- DL manuals

- Barranca Diamond

- Saw

- BD10

- Owner's Manual And Operating Instructions

Barranca Diamond BD10 Owner's Manual And Operating Instructions

BD10 Power Feed Trim Saw

Owner’s Manual and Operating Instructions

Caution: Read all safety and operating

instructions before using this equipment.

This manual MUST accompany the

equipment at all times.

Revision 109

Manual Part # 169351

03.2014

Barranca Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 630-7682

Phone: (310) 523-5867

Fax: (310) 257-3063

www.barrancadiamond.com

Summary of BD10

Page 1

Bd10 power feed trim saw owner’s manual and operating instructions caution: read all safety and operating instructions before using this equipment. This manual must accompany the equipment at all times. Revision 109 manual part # 169351 03.2014 barranca diamond products, inc. 1315 storm parkway torr...

Page 2

2 thank you for selecting the barranca diamond bd10 trim saw. We are certain that you will be pleased with your purchase. Barranca diamond takes pride in producing top quality products for hobbyists and commercial lapidary users throughout the world. This owner’s manual contains information necessar...

Page 3

3 safety precautions read and follow all safety, operating and maintenance instructions. Failure to read and follow these instructions could result in injury or death to you or others. Failure to read and follow these instructions could also result in damage and/or reduced equipment life. In order t...

Page 4

4 rotating or moving parts keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the saw with covers, shrouds, or guards removed. Maintain tools with care keep tools clean for the best and safest performance. Always follow maintenance instructions for lubri...

Page 5

5 direction of feed always feed work into a blade or cutter in the direction shown in this manual. All blades, grinding wheels or polishing belts should always be installed such that rotation is in the direction of the arrow imprinted on the blade, wheel or belt. Only operate at the proper speed sev...

Page 6

6 bd-10 safety warning california proposition 65 message silica dust warning grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz, brick clay, g...

Page 7

7 electrical requirements and grounding instructions in order to prevent potential electrical shock and injury, the following electrical safety precautions and symbols should be followed at all times! In case of a malfunction or breakdown, grounding provides a path of least resistance for electric c...

Page 8

8 to avoid the possibility of the appliance plug or receptacle getting wet, position the saw to one side of a wall mounted receptacle. This will prevent water from dripping onto the receptacle or plug. A “drip loop,” shown should be arranged by the user to properly position the power cord relative t...

Page 9

9 main motor leeson a4si7dr56 horsepower 1/3 hp motor voltage 115 volt/60hz / 220 volt/50hz amperage 5.8 amps / 3.5 amps motor rpm 1725 rpm fixed / 1425 rpm blade shaft 5/8" duty continuous motor arbor bearings ball bearings, permanently sealed arbor diameter 5/8" blade capacity 8", 9" or 10" diamet...

Page 10

10 bd10 oil/coolant roc cut roc cut from diamond pacific is a new synthetic water soluble cutting additive with rust inhibitors. Mix 30 to 1 (water to roc cut). Never run a diamond blade dry as this can immediately damage your blade. Use one of the oils/coolants recommended below. Coolant should be ...

Page 11

11 bd10 setup transport for ease of transport, place the hood over the saw table and tape the hood to the table. All sawing lubricant should be removed from the reservoir during transport of the saw. A. Belt guard b. Drain hose c. Hood d. Power toggle switch e. Blade guard a. Table b. Clutch plates ...

Page 12

12 bd10 operations and adjustments pre-start inspection place the bd10 trim saw on a flat surface such as a bench top or table. Set the toggle power switch to the middle/off position (fig. 1). Fig. 2. Cutting lubricant level should cover the bottom 1/4" of the blade fig. 1. Off position fig. 3. Unlo...

Page 13

13 fig. 5. Secure sludge plug start up inspect the belt tension. Check the four motor mounting bolts (fig. 6) to ensure they are tight and the motor is secure. The v-belt is adjusted and tensioned at the factory. If belt needs adjustment, loosen nut (fig. 8). Tighten or loosen screw (fig. 9) until b...

Page 14

14 start up lock the clutch plates by turning the knob clockwise (fig. 12). Be sure to securely tighten the knob on the vise as well (fig. 17). Now engage the power feed toggled right/engaged feed position and main motor to begin advancing the vise and rotating the blade (fig. 13). The power feed mo...

Page 15

15 fig. 17. Vise adjustment fig. 18. Vise cross-feed locking slab sawing mode at this point, the clutch should be engaged by turning the knob clockwise (fig. 12). The hood may be placed over the table to contain spray and misting. Slabbing of material can now be initiated by engaging the power feed ...

Page 16

16 fig. 22. Manual feed position fig. 23. Loosen vise fig. 24. Rotate vise up trim sawing mode slabbing of rock material to uniform thicknesses using the bd10 trim saw is best performed using the auto- matic power feed mode. However, manual trimming of slabs to desired shapes (preforming) can be ach...

