- DL manuals

- Baudoulin

- Engine

- 4M11G

- Maintenance manual

Baudoulin 4M11G Maintenance manual

Summary of 4M11G

Page 1

Maintenance manual of 4m11 series diesel engine for land power generators maintenance manual of 4m11 series diesel engine for land power generators.

Page 2

Maintenance manual of 4m11 series diesel engine for land power generators special notice the operator of the diesel engine must carefully read the product service manual of the diesel engine, strictly abide by the technical operation and maintenance specifications specified in the product service ...

Page 3

Maintenance manual of 4m11 series diesel engine for land power generators non-filtered air into the cylinders. Under severe working environment, increase the cleaning or replacement frequency of the air filter element, in order to prevent malfunctions (such as earlier wear) of diesel engine. the c...

Page 4

Maintenance manual of 4m11 series diesel engine for land power generators foreword this series diesel engine features compact structure, high operation reliability, excellent power and economy performances, rapid start, simple operations, convenient maintenances, and advanced emission performance. T...

Page 5

Maintenance manual of 4m11 series diesel engine for land power generators table of contents chapter i general information ··································································································· 1 1.1 exterior view of diesel engine ·········································...

Page 6

Maintenance manual of 4m11 series diesel engine for land power generators 3.2.5 diesel engine overheating ············································································· 25 3.2.6 abnormal exhaust gas color of diesel engine ····················································· 26 3.2.7 ...

Page 7

Maintenance manual of 4m11 series diesel engine for land power generators 4.4.3 disassembly, inspection, repair, and assembly of crankshaft ···································· 61 4.4.4 disassembly, inspection, repair, and assembly of flywheel and ring gear ··················· 63 4.4.5 disassembly, ...

Page 8

Maintenance manual of 4m11 series diesel engine for land power generators 4.9.1 disassembly and assembly of lubrication system ················································· 97 4.9.2 disassembly, inspection, repair, and assembly of oil pump ····································· 98 4.9.3 disassemb...

Page 9

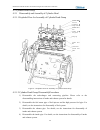

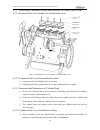

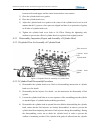

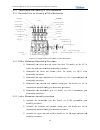

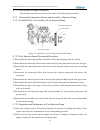

Maintenance manual of 4m11 series diesel engine for land power generators 1 chapter i general information 1.1 exterior view of diesel engine figure 1-1 exterior view of 4m11 diesel engine figure 1-2 intake and exhaust side of 4m11 diesel engine.

Page 10

Maintenance manual of 4m11 series diesel engine for land power generators 2 figure 1-3 flywheel end of 4m11diesel engine figure 1-4 fan end of 4m11diesel engine.

Page 11

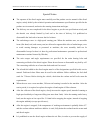

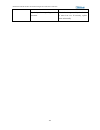

Maintenance manual of 4m11 series diesel engine for land power generators 3 1.2 model meaning of diesel engine 1.3 main specification of diesel engine table 1-1 main specification of 4m11 diesel engine item unit model engine type 4m11g engine type — four-stroke, water-cooling, in-line, direct-inject...

Page 12

Maintenance manual of 4m11 series diesel engine for land power generators 4 starter cold starting-with auxiliary starter ℃ -30 noise at 1m reach db(a) ≤115 b 10 lifetime km 500,000 1.4 unsealing of diesel engine after the diesel engine is unpacked, the user shall firstly count the diesel engine and ...

Page 13

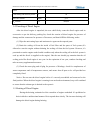

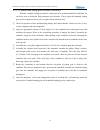

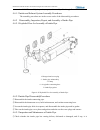

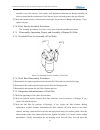

Maintenance manual of 4m11 series diesel engine for land power generators 5 a) b) figure 1- 1hoisting diagram of diesel engine every diesel engine is fitted with two special cylinder head bolts for hoisting of diesel engine. The end face of the hexagon head of these bolts has a m14 screw and a lifti...

Page 14

Maintenance manual of 4m11 series diesel engine for land power generators 6 and check fuel level from the fuel gauge or check the fuel tank. (3) check the engine oil level the engine oil level shall be between upper and lower markings of the oil dipstick. If necessary, add engine oil through the eng...

Page 15

Maintenance manual of 4m11 series diesel engine for land power generators 7 diesel engine may not run for more than 20 minutes at the speed 105% the rated speed or the output 110% the rated output. After the unloading, idle the diesel engine for (1~2) min before stop. Parameters and checking locatio...

Page 16

Maintenance manual of 4m11 series diesel engine for land power generators 8 electrolyte and unit voltage of the battery. If the diesel engine is not to be used for a long time and is under extremely low temperature, disassemble the battery and store in a warm indoor place. (6) stop: to stop the engi...

Page 17

Maintenance manual of 4m11 series diesel engine for land power generators 9 chapter ii maintenance guide 2.1 fuel oil, lubricating oil, coolant, and auxiliary materials for diesel engine 2.1.1 fuel oil summer: 0# diesel (gb 252) winter: generally -10# diesel fuel shall be used; however, -20# diesel ...

