- DL manuals

- Barranca Diamond

- Saw

- BD-2003E

- Owner's Manual

Barranca Diamond BD-2003E Owner's Manual

BD-2003E Pro Series Core Saw

Owner’s Manual & Parts List

04.2013

Revision 105

Manual Part# 166526

Caution: Read all safety and operating

instructions before using this equipment.

This manual MUST accompany the

equipment at all times.

Barranca Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 630-7682

Phone: (310) 523-5867

Fax: (310) 257-3063

www.barrancadiamond.com

Summary of BD-2003E

Page 1

Bd-2003e pro series core saw owner’s manual & parts list 04.2013 revision 105 manual part# 166526 caution: read all safety and operating instructions before using this equipment. This manual must accompany the equipment at all times. Barranca diamond products, inc. 1315 storm parkway torrance, ca 90...

Page 2

22 bd-2003 core saw introduction we at barranca diamond want to congratulate you on selecting the bd-2003e core saw. We are certain that you will be pleased with your purchase. Barranca diamond takes pride in introducing the finest products in the industry. Operated correctly, your bd-2003e core saw...

Page 3

3 bd-2003 core saw table of contents safety safety message/alert symbols safety warnings hazard symbols rules for safe operation electrical requirements and grounding instructions operation & safety decals safety decal locations product specifications saw features unpacking & transporting contents t...

Page 4

4 bd-2003 core saw safety safety precautions should be followed at all times when operating this equipment. Failure to read and understand the safety precaution and operating instructions could result in injury to yourself and others. This owner’s manual has been developed to provide complete instru...

Page 5

5 bd-2003 core saw safety california proposition 65 message some dust created by power sanding, sawing, grinding, drilling, and other construction activities con- tain chemicals known (to the state of california) to cause cancer, birth defects or other reproductive harm. Some examples of these chemi...

Page 6

6 bd-2003 core saw safety do not touch hot engine components while the machine is running or immediately after operating. Never touch the power cord with wet hands or while standing in water when it is con- nected to a power source. ( ( ) ) this hazard symbol means “over speed.” failure to follow in...

Page 7

7 bd-2003 core saw safety on / off • always wear proper respiratory, head, ear and eye protection equipment when operating this machine. • turn the “on/off” switch to the “off” position prior to connecting the machine to the power source. Never leave the machine unattended. Turn off electric motor w...

Page 8

8 • always cut in a straight line. Do not cut deeper than 1” per pass with a dry blade. Step cut to achieve deeper cuts. Never force, jam, wedge or twist the blade in a cut. Do not grind on the side of the blade. • do not touch a dry cutting blade immediately after use. These blades require several ...

Page 9

9 bd-2003 core saw safety maintenance safety • never lubricate components or attempt service on a running machine. • keep the machinery in proper running condition.Clean the machine after each day’s use. Follow instructions for changing accessories. Inspect tool periodically and, if damaged, have re...

Page 10

10 bd-2003 core saw safety warning in order to prevent electrical shock and injury, the following electrical safety precautions and symbols should be followed at all times! If permanently connected, this tool should be connected to a grounded metal permanent wiring system; or to a system having an e...

Page 11

11 to reduce the risk of electrocution, keep all connections dry and off the ground. A ground fault circuit interrupter (gfci) should be provided on the circuit(s) or outlet(s) to be used for this machine. Receptacles are available having built-in gfci protections and may be used for this measure of...

Page 12

12 bd-2003 core saw safety warning use only extensions cords that are intended for outdoor use. These extension cords are identified by a marking “acceptable for use with outdoor appliances; store indoors while not in use.” use only extension cords having an electrical rating not less than the ratin...

Page 13

13 bd-2003 core saw safety in order to help prevent accidental starting and to help make your work area “kidproof,” this machine is provided with a means to deactivate the functioning of the motor switch. The switch is equipped with a lockout tab that can be used with a lock to prevent movement of t...

