- DL manuals

- Basler

- Controller

- DGC-2020

- Instruction Manual

Basler DGC-2020 Instruction Manual - Contents

9400200990 Rev I

DGC-2020 Introduction

v

CONTENTS

• TIME OVERCURRENT CHARACTERISTIC CURVES................................................... A-1

www

. ElectricalPartManuals

Summary of DGC-2020

Page 1

Instruction manual for digital genset controller dgc-2020 publication: 9400200990 revision: i 07/08 www . Electricalpartmanuals . Com.

Page 2

Www . Electricalpartmanuals . Com.

Page 3: Introduction

9400200990 rev i dgc-2020 introduction i introduction this instruction manual provides information about the operation and installation of the dgc-2020 digital genset controller. To accomplish this, the following information is provided: • general information and specifications • controls and indica...

Page 4

Ii dgc-2020 introduction 9400200990 rev i first printing: november 2006 printed in usa © 2008 basler electric, highland illinois 62249 usa all rights reserved july 2008 it is not the intention of this manual to cover all details and variations in equipment, nor does this manual provide data for ever...

Page 5: Revision History

9400200990 rev i dgc-2020 introduction iii revision history the following information provides a historical summary of the changes made to this instruction manual (9400200990), bestcomsplus software, firmware package, and hardware of the dgc-2020, lsm- 2020, and cem-2020. Manual revision and date ch...

Page 6

Iv dgc-2020 introduction 9400200990 rev i firmware package version and date change 1.02.00, 08/07 • added 32 and 40q protection functions. • added automatic restart function and exercise timer. • added dual settings for 51, 27, and 59 functions. • added oil pressure crank disconnect enable. • modifi...

Page 7: Contents

9400200990 rev i dgc-2020 introduction v contents section 1 • general information ................................................................................................ 1-1 section 2 • human-machine interface ....................................................................................

Page 8

Vi dgc-2020 introduction 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 9: Section 1

9400200990 rev i dgc-2020 general information i section 1 • general information table of contents section 1 • general information ................................................................................................ 1-1 description.............................................................

Page 10

Ii dgc-2020 general information 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 11: Section 1

9400200990 rev i dgc-2020 general information 1-1 section 1 • general information description the dgc-2020 digital genset controller provides integrated engine-genset control, protection, and metering in a single package. Microprocessor based technology allows for exact measurement, setpoint adjustm...

Page 12

1-2 dgc-2020 general information 9400200990 rev i contact inputs and output contacts dgc-2020 controllers have one, dedicated emergency stop contact input and 16 programmable contact inputs. All contact inputs recognize dry contacts. The programmable inputs can be configured to initiate a pre-alarm ...

Page 13

9400200990 rev i dgc-2020 general information 1-3 lsm-2020 (load share module) the optional lsm-2020 in conjunction with the dgc-2020 provides load sharing between governors through an analog load share line. The lsm-2020 communicates through an ethernet port and provides access to the dgc-2020 via ...

Page 14

1-4 dgc-2020 general information 9400200990 rev i table 1-1. Special-order dgc-2020 controllers part number style number special features 9400200105 51anbnsnh001 9400200106 11anbnsnh001 curus recognized for use in hazardous locations. Specifications operating power nominal: 12 or 24 vdc range: 6 to ...

Page 15

9400200990 rev i dgc-2020 general information 1-5 terminals emergency stop: 46, 47 programmable input 1: 30, 2 input 2: 29, 2 input 3: 28, 2 input 4: 27, 2 input 5: 26, 2 input 6: 25, 2 input 7: 24, 2 input 8: 23, 2 input 9: 22, 2 input 10: 21, 2 input 11: 20, 2 input 12: 19, 2 input 13: 18, 2 input...

Page 16

1-6 dgc-2020 general information 9400200990 rev i output 5: 57, 55 (common) output 6: 58, 55 (common) output 7: 60, 59 (common) output 8: 61, 59 (common) output 9: 62, 59 (common) output 10: 64, 63 (common) output 11: 65, 63 (common) output 12: 66, 63 (common) ∗ contact rating is reduced to 3 a for ...

Page 17

9400200990 rev i dgc-2020 general information 1-7 power factor metering range: 0.2 leading to 0.2 lagging calculation method: pf = p (3-phase average) ÷ s (3-phase average) accuracy: ±0.02 ∗ ∗ applies when temperature is between -40°c to +70°c. Real power indicates total kw and individual line kw (4...

Page 18

1-8 dgc-2020 general information 9400200990 rev i generator protection functions overvoltage (59) and undervoltage (27) pickup range: 70 to 576 vac pickup increment: 1 vac inhibit frequency range: 20 to 400 hz (27 function only) activation delay range: 0 to 30 s activation delay increment: 0.1 s und...

Page 19

9400200990 rev i dgc-2020 general information 1-9 rs-485 (optional) baud: 9600 data bits: 8 parity: none stop bits: 1 terminals: 14 (a), 13 (b), and 12 (shield) canbus differential bus voltage: 1.5 to 3 vdc maximum voltage: –32 to +32 vdc with respect to negative battery terminal communication rate:...

Page 20

1-10 dgc-2020 general information 9400200990 rev i type tests shock and vibration: en60068-2-6 dielectric strength: iec 255-5 impulse: en60664-1 transients: en61000-4-4 static discharge: en61000-4-2 shock 15 g in 3 perpendicular planes vibration swept over the following ranges for 12 sweeps in each ...

Page 21

9400200990 rev i dgc-2020 general information 1-11 this equipment is suitable for use in class i, division 2, groups a, b, c, d, or non-hazardous locations only. Nfpa compliance complies with nfpa standard 110, standard for emergency and standby power. Ce compliance this product complies with the re...

Page 22

1-12 dgc-2020 general information 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 23: Section 2

9400200990 rev i dgc-2020 human-machine interface i section 2 • human-machine interface table of contents section 2 • human-machine interface ....................................................................................... 2-1 introduction.........................................................

Page 24

Ii dgc-2020 human-machine interface 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 25: Section 2

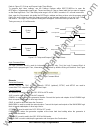

9400200990 rev i dgc-2020 human-machine interface 2-1 section 2 • human-machine interface introduction this section describes the components of the dgc-2020 human-machine interface (hmi). Dgc-2020 hmi components are located on the front panel (controls and indicators) and the rear panel (terminals a...

Page 26

2-2 dgc-2020 human-machine interface 9400200990 rev i table 2-1. Front panel hmi descriptions locator description a liquid crystal display. The backlit, 64 by 128 pixel lcd serves as the local information source for metering, alarms, pre-alarms, and protective functions. Display operation is maintai...

Page 27

9400200990 rev i dgc-2020 human-machine interface 2-3 permissions if communications access is active through the modem or usb, the front panel will display remote comms, front panel is read only and the summary screen. This informs the user that the front panel can only be used for viewing metering ...

Page 28

2-4 dgc-2020 human-machine interface 9400200990 rev i front panel display structure the front panel display begins with the summary screen. Pressing the right arrow key will open the main menu screen. The main menu screen consists of metering and settings. The metering screen branches are shown in f...

Page 29

9400200990 rev i dgc-2020 human-machine interface 2-5 p0052-37 settings general settings communications system params alarm configuration generator protection breaker management bias control multigen management enter password general settings refer to table 2-2 communications refer to table 2-3 syst...

Page 30

2-6 dgc-2020 human-machine interface 9400200990 rev i table 2-3. Communications screen branches • canbus setup o canbus enable o dtc enable o ecu conf o canbus addr o ecu opt slct o ecu pulsing o eng shtdn tm o pls cycl tm o ecu set tm o resp timeout • rs485 setup o comm baud o comm parity o modbus ...

Page 31

9400200990 rev i dgc-2020 human-machine interface 2-7 o cycle time o prestart rest config o oil prs crank disc • automatic restart o enable o attempts o interval • exercise timer o mode o run with load o start hour o start minute o run hours o run minutes • sensing trans o gen pt pri v o gen pt sec ...