Page 18

Maintenance manual of 4m11 series diesel engine for land power generators 10 20w-50 -15-45 note: 1) before starting the diesel engine, ensure to check the engine oil level within oil pan. 2) do not check the oil level while the diesel engine is running. 3) never mix special engine oil of weichai pow...

Page 19

Maintenance manual of 4m11 series diesel engine for land power generators 11 hec-Ⅱ-40 note: 1) make sure to periodically check the coolant and, to prevent the corrosion and damage, timely replace depending on actual situation. 2) it’s prohibited to use water or low quality coolant as the engine cool...

Page 20

Maintenance manual of 4m11 series diesel engine for land power generators 12 loctite 271 preventing looseness, fixing cup plug, oil drain hole loctite 277 for sealing between element and bore other cup plug loctite 270 sealing cylinder head top push rod -cylinder head loctite 518 (modified from loct...

Page 21

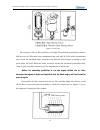

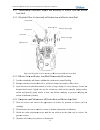

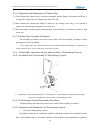

Maintenance m no check c prohib or is ab a order t no check manual of 4m1 otice: make k the oil leve check whet bited to start bove upper after the die to enable th otice: chec k the fuel lev 1 series diesel sure to che el. Ther the en t the diesel marking of esel engine he engine oi figure 2-2 ...

Page 22

Maintenance manual of 4m11 series diesel engine for land power generators 14 check the fuel level indication from the instrument panel. Add fuel if necessary. The diesel used shall meet the specification. Keep clean the diesel. It's better to place the diesel under stationary state for more than 72 ...

Page 23

Maintenance m 2.3 conte replac place horiz unscrew th screw the o screen, obs oil filler ca replac at the ① rot ② fill ③ app hand. ④ afte ⑤ star manual of 4m1 ents of ma ce engine oi zontally the he oil draina oil drainage serve the m ap. Figure ce engine oi replacemen ate counter- the new filt ...

Page 24

Maintenance manual of 4m11 series diesel engine for land power generators 16 figure 2-7 engine oil filter check and adjust the clearances of intake and exhaust valves. Check and adjust the clearances of intake and exhaust valves as per following procedure: ① under the cold status of diesel engine,...

Page 25

Maintenance m ③ che for th clearan loosen of adju other c ④ afte or 1st adjustm 1st c compres manual of 4m1 eck the clea he 4m11 di nces shall b n the adjustm ustment scr clearances b er the check t cylinder t ment sequen cylinder ssion stroke 1 series diesel rance betwe iesel engin be 0.2mm an ment...

Page 26

Maintenance m 4th c compres replac at the ① clo ② rot ③ app ④ tigh ⑤ ope ⑥ blee ⑦ che check c of loo system check f manual of 4m1 cylinder ssion stroke ce the fuel f replacemen se the valve ate counter- ply uniform hten new fu en the valve ed air from eck the airtig k intake syst check the in ...

Page 27

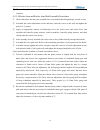

Maintenance manual of 4m11 series diesel engine for land power generators 19 figure 2-12 air filter the resistance of the air filter shall not be too high. The maximum permissible resistance shall not exceed 3kpa under non-contaminated state and shall be 5kpa under contaminated state. Check the maxi...

Page 28

Maintenance manual of 4m11 series diesel engine for land power generators 20 figure2-13 cleaning element notice: do not blow through the filter paper do not clean the filter paper by water or oil do not pat or beat the filter element strongly ensure to replace the damaged filter element and seal rin...

Page 29

Maintenance manual of 4m11 series diesel engine for land power generators 21 ⑦apply protective oil to all machined parts and easy rusting parts of the diesel engine. Seal for storage after above procedure is completed. To prevent the ingress of moisture and impurities into the diesel engine, seal al...

Page 30

Maintenance m 4 each d of high to the below op fa po temptation in 3.1 diagn t below ob symptom, li portion by cy the malfun the fuel su diesel engi determinat manual of 4m1 m11 series delivered die h precision normal mai : perations ag ailure to ful oorly manu n of cheap pr nappropria...

Page 31

Maintenance manual of 4m11 series diesel engine for land power generators 23 comparison method: for some assemblies or parts, the replacement method is adopted to determine the presence of malfunction. Note: 1. Judging the malfunction cause of diesel engine is a really precise work. Before the cau...

Page 32

Maintenance manual of 4m11 series diesel engine for land power generators 24 the leaks (if any). 3 starting system fault 3-1 insufficient voltage of battery charging and overhaul to battery 3-2 poor contact of electric circuit connectors check the circuit 3-3 no rotation or weak rotation of starter ...

Page 33

Maintenance manual of 4m11 series diesel engine for land power generators 25 1-5 low fuel quality or water content in fuel check fuel , and replace if necessary 2 insufficient compression pressure of cylinder 2-1 excessive wear of piston rings and cylinder sleeves check and replace piston rings and ...

Page 34

Maintenance manual of 4m11 series diesel engine for land power generators 26 3-1 insufficient or excessive oil check the oil dipstick and add/drain engine oil as per specification. 3-2 internal blockage of oil cooler clean or replace engine oil cooler 4 coolant temperature too high 4-1 insufficient ...

