- DL manuals

- Bauer

- Air Compressor

- G 120 II V

- Instruction Manual And Replacement Parts List

Bauer G 120 II V Instruction Manual And Replacement Parts List

Instruction Manual and Replacement Parts List

BAUER Compressors, Inc.

Phone: (757) 855-6006

1328 Azalea Garden Road

Fax: (757) 855-6224

Norfolk, Virginia 23502-1944

www.bauercomp.com

April 4, 2013

1st Edition, Rev. 0 Chg. 2

MNL-126509

© Bauer Compressors, Inc.

Mini Verticus

High Pressure Gas Compressor Units

G 120 II V

Summary of G 120 II V

Page 1

Instruction manual and replacement parts list bauer compressors, inc. Phone: (757) 855-6006 1328 azalea garden road fax: (757) 855-6224 norfolk, virginia 23502-1944 www.Bauercomp.Com april 4, 2013 1st edition, rev. 0 chg. 2 mnl-126509 © bauer compressors, inc. Mini verticus high pressure gas compres...

Page 2

G 120 ii v page i 1st edition, rev. 0 chg. 2 this information is believed to be accurate by bauer compressors, inc., as of it’s date of publication, but bauer offers no warranty regarding the accuracy, or continuing accuracy, of the information set forth herein. Bauer shall not be liable for inaccur...

Page 3: Table of Contents

Mnl-126509 april 4, 2013 page ii table of contents chapter 1: - - - - - - - - - - - - - - - - - - - - - introduction 1.1 how to use this manual......................................................................................................................................... 1 1.1.1 manual safe...

Page 4

G 120 ii v page iii 1st edition, rev. 0 chg. 2 3.1.6 inter-stage separator.........................................................................................................................................................20 3.1.6.1 maintenance......................................................

Page 5

Mnl-126509 april 4, 2013 page iv 4.2.2.3 cartridge ....................................................................................................................................................................... 65 4.2.2.4 cartridge handling ......................................................

Page 6

G 120 ii v page v 1st edition, rev. 0 chg. 2 6.6 plc inputs and outputs ........................................................................................................................................84 6.6.1 analog inputs to the plc. ............................................................

Page 7

Mnl-126509 april 4, 2013 page vi 8.3.6 reactivating the compressor unit ................................................................................................................................. 117 8.4 reproducible forms ..........................................................................

Page 8: List of Figures

G 120 ii v page vii 1st edition, rev. 0 chg. 2 list of figures chapter 1:- - - - - - - - - - - - - - - - - - - - - introduction figure 1-1 compressor identification label .............................................................................................................................2 ch...

Page 9

Mnl-126509 april 4, 2013 page viii figure 3-29 inlet assembly....................................................................................................................................................... 46 figure 3-30 automatic condensate drain ..............................................

Page 10

G 120 ii v page ix 1st edition, rev. 0 chg. 2 figure 6-17 electrical panel, interior, 60 hz ............................................................................................................................92 figure 6-18 electrical panel, interior, 50 hz ......................................

Page 11

Mnl-126509 april 4, 2013 page 1 chapter 1: introduction 1.1 how to use this manual this manual contains the operating and maintenance instructions for the bauer compressors, inc. Prod- ucts listed on the front cover. All instructions in this manual should be observed and carried out as written to pr...

Page 12

G 120 ii v page 2 1st edition, rev. 0 chg. 2 1.2 how to use the replacement parts list • a lozenge in the item number column indicates the part number for a complete assembly. • a dagger (†) in the qty column with or without an ellipse (…) in the part number column means the part is illustrated fo...

Page 13

Mnl-126509 april 4, 2013 page 3 1.3 how to use the appendix information contained in the appendix to this manual includes the following. • the safety instructions applicable to this product. They must be read, understood and complied with prior to operating the product. • the instructions for instal...

Page 14

G 120 ii v page 4 1st edition, rev. 0 chg. 2 1.4 unit specifications all specifications are subject to change without prior notice. G 120 ii v 7.5 hp medium nitrogen, helium and argon capacity 6.8 scfm (193 l/min) inlet pressure 0 - 3 psig (0 - 0.21 bar) operating pressure, max. 5,000 psig (350 bar)...

Page 15

Mnl-126509 april 4, 2013 page 5 chapter 2: operating instructions; maple system 2.1 description the following instructions apply to units that use the maple system touchscreen operator interface, mnr-0053 with program 31l . The electrical panel assembly will provide logical control and safety shutdo...

Page 16

G 120 ii v page 6 1st edition, rev. 0 chg. 2 2.1.2 operator interface the operator interface is a 4.3 inch, 256 color, 8 bit lcd with touchscreen operation. The operator interface is the input/output device for normal operation of the compressor unit. The compressor system is ready and able to opera...

Page 17

Mnl-126509 april 4, 2013 page 7 5. The on and off buttons control the compressor. These buttons should be used for normal starting and stopping of the compressor. In an emergency the emergency stop button should be used. 6. This x button closes the run screen and goes to the main menu screen. The co...

Page 18

G 120 ii v page 8 1st edition, rev. 0 chg. 2 2.1.2.2.2 alarms history this button displays the history of alarms. The date of the alarm history can be changed with the drop down arrow or the forward and backward arrows adjacent to the date. To return to the main menu screen touch the x in the upper ...

Page 19

Mnl-126509 april 4, 2013 page 9 to change the user level press the “user” button, select the desired user, and press “ok”. Then press the button below the words “enter password” and press the password numbers on the keypad. After entering the proper password press “ent” on the keypad to enter the pa...