Page 32

2-8 dgc-2020 human-machine interface 9400200990 rev i threshold activatn dly o high fuel level enable threshold activatn dly o active dtc (visible when dtc support is enabled.) enable o ecu comms fail (visible when ecu support is enabled.) enable o coolant level enable threshold o ...

Page 33

9400200990 rev i dgc-2020 human-machine interface 2-9 o oil press sendr fail config type activatn dly o fuel levl sendr fail config type activatn dly o voltage sense fail config type activatn dly o speed sendr fail time delay table 2-6. Generator protection screen branches • 27 undervo...

Page 34

2-10 dgc-2020 human-machine interface 9400200990 rev i hysteresis time delay alarm config • 40 loss of excitation o 3 / 1 phase settings pickup hysteresis time delay alarm config table 2-7. Breaker management screen branches • breaker hardware o mains fail transfer enable return de...

Page 35

9400200990 rev i dgc-2020 human-machine interface 2-11 o slip freq o regul offset o closing angle o vs>vd o time delay o fail delay table 2-8. Bias control screen branches • avr bias control o output (visible when lsm-2020 is enabled.) type o contact (visible when output type = contact.) type o ...

Page 36

2-12 dgc-2020 human-machine interface 9400200990 rev i • demand start stop o enable o start td 1 o start td 2 o stop td o start lvl 1 o start lvl 2 o stop lvl • sequencing o sequence id o mode o max gen start o max gen stop • network config rear panel all dgc-2020 terminals and connectors are locate...

Page 37

9400200990 rev i dgc-2020 human-machine interface 2-13 table 2-10. Rear panel hmi descriptions locator description a, d the majority of external, dgc-2020 wiring is terminated at 15-position connectors with compression terminals. These connectors plug into headers on the dgc-2020. The connectors and...

Page 38

2-14 dgc-2020 human-machine interface 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 39: Section 3

9400200990 rev i dgc-2020 functional description i section 3 • functional description table of contents section 3 • functional description ........................................................................................... 3-1 introduction........................................................

Page 40

Ii dgc-2020 functional description 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 41: Section 3

9400200990 rev i dgc-2020 functional description 3-1 section 3 • functional description introduction this section describes how the dgc-2020 functions. A detailed description of each function block is provided in the paragraphs under the heading of dgc-2020 function blocks. Dgc-2020 operating and me...

Page 42

3-2 dgc-2020 functional description 9400200990 rev i zero crossing detection the zero crossing of a-phase to b-phase or a-phase to c-phase (user-selectable) line voltage is detected and used to calculate the generator frequency. The zero crossing of a-phase to b-phase bus voltage is used to calculat...

Page 43

9400200990 rev i dgc-2020 functional description 3-3 coolant temperature sender connections are made at terminals 10 and 11 (sender common). Fuel level a current is provided to the fuel level sender. The developed voltage is measured and scaled for use by the internal circuitry. An open circuit or s...

Page 44

3-4 dgc-2020 functional description 9400200990 rev i connections for the programmable inputs are provided at terminals 15 (input 16) through 30 (input 1). The negative side of the battery voltage (terminal 2) serves as the return connection for the programmable inputs. Front panel hmi the front pane...

Page 45

9400200990 rev i dgc-2020 functional description 3-5 usb the rear-panel, mini-b usb socket enables local communication with a pc running bestcomsplus software. The dgc-2020 is connected to a pc using a standard usb cable. Bestcomsplus is a windows ® based communication software package that is suppl...

Page 46

3-6 dgc-2020 functional description 9400200990 rev i ecu parameter metric units english units update rate decimal place ∗ spn total fuel used liters gallons requested 1.5 s none 250 trip fuel liters gallons requested 1.5 s none 182 ∗ spn is suspect parameter number. Table 3-2. Engine configuration p...

Page 47

9400200990 rev i dgc-2020 functional description 3-7 table 3-3. Diagnostic information obtained over the can interface parameter transmission repetition rate active diagnostic trouble code 1 s lamp status 1 s previously active diagnostic trouble code on request request to clear active dtcs on reques...

Page 48

3-8 dgc-2020 functional description 9400200990 rev i rs-485 (optional) dgc-2020 controllers with the optional rs-485 communication port (style number xxxrxxxxx) can be monitored and controlled via a polled network using the modbus ® protocol. The rs-485 port supports a user-selectable baud rate of 1...

Page 49

9400200990 rev i dgc-2020 functional description 3-9 or none. Bestcomsplus is used to configure breaker management. Refer to section 4, bestcomsplus software, breaker management, for setting information. Determining breaker status the status of the breakers is determined by using bestlogic+ programm...

Page 50

3-10 dgc-2020 functional description 9400200990 rev i the genbrk and mainsbrk logic blocks contain both open and close logic outputs that can be configured to energize an output contact, which would in turn operate the breaker. The synchronizer screen in bestcomsplus is used to set the output contac...

Page 51

9400200990 rev i dgc-2020 functional description 3-11 event string event description event type auto_restart_fail_a automatic restart fail alarm auto_restart_in_progress automatic restart in progress status batt_chrg_fail_a battery charger fail alarm batt_chrg_fail_p battery charger fail pre-alarm b...

Page 52

3-12 dgc-2020 functional description 9400200990 rev i event string event description event type logic ouput_a logic output alarm logic ouput_p logic output pre-alarm loss_of_volt voltage sensing fail status loss_of_volt_a voltage sensing fail alarm loss_of_volt_p voltage sensing fail pre-alarm loss_...

Page 53: Section 4

9400200990 rev i dgc-2020 bestcomsplus software i section 4 • bestcomsplus software table of contents section 4 • bestcomsplus software ........................................................................................... 4-1 introduction...........................................................

Page 54

Ii dgc-2020 bestcomsplus software 9400200990 rev i bias control settings ............................................................................................................... 4-44 avr bias control settings .......................................................................................

Page 55

9400200990 rev i dgc-2020 bestcomsplus software iii figure 4-25. Configurable elements settings.......................................................................................... 4-26 figure 4-26. Configurable remote outputs settings ..............................................................

Page 56

Iv dgc-2020 bestcomsplus software 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 57: Section 4

9400200990 rev i dgc-2020 bestcomsplus software 4-1 section 4 • bestcomsplus software introduction bestcomsplus is a windows®-based, pc application that provides a user-friendly, graphical user interface (gui) for use with basler electric communicating products. The name bestcomsplus is an acronym t...

Page 58

4-2 dgc-2020 bestcomsplus software 9400200990 rev i table 4-1. System requirements for bestcomsplus and the .Net framework component requirement processor 400 mhz ram 128 mb 25 mb (if .Net framework is already installed on pc.) hard drive 250 mb (if .Net framework is not already installed on pc.) in...

Page 59

9400200990 rev i dgc-2020 bestcomsplus software 4-3 the bestcomsplus splash screen is shown for a brief time. See figure 4-3. Figure 4-3. Splash screen the bestcomsplus platform window opens. If a dgc-2020 is connected, select new connection from the communication pull-down menu and select dgc-2020....

Page 60

4-4 dgc-2020 bestcomsplus software 9400200990 rev i click on the activate button when you are ready to enter the activation key you received from basler electric. The device needs activated pop-up will appear. Refer to figure 4-5. Entering an activation key select the device from the device pull-dow...

Page 61

9400200990 rev i dgc-2020 bestcomsplus software 4-5 figure 4-6. Dgc-2020 connection the usb drivers are installed automatically during the bestcomsplus installation process. To select the correct com port, open windows ® device manager and expand the ports (com & lpt) tree. Locate the device named c...

Page 62

4-6 dgc-2020 bestcomsplus software 9400200990 rev i menu bars the menu bars are located near the top of the bestcomsplus screen (see figure 4-1). The upper menu bar has five pull down menus. With the upper menu bar, it is possible to manage settings files, setup communications, upload and download s...

Page 63

9400200990 rev i dgc-2020 bestcomsplus software 4-7 lower menu bar (dgc-2020 plug-in) view this clickable icon allows you to view the metering panel, settings panel, or show settings information. Open file this clickable icon is used to open a saved settings file. Connect/disconnect opens the dgc-20...