Page 35

Maintenance manual of 4m11 series diesel engine for land power generators 27 pump and fuel injectors. 3-3 late fuel supply timing and serious after-combustion adjust fuel supply advance angle 3-4 incorrect valve clearance or poor sealing status of valve check valve clearance and valve airtightness. ...

Page 36

Maintenance manual of 4m11 series diesel engine for land power generators 28 end bearing and clear metallic knocking sound (especially at low and high speeds) guarantee specified clearance. 6 excessive clearance between connecting rod and bearing, with dumb impact sound replace bearing 7 excessive c...

Page 37

Maintenance manual of 4m11 series diesel engine for land power generators 29 chapter iv disassembly and assembly of engine 4.1 overview during disassembly and assembly of engine, please follow operating instructions in this manual strictly and pay attention to operation steps containing danger and s...

Page 38

Maintenance manual of 4m11 series diesel engine for land power generators 30 decide to use a procedure or a method that is outside the range recommended in this manual, please make sure that such operation will not bring harm to yourself, any other person or the equipment. 4.1.2 safety sign table 4-...

Page 39

Maintenance manual of 4m11 series diesel engine for land power generators 31 4.1.3 used tools table 4-2used tools should any method or tool used is not recommended in this manual, the user must first ensure personal safety, and avoid jeopardizing the life of the user or other personnel, as well as g...

Page 40

Maintenance manual of 4m11 series diesel engine for land power generators 32 naturally secreted grease to help moisturize the skin. (9) do not clean the skin by gasoline, kerosene, fuel, thinner, or solvent. (10) upon detection of skin irritation, please immediately seek for medical treatment. (11) ...

Page 41

Maintenance manual of 4m11 series diesel engine for land power generators 33 notice: stop the engine during maintenance or service..

Page 42

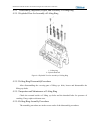

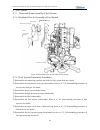

Maintenance manual of 4m11 series diesel engine for land power generators 34 4.2 cylinder head group 4.2.1 disassembly and assembly of cylinder head 4.2.1.1 exploded view for assembly of cylinder head group figure 4- 1 exploded view for assembly of cylinder head group 4.2.1.2 cylinder head group dis...

Page 43

Maintenance manual of 4m11 series diesel engine for land power generators 35 5) disassemble the lifting ring. 6) disassemble the cylinder head cover and the cylinder head cover gasket. 7) disassemble the fuel injector. For details , see the instructions for disassembly of fuel system; 8) disassemble...

Page 44

Maintenance manual of 4m11 series diesel engine for land power generators 36 4.2.2 disassembly, inspection, repair, and assembly of cylinder head group 4.2.2.1 exploded view for assembly of cylinder head cover figure 4-2 exploded view for assembly of cylinder head cover 4.2.2.2 cylinder head cover d...

Page 45

Maintenance manual of 4m11 series diesel engine for land power generators 37 2) spray clean engine oil to the contact area between rocker and valve, the contact area between rocker and tappet, and the center between above two contacts. 3) place the cylinder head cover gasket; 4) place the cylinder h...

Page 46

Maintenance m 5) 6) 7) 8) 4.2.3.3 in 1) b and ai locatio c intake varnish ① c out pe ② v unders wear o shown f manual of 4m1 head, tak ) disassem wearing disassem cylinder ) disassem gaskets i problem ) dissemb instructio ) disassem nspection a ) cylinder before disas ir leakage ons and ana clean th...

Page 47

Maintenance m range, the va then ch abnorm ② t the val to wea diesel inside outsid guidei shall b 2) u and rep check wh regard being 3) b damag or not, 4.2.3.4 c 1) 2) manual of 4m1 the cylinde alve sink do heck the se mal damage ② clearanc the inside d lve, and if t ar, it will r engine ope microme...

Page 48

Maintenance manual of 4m11 series diesel engine for land power generators 40 3) assemble the cylinder head onto the cylinder block. 4) loose cylinder head bolt; 5) tighten the cylinder head bolts to 30n.M, rotate the bolts for 120°±4°, and then rotate further for 120°±4°. 6) the tightening sequence ...

Page 49

Maintenance manual of 4m11 series diesel engine for land power generators 41 4.2.4 disassembly, inspection, repair, and assembly of oil-gas separator 4.2.4.1 exploded view for assembly of oil-gas separator figure 4-7 exploded view for assembly of oil-gas separator 4.2.4.2 oil-gas separator disassemb...

Page 50

Maintenance manual of 4m11 series diesel engine for land power generators 42 4.2.5 disassembly, inspection, repair, and assembly of lifting ring 4.2.5.1 exploded view for assembly of lifting ring 1- lifting ring 2- cylinder head bolt figure 4-8 exploded view for assembly of lifting ring 4.2.5.2 lift...

Page 51

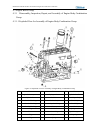

Maintenance manual of 4m11 series diesel engine for land power generators 43 4.3 engine block group 4.3.1 disassembly, inspection, repair, and assembly of engine body combination group 4.3.1.1 exploded view for assembly of engine body combination group figure 4-9 exploded view for assembly of engine...