Page 17

17 the rock slab to be trimmed should rest flat and firmly on the saw table in front of the blade prior to moving the toggle switch to the left/manual feed position. The user should use light but firm pressure to cut the slab in the manual mode letting the blade do the work and not force the slab in...

Page 18

18 fig. 28. Remove belt guard fig. 29. Belt tension fig. 30. Adjusting belt tension v-belt the bd10 trim saw blade arbor is powered by an ax-27 rubber v-belt from the electric motor. The v-belt is correctly tensioned at the factory. However, if it is necessary to service the belt, unplug the bd10 tr...

Page 19

19 power feed system and vise periodically the user should apply a thin coat of lubricating grease (wheel bearing or lithium grease) to the 3/8"- 24 screw feed rod to prevent the screw feed rod threads from becoming prematurely worn. If the threads on both the bronze clutch blocks should become worn...

Page 20

20 fig. 32. Blade arbor bolts blade arbor assembly and pulleys periodically, check the tightness of the four blade arbor housing mounting bolts (fig. 32) to make sure they are securely tightened to the oil reservoir. Should the 2" od die cast pulleys on either the motor or blade arbor shaft need to ...

Page 21

21 diamond blade periodically, the diamond blade on the bd10 trim saw will need to be resharpened should slow or poor sawing performance occur. Dull or “glazed over” diamonds will either not cut thus stalling the saw and shutting off the motor, or the rock vise and rock material will ride up the bla...

Page 22

22 fig. 36. Convex or recessed side of blade flange diamond blade installation and removal close saw table and tighten the wing nut. Be sure that the proper amount of lubricant is in the reservoir before starting the saw. Note: blade flanges must always be installed with their concave or recessed si...

Page 23

23 notes.

Page 24

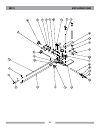

24 bd10 exploded view.

Page 25

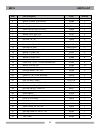

25 item part description part# quantity 1 nut, hex, 5/16 - 18 101196 4 2 wrench, tilesaw, 15/16 csd end 134684 1 3 flange, outer, 2 - 3/8 135830 2 4 bearing, ball, 17 x 40 x 12mm 137711 2 5 screw, soc hd cap, 1/4 - 20 x 1 151049 4 6 screw, 10 - 32 x 1/2 pan head phillips machine 151052 11 7 washer, ...

Page 26

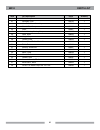

26 item part description part# quantity 40 table, comp 168791 1 41 assembly, vise 168792 1 42 vise drive motor assembly 168795 1 43 guard, belt, comp 168804 1 44 hood 168817 1 45 arbor housing casting comp 168825 1 46 shaft, arbor 168826 1 47 hinge, comp 168835 1 48 gasket, arbor 168892 1 49 screw, ...

Page 27

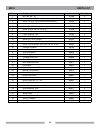

27 item part description part# quantity 1 screw, rnd hd, #8-32x1/2 152517 6 2 screw, hex hd fl 10-24x 5/16 159597 1 3 switch, feed toggle, 15a, dpdt 161052 1 4 screw, 4-40 x 3/4 socket head cap 164206 2 5 housing casting comp 168797 1 6 cover, housing comp 168802 1 7 gear motor 5 rpm 168832 1 8 swit...

Page 28

28 bd10 exploded view.

Page 29

29 item part description part# quantity 1 nut, hex, 3/8 - 16 101188 2 2 washer, flat, sae, 3/8 150923 3 3 screw, 10 -32 x 1/2 pan head phillips machine 151052 2 4 washer, #10 sae flat 154369 1 5 screw, pan hd, 1/4 - 20 x 1/4 157523 1 6 screw, soc hd set 1/4 - 20 x 1/4 157528 1 7 screw, set cup, #10 ...

Page 30

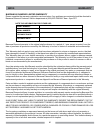

30 barranca diamond warrants to the original retail purchaser for a period of 1 year except as noted, from the date of purchase all products covered by this warranty to be free of defects in materials and workmanship. This warranty shall not apply to any parts that have been subjected to misuse or i...

Page 31

31 specifics applicable to limited warranty of diamond blades and core bits laser welded blade and bit warranty if the laser weld between the segment and the steel core or barrel fails during normal use, the blade or bit will be replaced free of charge. Blades and bits damaged due to careless or imp...

Page 32

32 bd10 service & warranty replacement parts replacement parts for this tool may be ordered from your barranca diamond distributor or directly from barranca diamond. Please have the following information ready before calling: • model and serial number of the machine • date of purchase • description ...

Page 33

33 notes.

Page 34

34 notes.

Page 35

35 notes.

Page 36

Barranca diamond products, inc. 1315 storm parkway torrance, ca 90501 toll-free: (800) 421-5830 phone: (310) 539-5221 fax: (310) 539-5158 www.Barrancadiamond.Com.