- DL manuals

- Barranca Diamond

- Saw

- BD7CW

- Owner's Manual And Operating Instructions

Barranca Diamond BD7CW Owner's Manual And Operating Instructions

BD7CW Trim Saw

Owner’s Manual and Operating Instructions

Caution: Read all safety and operating

instructions before using this equipment.

This manual MUST accompany the

equipment at all times.

Revision 100

01.2014

Manual Part No. 170833-OM

Barranca Diamond Products, Inc.

1315 Storm Parkway

Torrance, CA 90501

Toll-Free: (800) 630-7682

Phone: (310) 523-5867

Fax: (310) 257-3063

www.barrancadiamond.com

Summary of BD7CW

Page 1

Bd7cw trim saw owner’s manual and operating instructions caution: read all safety and operating instructions before using this equipment. This manual must accompany the equipment at all times. Revision 100 01.2014 manual part no. 170833-om barranca diamond products, inc. 1315 storm parkway torrance,...

Page 2

2 we at barranca diamond products want to thank you for selecting the barranca diamond bd7cw trim saw (part # 168765). We are certain that you will be pleased with your purchase. Barranca dia- mond takes pride in producing top quality and dependable products for both hobbyists and commer- cial lapid...

Page 3

3 safety precautions read and follow all safety, operating and maintenance instructions. Failure to read and follow these instructions could result in injury or death to you or others. Failure to read and follow these instructions could also result in damage and/or reduced equipment life. In order t...

Page 4

4 reduce the risk of unintentional starts make sure the on/off switch is in the off position before plugging in a power tool. Rotating or moving parts keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the motor with covers, shrouds or guards removed. Ma...

Page 5

5 bd7cw safety direction of feed all blades, grinding wheels or polishing belts should always be installed such that rotation is in the direction of the arrow imprinted on the blade, wheel or belt. Only operate at the proper speed severe personal injury and damage to the motor or equipment can resul...

Page 6

6 bd7cw safety warning california proposition 65 message some dust created by power sanding, sawing, grinding, drilling, and other construction activities con- tain chemicals known (to the state of california) to cause cancer, birth defects or other reproductive harm. Some examples of these chemical...

Page 7

7 bd7cw safety warning in order to prevent electrical shock and injury, the following electrical safety precautions and symbols should be followed at all times! If permanently connected this tool should be connected to a grounded metal permanent wiring system; or to a system having an equipment - gr...

Page 8

8 bd7cw safety warning warning to reduce the risk of electrocution, keep all connections dry and off the ground. A ground fault circuit interrupter (gfci) should be provided on the circuit(s) or outlet(s) to be used for this machine. Receptacles are available having built-in gfci protections and may...

Page 9

9 bd7cw safety to avoid the possibility of the appliance or plug receptacle getting wet, position the machine to one side of a wall mounted receptacle. This will prevent water from dripping into the receptacle or plug. A "drip loop," shown in the picture below, should be arranged by the user to prop...

Page 10

10 extension cord length nameplate amperes 115v 25' 50' 75' 100' 150' 200' 250v 50' 100' 150' 200' 300' 400' 0 - 5 16 16 16 14 12 12 5.1 - 8 16 16 14 12 10 • 8.1 - 12 14 14 12 10 • • 12.1 - 15 12 12 10 10 • • 15.1 - 20 10 10 10 • • • warning use of undersized extension cords result in low voltage to...

Page 11

11 bd7cw the bd7cw will manually cut specimens up to 1-3/16" (30mm) in height and has a 14" (356 mm) x 14" (356 mm) self-aligning tabletop. Blade lubricate approximately 1/3 gallon (1.3 liters) of lubricant is required to adequately cover the bottom of a 7-inch (178 mm) blade. See figure 5 for prope...

Page 12

12 bd7cw oil/coolant roc cut roc cut from diamond pacific is a new synthetic water soluble cutting additive with rust inhibitors. Mix 30 to 1 (water to roc cut). Never run a diamond blade dry as this can immediately damage your blade. Use one of the oils/coolants recommended below. Coolant should be...

Page 13

13 installation tools needed: • large standard screwdriver, phillips screwdriver, utility knife warning equipment damage: the 7-inch trim saw weighs approximately 28 lbs (13 kg). Fol- low safe practices to lift the unit from the shipping carton. Improper lifting can result in machine damage. Persona...

Page 14

14 power switch 1. Check that the power switch is in the off position. 2. Plug-in the power cord. Power test 1. Move the power switch to the on position to rotate the blade. (figure 6) 2. Check that the blade is rotating. This indicates the saw is functioning properly. 3. Move the power switch to th...

Page 15

15 figure 14: hood figure 8: slide vise forward figure 9: adjust rock vise jaws clamp figure 10: adjust blade guard figure 15: cutting figure 11: secure material figure 13: tighten cross-feed locking thumbscrew figure 12: adjust cross-feed knob cutting with the trim saw bd7cw cutting 1. Ensure the p...

Page 16

16 1. Holding the drain hose vertically, remove the drain hose cap. (figure 16) 2. Place drain hose in a five-gallon bucket or collection container. 3. Let the lubricant flow into the bucket for proper disposal. 4. The sludge residue will likely not flow through the hose and will remain inside the r...

Page 17

17 bd7cw maintenance the motor shaft has sealed ball bearings and requires no lubrication. The motor should be protected from spray when cutting without plastic hood in place. The motor is protected from thermal damage (overheating) with an automatic shut-off switch. If this should occur, shut off t...

Page 18

18 it will be necessary to access the blade for inspection or replacement. 1. Remove wing nut and lift table up. (figure 17) 2. Use a 18mm adjustable wrench and allen wrench to tighten or loosen the jam nut, right hand thread. (figure 19) diamond blade installation and removal figure 18: blade arbor...

Page 19

19 notes.

Page 20

20 1 2 3 4 5 6 7 8 9 10 11 12 13 14 17 19 21 37 22 23 24 25 26 27 28 29 31 32 33 30 34 35 36 15 6 24 bd7cw exploded view.

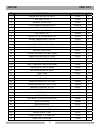

Page 21

21 item description part # qty. 1 screw, soc hd cap, 1/4 - 20 x 1 151049 2 2 nut, hex, 1/4 - 20 151893 2 3 washer, 1/4 sae flat 151915 2 4 plug, rubber drain w/o hole 153439-nl 1 5 washer, #10 split lock 153684 4 6 washer, #10 sae flat 154369 9 7 nut, hex 10 - 32 156269 5 8 screw, 10 - 32 x 1 hex he...

Page 22

22 notes.

Page 23

23 notes.

Page 24

24 bd7cw warranty barranca diamond warrants to the original retail purchaser for a period of 1 year except as noted, from the date of purchase all products covered by this warranty to be free of defects in materials and workmanship. This warranty shall not apply to any parts that have been subjected...

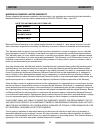

Page 25

25 bd7cw warranty specifics applicable to limited warranty laser welded blade and bit warranty if the laser weld between the segment and the steel core or barrel fails during normal use, the blade or bit will be replaced free of charge. Blades and bits damaged due to careless or improper use are not...

Page 26

26 bd7cw service & warranty replacement parts replacement parts for this tool may be ordered from your barranca diamond distributor or directly from bar- ranca diamond. Please have the following information ready before calling: • model and serial number of the machine • date of purchase • descripti...

Page 27

27 notes.

Page 28

Barranca diamond products, inc. 1315 storm parkway torrance, ca 90501 toll-free: (800) 421-5830 phone: (310) 539-5221 fax: (310) 539-5158 www.Barrancadiamond.Com.