Page 20

G 120 ii v page 10 1st edition, rev. 0 chg. 2 2.1.2.2.7 parameters this button takes the user to the parameters screens. There are a total of 9 screens. These parameters are set at the factory for each specific unit. Changing these parameters will change how the unit operates, so only users 2 and 3 ...

Page 21

Mnl-126509 april 4, 2013 page 11 2.2.2 to start unit. Press the green start button on the run screen. (see figure 2-3) if the pressure in the system is lower than the set “start pressure”, the drive motor will start up powering the compressor. If the system’s pressure is higher than the set “start p...

Page 22

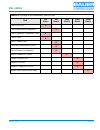

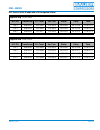

G 120 ii v page 12 1st edition, rev. 0 chg. 2 table 2-1: calendar maintenance interval tasks task monthly annually every two years calibrate co monitor x check oil level x check final pressure shutdown x check automatic condensate drain x check v-belt x service intake filter x check all connections ...

Page 23

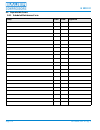

Mnl-126509 april 4, 2013 page 13 table 2-2: operating hours maintenance interval tasks task 250 hours 500 hours 1,000 hours 2,000 hours 3,000 hours check oil level x check final pressure shutdown x check automatic condensate drain x check v-belt x service intake filter x check all connections for le...

Page 24

G 120 ii v page 14 1st edition, rev. 0 chg. 2 2.3 screen flow figure 2-8 operator interface screen flow st ar t up r un screen on off main menu ru n changab le date login st a tus p arameters configura tion t ools cont a c t retur n to run screen abo v e alarms hist or y users 1, 2, & 3 current stat...

Page 25

Mnl-126509 april 4, 2013 page 15 chapter 3: ik120 ii c & g 3.1 maintenance and parts 3.1.1 description the ik120 ii c & g compressors are used to compress gases up to a maximum of 5,000 psi. Both com- pressors are three cylinder, three stage air cooled, oil lubricated reciprocating compressors. The ...

Page 26

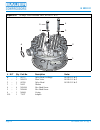

G 120 ii v page 16 1st edition, rev. 0 chg. 2 3.1.3 air flow diagram refer to figure 3-2. The gas is drawn in through intake connector (1), compressed to the final pressure in cylinders (2, 3, 4,) and cooled by intercoolers (5, 6) and after cooler (7). The safety valves (8,9, 10) pro- tect from over...

Page 27

Mnl-126509 april 4, 2013 page 17 3.1.4 compressor lubrication 3.1.4.1 description refer to figure 3-3. The compressor is provided with forced-feed lubrication. The oil pressure is pro- duced by a low speed gear pump (1). The oil pressure is approximately 73 psi (5 bar). The oil pump (1) is coupled t...

Page 28

G 120 ii v page 18 1st edition, rev. 0 chg. 2 lubrication. Oil level must also not exceed the maximum mark as this will cause excessive lubrication of the compressor and may result in a carbon buildup on the valves. 3.1.4.3 oil change interval every 2,000 operating hours or biennially; whichever com...

Page 29

Mnl-126509 april 4, 2013 page 19 3.1.4.4 oil change 1. Run the compressor until it is warm then shut it down. 2. (see figure 3-5). Remove the cap (1) from the oil filler neck. 3. Drain oil while it is still warm by means of the oil drain plug. 4. (see figure 3-6). Remove the two bolts (1) with a 13 ...

Page 30

G 120 ii v page 20 1st edition, rev. 0 chg. 2 3.1.6 inter-stage separator an inter-stage separator is mounted on the compressor block. This separator is designed to remove oil and water which accumulates due to the cooling of the medium after the compression process. Separation is achieved by means ...

Page 31

Mnl-126509 april 4, 2013 page 21 3.1.6.1 maintenance the inter-stage separator requires no maintenance. 3.1.7 cooling 3.1.7.1 general the cylinders of the compressor, the inter-stage coolers and the after cooler are air cooled. For this pur- pose the compressor is equipped with a fanwheel which draw...

Page 32

G 120 ii v page 22 1st edition, rev. 0 chg. 2 3.1.8.2 general instructions for changing the valves • always replace valves as a complete set. • carefully clean dirty valves. Never use a sharp tool for this purpose. Soak the valves in varsol and clean with a soft brush. • check the individual compone...

Page 33

Mnl-126509 april 4, 2013 page 23 3.1.8.3 changing the ik120 ii c & g, 1st stage valve the intake and pressure valve of the ik120 ii c & g 1st stage are in a combined plate valve under the valve head. Refer to figure 3-11 1. Remove valve head (1). 2. Note orientation of plate valve (32) before removi...

Page 34

G 120 ii v page 24 1st edition, rev. 0 chg. 2 3.1.8.4 removing the ik120 ii c & g, 2nd stage valves. See figure 3-12 and proceed as follows: 1. Remove the intake and pressure lines from the valve head (7). 2. Remove the screws (8) holding the valve head onto the cylinder. 3. Insert two 8 mm diameter...

Page 35

Mnl-126509 april 4, 2013 page 25 8. Remove the pressure plug (3) and take out the valve parts. 9. Clean the intake valve and pressure valve assembly, preferably with an ultrasonic cleaner and check for wear and damage. 10. Valve seats and valves must not show any signs of wear or damage. Replace dam...

Page 36

G 120 ii v page 26 1st edition, rev. 0 chg. 2 8. Replace the valve head (7) on the cylinder and secure it with the screws (8). 9. Reconnect the intake and pressure lines. 3.1.8.6 removing the ik120 ii c & g, 3rd stage valves 1. Remove the intake and pressure lines from the valve head (2). 2. Remove ...

