Summary of Junior II-B-F01

Page 3: Instruction Manual

Instruction manual junior ii i introduction this manual contains operating instructions and maintenance schedules for the high pressure breathing air compressor unit warning ! Pneumatic high pressure system ! The breathing air produced with the compressor units de scribed in this manual is subject ...

Page 4: Instruction Manual

A b c instruction manual junior ii ii dear customer we are happy to give you advice on any questions regarding your bauer compressor and help as soon as possible with any arising problems. You can contact us mondays to thursdays from 08 00 till 16 30 , fridays from 08 00 till 14 00 on phone no. (089...

Page 5: Instruction Manual

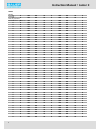

Instruction manual junior ii iii contents 1. General 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2. Safety measures 5 . . . . . . . . . . . . . . . . . . . . 3. Location, operation, bottle filling 9 . . . 4. Maintenance 17 . . . . . . . . . . . . . . . . . . . . . . . 5. Storage, prese...

Page 6: Instruction Manual

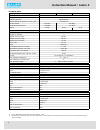

Instruction manual junior ii iv notes model: serial no..: date of purchase: dealer address / phone no.:.

Page 7: Instruction Manual

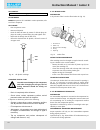

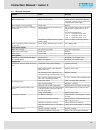

11 12 13 14 1 3 8 4 10 6 5 7 2 9 instruction manual junior ii 1 1. General purpose the junior ii breathing air compressor is designed to com press air for breathing as required in diving applications. The max. Allowable operating pressure (adjusted pressure on final pressure safety valve) is 225 ba...

Page 8: Instruction Manual

Instruction manual junior ii 2 1 filling hose 2 filling valve with pressure gauge 3 motor terminal box 4 three-phase motor 5 final pressure safety valve 6 handle 7 fanwheel cover 8 b-timer 9 condensate drain valves 10 mains plug with on-off switch and motor protection circuit breaker (dep. On countr...

Page 9: Instruction Manual

Instruction manual junior ii 3 1 2 4 3 7 8 5 9 1 filling hose 2 filling valve with pressure gauge 3 final pressure safety valve 4 filter system p21 5 b-timer (optional) 6 pressure maintaining valve 7 filling connector 8 intake filter 9 v-belt cover 6 fig. 4 compressor unit with electric motor, v-bel...

Page 10: Instruction Manual

Instruction manual junior ii 4 technical data compressor unit juniorii-b-f01 juniorii-e juniorii-w medium air delivery a) 100 l/min. (3,5 scfm) operating pressure pn200/pn300 pressure setting, final pressure safety valve 225/330 bar sound pressure 87 db(a) 86 db(a) sound (immersion) power 100 dba) 9...

Page 11: Instruction Manual

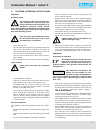

Mv3 − a/10/06 warning instruction manual junior ii 5 2. Safety measures 2.1. Notes and warning signs notes and warning signs displayed on compressors accord ing to model, application or equipment. Warning hot surfaces, do not touch! Danger of burning by touching cylinders, cylinder heads and pressu...

Page 12: Instruction Manual

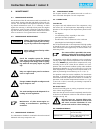

Instruction manual junior ii 6 pecially the safety notices chapter. When work is already underway it is too late. This is particularly relevant for temporary personnel, e.G. Maintenance personnel. • personnel may not wear long hair loose, loose clothing or jewellery, including rings. There is a dang...

Page 13: Instruction Manual

Instruction manual junior ii 7 • ensure safe and environmentally friendly disposal of con sumables and old parts. 2.3.5. Particular areas of danger • use only original fuses with specified current rating. If there is a failure in the electric energy supply, shut the unit down immediately. • work on...

Page 14: Instruction Manual

Instruction manual junior ii 8 the critically stressed areas of the vessels are examined by means of suitable testing methods, in order to ensure the operating safety. After having reached the total permissible number of load cycles, the vessel must be exchanged and scrapped. Record the number of lo...

Page 15: Instruction Manual

Warning instruction manual junior ii 9 3. Location, operation, bottle filling location outdoor location the compressor unit is not seawater resis tant. At operation in salty air spray com pressor with anticorrosive protection (e. G. Quicksilver corrosion guard). Electric driven units should be ope...

Page 16: Instruction Manual

Warning warning warning instruction manual junior ii 10 units with three phase current motor, additionally: - immediately after switching on the system for the first time check the direction of rotation of the motor for com pliance with the arrow on the unit. If motor turns in the wrong direction, ...

