the cutter pins [1-20]. * when the blade adjusting nut [1-1] is tightened, the bedknife is lowered (to avoid contact between the reel and bedknife at the time of assembly). 10) remove the two bolts [1-25] that secure...

Page 13

10 10 11 14) remove the 6 bolt 10 , 6 s washer , clutch retainer spring [6-56], and remove the h/l change lever [6-91] from left side cover. 15) loosen the hexagon socket head bolt on the wheel driving fitting, amd then remove the fitting. Remove the key [4-11] from the drum shaft. 16) unscrew the s...

Page 14

10 10 11 16 left hand threaded nut 3p1.5 3.2 compression spring 26.922 2spcc washer 1635 cover models not equipped with a groomer remove the bolt and nut, and detach the cover [1-28]. Remove the two left nuts [1-32], washer [1-34], and spring [1-35]. * the nuts are left-hand threaded..

Page 15

12 12 13 19) detach the o-ring p18 [1-33] and the pin lock cover [1-44] from the reel shaft on the left frame, and using a pin remover remove the needle roller [1-45] and left bearing collar [1-43]. * make sure that the 20-tooth reel gear has been re- moved. 20) remove the tapered roller bearing [1-...

Page 16

12 12 13 1) using a flathead screwdriver, remove the oil seal [1-38]. * be careful not to scratch the frame. 2) remove the bearing core[1-36] by hammering a flat- head screwdriver equally around the bearing. (pay attention to the direction of hammering.) * since the outer bearing is not pressed fit,...

Page 17

14 14 15 6) hammer the oil seal [1-38] into the housing. * the oil seal needs to be hammered deep inside while paying attention to the direction of the housing and oil seal. 7) hammer the tapered bearing core [1-36] into the hous- ing [1-58]. * please make sure that the direction of the bearing is p...

Page 18

14 14 15 11) insert the spline side of the reel cutter into the left frame [6-43]. * be careful not to damage the oil seal. 12) set up the reel cutter by reversing the steps to remove it. * please refer to pages 12-12). (install the right reel housing on the right frame.) 13) set the right reel hous...

Page 19

16 16 17 16) insert an item such as a wooden hammer handle into the reel cutter to prevent the reel from turning. 17) set the spring [1-35] and the gear [8-46] on the right reel housing while making sure that the direction and the order are correct. * the gear and nut are left-hand threaded. * make ...

Page 20

16 16 17 * place the bedknife comp on a stable workbench dur- ing the replacement. Remove the bedknife [1-17,18,64,65,66,67,68] by loos- ening the screw [1-19] with an impact driver or punch. Attaching the bedknife place the bedknife base [1-15,16,69] on a stable workbench and attach the bedknife [1...

Page 21

18 18 19 3) align the punch mark of the cam bush on both sides to the mowing direction. 4) make sure that the reel cutter and bedknife contact. 5) try to cut a strip of newspaper from left to right while gently turning the reel (at 5 to 6 different places) * if the reel and bedknife are not yet enga...

Page 22

18 18 19 8) tighten the fulcrum seat [1-5] to the right and left frames with the bolt [1-4]. In case there are clearance between the frame and the fulcrum seat, set 1-5 piec- es of 0.4spcc washer 1220 for clearance adjustment to clear the clearance. 9) match the center of the fulcrum seat hole and t...

Page 23

20 20 21 5) apply grease on the 33-tooth reel gear and 42-tooth reel gear [1-46] , 36-tooth reel gear and 45-tooth reel gear [6-54] and the lip surface of the oil seal on both sides of the cover. Attach the left cover [6-89] as shown in the illustration. 6) secure the left cover [6-89] with the six ...

Page 24

20 20 21 equipped with the groomer 1) apply the grease (excelite ep no.2) to the 20-tooth reel gear [8-46]. Apply the grease also to the vertical gear case’s o-ring [8-48]. (make sure that the o-ring is firmly fitted into the groove.) 2) fit the vertical gear case over the 20-tooth reel gear [8-46]....

Page 25

22 22 23 1) set the reel cover into the groove behind the bedknife base. 2) secure it with the two bolts [1-25]. Bolt x 2 (left & right) reel cover reel cover bedknife base bolt [4] installation of the reel cover cover models not equipped with a groomer attach the cover. * after making sure that the...

Page 26

22 22 23 1) set up the stand and remove the traveling wheels. First, loosen the hexagon socket head bolt on the wheel driving fitting, and then remove the fitting. Remove the key [4-11] from the outer drum shaft. Use an item such as a wooden hammer handle to pre- vent the reel from turning, and remo...

Page 27

24 24 25 * make sure that the changeover clutch lever is fitted tightly into the groove of the #7 gear. Apply enough grease to the gear tooth surface and bearings when assembling them. 5) before attaching the cover, verify the gears’ movement and the number of the washers. If the cover doesn’t fit w...