Page 37

Mnl-126509 april 4, 2013 page 27 3.1.8.7 reassembling the valves of the 3rd stage 1. Replace the intake valve (1) using the special valve tool to tighten it. 2. Check the intake valve functions correctly by blowing compressed air through the valve in the direction of flow. 3. Secure the intake valve...

Page 38

G 120 ii v page 28 1st edition, rev. 0 chg. 2 3.1.9 replacement parts list # kit qty part no. Description notes 1 076743 crankcase assembly with accessories, driving gear 1 … 1 76740 crankcase 2 … 1 083399 crankshaft, complete ik120 ii -g/c 3 … 1 n2638 roller bearing 4 … 2 n2635 circlip 5 … 1 66209 ...

Page 39

Mnl-126509 april 4, 2013 page 29 figure 3-17 (cont.) crankcase assembly # kit qty part no. Description notes 13 … 1 73830 oil filling pipe 14 … 1 n4776 o-ring 15 … 2 n1506 hex head bolt 16 … 8 n58 washer 17 … 1 n4261 gasket 18 … 1 n2796 plug 19 … 2 n25475 oil sight gauge 20 a.. 1 n1316 gasket 21 … 1...

Page 40

G 120 ii v page 30 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 080826 piston and cylinder assembly ik120 ii c 1 … 1 80734 cylinder, ik120 ii c 88 mm 2 ..C 1 n4654 o-ring 3 … 1 069975 piston assembly, ik120 ii c 88 mm (includes #4-6) 4 … 2 n484 circlip 5 … 1 — piston pin 6 … 1 n...

Page 41

Mnl-126509 april 4, 2013 page 31 # kit qty part no. Description notes 1 85948 piston and cylinder assembly 2nd stage 1 … 1 62477 cylinder 2 ..C 1 n7063 o-ring 3 … 1 83404 guide cylinder 4 ..C 1 n2640 o-ring 5 ..C 4 nut-0119 self locking hex nut 6 … 4 was-0021 washer 7 … 4 n2790 stud 1 072249 piston ...

Page 42

G 120 ii v page 32 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 83400 piston and cylinder assembly 3rd stage 1 .B. 1 078043 piston and sleeve assembly see figure 3-21 2 … 1 82480 cylinder 3 ..C 1 n7063 o-ring 4 … 1 83404 guide cylinder 5 ..C 1 n2640 o-ring 6 ..C 4 nut-0119 self ...

Page 43

Mnl-126509 april 4, 2013 page 33 # kit qty part no. Description notes 1 078043 piston and sleeve assembly 1 … † — piston available only with 078043 2 a.. 1 n23755 o-ring 3 … † — piston liner available only with 078043 4 … 1 n25376 piston ring set available only with 078043 figure 3-21 piston and sle...

Page 44

G 120 ii v page 34 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 80727 valve head, 1st stage ik120 ii c & g 1 … 1 n26531 plate valve ik120 ii c & g 2 … 1 80709 valve head ik120 ii c & g 3 … 7 n102 washer 4 … 6 n26568 hex head screw 5 … 1 n26646 hex head screw 6 … 1 n4869 o-ring n...

Page 45

1 2 3 4 5 9 8 6 10 7 this page is inserted to provide proper page sequencing.

Page 46

G 120 ii v page 36 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 69955 valve head, 2nd stage 1 … 1 14123 valve head 2 .B. 1 012841 intake valve assembly items 3 - 7 3 … 1 † intake valve body available only with 012841 4 … 1 † spring available only with 012841 5 … 1 † valve plate ...

Page 47

Mnl-126509 april 4, 2013 page 37 figure 3-23 (cont.) 2nd stage valves and valve head # kit qty part no. Description notes 14 a.. 1 n3521 o-ring 15 … 1 14332 spring washer 16 … 1 14124 coupling 17 .B. 1 71064 stud 18 a.. 1 n3625 gasket 19 … 1 n84 cap nut 20 … 6 19550 allen screw.

Page 48

G 120 ii v page 38 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 082096 valve head assembly, 3rd stage 1 .B. 1 081409 intake valve 2 … 1 082087 valve head 3 a.. 1 n2789 o-ring 4 .B. 1 014121 pressure valve 5 … 1 82086 valve head cover 6 a.. 1 n124608 stud 7 a.. 1 n3625 gasket 8 …...

Page 49

Mnl-126509 april 4, 2013 page 39 item qty part no. Description notes 1 82552 flywheel assembly 1 1 n1386 shaft key 2 1 82553 hub 3 1 80975 washer 4 1 n176 split washer 5 1 n26666 bolt 6 1 82496 flywheel 7 4 n108 spring washer 8 4 n19548 allen screw figure 3-25 flywheel 1 2 3 4 5 6 7 8.

Page 50

G 120 ii v page 40 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 081799 inter-stage separator assembly 1 … 1 81148 plate 2 … 1 81643 hollow screw 3 … 1 76613 inset assembly 4 a.. 1 n3556 o-ring 5 … 1 13937 knurled ring 6 … 1 n1316 gasket 7 … 1 n20215 fitting 8 … 1 072935 safety v...

Page 51

1 2 3 4 5 9 8 6 10 7 this page is inserted to provide proper page sequencing.

Page 52

G 120 ii v page 42 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 83417 lubricating system items 1 - 14 1 … 1 77885 oil filter cover 2 … 1 n4058 o-ring 3 … 1 n25327 o-ring 4 … 1 77774 rubber gasket 5 … 1 n25326 filter element 6 … 1 77878 oil pump cover 7 … 2 n634 allen screw 8 … 2...