Page 52

Maintenance m 10 11 12 13 14 4.3.1.2 en ① disa ② disa ③ disa ④ disa ⑤ disa 4.3.1.3 c p a and th (1 a b c (2 a b c t below (3 manual of 4m1 o-shap o-shap cu de weld ngine bod assemble th assemble th assemble th assemble th assemble th checking a point 1: asse apply lubric en tighten t 1) tighten sequ...

Page 53

Maintenance manual of 4m11 series diesel engine for land power generators 45 2nd cylinder - 3rd cylinder -4th cylinder - 1st cylinder (4) control range of tightening torque for cylinder head bolts: m14-12.9: (230~300) n·m m14-10.9: (190~285) n·m point 2: assembly assemble the grease-applied seal rin...

Page 54

Maintenance m 4.3.1.4 en a 4.3.2 d 4.3.2.1 ex 4.3.2.2 d ① ② 4.3.2.3 in p c c must b line sh and sc parts m a t to two manual of 4m1 ngine bod assembly of disassembl xploded v fig disassembl ① disassemb ② disassemb nspection a point 1: check: check and c be clean. Th hall be free cratch durin must be...

Page 55

Maintenance manual of 4m11 series diesel engine for land power generators 47 step and rotate the bolts for 90º±4º for the 2nd step. Figure 4-12 tightening of main bearing bolts point 2: assembly assemble the thrust bearing cap to the rear end of cylinder block and assemble non-thrust bearing caps fo...

Page 56

Maintenance m 4.3.3 d 4.3.3.1 ex 4.3.3.2 d ① ② ③ ④ 4.3.3.3 in p c presen a inter tf r manual of 4m1 disassembl xploded v disassemb ① disassemb ② disassemb ③ disassemb ④ disassem nspection a point 1: checking: c nce of dama assembly: 1) kno ventila rmediate ge ender intermedia radial seal ri h 1 seri...

Page 57

Maintenance m p a b and th clean e such m d t disasse 4.3.3.4 fr t proced manual of 4m1 2) app with 3) alig wal 4) inse tigh point 2: assembly before assem he assemblin engine oil o manner that disassembly the oil sea embled. Ront wall the assembl dures. 1 series diesel ply the seal hout broken figu...

Page 58

Maintenance m 4.3.4 d 4.3.4.1 ex 4.3.4.2 fl ① ② observ ③ 4.3.4.3 in p c surfac junctio bolts, s s directi sequen manual of 4m1 disassembl xploded v lywheel c ① disassemb ② disassemb vation hole c ③ disassemb nspection a point 1: asse check the fl es of cylind on surface 6 m12-10.9 step 1: pre-a step...

Page 59

Maintenance manual of 4m11 series diesel engine for land power generators 51 figure 4-18 tightening sequence of bolts notice: for above-mentioned high-strength bolts, apply lubricating oil to the threads and support surface before assembly. 4.3.4.4 flywheel cover assembly procedures the assembly pro...

Page 60

Maintenance manual of 4m11 series diesel engine for land power generators 52 4.3.5 disassembly, inspection, repair, and assembly of oil pan 4.3.5.1 exploded view for assembly of oil pan 1 - combination washer 2 - combination seal washer 3 - magnetic plug 4 - hexagon head plug 5 - screw plug 6 - squa...

Page 61

Maintenance m 4.3.5.4 o t 4.3.6 d 4.3.6.1 ex 4.3.6.2 pi ① ② 4.3.6.3 in p ① pressu ② ③ p c of the 4.3.6.4 pi a manual of 4m1 3) insert 20~35 oil pan ass the assembl disassembl xploded v iston nozz ① disassemb ② disassemb nspection a point 1: asse ① compress ure plate. ② compress ③ tighten th point 2:...

Page 62

Maintenance m 4.3.7 d 4.3.7.1 ex 4.3.7.2 th ① ② ③ 4.3.7.3 in p t thrust cap. 4.3.7.4 th a manual of 4m1 disassembl xploded v hrust half ① disassemb ② disassemb ③ disassemb nspection a point 1: asse the thrust pl places outw hrust half assembly of 1 series diesel ly, inspect view for a figure 4-2 fri...

Page 63

Maintenance m 4.3.8 d 4.3.8.1 ex 4.3.8.2 fr 4.3.8.3 in p c c cylind a rear o gaske blot manual of 4m1 disassembl xploded v fig ront and r 1) disa 2) disa 3) disa 4) disa nspection a point 1: check check and e der block are assembly 1) wip cyli 2) app peri 3) kno asse pneu oil seal et rear oil 1 seri...

Page 64

Maintenance manual of 4m11 series diesel engine for land power generators 56 figure 4-23 tightening sequence of bolts point 2: check check and ensure that the inner sealing surface of the seal ring is free of damage, the oil seal rubber is free of damage, and the rear oil seal cap is clean, without ...