Page 17: Instruction Manual

Instruction manual junior ii 11 scavenging the compressor unit co 2 is present in the atmosphere with a natural amount of 350 to 400 ppm v . The molecular sieve used in the purifier for drying the breathing air is, as well as other capabilities, able to adsorb co 2 which is accumulated in the cartri...

Page 18: Instruction Manual

Instruction manual junior ii 12 shut-down procedure - close filling valve. Units with electric motor: - three-phase current: the motor is switched off by turn ing the switch (1, fig. 12) to 0. - alternating current: set 0 - i switch to 0. Units with petrol engine: - shut down petrol engine with sto...

Page 19: Instruction Manual

Fig. 13 b-timer 1 key symbol (maintenance due) 2 letter symbol (maintenance type) 3 low battery symbol 4 cartridge saturation indicator 5 operating hours or cartridge number 6 mode select key 7 enter key 1 2 3 4 5 6 7 instruction manual junior ii 13 b-timer (optional) introduction read operating ins...

Page 20: Instruction Manual

Fig. 14 fig. 15 battery fig. 16 fig. 17 1 2 instruction manual junior ii 14 a = 500 hours or 1 year b = 1000 hours or 1 year c = 2000 hours or 2 years • battery symbol indicating that the lithium battery is low and has to be changed. All data are stored and will not be lost when changing battery. Th...

Page 21: Instruction Manual

Fig. 18 fig. 19 fig. 20 fig. 21 fig. 22 instruction manual junior ii 15 operation the b-timer is activated when starting the compressor. Compressor operation is indi cated by the flashing “h” symbol. To switch on the b-timer press one of the keys on the display. Main menue will be displayed (fig. 1...

Page 22: Instruction Manual

Fig. 23 fig. 24 fig. 25 instruction manual junior ii 16 setup to enter the setup for the different functions of the b-timer press the and keys on the display simultaneously for more than 5 seconds from the cartridge number display (fig. 21). Filter symbol starts flashing (fig. 23) indicating the set...

Page 23: Instruction Manual

Warning warning instruction manual junior ii 17 4. Maintenance 4.1. Maintenance record we recommend that all maintenance work is recorded in the service book, showing the date and details of the work car ried out. This will help to avoid expensive repairwork caused by missed maintenance work. If it...

Page 24: Instruction Manual

Instruction manual junior ii 18 oil capacity junior ii approx. 360 ml oil packages bauer compressor oil is available in various quantities, refer to oil list in chapter 8. Oil change - run compressor warm. - remove oil dipstick. - drain oil while still warm by means of oil drain plug. Re place the ...

Page 25: Instruction Manual

Instruction manual junior ii 19 fig. 28 condensate drain taps 1 2 3 4.4.4. Filter system p21 description the air leaving the final stage is cooled in the after-cooler to approx. 10 - 15 °c (18 - 27 °f) above ambient temperature and then enters filter system p21 with triplex longlife car tridge (fig...

Page 26: Instruction Manual

Warning instruction manual junior ii 20 fig. 30 safety bore venting bore no cartridge cartridge installed lifetime the filter system is subject to dy namic load. It is designed for a cer tain number of load cycles, which originate from an abrupt pressure loss at condensate drain (1 load cycle i.E....

Page 27: Instruction Manual

Warning instruction manual junior ii 21 alent to between 10 and 13 operating hours at a filling pres sure of 200 bar. The longer service life of the cartridge at a filling pressure of 300 bar is annihilated by the larger volume of filled air per bottle, therefore the possible number of bottle filli...

Page 28: Instruction Manual

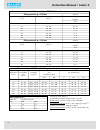

Instruction manual junior ii 22 1. Filter cartridge 057679: lifetime [hours] filling pressure p = 200 bar junior ii ambient temperature tu [ °c] final separator temperature tab [ °c] delivery q [l/min] 100 10 20 - 24 26 - 21 15 25 - 29 20 - 16 20 30 - 34 15 - 12 25 35 - 39 11 - 9 30 40 - 44 9 - 7 35...

Page 29: Instruction Manual

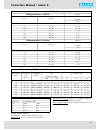

Instruction manual junior ii 23 2. Filter cartridge 059183: lifetime [hours] filling pressure p = 200 bar junior ii ambient temperature tu [ °c] final separator temperature tab [ °c] delivery q [l/min] 100 10 20 - 24 22 - 18 15 25 - 29 17 - 13 20 30 - 34 13 - 10 25 35 - 39 10 - 8 30 40 - 44 8 - 6 35...