Page 53

Mnl-126509 april 4, 2013 page 43 figure 3-27 (cont.) lubrication system assembly # kit qty part no. Description notes 14 … 1 81050 regulating valve 15 … 4 n1316 gasket 16 … 3 n52 plug 17 … 1 83420 connecting tube assembly 18 … 1 n20237 male connector.

Page 54

G 120 ii v page 44 1st edition, rev. 0 chg. 2 # kit qty part no. Description notes 1 83456 ik120 ii c & g cooling system 1 … 1 79486 intercooler, 1st to 2nd stage 2 … 1 78195 intercooler, 2nd to 3rd stage 3 … 1 070724 aftercooler 4 … 1 78200 fanwheel guard 5 … 1 81802 safety valve, 1st stage 11 bar ...

Page 55

Mnl-126509 april 4, 2013 page 45 figure 3-28 (cont.) cooling system # kit qty part no. Description notes 15 … 1 n3610 screw cap, ss 16 … 1 n20327 t- connector 17 … 1 n15175 plug 18 … 1 n7433 screw cap, ss 19 … 2 n26751 coupling 20 … 1 n20183 connector 21 … 2 77894 clamp 22 … 2 n2460 washer 23 … 2 n1...

Page 56

G 120 ii v page 46 1st edition, rev. 0 chg. 2 item qty part no. Description notes 1 1 sen-0055 pressure sensor 0 -30 psia, 1-11 v 2 1 gag-00011w pressure gauge 30 hg - 15 psi 3 1 flr-0009 filter, particulate gas tight — 1 elm-0040 filter element 40 µm figure 3-29 inlet assembly 1 2 3 inlet from supp...

Page 57

Mnl-126509 april 4, 2013 page 47 3.1.10 troubleshooting and repair 3.1.10.1 troubleshooting table trouble cause remedy no oil pressure low oil level check oil level oil foam in crankcase 1. Last stage piston worn 2. Last stage pressure valve defective 1. Operate compressor with final stage valve hea...

Page 58

G 120 ii v page 48 1st edition, rev. 0 chg. 2 3.1.10.2 repair instructions repair work can be carried out on the compressor block to a certain extent but a certain level of experi- ence and skill is necessary. It should be noted however that no repair should be carried out on the crank- shaft nor on...

Page 59

Mnl-126509 april 4, 2013 page 49 3.2 three stage automatic condensate drain system 3.2.1 description the automatic condensate drain is an optional system and may not be included with your unit. The automatic condensate drain system operates electropneumatically and is comprised of the following: an ...

Page 60

G 120 ii v page 50 1st edition, rev. 0 chg. 2 3.2.1.1 normal operation the normally open solenoid valve (1) controls the condensate draining of the intermediate separator (2). The normally open condensate drain valve (4) controls the condensate draining of the oil and water sepa- rator. The two valv...

Page 61

Mnl-126509 april 4, 2013 page 51 the control air closes the condensate drain valve (4). Once the valve closes, the compressor delivers to the consuming device. 3.2.1.4 standstill drainage at compressor shutdown, the solenoid valve (1) is de-energized and opens. This drains the condensate and relieve...

Page 62

G 120 ii v page 52 1st edition, rev. 0 chg. 2 3.2.4 acd replacement parts list item qty part no. Description notes 1 dgm-2280 3 stage compressor acd reference only 1 1 n27288 electric coil 115 vac or 1 n27757 electric coil 12 vdc 2 1 n27099 solenoid valve 3 1 plt-0297 blank-off plate 4 1 mfd-0035 ma...

Page 63

Mnl-126509 april 4, 2013 page 53 item qty part no. Description notes 1 — acd valve and manifold assembly 1 1 075169 condensate drain valve assembly 2 1 plt-0297 blank off plate 3 2 n00638 o-ring 4 1 mfd-0035 condensate manifold 5 2 n00829 socket head cap screw 6 2 n03625 copper gasket 7 1 n02507 o-r...

Page 64

G 120 ii v page 54 1st edition, rev. 0 chg. 2 3.3 condensate collector during compression the water content of the air is also compressed. The resulting water is removed after each compression stage and is collected through the automatic condensate drain system. This water, additionally, has a small...

Page 65

Mnl-126509 april 4, 2013 page 55 3.3.1 condensate collector replacement parts list item qty part no. Description notes 1 1 cap-0056 condensate collector cover 2 1 gkt-0065 gasket 3 2 elm-0160 fine filter element 4 2 elm-0161 coarse filter element 5 1 hus-0050 condensate collector, inner 6 1 hus-0060...

Page 66

G 120 ii v page 56 1st edition, rev. 0 chg. 2 chapter 4: purification system 4.1 introduction the purpose of all bauer breathing air purification systems is to remove carbon monoxide, oil, water, taste and odor from the compressed air stream before final delivery. The purpose of all bauer industrial...

Page 67

Mnl-126509 april 4, 2013 page 57 4.1.3 manual condensate drainage the condensate must be drained from the oil and water separator before changing any cartridge, before beginning each filling procedure and in the absence of an automatic condensate drain (acd) system, every fifteen minutes during the ...

Page 68

G 120 ii v page 58 1st edition, rev. 0 chg. 2 4.1.4.2 purification system dataplate refer to the compressor unit purification system data plate (figure 4-3) on the compressor front to deter- mine your purification system model and specifications. 4.1.4.3 cartridge installation dataplate the function...