Page 65

Maintenance m 4.4 crank 4.4.1 d 4.4.1.1 ex 4.4.1.2 c 1 tighten turn th connec hamm the cy sequen 2 the bel 3 other p 4.4.1.3 c the assem manual of 4m1 k connect disassembl xploded v f crank conn . Inspectio ning torque he piston t cting rod ca mer. Care sho ylinder bloc nce. . Unscrew t lt pulley, t...

Page 66

Maintenance manual of 4m11 series diesel engine for land power generators 58 4.4.2 disassembly, inspection, repair, and assembly of piston connecting rod group 4.4.2.1 exploded view for assembly of piston connecting rod figure 4-25 assembling diagram of piston and connecting rod subassembly figure 4...

Page 67

Maintenance manual of 4m11 series diesel engine for land power generators 59 tightening torque of connecting rod bolts. 2. Tilt the engine, turn the piston to be disassembled to the bottom dead center, and disassemble the connecting rod bolts and connecting rod cap. 3. Turn to the top dead center, k...

Page 68

Maintenance m nu in up 4. W pa 5. A its rin of is an sh 6. M ap pa of th on co cl 7. Co to sa manual of 4m1 umbers, and nto the pisto pward, and t wipe clean th arts, and app djust direct s opening e ng is assem f the first rin staggered f nd is at posi hown in figu manually ro pproximatel arts of t...

Page 69

Maintenance m 4.4.3 d 4.4.3.1 ex 4.4.3.2 c 1. 2. 3. 4.4.3.3 in 1. 2. 3. 4. 5. 6. 4.4.3.4 c 1. W 2. Pr w 2.1 be wh hex screw manual of 4m1 disassembl xploded v camshaft d enable th put them disassem end bear cranksha all parts nspection a check w have cra dredging check w are linear check w check w c...

Page 70

Maintenance manual of 4m11 series diesel engine for land power generators 62 2.2 after the upper bearing is assembled, it shall be aligned to the oil hole and oil groove on the cylinder body, and the bearing deviating from the oil hole by 1/5-1/4 shall not be assembled; the upper bearing shall be co...

Page 71

Maintenance m 4.4.4 d 4.4.4.1 ex 4.4.4.2 fl the di 4.4.4.3 in 1. 2. 3. 4.4.4.4 fl 1. 2. Manual of 4m1 disassembl xploded v lywheel an isassembly p nspection a check w check th check w lywheel an fix the fl knock in 1 series diesel figure 4- ly, inspect view for a figure 4 nd gear r procedures and ma...

Page 72

Maintenance m 3. 3-1 ap 3-2 fl tighte 4.4.5 d pulley 4.4.5.1 ex 4.4.5.2 to u subass turn. 4.4.5.3 in 1. 2. 3. Manual of 4m1 parallel p after ins flywheel pply lubrica lywheel bol ening torque disassembl y and hub xploded v figure 4- 3 orsional d unscrew the sembly, uns nspection a check th check w c...

Page 73

Maintenance manual of 4m11 series diesel engine for land power generators 65 4.4.5.4 torsional damper and pulley assembly procedures after the assembly of timing gear, assemble the wheel hub, torsion damper, and pulley in turn. 1. Fix the wheel hub onto the crankshaft by hexagon socket cylindrical h...

Page 74

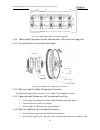

Maintenance manual of 4m11 series diesel engine for land power generators 66 is directly assembled. During assembly, pay attention that the lips should be aligned, and applied with a small amount of oil. 4.4.7 disassembly, inspection, repair, and assembly of secondary balance mechanism 4.4.7.1 explo...

Page 75

Maintenance manual of 4m11 series diesel engine for land power generators 67 figure 4-34 diagram for markings of engine double-stage balance mechanism rotate the double-stage balance mechanism and mark the addendum and flank of 1st tooth at zero-point position by a white marker pen, as shown in figu...

Page 76

Maintenance manual of 4m11 series diesel engine for land power generators 68 figure 4-36 diagram for markings of engine double-stage balance mechanism 4. Withdraw the locating bar and insert the bolt. Note: differentiate the bolt length and ensure there is no plain washer or spring washer. 5. Pre-ti...

Page 77

Maintenance m 4.5.1 d 4.5.1.1 ex 4.5.1.2 v 4.5.1.3 v hexagon b rocker arm se shaft spring ci adjusting scre upper seat of inner valv lower seat of v exhaus tappet engi manual of 4m1 disassembl xploded v valve mech 1) disa rock 2) disa disa 3) disa disa 4) disa cam 5) disa disa valve mech 1) ass asse...

Page 78

Maintenance m 4.5.2 d 4.5.2.1 ex 4.5.2.2 c ① turn t blocka ② check ③ check ④ on th enable fasteni hexago camsh ⑤ disass plate, 4.5.2.3 in ① check bearin ② check wheth the too manual of 4m1 4) ass proc 5) ass and disassembl xploded v camshaft a the camsha age; k visually fo k the backlas e working e ...

Page 79

Maintenance manual of 4m11 series diesel engine for land power generators 71 4.5.2.4 camshaft and timing gear assembly procedures with the camshaft, timing gear and air compressor drive geardisassembled, check them for excessive wear or deviation from parameter specifications. If any, repair the cam...