Page 64

4-8 dgc-2020 bestcomsplus software 9400200990 rev i front panel hmi the contrast a of the front panel lcd (liquid crystal display) can be adjusted to suit the viewing angle used or compensate for environmental conditions. A power saving feature, referred to as sleep mode b , will turn the front pane...

Page 65

9400200990 rev i dgc-2020 bestcomsplus software 4-9 dgc-2020 information about a dgc-2020 communicating with bestcomsplus can be obtained on the device info tab of bestcomsplus. Select application version a when configuring dgc-2020 settings off-line. When on-line, read-only information includes the...

Page 66

4-10 dgc-2020 bestcomsplus software 9400200990 rev i a application version: when configuring dgc-2020 settings off-line, the application version for the unit to be configured must be selected. Select 1.01.00, >=1.01.00 & >=1.02.00. B application version: read-only value obtained when bestcomsplus is...

Page 67

9400200990 rev i dgc-2020 bestcomsplus software 4-11 o sleep mode o date/time o all sender fail time delays o metric conversion o low fuel pre-alarm level o low fuel alarm level o pre-start contact after cranking o cooldown time o pre-crank time delay o reset of maintenance interval o all controls o...

Page 68

4-12 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-12. Clock setup a utc offset (min): adjustable from -1,440 to 1,440 minutes in increments of 1. B dst configuration: disabled, fixed, or floating. C start day: fixed dst configuration month (january to december), day of month (1 to 31 in ...

Page 69

9400200990 rev i dgc-2020 bestcomsplus software 4-13 speed ±120 rpm. A setting of 0% will cause the engine to run at 120 rpm below the base speed, a setting of 50% will cause the engine to run at the base speed, and a setting of 100% will cause the engine to run at 120 rpm above the base speed. The ...

Page 70

4-14 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-13. Canbus setup a enable ecu support: check box to enable ecu support. B enable dtc support: check box to enable dtc support. C canbus address: accepts an address number from 0 to 253 in increments of 1. D ecu config: standard, volvo pen...

Page 71

9400200990 rev i dgc-2020 bestcomsplus software 4-15 • 32 trip pre-alarm • 40 trip pre-alarm • 47 trip pre-alarm • 51-1 trip pre-alarm • 51-2 trip pre-alarm • 59-1 trip pre-alarm • 59-2 trip pre-alarm • 81o trip pre-alarm • 81u trip pre-alarm • auto restart failure alarm • auxiliary input x closed (...

Page 72

4-16 dgc-2020 bestcomsplus software 9400200990 rev i dial-out the dgc-2020 uses telelocator alphanumeric protocol (tap) version 1.7 when communicating with paging companies. This data format d specifies seven data bits with even parity. If required, eight data bits with no parity may be specified. T...

Page 73

9400200990 rev i dgc-2020 bestcomsplus software 4-17 figure 4-15. Rs-485 setup a baud rate: a value of 1200, 2400, 4800, or 9600 may be selected. B parity: no parity, odd parity, or even parity. C modbus address: a value of 1 to 247 may be entered in increments of 1. System parameters system paramet...

Page 74

4-18 dgc-2020 bestcomsplus software 9400200990 rev i the low line scale factor setting k is used to automatically adjust the eps threshold settings in applications that may utilize more than one type of genset connections. The scale factor setting is implemented when the dgc-2020 senses a contact cl...

Page 75

9400200990 rev i dgc-2020 bestcomsplus software 4-19 figure 4-16. System settings a generator connection: delta, wye, 1-phase a-b, 1-phase a-c, or 4-wire delta. B genset kw rating: adjustable from 5 to 9,999 kw in 1 kw increments. C rated volts: adjustable from 1 to 999 vac in 1 vac increments. D ra...

Page 76

4-20 dgc-2020 bestcomsplus software 9400200990 rev i output can be configured to open upon the conclusion of engine cranking or remain closed as long as the engine is running g . The pre-start can be configured h during the resting state. If preheat before crank is selected, the pre- start output wi...

Page 77

9400200990 rev i dgc-2020 bestcomsplus software 4-21 figure 4-18. Automatic restart settings a auto restart enable: enable or disable. B auto restart interval: adjustable from 0.5 to 30 minutes in 0.5 minute increments. C auto restart attempts: adjustable from 1 to 10 in increments of 1. Exercise ti...

Page 78

4-22 dgc-2020 bestcomsplus software 9400200990 rev i sensing transformers three sets of transformer settings configure the dgc-2020 for operation with a specific system. These settings, along with the generator voltage, generator current, and bus voltage detected by the dgc-2020, enable the dgc-2020...

Page 79

9400200990 rev i dgc-2020 bestcomsplus software 4-23 to make identifying the contact inputs easier, a user-assigned name c can be given to each input. Contacts can be recognized d always or while the engine is running only. Bestcomsplus settings for the configurable contact inputs (dgc-2020, program...

Page 80

4-24 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-22. Programmable functions settings a auto transfer switch input: select input (none, 1-16) and contact recognition (always or while engine running only). B grounded delta override: select input (none, 1-16) and contact recognition (alway...

Page 81

9400200990 rev i dgc-2020 bestcomsplus software 4-25 figure 4-23. Configurable remote inputs settings a alarm configuration: none, prealarm, or alarm. B activation delay: adjustable from 0 to 300 s in 1 s increments. C label text: an alphanumeric character string with a maximum of 16 characters. D c...

Page 82

4-26 dgc-2020 bestcomsplus software 9400200990 rev i to make identifying the element easier, each of the elements can be given a user-assigned name c . Elements can be recognized d always or while the engine is running only. Bestcomsplus settings for the elements (dgc-2020, programmable outputs, con...

Page 83

9400200990 rev i dgc-2020 bestcomsplus software 4-27 alarm configuration dgc-2020 alarms and pre-alarms can be used to annunciate system, genset, and engine sender conditions. The description of the alarm configuration settings is organized as follows: • pre-alarms • alarms • sender failure pre-alar...

Page 84

4-28 dgc-2020 bestcomsplus software 9400200990 rev i engine kw overload by comparing the genset power output with the rated genset output, the level of engine loading can be determined. Three engine overload pre-alarms are available that monitor three-phase real power when three-phase sensing is act...

Page 85

9400200990 rev i dgc-2020 bestcomsplus software 4-29 lsm comm failure lsm-2020 communication failure pre-alarm settings q consist of a single enable/disable setting. If enabled, an lsm-2020 communication failure pre-alarm is annunciated when communication between an optional lsm-2020 and dgc-2020 is...

Page 86

4-30 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-27. Pre-alarms configuration a high fuel level: enable or disable, threshold is adjustable from 0 to 100% in 1 % increments. B low battery voltage: enable or disable, threshold is adjustable from 6 to 12 vdc (12 vdc battery) or 12 to 24 v...

Page 87

9400200990 rev i dgc-2020 bestcomsplus software 4-31 h high coolant temp: enable or disable, threshold is adjustable from 100 to 280 °f or 38 to 138°c in 1° increments. Activation time delay is fixed at 60 s. I low coolant temp: enable or disable, threshold is adjustable from 35 to 150 °f or 2 to 65...

Page 88

4-32 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-28. Alarms configuration a high coolant temp: enable or disable, threshold is adjustable from 100 to 280 °f or 38 to 138°c in 1° increments. Arming time delay is fixed at 60 s. B low oil pressure: enable or disable, threshold is adjustabl...

Page 89

9400200990 rev i dgc-2020 bestcomsplus software 4-33 figure 4-29. Sender fail configuration a coolant temp sender fail: none, alarm, or prealarm, time delay adjustable from 5 to 30 min in 1 min increments. B oil pressure sender fail: none, alarm or prealarm, time delay adjustable from 0 to 300 s in ...

Page 90

4-34 dgc-2020 bestcomsplus software 9400200990 rev i the hysteresis setting d functions as an undervoltage dropout by preventing rapid switching of the pickup output. A frequency-based inhibit setting e prevents a 27 trip from occurring during an undervoltage condition associated with system startup...

Page 91

9400200990 rev i dgc-2020 bestcomsplus software 4-35 bestcomsplus voltage protection settings (dgc-2020, generator protection, voltage, overvoltage) are illustrated in figure 4-32. The 59-1 element is shown. Figure 4-31. Overvoltage protection settings a pickup: adjustable from 70 to 576 vac in 1 va...