Page 69

Mnl-126509 april 4, 2013 page 59 4.1.6 industrial purification system configurations 4.1.7 cartridge operating life every bauer purification system is designed to process a certain volume of air before the cartridges require replacement. By using special test equipment that measures the quality of a...

Page 70

G 120 ii v page 60 1st edition, rev. 0 chg. 2 is suggested that it be copied, placed in a protective folder and kept with the unit to record the adjusted operating hours. An example of how this form is used is shown in figure 4-5. 4.1.7.1 calculating the maximum cartridge operating hours 1. From the...

Page 71

Mnl-126509 april 4, 2013 page 61 figure 4-4 correction factor for cartridge operating hours figure 4-5 example record of adjusted operating hours °f [ °c x 9/5 +32 ] °c [ (°f - 32) x 5/9 ] correction factor 50 122 0.21 40 104 0.34 30 86 0.58 20 68 1.00 10 50 1.81 0 32 3.44 0.0 0.5 1.0 1.5 2.0 2.5 3....

Page 72

G 120 ii v page 62 1st edition, rev. 0 chg. 2 4.1.7.3 air purification cartridge operating hours form date operating hours ambient temp. + 18°f during compression correction factor adjusted cartridge hours today total.

Page 73

Mnl-126509 april 4, 2013 page 63 4.2 p1 purification system 4.2.1 major components the p1 purification system major components are a oil and water separator and a purification chamber. Figure 4-6 shows the functional interconnection of all the components. Figure 4-6 p1 purification system 1. Oil and...

Page 74

G 120 ii v page 64 1st edition, rev. 0 chg. 2 4.2.2 component description 4.2.2.1 oil & water (condensate) separator the air leaving the final stage is cooled in the aftercooler to approximately 18 - 27° f (10 -15° c) above ambient temperature and then enters the oil and water separator. The oil and...

Page 75

Mnl-126509 april 4, 2013 page 65 4.2.2.2 chamber each chamber is made up of an anodized aluminum housing and a filtering cartridge. There are two gen- eral types of filtering cartridges, drying or purifying. The cartridge type is determined by the ingredients packed in the cartridge. The chamber is ...

Page 76

G 120 ii v page 66 1st edition, rev. 0 chg. 2 4.2.2.7 bleed valve a manually operated valve used to release the pressure in the chamber before maintenance. 4.2.2.8 pressure maintaining valve the pressure maintaining valve ensures that pressure is built up in the system from the start of delivery, th...

Page 77

Mnl-126509 april 4, 2013 page 67 4.3.2 cartridge replacement to change the purification cartridge, proceed as follows. (see figure 4-11) 1. Disconnect the power and shut off the inlet supply line, if applicable. 2. Depressurize the system by means of the bleed valve. 3. Unscrew the chamber head usin...

Page 78

G 120 ii v page 68 1st edition, rev. 0 chg. 2 4. Pull out the cartridge using the lifting ring on top of the cartridge. 5. Dry the inside of the chamber with a clean cloth and check for corrosion. 6. Replace all corroded parts with new bauer parts. 7. Remove the shipping covering and the protective ...

Page 79

Mnl-126509 april 4, 2013 page 69 4.4 replacement parts list item qty part no. Description notes 1 1 079416 oil and water separator see figure 4-13 2 1 011430 condensate drain valve 3 2 val-0007 check valves 4 1 080143 10” purification chamber see figure 4-14 5 1 val-0377 bleed valve 6 1 val-0053 pre...

Page 80

G 120 ii v page 70 1st edition, rev. 0 chg. 2 item qty part no. Description notes 1 079416 oil and water separator assembly 1 † … separator head available only with 079416 2 2 n04586 o-ring 3 1 061860 sintered metal filter 3a 1 n15133 o-ring 3b 2 n04496 o-ring, small 3c 2 n04385 o-ring, large 3d 1 0...

Page 81

Mnl-126509 april 4, 2013 page 71 item qty part no. Description notes 1 080143 chamber assembly 10” 1 2 012293 tool post screw 2 1 061237 cover plate 3 † … filter head available only with 080143 4 2 n04736 back-up ring 5 2 n04735 o-ring 6 † … filter housing available only with 080143 7 † … filter bot...

Page 82

G 120 ii v page 72 1st edition, rev. 0 chg. 2 chapter 5: compressor drive; g 120 ii v 5.1 vertical compressor drive the compressor is driven by the drive motor through a v-belt. The direction of rotation, as seen facing the flywheel, is counterclockwise. Observe the arrow on the compressor block. Ch...

Page 83

Mnl-126509 april 4, 2013 page 73 5.3 replacement part list item qty part no. Description notes g 120 ii v, 60 hz 1 1 ik120 ii c compressor block 2 1 bet-0214 v-belt 3 1 idl-0010 idler with 1 ply-0006 idler pulley 4 1 she-0139 sheave 5 1 bus-0002 sheave bushing 6 1 mtr-0033 electric motor 7.5 hp, 3 p...

Page 84

G 120 ii v page 74 1st edition, rev. 0 chg. 2 figure 5-2 (cont.) g 120 ii v drive with idler item qty part no. Description notes g 120 ii v, 50 hz 1 1 ik120 ii c compressor block 2 1 bet-0259 v-belt 3 1 idl-0010 idler with 1 ply-0006 idler pulley 4 1 she-0321 sheave 5 1 bus-0158 sheave bushing 6 1 m...

Page 85

Mnl-126509 april 4, 2013 page 75 chapter 6: electrical panel, asy-1058 xl 6.1 overview these instructions apply to units that use electrical panel , asy-1058 xl and operator interface . The electrical panel, asy-1058 xl, provides logical control and safety shutdowns for the compressor equipment. All...