Page 80

Maintenance m ⑦ after t and oi the ca and th gear. T m10 b seal pa t manual of 4m1 the adjustm il-free cams mshaft. Pre en pre-tight tighten the bolts and 55 aint. Turn the cran 1 series diesel figure 4-3 ment and alig shaft gear b e-tighten the ten the conn gear conne 5~60n.M fo nkshaft and interm ...

Page 81

Maintenance m 4.5.3 d arm 4.5.3.1 ex 4.5.3.2 r ① turn th ② measu ③ upon hexago rocker rocker 4.5.3.3 in ① clean crackin ② check ③ check presen ④ check r adj manual of 4m1 disassembl shaft xploded v figure 4 rocker arm he cranksha ure clearanc detection o on head scr r, and butte rs of differen nspec...

Page 82

Maintenance manual of 4m11 series diesel engine for land power generators 74 ⑤ measure the rocker arm hole diameter and rocker arm shaft diameter, and calculate the fitting clearance. 4.5.3.4 rocker arm and rocker arm shaft assembly procedures ① check and ensure that the parts assembled are clean wi...

Page 83

Maintenance m 4.5.4 d 4.5.4.1 ex 4.5.4.2 ta ① after t rod, an ② after arrang 4.5.4.3 in ① clean ② check ③ check ④ check ⑤ check ⑥ check 4.5.4.4 ta ① check with a and ch ② apply evenly ③ place t shall r camsh ④ assem intactn manual of 4m1 disassembl xploded v f appet and the rocker a nd put it asi di...

Page 84

Maintenance manual of 4m11 series diesel engine for land power generators 76 ⑤ apply clean lubricating oil to the push rods. Ensure that the push rod ends are sufficiently lubricated. ⑥ assemble the push rods and lightly insert the push rods into the tappets through the cylinder head. 4.5.5 disassem...

Page 85

Maintenance manual of 4m11 series diesel engine for land power generators 77 ① apply some molybdenum disulfide paste on the intake and exhaust valve stems evenly, and assemble the intake and exhaust valves into the cylinder head, ensuring that the intake and exhaust valves slide in the guide, withou...

Page 86

Maintenance manual of 4m11 series diesel engine for land power generators 78 ③ screw one m8 bolt into the intermediate gear shaft to pull out the shaft. Take cautions to prevent the falloff of intermediate gear and disassemble the intermediate gear along with idler shaft. 4.5.6.3 inspection and main...

Page 87

Maintenance manual of 4m11 series diesel engine for land power generators 79 4.6.1 disassembly and assembly of intake and exhaust system 4.6.1.1 exploded view for assembly of intake and exhaust system 1— intake pipe 2 - exhaust pipe 3 - turbocharger oil inlet subassembly 4 - turbocharger 5 - turboch...

Page 88

Maintenance manual of 4m11 series diesel engine for land power generators 80 section 4.6.2 “disassembly, inspection, repair, and assembly of intake pipe”. 4.6.1.3 intake and exhaust system assembly procedures the assembly procedures are in the reverse order of the disassembly procedures. 4.6.2 disas...

Page 89

Maintenance manual of 4m11 series diesel engine for land power generators 81 required to replace the pipe with a new one. ② check the gasket of intake pipe for deformation, tear and absence. If necessary, replace it with a new one. 4.6.2.4 intake pipe assembly procedures assembly procedures are in t...

Page 90

Maintenance manual of 4m11 series diesel engine for land power generators 82 ③ loosen the lock nut, take out the turbocharger gasket, and take out the stud. 4.6.3.3 inspection and maintenance of exhaust pipe ① check whether the exhaust pipe is cracked or damaged, and the flange is deformed, and if a...

Page 91

Maintenance manual of 4m11 series diesel engine for land power generators 83 that the bearing is worn abnormally or collision or jamming between the rotating part and the stationary part occurs, it is required to analyze cause and carry out troubleshooting. 2. Check the run-out of rotor enable the d...

Page 92

Maintenance manual of 4m11 series diesel engine for land power generators 84 figure 4-49 diagram for measurement of radial play daily maintenance: 1. Check whether the connecting pipe between the turbocharger and the engine is loosened or not, and if any, eliminate the problem. 2. Check whether the ...

Page 93

Maintenance manual of 4m11 series diesel engine for land power generators 85 the oil inlet pipe subassembly. Rotate the turbocharger impeller to determine whether it rotates freely without jamming. 7. Assemble the return pipe and pipe clamp of the turbocharger, and tighten them. Note that the two pi...

Page 94

Maintenance manual of 4m11 series diesel engine for land power generators 86 4.7 fuel system 4.7.1 disassembly and assembly of fuel system 4.7.1.1 exploded view for assembly of fuel system figure 4-50 exploded view for assembly of fuel system 4.7.1.2 fuel system disassembly procedures ① disassemble ...

Page 95

Maintenance manual of 4m11 series diesel engine for land power generators 87 4.7.1.3 fuel system assembly procedures the assembly procedures are in the reverse order of the disassembly procedures. 4.7.2 disassembly, inspection, repair, and assembly of injection pump 4.7.2.1 exploded view for assembl...