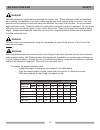

Page 14: Notice

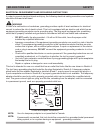

14 most motor problems are caused by improper voltage and extension cords. Cord should be one-piece and short as possible. Cord selection should match the following table. 1-2 h.P. 25’ 50’ 75’ 100’ 150’ 250’ max. Cord length max. Cord length max. Cord length no. 12 wire no. 10 wire no. 8 wire 115v 2...

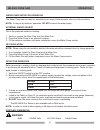

Page 15

15 bd-2003 core saw safety safety decal locations decal e decal location description a motor - front warning - silica b motor - rear service or warranty information c belt guard caution - general safety information d motor - front warning - read manual e blade guard warning - replace blade guard f b...

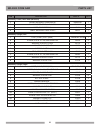

Page 16

16 * the bd-2003e pro series is also available with a 50hz motor. Bd-2003 core saw product specifications motor baldor 3hp voltage 230v motor rpm 3,450 blade rpm 3,100 blade capacity 14” (350mm) arbor 1” (25mm) table travel 29” max. Core sample length 12” max. Core sample diameter 5” min. Core sampl...

Page 17

17 bd-2003 core saw unpacking & transporting unpacking contents your bd-2003e has been shipped from the factory thoroughly inspected. Only minimal assembly is required. Bd-2003e pro series core saw owner’s manual www.Barrancadiamond.Com caution: read all safety and operating instructions before usin...

Page 18

18 bd-2003 core saw transport transporting caution the bd-2003e weighs approximately 162 lbs. Use proper lifting techniques and care when lifting and transporting. Never transport the bd-2003e with water in the water basin. 1. Verify the movable cutting head is locked in the down position and the mo...

Page 19

19 1. Ensure the on/off switch is in the off position. 2. Verify the movable cutting table moves freely along the guide rails. 3. Inspect the diamond blade for damage, cracks and debonding; verify the blade is correct for the material being cut. 4. Inspect the pump assembly for damage - ensure the c...

Page 20

20 bd-2003 core saw setup & assembly movable cutting table installation (a) while holding the front, position movable cutting table roller wheels above guide rails. (b) seat movable cutting table roller wheels on saw guide rails. (c) verify movable cutting table is seated correctly by moving table b...

Page 21

21 warning note: if using a dry blade for operation, do not connect the water pump. Note: when using the re-circulation method, the water should be changed often for longer pump life. Note: in order to avoid breaker tripping, a 20-amp circuit breaker should be used. The water pump can be setup for o...

Page 22

22 bd-2003 core saw operation & maintenance (a) if locked, loosen cutting head knob by turning counter-clockwise (a) inspect belts (b) check tension (c) loosen mounting bolts this method is preferred when cutting small objects. Cut in smooth, even strokes. Do not force the saw to cut. 1. If locked, ...

Page 23

23 bd-2003 core saw maintenance (a) loosen motor strap (d) install new belt (g) check tension (b) push motor forward (e) seat belt in pulley groove (h) continue adjustments (c) remove old belt (f) tighten motor strap (i) tighten motor bolts 4. Loosen the motor adjustment strap using a 9/16 inch wren...

Page 24

24 bd-2003 core saw troubleshooting blade will not cut 1. Blade is too hard for material being cut. Use a softer bonded blade. Select proper blade specification for material being cut. 2. Blade has become dull as a result of being used on too hard a material. Improper blade specification; blade is t...

Page 25

25 loss of tension 1. Steel center has been overheating as a result of blade spinning on arbor. Check water flow, distribution and lines. Tighten the blade shaft nut. Make certain the drive pin is functioning (on concrete saws). 2. Steel center has been overheating from rubbing the side of material ...

Page 26

26 cracks in steel center 1. Blade flutters in cut as a result of blade losing tension. Tighten the blade shaft nut. Make sure blade is running at proper tensioned speed and that drive pin is functioning properly. 2. Blade specification is too hard for the material being cut. Use a softer blade bond...