Page 86

G 120 ii v page 76 1st edition, rev. 0 chg. 2 wiring and connectors for attachment to wire harnesses. The panel is built to match the horsepower, voltage, phase and frequency of the customer’s requirements. 6.2.1 wiring diagram the wiring diagram for your specific compressor unit is stored inside th...

Page 87

Mnl-126509 april 4, 2013 page 77 6.4 electrical panel components 6.4.1 programable logic controller (plc) the plc is 24 i/o and 120 vac. The data stored in ram is protected for 100 hours, in event of a power loss. Figure 6-3 plc, cnt-0078 1. Status leds 2. Output leds 3. Output connections cover 4. ...

Page 88

G 120 ii v page 78 1st edition, rev. 0 chg. 2 6.4.2 replacing the plc replacing the plc does not require removal of any wiring as the connections are made with push in con- nector blocks. To replace the plc proceed as follows. 1. Turn off unit and disconnect from main power supply. 2. Lift the input...

Page 89

Mnl-126509 april 4, 2013 page 79 10. Remove the eeprom and replace the eeprom protective cover. 11. Restore power and operate the unit. 6.4.5 hourmeter the panel is equipped with an hourmeter. The hourmeter is not resettable and used to monitor the run hours of the compressor. It is powered by 120 v...

Page 90

G 120 ii v page 80 1st edition, rev. 0 chg. 2 6.4.7 motor starter. See figure 6-7. This application will require an across the line iec starter with thermal overloads and its size will be based on the voltage and motor horsepower. Control voltage is 120 vac. See paragraph 6.9 to paragraph 6.13 for t...

Page 91

Mnl-126509 april 4, 2013 page 81 6.4.10 power supply the power supply is a 24 volt 1.3 amp power supply used to provide power to the optional communi- cations modules and operator interface, mnr-0049. It is not standard in all models. 6.5 alarms the following paragraphs describe the warning and alar...

Page 92

G 120 ii v page 82 1st edition, rev. 0 chg. 2 6.5.2 securus ® electronic moisture monitor system the compressor purification system may be equipped with an optional securus ii ® electronic moisture monitor system. The securus ii ® electronic moisture monitor system warns the operator in advance of e...

Page 93

Mnl-126509 april 4, 2013 page 83 6.5.3 compressor high temperature see figure 6-11. The compressor high temperature switch is mounted on the high pressure compressor block, on the third, fourth or fifth stage head, depending on model. Under normal operating conditions, the switch is closed. On a hig...

Page 94

G 120 ii v page 84 1st edition, rev. 0 chg. 2 the alarm will be displayed on the operator interface. The operator should drain the condensate from the tank and resume operation of the equipment. 6.5.7 motor starter overload trip the compressor overload relay is located in the electrical panel, see f...

Page 95

Mnl-126509 april 4, 2013 page 85 6.6.1 analog inputs to the plc. The air pressure switch and the oil pressure switch are connected in parallel and provide their input to the plc through plc input terminal m. Table 6-2: plc inputs table 6-3: plc outputs i0.0 securus ii ® monitor alarm q0.0 motor cont...

Page 96

G 120 ii v page 86 1st edition, rev. 0 chg. 2 6.7 wiring harness layout table 6-4: wiring harness, hns-0116 description legend wire colors pin plc in plc out co monitor (optional) co brown/white 1 co sv black/yellow 2 co common gray/white 22 e-stop pushbutton 1pb black 3 white/red 9 acd 1 acd1 blue/...

Page 97

Mnl-126509 april 4, 2013 page 87 temperature switch 1ts yellow 23 i0.2 violet 24 not assigned blue 25 i0.6 orange 26 high inlet pressure switch a 3ps white/orange 27 i1.0 red/yellow 28 condensate alarm ca gray 31 i0.4 pink 32 co monitor alarm coa white/black 33 i0.3 red/white 34 securus ii sec ii bl...

Page 98

G 120 ii v page 88 1st edition, rev. 0 chg. 2 6.8 replacement parts list item qty part no. Description notes 1 1 mnr-0053 maple system, touch panel 2 1 swt-0308 emergency stop switch figure 6-14 control pane 1 2.

Page 99

Mnl-126509 april 4, 2013 page 89 item qty part no. Description notes 1 asy-1058 xl electrical panel front view 1 1 lbl-0167 warning label, disconnect power 2 1 — voltage label 3 1 hmr-0036 hourmeter — 1 gkt-0069 gasket, hourmeter 4 1 opr-0020 overload reset button 5 1 ind-0005 audible alarm optional...

Page 100

G 120 ii v page 90 1st edition, rev. 0 chg. 2 item qty part no. Description notes 1 asy-1058 xl electrical panel bottom view 1 1 cab-0081 cable, plc to enc connects to mnr-0053 2 1 cab-0075 cable, 4 receptacle connector connects to air pressure sensor 3 1 cab-0075 cable, 4 receptacle connector conne...

Page 101

1 2 3 4 5 9 8 6 10 7 this page is inserted to provide proper page sequencing.

Page 102

G 120 ii v page 92 1st edition, rev. 0 chg. 2 item qty part no. Description notes 1 asy-1058 xl electrical panel, 60 hz assembly interior view 1 1 spl-0077 power supply, 24 vdc, 1.3 a 2 1 — terminal see figure 6-18.A to figure 6-18.J 3 1 — motor starter see figure 6-18.A to figure 6-18.J 4 1 — overl...