Page 30: Instruction Manual

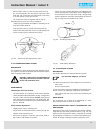

Instruction manual junior ii 24 4.4.5. Pressure maintaining valve description a pressure maintaining valve is mounted at the outlet of the filter system p21. It ensures that pressure is built up in the filter even from the start of delivery, thus achieving a constant, optimum filtra tion. It will a...

Page 31: Instruction Manual

Instruction manual junior ii 25 fig. 33 final pressure gauge mark maintenance we recommend that the final pressure gauge is checked from time to time. For this purpose we have developed a special test pressure gauge with an adaptor which immedi ately recognizes any deviations in readings (see high ...

Page 32: Instruction Manual

Instruction manual junior ii 26 changing the valves of the 1st stage intake and pressure valves of the 1st stage are combined in one plate valve under the valve head, see fig. 36. 1 valve head 2 gasket 3 plate valve 4 o-ring 5 valve head screw 6 washer 7 nut fig. 36 valve head 1st stage 5 6 7 2 3 1 ...

Page 33: Instruction Manual

Instruction manual junior ii 27 - remove allen screws (7), take off valve head cover (6). - put two screwdrivers into the groove of pressure valve body (fig. 39). If necessary turn valve loose at first using a 13 mm spanner on the flat surfaces. - lift out pressure valve (3) together with o-ring (2)...

Page 34: Instruction Manual

Instruction manual junior ii 28 motor protection switch (three-phase motor) the motor is switched on manually by turning the switch to 1 (fig. 43). It is switched off manually by turning the switch to 0. For safety of the operating personnel all voltage carrying parts have a protective cover. After ...

Page 35: Instruction Manual

Instruction manual junior ii 29 4.5. Trouble-shooting trouble cause remedy drive motor (electric) motor will not start electric circuitry faulty check all fuses, terminal connections, wire leads, make sure that motor data complies with mains supply motor/engine runs eccentrically v-belt worn replace...

Page 36: Instruction Manual

Instruction manual junior ii 30 remedy cause trouble high oil consumption piston rings, pistons or cylinders worn out replace defective parts intake filter clogged replace filter cartridge compressor too hot enhance cooling air escaping through cartridge safety bore cartridge missing insert cartridg...

Page 37: Instruction Manual

Instruction manual junior ii 31 5. Storage, preservation general if the compressor is put out of service for more than six months, the unit should be preserved in accordance with the following instructions: make sure the compressor is kept in doors in a dry, dust free room. Only cover the compresso...

Page 38: Instruction Manual

Instruction manual junior ii 32 6. Repair instructions general preventive maintenance usually involves replacing the valves, gaskets and sealing rings as well as carrying out the mainten ance work. Repair work can be carried out on the compressor block to a certain extent but a certain experience a...

Page 39: Instruction Manual

* exception: mounting bolts of final pressure safety valve: 10 nm instruction manual junior ii 33 7. Tables tightening torque values unless otherwise specified in text, the fol lowing torque values apply. All valve head screws require torque wrench tightening! The indicated torque values are valid ...

Page 40: Instruction Manual

Instruction manual junior ii 34 lubrication chart usage lubricants rubber and plastic parts, filter housing threads weicon wp 300 white part no. N19752 or bauer special grease part no. 072500 sealing rings bauer special grease part no. 072500 shaft seal (seal) shaft seal (shaft) bauer special grease...

Page 41: Instruction Manual

Instruction manual junior ii 35 8. Annex • schematic diagram lubricating oil list parts list.

Page 42: Instruction Manual

Instruction manual junior ii 36.

Page 43: Instruction Manual

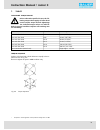

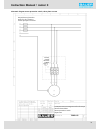

Hauptsicherung bauseits / main fuse by customer / fusible principal coté client ein/aus on/off marche/ arrêt schaltplan/schematic diagram/schéma électrique motorschutzschalter motor protection switch disjoncteur 76942−s1 instruction manual junior ii 37 schematic diagram motor protection switch, thre...

Page 44: Instruction Manual

Instruction manual junior ii 38.

Page 45: Oil List

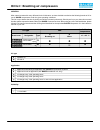

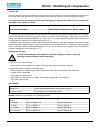

Oil list breathing air compressors general after extensive tests with many different kinds of lubricants, we have decided to authorize the following brands of oil for use in bauer compressors under the given operating conditions. This list is up to date at the time of printing and will be reviewed c...

Page 46: Oil List

Oil list breathing air compressors type of oil due to the thermal load on the compressor only high quality oil should be used. You are recommended to restrict oils to those which have been approved by us and are listed in the instruction manual or in the lubricating list on page 1. Our compressor un...