Page 92

4-36 dgc-2020 bestcomsplus software 9400200990 rev i frequency protection (81o/u) two sets of frequency protection settings are provided: one for underfrequency (81u) and one for overfrequency (81o). Underfrequency (81u) an underfrequency condition is annunciated when the generator frequency decreas...

Page 93

9400200990 rev i dgc-2020 bestcomsplus software 4-37 power protection settings automatically switch from the three-phase settings to the single-phase reverse power protection settings. The 32 element monitors three-phase real power when three-phase sensing is active or single-phase real power if sin...

Page 94

4-38 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-35. Generator capability curve vs. 40q response if reactive power is within the 40q tripping region for the duration of the 40q activation delay setting b , a loss of excitation condition is annunciated. A loss of excitation annunciation ...

Page 95

9400200990 rev i dgc-2020 bestcomsplus software 4-39 ct secondary side (dgc-2020). When a single-phase override contact input is received by the dgc- 2020, the overcurrent protection settings automatically switch from the three-phase settings to the single- phase overcurrent protection settings. Whe...

Page 96

4-40 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-37. Overcurrent protection settings a pickup: adjustable from 0.9 to 7.75 aac for 5 aac current sensing (style number 5xxxxxxxx) or 0.18 to 1.18 aac for 1 aac current sensing (style number 1xxxxxxxx). B alarm configuration: none, alarm, o...

Page 97

9400200990 rev i dgc-2020 bestcomsplus software 4-41 when a close command is issued, the dgc-2020 monitors the breaker status and annunciates a breaker failure if the breaker does not close within the time defined by the breaker-close wait-time delay k . Typically, this parameter is set to be longer...

Page 98

4-42 dgc-2020 bestcomsplus software 9400200990 rev i k breaker close wait time: adjustable from 0.1 to 600 s in 0.1 s increments. L dead bus close enable: enable or disable. Bus condition detection dgc-2020 detection of dead bus voltages (for dead bus breaker closure) is controlled by a dead bus thr...

Page 99

9400200990 rev i dgc-2020 bestcomsplus software 4-43 d gen and bus stable undervoltage pickup and dropout: adjustable from 10 to 12,000 vac in 1 vac increments. E gen and bus stable overfrequency pickup and dropout: adjustable from 46 to 64 hz in 0.05 hz increments for 50/60 hz generator frequency (...

Page 100

4-44 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-40. Synchronizer settings a sync type: phase lock loop or anticipatory. B slip frequency: adjustable from 0.05 to 0.5 hz in 0.05 hz increments. C fgen>fbus: enable or disable. D breaker closing angle: adjustable from 3 to 20 ° in 1 ° incr...

Page 101

9400200990 rev i dgc-2020 bestcomsplus software 4-45 figure 4-41. Avr bias control settings a bias control output type: contact or analog. B bias control contact type: continuous or proportional. C correction pulse width: adjustable from 0 to 99.9 s in 0.1 s increments. D correction pulse interval: ...

Page 102

4-46 dgc-2020 bestcomsplus software 9400200990 rev i kw control - real power control settings when enabled k , the dgc-2020, used in conjunction with an optional lsm-2020, can accomplish kw sharing between similarly equipped generators. Kw control is disabled when an optional lsm-2020 is not connect...

Page 103

9400200990 rev i dgc-2020 bestcomsplus software 4-47 figure 4-42. Governor bias control settings a bias control output type: contact or analog. B bias control contact type: continuous or proportional. C correction pulse width: adjustable from 0 to 99.9 s in 0.1 s increments. D correction pulse inter...

Page 104

4-48 dgc-2020 bestcomsplus software 9400200990 rev i 7. Introduce transients to the system and observe the error recovery time. 8. Ki can be slowly increased to improve this error recovery time, but avoid increasing too much causing the system to become unstable. 9. With the pid values tuned as abov...

Page 105

9400200990 rev i dgc-2020 bestcomsplus software 4-49 figure 4-44. Governor output settings a output type: voltage or current. B response: increasing or decreasing. C min output current: adjustable from 4 to 20 ma in 0.1 ma increments. D max output current: adjustable from 4 to 20 ma in 0.1 ma increm...

Page 106

4-50 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-46. Demand start/stop a demand start stop enable: enable or disable. B delayed start level: adjustable from 0 to 1 in increments of 0.001. C start level timeout: adjustable from 0 to 600 seconds in 0.1 s increments. D delayed stop level: ...

Page 107

9400200990 rev i dgc-2020 bestcomsplus software 4-51 balanced service time if this mode is selected, units will seek to sort the start priority of all non-disabled networked units in ascending order of service hours remaining. In this configuration, a network of units will respond to a demand start ...

Page 108

4-52 dgc-2020 bestcomsplus software 9400200990 rev i bestcomsplus network configuration settings (dgc-2020, multigen management, network configuration) are illustrated in figure 4-48. Figure 4-48. Network configuration settings a expected seq id: adjustable from 0 to 255. Programmable senders the se...

Page 109

9400200990 rev i dgc-2020 bestcomsplus software 4-53 figure 4-49. Programmable senders settings a sender points: accepts up to 11 user-defined sender resistance points. B sender slope: positive or negative causes sender points to be sorted and displayed accordingly. C sender point curve: automatic p...

Page 110

4-54 dgc-2020 bestcomsplus software 9400200990 rev i opening a settings file to open a new instance of a settings file into bestcomsplus, pull down the file menu and choose open. The open dialog box appears. This dialog box allows you to use normal windows ® techniques to select the file that you wa...

Page 111

9400200990 rev i dgc-2020 bestcomsplus software 4-55 a dialog box will appear and notify you if any differences were found. The bestcomsplus settings compare dialog box (figure 4-51) is displayed where you can view all settings (show all settings), view only the differences (show settings difference...

Page 112

4-56 dgc-2020 bestcomsplus software 9400200990 rev i 3. You will be asked to save the current settings file. Select yes or no. 4. When the basler electric device package uploader screen (figure 4-52) appears, click on the open button to browse for the device package you have received from basler ele...

Page 113

9400200990 rev i dgc-2020 bestcomsplus software 4-57 8. After file(s) have been uploaded, click the close button on the basler electric device package uploader screen. Metering explorer the metering explorer is a convenient tool within bestcomsplus used to navigate through the following metering scr...

Page 114

4-58 dgc-2020 bestcomsplus software 9400200990 rev i p0 04 2-1 5 09 -2 0- 0 6 a c e b d figure 4-55. Metering, docking options table 4-2. Explanation of call-outs on figure 4-55 call- out symbol explanation a holding the left mouse button down on a metering tab and dragging it to one of the four arr...

Page 115

9400200990 rev i dgc-2020 bestcomsplus software 4-59 engine this screen provides information and metering of engine components. Refer to figure 4-56. Figure 4-56. Metering, engine generator this screen provides metering of generator voltages and currents. Refer to figure 4-57. Figure 4-57. Metering,...

Page 116

4-60 dgc-2020 bestcomsplus software 9400200990 rev i run statistics this screen provides cumulative run statistics, session run statistics, and commission date. Refer to figure 4-59. The maintenance interval can be reset through this screen. Figure 4-59. Metering, run statistics status this screen i...

Page 117

9400200990 rev i dgc-2020 bestcomsplus software 4-61 inputs configurable local inputs this screen indicates the status of local inputs, configurable input alarms, and configurable input pre- alarms. A red led indicates that the status is true. Refer to figure 4-61. Figure 4-61. Metering, inputs, con...

Page 118

4-62 dgc-2020 bestcomsplus software 9400200990 rev i outputs configurable local outputs this screen indicates the status of configurable local outputs. A red led indicates that the status is true. Refer to figure 4-63. Figure 4-63. Metering, outputs, configurable local outputs configurable elements ...

Page 119

9400200990 rev i dgc-2020 bestcomsplus software 4-63 configurable remote outputs when an optional cem-2020 (contact expansion module) is connected, the status of the configurable remote outputs are shown on this screen. A red led indicates that the status is true. Refer to figure 4-65. Figure 4-65. ...