Page 103

Mnl-126509 april 4, 2013 page 93 figure 6-17 (cont.) electrical panel, interior, 60 hz item qty part no. Description notes 5 1 cnt-0078 plc controller 6 1 cnt-0070 analog expansion module 7 1 rly-0116 relay, 24 vdc 10 amp. 8 1 — transformer see figure 6-18.A to figure 6-18.J 9 2 — fuse, primary see ...

Page 104

G 120 ii v page 94 1st edition, rev. 0 chg. 2 item qty part no. Description notes 1 asy-1058 xl electrical panel, 50 hz assembly interior view 1 1 spl-0077 power supply, 24 vdc, 1.3 a 2 1 — terminal see figure 6-18.A to figure 6-18.J 3 1 — motor starter see figure 6-18.A to figure 6-18.J 4 1 — overl...

Page 105

Mnl-126509 april 4, 2013 page 95 figure 6-18 (cont.) electrical panel, interior, 50 hz item qty part no. Description notes 5 1 cnt-0078 plc controller 6 1 cnt-0070 analog expansion module 7 1 rly-0116 relay 10 amp., 24 vdc 8 1 hol-0111 fuse holder 25 amp., 400 v — 1 — fuse, secondary see figure 6-18...

Page 106

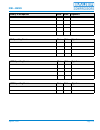

G 120 ii v page 96 1st edition, rev. 0 chg. 2 6.9 parts list for models with a 5 horsepower motor figure 6-18.A 5 hp, 60 hz vac/ph transformer pri. Fuses sec. Fuse starter relay term. 208/1 trr-0089 fus-0090 fus-0018 srt-0233 rly-0177 ter-0175 208/3 trr-0089 fus-0090 fus-0018 srt-0233 rly-0174 ter-0...

Page 107

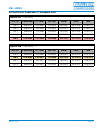

Mnl-126509 april 4, 2013 page 97 6.10 parts list for models with a 7½ horsepower motor figure 6-18.C 7½ hp, 60 hz vac/ph transformer pri. Fuses sec. Fuse starter relay term. 208/1 trr-0089 fus-0090 fus-0018 srt-0241 rly-0186 ter-0175 208/3 trr-0089 fus-0090 fus-0018 srt-0233 rly-0176 ter-0175 230/1 ...

Page 108

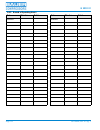

G 120 ii v page 98 1st edition, rev. 0 chg. 2 6.11 parts list for models with a 10 horsepower motor figure 6-18.E 10 hp, 60 hz vac/ph transformer pri. Fuses sec. Fuse starter relay term. 208/1 trr-0090 fus-0092 fus-0019 srt-0234 rly-0180 ter-0174 208/3 trr-0090 fus-0092 fus-0019 srt-0233 rly-0177 te...

Page 109

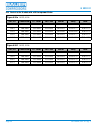

Mnl-126509 april 4, 2013 page 99 6.12 parts list for models with a 15 horsepower motor figure 6-18.G 15 hp, 60hz vac/ph transformer pri. Fuses sec. Fuse starter relay term. 208/3 trr-0090 fus-0092 fus-0019 srt-0241 rly-0185 ter-0175 230/3 trr-0090 fus-0092 fus-0019 srt-0241 rly-0183 ter-0175 460/3 t...

Page 110

G 120 ii v page 100 1st edition, rev. 0 chg. 2 6.13 parts list for models with a 20 horsepower motor figure 6-18.I 20 hp, 60 hz vac/ph transformer pri. Fuses sec. Fuse starter relay term. 208/3 trr-0090 fus-0092 fus-0019 srt-0234 rly-0180 ter-0174 230/3 trr-0090 fus-0092 fus-0019 srt-0241 rly-0185 t...

Page 111

Mnl-126509 april 4, 2013 page 101 chapter 7: indicators & valves 7.1 description the hour meter is used to record the number of hours the unit has been operated. The unit is also equipped with one or more of the following pressure indicators. Interstage pressure gauges- indicate the pressure between...

Page 112

G 120 ii v page 102 1st edition, rev. 0 chg. 2 table 7-1: pressure gauges, 2.5” psi & bar part number pressure range gag-0042w 0 - 100 psi (6.89 bar) gag-0006w 0 - 200 psi (13.79 bar) gag-0007w 0 - 600 psi (41.37 bar) gag-0008w 0 - 1,500 psi (103.42 bar) gag-0031w 0 - 3,000 psi (207 bar) gag-0009w 0...

Page 113

Mnl-126509 april 4, 2013 page 103 7.1 nonadjustable valves the condensate drain valve, bleed valve and check valves are not adjustable. The condensate drain valve and bleed valve have seats and seals which should be replaced if the valve leaks. Check valves are not adjustable or repairable and must ...

Page 114

G 120 ii v page 104 1st edition, rev. 0 chg. 2 7.3 safety valves the safety valves are adjusted at the factory to the required pressure and do not normally require mainte- nance or readjustment. In case readjustment does become necessary, have the safety valve adjusted by a bauer qualified technicia...

Page 115

Mnl-126509 april 4, 2013 page 105 chapter 8: appendix 8.1 safety 8.1.1 general safety precautions • read the operating manual before installing or operating this compressor unit. Follow appropriate handling, operation and maintenance procedures from the very beginning. The maintenance schedule conta...

Page 116

G 120 ii v page 106 1st edition, rev. 0 chg. 2 • allow the compressor to cool before servicing. Whenever the compressor is shut down and over- heating is suspected, a minimum period of 15 minutes must elapse before opening the crankcase. Premature opening of the crankcase of an overheated unit can r...