Page 28

24 24 25 1) set up the stand and remove the traveling wheels. First, loosen the hexagon socket head bolt [4-10] on the wheel driving fitting, and then remove the fitting. Remove the key [4-11] from the outer drum shaft. Unscrew the six bolts [6-2] and remove the right cover [6-3]. * use a permanent ...

Page 29

26 26 27 1) set up the stand and remove the traveling wheels. Remove the left cover [6-89]. * for more information, refer to sections “ [5] overhaul of the inside of the gear case (left)” or “ [6] overhaul of the inside of the gear case (right)”. 2) remove the #1 and #2 gears. 3) remove the right co...

Page 30

26 26 27 6) gently hold both ends of the drum shaft with panto- graph jacks. (if no pantograph jack is available, use an alterna- tive and make sure that the drum shaft doesn’t come down.) 7) remove the right and left drum housings [6-29] out- ward. * if they don’t come off, remove them by tightenin...

Page 31

28 28 29 oil seal oil seal 1) remove the outer drum shaft [4-15] by unscrewing the four bolts [4-16] on each side. * secure the drum so that it doesn’t turn when loosening the bolts. 2) remove the stop rings [4-17] on both sides. Separate the right from the left drum, and remove one of them. * if an...

Page 32

28 28 29 5) have a new bearing and oil seal available, and apply grease to the lip surface of the oil seal. 6) pay attention to the direction of the oil seal and bear- ing. Hammer them parallel to the drum. (hammer the bear- ing and oil seal all the way inside.) 7) insert the intermediate drum shaft...

Page 33

30 30 31 clutch cover receiver bolt left cover bolt [6-2] bolt [6-30] bolt [6-94] hexagon socket head bolt wheel driving fitting key [9] removing / installing / disassembling / assembling the transmission shaft 1) set up the stand first, and then remove the traveling wheels on both sides. 2) open th...

Page 34

30 30 31 needle roller collar right transmission shaft stop ring needle roller 6) remove the nut [6-6] from the #3 gear. (left-hand threaded) loosen the nut while holding the #1 gear with a flat- head screwdriver to keep the #3 gear from turning. (hold the flathead screwdriver vertical to the teeth ...

Page 35

32 32 33 right transmission shaft right frame side collar (right frame side) stop ring (right frame side) collar (left frame side) stop ring (left frame side) left frame side 10) remove the 16-tooth right differential gear [6-66]. 11) first pull out the transmission shaft [6-36,80,101] in the direct...

Page 36

32 32 33 screwdriver 15) tighten the gear by turning it all the way to the left, and then turn it back to the right a quarter of a circle. (left- hand threaded) then, secure it with the lock nut [6-6]. * to avoid overstretching the transmission shaft, loosen it slightly..

Page 37

34 34 35 1) fold the stand and let the drum touch the ground. 2) set the changeover clutch lever to “reel on” position. Hold a flathead screwdriver against the 51-tooth gear [6-85] to keep it from turning, and then remove the nut from the 16-tooth [5-39]. Remove the disc spring washer and detach the...

Page 38

34 34 35 6) pull out the clutch shaft ass’y. 7) secure the clutch shaft ass’y [5-24,25,51] on a vice. Pull out the tapered pin [5-27] using a pin remover. * when securing the clutch shaft ass’y on a vice, wrap it with a waste cloth to avoid scratching the surface. * since the pin is tapered, remove ...

Page 39

36 36 37 11) install in the following order: the collar [5-38], gear [5- 39], washer [5-40], disc spring washer [5-41], and nut [5-42]. When tightening the nut, hold a flathead screwdriver against the gear a (51-tooth gear) to keep it from turn- ing. 12) when installing the engine, fit the facing in...

Page 40

36 36 37 [11] disassembling / assembling / adjusting the brake wire mounting bracket brake ass'y brake shoe brake shoe sandpaper bring down a a a b b b wire mounting bracket brake ass'y 1) remove the two bolts [7-53] from the wire mounting bracket. Remove the three bolts [7-53] from the brake ass’y....

Page 41

38 38 39 6) make sure the brake works by gripping the brake lever. (if the brake doesn’t work, adjust it by tightening the adjusting nut of the brake wire.) * set the brake shoe so that it does not always touch the brake drum. (avoid the brake always being engaged.) the brake may be engaged if, when...

Page 42

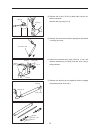

38 38 39 1) remove the tall nut [2-1], disc spring washer [2-2], washer [2-3], and square-root bolt [2-7] from the left roller bracket on the left frame. 2) first loosen the lock nut [2-26] on the right bracket and then the stopper bolt [2-25]. 3) remove the 15 extension pin 19 [2-5] while supportin...

Page 43

40 40 41 7) remove the oil seal [2-12] on both sides using a flat- head screwdriver. Remove the stop ring [2-13]. 8) remove the front roller shaft by tapping the end which is sticking out more. 9) secure the removed front roller shaft on a vice, and remove the bearing [2-14,15] from the shaft using ...