Page 120

4-64 dgc-2020 bestcomsplus software 9400200990 rev i alarms this screen indicates the status of alarms, pre-alarms, sender fail, and generator protection. A green led indicates that the status is true. Alarms and pre-alarms are reset when the dgc-2020 is set to the off mode. The sync fail at gen bre...

Page 121

9400200990 rev i dgc-2020 bestcomsplus software 4-65 and each record contains a time stamp of the first and last event occurrence, and the number of occurrences for each event. In addition, each record contains details of the time, date, and engine hours for the most recent 30 occurrences of the eve...

Page 122

4-66 dgc-2020 bestcomsplus software 9400200990 rev i figure 4-68. Metering, event log, sorted by event id j1939 ecu the ecu reports operating information to the dgc-2020 through the can interface when the ecu is configured for volvo penta. Operating parameters and diagnostic information, if supporte...

Page 123

9400200990 rev i dgc-2020 bestcomsplus software 4-67 engine configuration this screen displays engine configuration. Refer to figure 4-70. Figure 4-70. Metering, engine configuration active dtc and previously active dtc this screen is used for viewing, downloading, and clearing dtc (diagnostic troub...

Page 124

4-68 dgc-2020 bestcomsplus software 9400200990 rev i mtu mdec the mtu mdec reports operating information to the dgc-2020 through the can interface when the ecu is configured for mtu mdec. Operating parameters and diagnostic information, if supported by the mtu mdec, are decoded and displayed on thes...

Page 125

9400200990 rev i dgc-2020 bestcomsplus software 4-69 summary this screen displays a metering summary. Refer to figure 4-74. Figure 4-74. Metering, summary www . Electricalpartmanuals . Com.

Page 126

4-70 dgc-2020 bestcomsplus software 9400200990 rev i control controls for stopping/starting the engine, controls for opening/closing breakers, and controls for opening/closing switches are accessed through the control branch. Figure 4-75. Metering, control the following controls are available by usi...

Page 127

9400200990 rev i dgc-2020 bestcomsplus software 4-71 generator network status this screen (figure 4-77) displays the detected sequencing ids of the lsm-2020’s on the network. This can only be accomplished when an optional lsm-2020 (load share module) is connected to the dgc- 2020 and actively commun...

Page 128

4-72 dgc-2020 bestcomsplus software 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 129: Section 5

9400200990 rev i dgc-2020 bestlogic+ programmable logic i section 5 • bestlogic+ programmable logic table of contents section 5 • bestlogic+ programmable logic............................................................................. 5-1 introduction..................................................

Page 130

Ii dgc-2020 bestlogic+ programmable logic 9400200990 rev i tables table 5-1. I/o group, names and descriptions ........................................................................................ 5-2 table 5-2. Components group, names and descriptions................................................

Page 131: Section 5

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-1 section 5 • bestlogic+ programmable logic introduction bestlogic+ programmable logic is a programming method used for managing the input, output, protection, control, monitoring, and reporting capabilities of basler electric's dgc-2020 digi...

Page 132

5-2 dgc-2020 bestlogic+ programmable 9400200990 rev i bestlogic+ composition there are three main groups of objects used for programming bestlogic+. These groups are i/o, components, and elements. For details on how these objects are used to program bestlogic+, see the paragraphs on programming best...

Page 133

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-3 name description symbol status input cool down timer active true when the cool down timer is timing out. Status input emergency stop true when the emergency stop button has been pressed. Status input engine running true while the engine is ...

Page 134

5-4 dgc-2020 bestlogic+ programmable 9400200990 rev i name description symbol status input pre start condition in effect true while in the pre-start state. Status input reset active true while the reset button on the hmi is pressed. Status input run mode true when the dgc-2020 is in run mode. Status...

Page 135

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-5 name description symbol global alarm true when one or more alarms are set. Global sender fail true when one or more of the sender fails are configured as alarms and are true. Hi coolant temp true when the high coolant temp alarm settings ha...

Page 136

5-6 dgc-2020 bestlogic+ programmable 9400200990 rev i name description symbol engine kw over load 1 true when the engine kw overload 1 pre-alarm settings have been exceeded. Engine kw over load 2 true when the engine kw overload 2 pre-alarm settings have been exceeded. Engine kw over load 3 true whe...

Page 137

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-7 name description symbol multiple load share modules detected true when more than one lsm-2020 is connected. Network id missing error true if an expected sequence id of an optional lsm- 2020 is not detected on the network. Expected sequence ...

Page 138

5-8 dgc-2020 bestlogic+ programmable 9400200990 rev i name description symbol or input output 0 0 0 0 1 1 1 0 1 1 1 1 nor input output 0 0 1 0 1 0 1 0 0 1 1 0 xor input output 0 0 0 0 1 1 1 0 1 1 1 0 xnor input output 0 0 1 0 1 0 1 0 0 1 1 1 not input output 0 1 1 0 pickup and dropout timers drop ou...

Page 139

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-9 other comment block enter user comments. Elements this group contains logic block objects for the 51, 27, 47, 59, 81, 32, and 40 elements. It also contains logic block objects for generator breaker, avr raise/lower, governor raise/lower, lo...

Page 140

5-10 dgc-2020 bestlogic+ programmable 9400200990 rev i name description symbol 59-2trip true when the 59-2 overvoltage is in a trip condition. Connect to another logic block input. 81trip true when the 81 frequency is in a trip condition. Connect to another logic block input. Other element objects a...

Page 141

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-11 name description symbol mainsbrk used to control the mains breaker. Connect the inputs and outputs to inputs and outputs of other logic blocks. (this item is only available when the mains breaker hardware in configured on the breaker hardw...

Page 142

5-12 dgc-2020 bestlogic+ programmable 9400200990 rev i copying and renaming preprogrammed logic schemes copying a saved logic scheme to the active logic (logic name) and assigning a unique name is accomplished by loading the saved logic scheme into bestcomsplus and then typing over the logic scheme'...

Page 143

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-13 • only ten gates per logic level. All output blocks and input sides of element blocks are at the maximum logic level of the diagram. All gates are pushed forward/upwards in logic levels and buffered to reach the final output block or eleme...

Page 144

5-14 dgc-2020 bestlogic+ programmable 9400200990 rev i refer to figure 5-2, pickup and dropout logic timer blocks. To program logic timer settings, use the settings explorer within bestcomsplus to open the bestlogic+ programmable logic/logic timers tree branch. Enter a name label that you want to ap...

Page 145

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-15 logic alarm elements the dgc-2020 activates a logic alarm when the logicalm input is true. A logic pre-alarm is activated when the logicpalm input is true. Configurable elements configurable elements (confelmnt1-8) are connected to the log...

Page 146

5-16 dgc-2020 bestlogic+ programmable 9400200990 rev i printing a bestlogic+ file to view a preview of the printout, click on the print preview icon located on the bestlogic+ programmable logic toolbar. If you wish to print to a printer, select the printer icon in the upper left corner of the print ...

Page 147

9400200990 rev i dgc-2020 bestlogic+ programmable logic 5-17 figure 5-7. Example 3 - multiple logic connections www . Electricalpartmanuals . Com.

Page 148

5-18 dgc-2020 bestlogic+ programmable 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 149: Section 6

9400200990 rev i dgc-2020 installation i section 6 • installation table of contents section 6 • installation .................................................................................................................. 6-1 general ...................................................................

Page 150

Ii dgc-2020 installation 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 151: Section 6

9400200990 rev i dgc-2020 installation 6-1 section 6 • installation general dgc-2020 controllers are delivered in sturdy cartons to prevent shipping damage. Upon receipt of a system, check the part number against the requisition and packing list for agreement. Inspect for damage, and if there is evi...

Page 152

6-2 dgc-2020 installation 9400200990 rev i figure 6-2. Overall dimensions www . Electricalpartmanuals . Com.

Page 153

9400200990 rev i dgc-2020 installation 6-3 connections dgc-2020 connections are dependent on the application. Incorrect wiring may result in damage to the controller. Terminations all dgc-2020 terminals are located on the rear panel of the controller. There are three types of interface terminals: a ...