Page 117

Mnl-126509 april 4, 2013 page 107 8.1.2 safety warning labels notes, labels and warning signs are displayed on the compressor unit according to model, application or equipment and may include any of the following. Hot surfaces do not touch! Danger of burning if cylinders, cylinder heads, or pressure...

Page 118

G 120 ii v page 108 1st edition, rev. 0 chg. 2 8.2 unpacking, handling and installation 8.2.1 unpacking and handling this compressor unit is packaged according to the requirements for shipping via the requested type of carrier service. It is possible that the compressor unit could have been damaged ...

Page 119

Mnl-126509 april 4, 2013 page 109 8.2.2 installation of the compressor unit 8.2.2.1 general the floor site must be capable of supporting the weight of the unit. Secure the compressor unit to the floor using ½” lag bolts. Position the unit so that it is level. Permissible inclination of the compresso...

Page 120

G 120 ii v page 110 1st edition, rev. 0 chg. 2 observe and maintain an ambient temperature range of 40 - 115 °f (5 - 45 °c). The area in which the compressor unit is installed should be well lit and easily accessible to facilitate ser- vicing and routine maintenance. 8.2.2.2 ventilation during norma...

Page 121

Mnl-126509 april 4, 2013 page 111 8.2.2.2.4 forced ventilation forced ventilation should be utilized on units with drive power higher than 20 hp. For units with lower powered drive natural ventilation may be used. To determine the size of the required intake and exhaust openings for forced ventilati...

Page 122

G 120 ii v page 112 1st edition, rev. 0 chg. 2 high levels of co 2 are another cause of breathing air to become contaminated. Co 2 limits are 1,000 ppm. And most fresh air already contains about 330 ppm. A number of people inside poorly ventilated rooms can easily bring the co 2 levels up to 600 ppm...

Page 123

Mnl-126509 april 4, 2013 page 113 8.2.5 installation procedures 1. Use pvc pipe for ease of installation. 2. Ensure pipe is attached securely to the wall. 3. Terminate the pvc pipe 3 to 5 ft from the compressor intake with a stub reducer the same size as the compressor inlet housing pipe. 8.2.6 elec...

Page 124

G 120 ii v page 114 1st edition, rev. 0 chg. 2 the label shown in figure 8-4 indicates where the incoming power is connected to the compressor unit electrical enclosure. This label must be removed before using the equipment. The use of improperly sized wire can result in sluggish operation, unnecess...

Page 125

Mnl-126509 april 4, 2013 page 115 in the above tables, all values are based on 1996 nec articles 430 and 310 (nfpa 70). These values are provided as a general guide; however, the information given on the motor nameplate supersedes the above information. 8.2.7 pneumatic leaks each unit is tested prio...

Page 126

G 120 ii v page 116 1st edition, rev. 0 chg. 2 8.3 long term storage 8.3.1 general if the compressor unit will be out of service for more than six months, it should be preserved in accor- dance with the following instructions: 1. Make sure that the compressor is kept indoors in a dry, dust-free room...

Page 127

Mnl-126509 april 4, 2013 page 117 8.3.4 preventive maintenance during storage operate the compressor once every six months as follows: 1. Remove the dust cap from the inlet port and install the inlet filter. 2. Open the outlet valve and allow the system to run approximately 5 minutes until there is ...

Page 128

G 120 ii v page 118 1st edition, rev. 0 chg. 2 8.4 reproducible forms 8.4.1 scheduled maintenance form daily para. Date signature.

Page 129

Mnl-126509 april 4, 2013 page 119 weekly or as required. Para. Date signature 500 operating hours. Para. Date signature 1,000 operating hours. Para. Date signature 2,000 operating hours. Para. Date signature.

Page 130

G 120 ii v page 120 1st edition, rev. 0 chg. 2 3,000 operating hours. Para. Date signature annually. Para. Date signature biennially. (every two years) para. Date signature.

Page 131

Mnl-126509 april 4, 2013 page 121 8.4.2 air purification cartridge operating hours date operating hours ambient temp. + 18°f during compression correction factor adjusted cartridge hours today total.

Page 132

G 120 ii v page 122 1st edition, rev. 0 chg. 2 8.4.3 record of operating hours date minutes total date minutes total subtotal: subtotal:.

Page 133

Mnl-126509 april 4, 2013 page 123 8.5 reference data 8.5.1 tightening torque values 1. Unless otherwise specified in text, the torque values in table 1 apply. 2. The indicated torque values are valid for bolts in greased condition. 3. Self locking nuts must be replaced on reassembly 4. Pipe connecti...

Page 134

G 120 ii v page 124 1st edition, rev. 0 chg. 2 8.5.4 approved lubricants chart unless otherwise specified in text, use the lubricants in table 2. 8.5.5 glossary of abbreviations and acronyms ac activated charcoal, removes odor and taste acd automatic condensate drain asme american society of mechani...

Page 135

Mnl-126509 april 4, 2013 page 125 8.6 additional documents 8.6.1 diagrams and drawings any included drawings, wiring diagrams, pneumatic flow diagrams, etc., will be bound next to the back cover in a hardcopy manual or included as a separate file on a cd. 8.6.2 other documents oem manuals and other ...

Page 137

Corrections & comments in an effort towards constant improvement, the documentation section of bauer compressors, inc. Would like to give you the opportunity to suggest improvements or corrections to this manual. If you find any inaccuracies or have suggestions feel free to e-mail us at: documentati...

Page 138: Bauer Compressors, Inc.

Bauer compressors, inc. Attn: documentation 1328 azalea garden rd. Norfolk, va 23502-1944 fold here fold here place tape or glue here postage here.