Page 96

Maintenance m ③ observe presen upon two en ④ observe or was 4.7.2.4 fu th 4.7.2.5 a a) turn th flywhe zero-p b) as sho alignm the en advanc pump forms manual of 4m1 e the air pip nce of air le detection of nds. E the lubrica shers of holl uel injecti he assembly adjustment he flywheel eel with ma po...

Page 97

Maintenance m c) as sho wrench large f verify till the rotatio incorre bolts a 4.7.3 d 4.7.3.1 ex 4.7.3.2 h ① disass cylind manual of 4m1 figu own in figu h. Ensure th flange durin the advance e diesel just on angle of t ect, re-adjus are tightened disassembl xploded v fig high-pressu semble the c d...

Page 98

Maintenance manual of 4m11 series diesel engine for land power generators 90 ② disassemble the connecting nuts between high pressure fuel pipe and various cylinders of fuel injection pump in turn. 4.7.3.3 inspection and maintenance of high-pressure oil pipe ① observe the external surface of high pre...

Page 99

Maintenance manual of 4m11 series diesel engine for land power generators 91 deposit and other impurities, in order to ensure the sealing performance. Never incorrectly assemble every fuel injector, seal washer, and adjustment shim thereon during assembly, in order to ensure that the protrusions of ...

Page 100

Maintenance manual of 4m11 series diesel engine for land power generators 92 manual pump on strainer to bleed air from the filter. 4.7.5.4 fuel filter assembly procedures the assembly procedures are in the reverse order of the disassembly procedures. However, during replacement of filter element, it...

Page 101

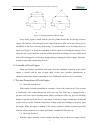

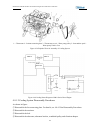

Maintenance manual of 4m11 series diesel engine for land power generators 93 1— thermostat 2 - coolant connecting hose 3 - thermostat cover 4 - water pump pulley 5 - intermediate pad 6 - water pump7- belt 8- fan figure 4-59 exploded view for assembly of cooling system figure 4-60 cooling route diagr...

Page 102

Maintenance manual of 4m11 series diesel engine for land power generators 94 ⑤ disassemble the thermostat. For details, see 4.8.3.2 thermostat disassembly procedures. Disassemble the inlet pipe . ⑥ disassemble the air compressor and hydraulic pump. ⑦ disassemble the water pump and water pipe joint. ...

Page 103

Maintenance manual of 4m11 series diesel engine for land power generators 95 ③ disassemble the hexagon head bolts and spring washers from the water pump and disassemble the water pump. ④ disassemble the washers and intermediate pads of water pump. 4.8.2.3 inspection and maintenance of water pump ① c...

Page 104

Maintenance manual of 4m11 series diesel engine for land power generators 96 4.8.3.3 inspection and maintenance of thermostat ① check the clamps for failure. If any, replace them. ② check the coolant hoses for cracks. If any, replace them . ③ check the thermostat for breakage. If any, replace it. 4....

Page 105

Maintenance manual of 4m11 series diesel engine for land power generators 97 4.9 lubrication system 4.9.1 disassembly and assembly of lubrication system 4.9.1.1 exploded view for assembly of lubrication system 1 - engine oil filter 2 - engine oil cooler 3 - engine oil filter seat 4 - oil sump 5 - en...

Page 106

Maintenance m 4.9.1.4 lu 4.9.2 d 4.9.2.1 ex 4.9.2.2 o loosen tw manual of 4m1 ubrication disassembl xploded v oil pump d wo hexagon oil pan 1 series diesel n system d f ly, inspect view for a figure 4 disassemb flange bolt oil suc rock p l engine for la diagram figure 4-65 l tion, repa assembly o 4-...

Page 107

Maintenance manual of 4m11 series diesel engine for land power generators 99 pump, as shown in figure 4-58. 4.9.2.3 inspection and maintenance of oil pump ① check the engine oil pump for cracks. Check whether the inner cavity of the pump is smooth. If necessary, disassemble the pump. ② check the eng...

Page 108

Maintenance manual of 4m11 series diesel engine for land power generators 100 use defect or damage. ② tighten the filter as per the specification indicated on filter cover. 4.9.4 disassembly, inspection, repair, and assembly of oil cooler 4.9.4.1 exploded view for assembly of oil cooler figure 4-68 ...

Page 109

Maintenance m 4.9.5 d contr 4.9.5.1 d 4.9.5.2 m loosen and 4.9.5.3 in ① check th one. ② check th 4.9.5.4 m ① before t and fu ② clean th ③ assemb plug. Manual of 4m1 disassembl rol valve disassembl figure 4 main oil p d disassemb nspection a he main oil he main oil main oil-w the assembly unctional d...

Page 110

Maintenance m 4.9.6 d 4.9.6.1 ex 4.9.6.2 o loosen typ take ou 4.9.6.3 in check the 4.9.6.4 o ① beforeas damag ② clean th filter; ③ assemb ④ assemb manual of 4m1 disassembl xploded v oil suction pe i hexagon ut the engin nspection a oil suction oil suction ssembly, ch ge. They sha he junction le the ...