Page 154

6-4 dgc-2020 installation 9400200990 rev i table 6-2. Generator current sensing terminals terminal description 68 (ia–) 69 (ia+) a-phase current sensing input 71 (ib–) 72 (ib+) b-phase current sensing input 74 (ic–) 75 (ic+) c-phase current sensing input generator voltage sensing the dgc-2020 accept...

Page 155

9400200990 rev i dgc-2020 installation 6-5 table 6-5. Sender input terminals terminal description 8 (oil) oil pressure sender input 9 (fuel) fuel level sender input 10 (coolant) coolant temperature sender input 11 (sender com) sender return terminal magnetic pickup input the magnetic pickup input ac...

Page 156

6-6 dgc-2020 installation 9400200990 rev i output contacts the dgc-2020 has three sets of fixed-function output contacts: pre, start, and run. The pre contacts supply battery power to the engine glow plugs, the start contacts supply power to the start solenoid, and the run contacts supply power to t...

Page 157

9400200990 rev i dgc-2020 installation 6-7 can interface these terminals provide communication using the sae j1939 protocol or the mtu/mdec protocol and provide high-speed communication between the dgc-2020 and an ecu on an electronically controlled engine. Connections between the ecu and dgc-2020 s...

Page 158

6-8 dgc-2020 installation 9400200990 rev i 3-phase wye connections for typical applications figure 6-3. 3-phase wye connections for typical applications www . Electricalpartmanuals . Com.

Page 159

9400200990 rev i dgc-2020 installation 6-9 3-phase delta connections for typical applications figure 6-4. 3-phase delta connections for typical applications www . Electricalpartmanuals . Com.

Page 160

6-10 dgc-2020 installation 9400200990 rev i single-phase a-b connections for typical applications figure 6-5. Single-phase a-b connections for typical applications www . Electricalpartmanuals . Com.

Page 161

9400200990 rev i dgc-2020 installation 6-11 single-phase a-c connections for typical applications figure 6-6. Single-phase a-c connections for typical applications www . Electricalpartmanuals . Com.

Page 162

6-12 dgc-2020 installation 9400200990 rev i connections for volvo penta edc iii applications engines equipped with volvo penta edc iii controllers can receive engine control commands (such as start and stop) from the dgc-2020 through the sae j1939 communication interface. To invoke this feature, the...

Page 163

9400200990 rev i dgc-2020 installation 6-13 3-phase wye connections for volvo penta edc iii applications figure 6-7. 3-phase wye connections for volvo penta edc iii applications www . Electricalpartmanuals . Com.

Page 164

6-14 dgc-2020 installation 9400200990 rev i 3-phase delta connections for volvo penta edc iii applications figure 6-8. 3-phase delta connections for volvo penta edc iii applications www . Electricalpartmanuals . Com.

Page 165

9400200990 rev i dgc-2020 installation 6-15 single-phase a-b connections for volvo penta edc iii applications figure 6-9. Single-phase a-b connections for volvo penta edc iii applications www . Electricalpartmanuals . Com.

Page 166

6-16 dgc-2020 installation 9400200990 rev i single-phase a-c connections for volvo penta edc iii applications figure 6-10. Single-phase a-c connections for volvo penta edc iii applications www . Electricalpartmanuals . Com.

Page 167

9400200990 rev i dgc-2020 installation 6-17 connections with lsm-2020 and cem-2020 the lsm-2020 (load share module) and cem-2020 (contact expansion module) are optional modules that may be installed with the dgc-2020. These modules interface to the dgc-2020 via canbus, thus the canbus terminals are ...

Page 168

6-18 dgc-2020 installation 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 169: Section 7

9400200990 rev i dgc-2020 maintenance and troubleshooting i section 7 • maintenance and troubleshooting table of contents section 7 • maintenance and troubleshooting.................................................................... 7-1 maintenance .....................................................

Page 170

Ii dgc-2020 maintenance and troubleshooting 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 171: Section 7

9400200990 rev i dgc-2020 maintenance and troubleshooting 7-1 section 7 • maintenance and troubleshooting maintenance preventative maintenance consists of periodic replacement of the backup battery (optional) and periodically checking that the connections between the dgc-2020 and the system are clea...

Page 172

7-2 dgc-2020 maintenance and troubleshooting 9400200990 rev i step 5. Verify that the correct sender curves are being used. Step 6. Ensure that the senders are operating properly. Incorrect display of generator voltage step 1. Verify that all wiring is properly connected. Refer to figures 6-3 throug...

Page 173: Section 8

9400200990 rev i dgc-2020 lsm-2020 (load share module) i section 8 • lsm-2020 (load share module) table of contents section 8 • lsm-2020 (load share module) ................................................................................ 8-1 general information..........................................

Page 174

Ii dgc-2020 lsm-2020 (load share module) 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 175: Section 8

9400200990 rev i dgc-2020 lsm-2020 (load share module) 8-1 section 8 • lsm-2020 (load share module) general information the lsm-2020 is a remote auxiliary device that interfaces to the dgc-2020 and provides analog outputs to the power system in the form of analog bias signals to the voltage regulato...

Page 176

8-2 dgc-2020 lsm-2020 (load share module) 9400200990 rev i type tests shock 15 g in 3 perpendicular planes vibration swept over the following ranges for 12 sweeps in each of three mutually perpendicular planes with each 15-minute sweep consisting of the following: 5 to 29 to 5 hz: 1.5 g peak for 5 m...

Page 177

9400200990 rev i dgc-2020 lsm-2020 (load share module) 8-3 functional description load share overview a generator is paralleled with other generators on an island system, which is not connected to the utility. The generator shares load with other generators on the system via the load share line. The...

Page 178

8-4 dgc-2020 lsm-2020 (load share module) 9400200990 rev i bestcomsplus software bestcomsplus provides the user with a point-and-click means to set and monitor the lsm-2020. Installation and operation of bestcomsplus is described in section 4, bestcomsplus software. Lsm-2020 plugin for bestcomsplus ...

Page 179

9400200990 rev i dgc-2020 lsm-2020 (load share module) 8-5 device security setup password protection guards against unauthorized changing of lsm-2020 communication settings. Passwords are case sensitive. Oem access is the only level of password protection available. This password level allows access...

Page 180

8-6 dgc-2020 lsm-2020 (load share module) 9400200990 rev i 5.50 [139.7] 15 16 17 18 6.38 [162.0] 7.50 [190.5] 8.38 [212.8] 1.39 [35.3] 1 2 3 4 5 6 7 8 9 10 11 12 13 14 p0052-36 p2 j3 figure 8-3. Lsm-2020 overall dimensions connections lsm-2020 connections are dependent on the application. Incorrect ...

Page 181

9400200990 rev i dgc-2020 lsm-2020 (load share module) 8-7 operating power the lsm-2020 operating power input accepts either 12 vdc or 24 vdc and tolerates voltage over the range of 6 to 32 vdc. Operating power must be of the correct polarity. Although reverse polarity will not cause damage, the lsm...

Page 182

8-8 dgc-2020 lsm-2020 (load share module) 9400200990 rev i can interface these terminals provide communication using the sae j1939 protocol and provide high-speed communication between the lsm-2020 and the dgc-2020. Connections between the lsm-2020 and dgc-2020 should be made with twisted-pair, shie...

Page 183

9400200990 rev i dgc-2020 lsm-2020 (load share module) 8-9 lsm-2020 dgc-2020 other devices p0053-08 engine 120 ohm termination 120 ohm termination can-h can-l cem-2020 (optional) figure 8-5. Canbus interface with dgc-2020 providing one end of the backbone ethernet port the lsm-2020 has ethernet capa...

Page 184

8-10 dgc-2020 lsm-2020 (load share module) 9400200990 rev i connections using avr’, gov’, and ls’ additional terminals provide a landing point to add series resistance to the gov, avr, and ls analog outputs. These terminals are not internally connected to the lsm-2020. Figure 8-7 illustrates connect...