Page 27

27 notes.

Page 28

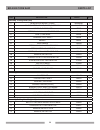

28 bd-2003 core saw parts list item description part # qty. Assembly, frame, brick saw (barranca) 1 frame, weldment (barranca) 158845-bd 1 2 plug, rubber drain, no logo 153439-nl 1 3 label, bd core saw 166494 2 4 label, masonry label sheet 166011 1 assembly, upright, left 1 post (comp) post (raw) 15...

Page 29

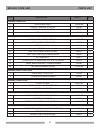

29 bd-2003 core saw parts list item description part# qty. Assembly, cutting head (elec) 1 head, motor mount (comp) 160346-bd 1 2 clamp, motor mount (comp), barranca 160397-bd 2 3 housing, pivot shaft 157979 1 4 screw, 5/16-18 x 1-1/4, hex head cap 153950 4 5 shaft, threaded 150585 1 6 bearing, pivo...

Page 30

30 item description part # qty. Assembly, blade shaft 1 assy, blade shaft 154636-bd 1 2 pulley, 1 groove, 2-1/2 x 3/4 133140 1 3 screw, 5/16-18 x 3/8 set 157083 2 4 key, 1-1/8 x 3/16 150344 1 assembly, blade guard 1 blade guard, (comp) barranca 158886-bd 1 2 stud, blade guard pivot 150581 1 3 nut, 1...

Page 31

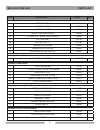

31 item description part# qty. Assembly, table cont... 4 nut, 1/4-20, keps 153491 4 5 wheel, roller 133090 4 6 nut, 5/16 -18 keps 153942 4 7 wood strip, table insert 158283 1 8 screw, #6 x 1 bugle head phillips 159906 2 9 jig, core saw 161122 1 10 nut, hex, 3/8 - 16 101188 4 11 washer, flat, 3/8 sae...

Page 32

32 item description part# qty. Assembly, mtr 230v 1 ph 60 hz 3 hp 1 assy, motor, 230v 60 hz 3 hp 166493 1 2 pulley, 1 groove, 2-1/4 x 5/8 133157 1 3 screw, 5/16-18 x 1/4, set 152607 2 4 nut, 5/16-18 w/external tooth washer 153942 4 5 washer, 5/16 sae, flat 151754 4 assembly, 30a switch, (barranca) 1...

Page 33

33 notes.

Page 34

34 bd-2003 core saw general product information types of cutting there are two basic types of cutting-dry or wet. The choice of which type of blade to use depends on: • the requirements of the job • the machine/tool utilizing the diamond blade • the preference of the operator in the case of dry cutt...

Page 35

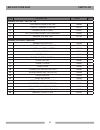

35 bd-2003 core saw accessories item number description 1 132332 adjustable cutting guide 2 133090 roller wheel 3 156427 protective wooden strip 4 151723 belt 5 152792 dressing stick 6 153439-nl rubber drain plug.

Page 36

36 bd-2003 core saw contact and limited warranty barranca diamond warrants to the original retail purchaser for a period of 1 year except as noted, from the date of purchase all products covered by this warranty to be free of defects in materials and workmanship. This warranty shall not apply to any...

Page 37

37 bd-2003 core saw contact & limited warranty specifics applicable to limited warranty of diamond blades and core bits: laser welded blade and bit warranty: if the laser weld between the segment and the steel core or barrel fails during normal use, the blade or bit will be replaced free of charge. ...

Page 38

38 bd-2003 core saw contact & limited warranty replacement parts replacement parts for this tool may be ordered from your barranca diamond distributor or directly from bar- ranca diamond. Please have the following information ready before calling: • model and serial number of the machine • date of p...

Page 39

39 notes.

Page 40

Barranca diamond products, inc. 1315 storm parkway torrance, ca 90501 toll-free: (800) 421-5830 phone: (310) 539-5221 fax: (310) 539-5158 www.Barrancadiamond.Com.