Page 111

Maintenance manual of 4m11 series diesel engine for land power generators 103 4.10 starting system 4.10.1 disassembly, inspection, repair, and assembly of starter 4.10.1.1 exploded view of starter figure 4-71 exploded view of starter 4.10.1.2 starting system disassembly procedures ① disassemble the ...

Page 112

Maintenance manual of 4m11 series diesel engine for land power generators 104 4.11 vehicles accessories system 4.11.1 disassembly, inspection, repair, and assembly of alternator 4.11.1.1 exploded view for assembly of alternator figure 4-72 exploded view for assembly of alternator 4.11.1.2 starter di...

Page 113

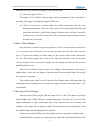

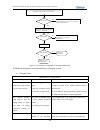

Maintenance manual of 4m11 series diesel engine for land power generators 105 打开车辆电源开关将测试灯连接在发电机的b+和e (负极)端 测试灯是否亮 将接e端转接发电机d+端 测试灯是否亮 是 是 起动发动机 测试灯是否亮 发电机无故障 否 发电机故障 是 是 否 说明发电机的b+端没有电压,同蓄 电池的正极端之间的导线有故障 说明发电机的d+端的内部电器 线路出现问题 否 figure 4-73 flowchart for judgment of alternator malfunction ② malfunct...

Page 114

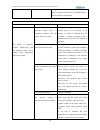

Maintenance manual of 4m11 series diesel engine for land power generators 106 the charging indicator lamp fails to turn off while the engine is running. Exciting terminal is within 1~3v. Indicator lamp or loose connection in circuit. Adjust the indicator lamp power or check the circuit connectors an...

Page 115

Maintenance manual of 4m11 series diesel engine for land power generators 107 voltage. The alternator regulator, rectifier bridge, stator, or internal connection may be malfunctioned and need repair or replacement. B) low charging voltage malfunction 2: low charging voltage vehicle symptom fault det...

Page 116

Maintenance manual of 4m11 series diesel engine for land power generators 108 check for presence of high temperature due to looseness, oxidation, or loose connection at the joint between wire and bolt of charging system. Grind the wire lugs with oxidized surfaces and the housing surface for assembly...

Page 117

Maintenance manual of 4m11 series diesel engine for land power generators 109 observe the battery surfaces for cleanliness and dryness and check whether the wiring terminals and clamps are in good fit. Replace as soon as possible in event of any damage. Check the phase output voltage of alternator (...

Page 118

Maintenance manual of 4m11 series diesel engine for land power generators 110 it. Speed-dependent squealing within alternator this is the noise generated by the vibration of stator iron core. If necessary, replace stator subassembly..

Page 119

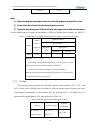

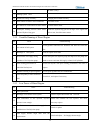

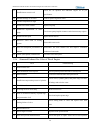

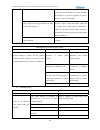

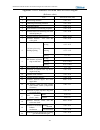

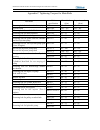

Maintenance manual of 4m11 series diesel engine for land power generators 111 appendix a fit clearances for main parts of diesel engine (reference value) sn. Item theoretical value (mm) 1 main bearing clearance 0.08~0.11 2 connecting rod bearing clearance 0.07~0.10 3 crankshaft endplay 0.04~0.25 4 a...

Page 120

Maintenance manual of 4m11 series diesel engine for land power generators 112 appendix b wear evaluation references for main friction pairs in diesel engine (reference value) wear limit mm clearance limit mm closed gap of the 1st piston ring 1.70 - height of the 1st piston ring 0.10 - closed gap of ...

Page 121

Maintenance manual of 4m11 series diesel engine for land power generators 113 thickness of thrust bearing 0.40 - intake valve sink 0.04*d (1) intake valve seat 0.75 intake valve seat 0.75 exhaust valve sink 0.04*d (1) exhaust valve seat 0.85 exhaust valve seat 0.85 inside diameter of intake valve gu...

Page 122

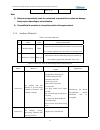

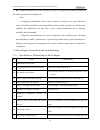

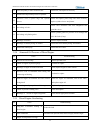

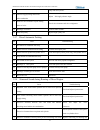

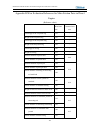

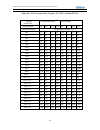

Maintenance manual of 4m11 series diesel engine for land power generators 114 appendix c tightening torques for main bolts bolt name bolt specification control value (n.M) inspection value (n.M) fastening bolt for intake and exhaust pipes m10 45~50 45~60 flywheel bolt m16-10.9 285~295 285~340 fasten...

Page 123

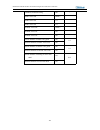

Maintenance manual of 4m11 series diesel engine for land power generators 115 appendix d recommended torques for other standard bolts friction coefficient 0.125(galvanization) 0.14(shining) strength grade 6.9 8.8 10.9 12.9 6.9 8.8 10.9 12.9 bolt specification recommended torque n·m m4 2.3 2.7 3.8 4....