Page 44

40 40 41 preparation of replacement parts have the replacement parts ready beforehand. 1) apply some grease inside the oil seal [2-14]. Insert the bearing [2-15] into the oil seal firmly by tapping it with a wooden hammer. 2) apply grease to the lip surface of the oil seal [2-12] which is to be set ...

Page 45

42 42 43 using a driving tool, pound in the bearing and oil seal set all the way. (drive them in below the stop ring’s groove.) 4) insert the stop ring [2-13]. 5) pound in the oil seal [2-12] on the outside. (up to the edge of the roller) 6) insert the washer from the end of the roller shaft that ha...

Page 46

42 42 43 8) install the washer [2-8] and bracket [2-24] as shown in the illustration. Set and secure the flat end of the roller shaft into the stopper bolt side, and lock it. Stopper bolt washer lock nut washer front roller set in 15 extension pin 19 driving tool oil seal 9) as shown in the illustra...

Page 47

44 44 45 1) the steps are the same as those with the groomer. 2) the shape of the brackets is different. Instead of bolts and lock nuts, the hollow set is used. The hollow set is used on the flat end side of the roller shaft. [13] disassembling/assembling the front roller (without a groomer) hollow ...

Page 48

44 44 45 6 bolt 10 6s washer 6 washer clutch retainer spring clutch lever 1) refer to #1 of equipped with the groomer on page 8 for removing the front groomer from the main unit. Left vertical housing 2) remove the left vertical housing [8-63]. 3) pay attention to the direction of the oil seal [8-27...

Page 49

46 46 47 6) unscrew the four bolts [8-14,15] from the gear case cover, and then remove the cover [8-12]. 7) remove the 20-tooth vertical gear [8-30]. * lock the nut [8-76] on the groomer using a screw wrench, and remove the nut [8-29](left-hand threaded) which secures the 20-tooth vertical gear. 8) ...

Page 50

46 46 47 punch mark collar rotate the hexagon end by one side each time dethatching blade [15] setting of dethatching blades 10) loosen the lock nut [8-72] and then the hollow set [8- 71]. 11) secure the 17 special nut (groomer blade locking nut) [8-76] on the spine side using a screw wrench, re- mo...

Page 51

48 48 49 spacer spacer front roller 17 special nut dethatching blade [16] adjusting the front groomer 3) finally, insert the 17 special nut (groomer blade lock- ing nut) [8-76], secure it with the hollow set [8-71], and lock it with the lock nut [8-72]. * please do not tightened to much power. (torq...

Page 52

48 48 49 [17] disassembling/assembling the igca roller 1) remove the washer [13-10], shaft [13-11], and snap pin [13-12] from the rear frame stay[7-92]. 2) raise the catcher arm and remove it from the mower. 3) unfasten the bolts [13-15] of both side of the catcher arm. To prevent roller shaft from ...

Page 53

50 50 51 4) remove the oil seal [13-22] on both sides using a flat- head screwdriver. Remove the stop ring [13-21]. 5) remove the front roller shaft by tapping the end which is sticking out more. 6) secure the removed front roller shaft on a vice, and remove the bearing [13-19,20] from the shaft usi...

Page 54

50 50 51 preparation of replacement parts have the replacement parts ready beforehand. 1) apply some grease inside the oil seal [13-20]. Insert the bearing [13-19] into the oil seal firmly by tapping it with a wooden hammer. 2) apply grease to the lip surface of the oil seal [13-22] which is to be s...

Page 55

52 52 53 using a driving tool, pound in the bearing and oil seal set all the way. (drive them in below the stop ring’s groove.) 4) insert the stop ring [13-21]. 5) pound in the oil seal [13-22] on the outside. (up to the edge of the roller) 6) insert the washer from the end of the roller shaft. Inse...

Page 56

52 52 53 8) screw bolt [13-15] and s washer [13-16] through hole on catcher arm [13-3] and into roller shaft [13-17]. Re- peat for both sides. 9) tighten and lock bolt [13-15]. To prevent roller shaft [13-17] from spinning, slide a screw driver through the hole of the roller shaft and hold for suppo...

Page 57

54 54 55 [18] ajusting the arm stopper 1) adjust distance of catcher arm [13-3] by tightening or loosening arm stoppers [13-5]. Recommended space between the arm stopper and stopper brackets [13-6,8] should be 1 mm, when the front roller [3-37] is parallel with the roller [13-23] of catcher arm. 2) ...

Page 58

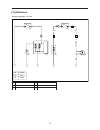

54 54 55 [19] reference bl bl black bu blue w white bl bl bu w or bu w (1) (2) (3) (1) engine switch (2) spark plug (3) ignition coil (4) (5) (6) (4) coil assy., lamp (5) headlight switch (6) headlight wiring diagrams (gx120).

Page 59

56.

Page 60

Lm56ga--sm--usz/09m-00-spec.