Page 185: Section 9

9400200990 rev i dgc-2020 cem-2020 (contact expansion module) i section 9 • cem-2020 (contact expansion module) table of contents section 9 • cem-2020 (contact expansion module) ............................................................... 9-1 general information......................................

Page 186

Ii dgc-2020 cem-2020 (contact expansion module) 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 187: Section 9

9400200990 rev i dgc-2020 cem-2020 (contact expansion module) 9-1 section 9 • cem-2020 (contact expansion module) general information the optional cem-2020 is a remote auxiliary device that provides additional contact inputs and outputs to the dgc-2020. Features cem-2020’s have the following feature...

Page 188

9-2 dgc-2020 cem-2020 (contact expansion module) 9400200990 rev i halt (highly accelerated life testing) halt is used by many manufacturers to prove that their products will provide the user with many years of reliable service. Halt subjects the device to extremes in temperature, shock, and vibratio...

Page 189

9400200990 rev i dgc-2020 cem-2020 (contact expansion module) 9-3 bestcomsplus software bestcomsplus provides the user with a point-and-click means to set and monitor the contact expansion module. Installation and operation of bestcomsplus is described in section 4, bestcomsplus software. Installati...

Page 190

9-4 dgc-2020 cem-2020 (contact expansion module) 9400200990 rev i connections contact expansion module connections are dependent on the application. Incorrect wiring may result in damage to the module. Terminations the terminal interface consists of plug-in connectors with screw-down compression ter...

Page 191

9400200990 rev i dgc-2020 cem-2020 (contact expansion module) 9-5 figure 9-2. Input contact and output contact terminals can interface these terminals provide communication using the sae j1939 protocol and provide high-speed communication between the contact expansion module and the dgc-2020. Connec...

Page 192

9-6 dgc-2020 cem-2020 (contact expansion module) 9400200990 rev i dgc-2020 cem-2020 other devices p0053-09 engine 120 ohm termination 120 ohm termination can-h can-l lsm-2020 (optional) figure 9-3. Canbus interface with cem-2020 providing one end of the backbone cem-2020 dgc-2020 other devices p0053...

Page 193: Characteristic Curves

9400200990 rev i dgc-2020 time overcurrent characteristic curves i appendix a • time overcurrent characteristic curves table of contents appendix a • time overcurrent characteristic curves ...................................................A-1 introduction ..............................................

Page 194

Ii dgc-2020 time overcurrent characteristic curves 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 195: Characteristic Curves

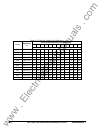

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-1 appendix a • time overcurrent characteristic curves introduction the inverse time overcurrent characteristic curves provided by the dgc-2020 (style xxxxxxexx only) closely emulate most of the common electromechanical, induction-dis...

Page 196

A-2 dgc-2020 time overcurrent characteristic curves 9400200990 rev i table a-1. 51 time characteristic curve constants trip characteristic constants curve selection curve name a b c n k s1 s, s1, short inverse 0.2663 0.03393 1.0000 1.2969 0.0280 s2 s2, short inverse 0.0286 0.02080 1.0000 0.9844 0.02...

Page 197

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-3 table a-2. Characteristic curve cross-reference curve curve name similar to s1 s, s1, short inverse abb co-2 s2 s2, short inverse ge iac-55 l1 l, l1, long inverse abb co-5 l2 l2, long inverse ge iac-66 d d, definite time abb co-6 m...

Page 198

A-4 dgc-2020 time overcurrent characteristic curves 9400200990 rev i table a-3 .Time dial setting cross-reference electromechanical relay time dial setting 0.5 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 curve equivalent to basler electric equivalent time dial setting s, s1 abb co-2 0.3 0.8 1.7 2....

Page 199

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-5 figure a-1. Time characteristic curve s, s1, short inverse (similar to abb co-2) www . Electricalpartmanuals . Com.

Page 200

A-6 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-2. Time characteristic curve s2, short inverse (similar to ge iac-55) www . Electricalpartmanuals . Com.

Page 201

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-7 figure a-3. Time characteristic curve l, l1, long inverse (similar to abb co-5) www . Electricalpartmanuals . Com.

Page 202

A-8 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-4. Time characteristic curve l2, long inverse (similar to ge iac-66) www . Electricalpartmanuals . Com.

Page 203

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-9 figure a-5. Time characteristic curve d, definite time (similar to abb co-6) www . Electricalpartmanuals . Com.

Page 204

A-10 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-6. Time characteristic curve m, moderately inverse (similar to abb co-7) www . Electricalpartmanuals . Com.

Page 205

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-11 figure a-7. Time characteristic curve i, i1, inverse time (similar to abb co-8) www . Electricalpartmanuals . Com.

Page 206

A-12 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-8. Time characteristic curve i2, inverse time (similar to ge iac-51) www . Electricalpartmanuals . Com.

Page 207

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-13 figure a-9. Time characteristic curve v, v1, very inverse (similar to abb co-9) www . Electricalpartmanuals . Com.

Page 208

A-14 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-10. Time characteristic curve v2, very inverse (similar to ge iac-53) www . Electricalpartmanuals . Com.

Page 209

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-15 figure a-11. Time characteristic curve e, e1, extremely inverse (similar to abb co-11) www . Electricalpartmanuals . Com.

Page 210

A-16 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-12. Time characteristic curve e2, extremely inverse (similar to ge iac-77) www . Electricalpartmanuals . Com.

Page 211

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-17 figure a-13. Time characteristic curve a, standard inverse www . Electricalpartmanuals . Com.

Page 212

A-18 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-14. Time characteristic curve b, very inverse www . Electricalpartmanuals . Com.

Page 213

9400200990 rev i dgc-2020 time overcurrent characteristic curves a-19 figure a-15. Time characteristic curve c, extremely inverse www . Electricalpartmanuals . Com.

Page 214

A-20 dgc-2020 time overcurrent characteristic curves 9400200990 rev i figure a-16. Time characteristic curve g, long time inverse www . Electricalpartmanuals . Com.

Page 215: Appendix B

9400200990 rev i dgc-2020 modbus ™ communication i appendix b • modbus™ communication table of contents introduction .......................................................................................................................... B-1 general overview ..........................................

Page 216

Ii dgc-2020 modbus ™ communication 9400200990 rev i this page intentionally left blank. Www . Electricalpartmanuals . Com.

Page 217: Appendix B

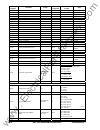

9400200990 rev i dgc-2020 modbus ™ communication b-1 appendix b • modbus™ communication introduction general overview an optional feature of the dgc-2020 performs modbus communications by emulating a subset of the modicon 984 programmable controller. This document describes the modbus communications...

Page 218

B-2 dgc-2020 modbus ™ communication 9400200990 rev i data block field the query data block contains additional information needed by the slave to perform the requested function. The response data block contains data collected by the slave for the queried function. An error response will substitute a...

Page 219

9400200990 rev i dgc-2020 modbus ™ communication b-3 • function 08, subfunction 00 - diagnostics: return query data • function 16 - preset multiple registers, non-broadcast & broadcast the only broadcast query supported by the dgc-2020 is the preset multiple registers query. Read holding registers r...

Page 220

B-4 dgc-2020 modbus ™ communication 9400200990 rev i preset multiple registers, non-broadcast & broadcast preset multiple registers - general query: this query message requests a register or block of registers to be written. The data block contains the starting address and the quantity of registers ...

Page 221

9400200990 rev i dgc-2020 modbus ™ communication b-5 • there are several instances of registers that are grouped together (signified as dp or tp) to collectively represent a single numerical (vs. Ascii string) dgc-2020 parameter value. A query to write a subset of such a register group will result i...

Page 222

B-6 dgc-2020 modbus ™ communication 9400200990 rev i the same byte alignments are required to write. Long integer data format (int32) the modbus long integer data format uses two consecutive holding registers to represent a 32-bit data value. The first register contains the low-order 16 bits and the...

Page 223

9400200990 rev i dgc-2020 modbus ™ communication b-7 double precision data format (dp) the modbus double precision data format (dp) uses 2 consecutive registers to represent a data value. The first register contains the high-order 16 bits of double precision data, and is the actual data value / 10,0...

Page 224

B-8 dgc-2020 modbus ™ communication 9400200990 rev i mapping - dgc 2020 parameters into modicon address space table conventions table b-3 uses the conventions outlined in this section. The “data format” column uses the following abbreviations: • dp - double precision • tp - triple precision • fp – f...

Page 225

9400200990 rev i dgc-2020 modbus ™ communication b-9 table b-3. Legacy parameter table holding register parameter range read/write supported data format units 40001-18 reserved parameter settings 40019 emergency stop 0-1 w 0 =off 1 =stop 40020 remote start / stop 0-1 w 0 =stop 1 =start 40021-22 rese...

Page 226

B-10 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 40049 threshold 3-100 r w psi low battery voltage pre-alarm 40050 enable 0-1 r w 0 =off 1 =on 40051 threshold 60-120 (12v) 120-240 (24v) r w .1 volts dc 40052 pre-alarm activ...

Page 227

9400200990 rev i dgc-2020 modbus ™ communication b-11 holding register parameter range read/write supported data format units 40082 alarm codes individual bits are 0 or 1 r - b0=high coolant temperature b1=low coolant level b2=low fuel level b3=emergency stop b4=sender failure b5=over crank b6=over ...

Page 228

B-12 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 40110 phase a rms current r - rms amps 40111 phase b rms current r - rms amps 40112 phase c rms current r - rms amps 40113 phase a apparent power(a) r - dp kva x 10000 40114 ...

Page 229

9400200990 rev i dgc-2020 modbus ™ communication b-13 holding register parameter range read/write supported data format units 40281 embedded code version number (a) 0-99 r 40282 embedded code version number (b) 0-9999 r 40283 embedded code version number (c) 0-9999 r 40287-97 reserved 40298 read rel...

Page 230

B-14 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 40319 active dtc number 7 – upper two bytes 0-65535 r half of a set of dtc data as defined in sae j1939-73 40320 active dtc number 6 – lower two bytes 0-65535 r half of a set...

Page 231

9400200990 rev i dgc-2020 modbus ™ communication b-15 holding register parameter range read/write supported data format units 40351 previous dtc number 10 – upper two bytes 0-65535 r half of a set of dtc data as defined in sae j1939-73 40352 previous dtc number 11 – lower two bytes 0-65535 r half of...

Page 232

B-16 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 40372 can communications diagnostics for use when can is enabled. Individual bits are 0 or 1 r bit 12 - .Engine run time bit 11 – data failure status. Previous active dtcs cl...

Page 233

9400200990 rev i dgc-2020 modbus ™ communication b-17 holding register parameter range read/write supported data format units 40388 j1939 engine start/stop configuration 0-65535 r w 0 = not configured; 1 = volvo penta edc3; 2 = mtu mdec 40395 ecu settling time 0-65535 r w milliseconds 40396 ecu puls...

Page 234

B-18 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 40448 air inlet temperature -40 to +210 °c (-40 to 410 °f) r 1 °c/bit gain, -40 °c offset 40449 boost pressure 0 to +500 kpa (0 to 72.5 psi) r 2 kpa/bit gain, 0 kpa offset 40...

Page 235

9400200990 rev i dgc-2020 modbus ™ communication b-19 holding register parameter range read/write supported data format units 40504 led status individual bits are 0 or 1 r bits indicate status of led’s: b0 = run b1 = off b2 = auto b3 = alarm b4 = load b5 = not in auto 40507 read relay image of both ...

Page 236

B-20 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units overvoltage 40624 59 pick-up – 3-phase 70-576 r w volts ac 40625 59 time delay – 3-phase 0-300 r w 0.0-30.0 seconds 40626 59 alarm config. – 3-phase 0-2 r w 0=none, 1=pre-ala...

Page 237

9400200990 rev i dgc-2020 modbus ™ communication b-21 holding register parameter range read/write supported data format units 40737 commission start month 1-12 r w month 40738 commission start day 1-31 r w day 40739 commission start year 0-99 r w year 40740-41 cumulative run hours x 60 0-4294967295 ...

Page 238

B-22 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 42010 reserved 42012 mains breaker configured 0-1 r w 0 = not configured, 1 = configured 42014 mains breaker open pulse time 1-80 r w milliseconds * 10 42016 mains breaker cl...

Page 239

9400200990 rev i dgc-2020 modbus ™ communication b-23 holding register parameter range read/write supported data format units 42756 gen sensing stable undervoltage pickup 100-12000 r w (volts / 10) in increments of 10 42758 gen sensing stable undervoltage dropout 100-12000 r w (volts / 10) in increm...

Page 240

B-24 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 43450-498 future use system configuration and status 43500 rated volts 1-999 r w volts in increments of 1 43502 pre-start contact config 0-1 r w 0 = open after disconnect 1 =...

Page 241

9400200990 rev i dgc-2020 modbus ™ communication b-25 holding register parameter range read/write supported data format units 43786 virtual input 4 close 0-1 r w a value of 1 will close the virtual input 4 switch 43788 virtual input 4 open 0-1 r w a value of 1 will open the virtual input 4 switch 43...

Page 242

B-26 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 44268 phase imbalance activation delay 0-300 r w (seconds / 10) in increments of 1 44270 phase imbalance alarm configuration 0-2 r w 0 = none 1 = alarm 2 = pre-alarm 44272 3 ...

Page 243

9400200990 rev i dgc-2020 modbus ™ communication b-27 holding register parameter range read/write supported data format units 44324 3 phase overcurrent curve (51-2) 0-16 r w 0 = s1 curve 1 = s2 curve 2 = l1 curve 3 = l2 curve 4 = d curve 5 = m curve 6 = i1 curve 7 = i2 curve 8 = v1 curve 9 = v2 curv...

Page 244

B-28 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 44356 3 phase overvoltage alarm configuration (59-2) 0-2 r w 0 = none 1 = alarm 2 = pre-alarm 44358 1 phase overvoltage pickup (59-2) 70-576 r w volts in increments of 1 4436...

Page 245

9400200990 rev i dgc-2020 modbus ™ communication b-29 holding register parameter range read/write supported data format units 44422 1 phase loss of excitation hysteresis 10-100 r w deci-percent in increments of 1 44424-498 future use alarms 44500 high coolant temp alarm enable 0-1 r w 0 = disable 1 ...

Page 246

B-30 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 44564 low oil press. Pre-alarm enable 0-1 r w 0 = disable 1 = enable 44566 low oil press. Pre-alarm threshold 3-150 r w psi in increments of 1 44568 metric low oil press. Pre...

Page 247

9400200990 rev i dgc-2020 modbus ™ communication b-31 holding register parameter range read/write supported data format units 44630 avr bias output limit pre-alarm activation delay 1-15 r w seconds in increments of 1 44632 avr bias output limit pre-alarm enable 0-1 r w 0 = disable 1 = enable 44634 g...

Page 248

B-32 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 44812 alarm metering 0 - 4294967295 r bit 0 = overspeed bit 1 = hi coolant temp bit 2 = low oil pressure bit 3 = low fuel level bit 4 = global sender fail bit 5 = loss of ecu...

Page 249

9400200990 rev i dgc-2020 modbus ™ communication b-33 holding register parameter range read/write supported data format units 44828 local input metering 0 - 4294967295 r bit 0 = input 1 bit 1 = input 2 bit 2 = input 3 bit 3 = input 4 bit 4 = input 5 bit 5 = input 6 bit 6 = input 7 bit 7 = input 8 bi...

Page 250

B-34 dgc-2020 modbus ™ communication 9400200990 rev i holding register parameter range read/write supported data format units 44880 generator status 0 - 11 r 0 = reset state 1 = ready state 2 = cranking state 3 = resting state 4 = running state 5 = alarm state 6 = prestart state 7 = cooling state 8 ...

Page 251

Route 143, box 269, highland, illinois u.S.A. 62249 tel +1 618.654.2341 fax +1 618.654.2351 e-mail: info@basler.Com no. 1300 north zhongshan road, wujiang economic development zone suzhou, jiangsu province - p.R. China 215200 tel +86(0)512 6346 1730 fax +86(0)512 6346 1760 e-mail: beichina@basler.Co...