Summary of mariner 320

Page 3: Mariner 320

Mariner 320 instruction manual breathing air compressors i introduction this manual contains operating instructions and mainte nance schedules for the high pressure breathing air compres sors warning ! Pneumatic high pressure system ! The breathing air produced with the compressor units de scribe...

Page 4: Instruction Manual

Instruction manual breathing air compressors ii table of contents 1. General 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2. Safety measures 11 . . . . . . . . . . . . . ....

Page 5: Instruction Manual

Instruction manual breathing air compressors iii annex air flow diagram 80721 pneumatic parts list 76360 schematic diagram for unit with motor protection switch 76942-s01 schematic diagram for unit with compressor control system 80228 schematic diagram for unit with honda engine and automatic conden...

Page 6: Instruction Manual

Instruction manual breathing air compressors iv notes model: serial no.: date of purchase: dealer address/phone no.:.

Page 7: Instruction Manual

Instruction manual breathing air compressors 1 1. General purpose and short description the mariner 320 high pressure compressors are designed to compress air for breathing as required in diving and fire fight ing applications. The max. Allowable operating pressure (ad justed pressure on final pre...

Page 8: Instruction Manual

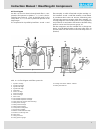

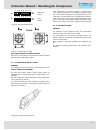

Instruction manual breathing air compressors 2 1 motor intake filter 2 motor exhaust 3 fuel tank 4 filling valve 5 oil filler neck 6 compressor block 7 compressor intake filter 8 final pressure safety valve 8 safety valve 9 rope starter 10 hinged motor plate 11 condensate drain tap 12 filling manifo...

Page 9: Instruction Manual

Instruction manual breathing air compressors 3 1 3 7 6 10 2 5 9 8 4 11 1 electric control unit 2 filling valve 3 oil filler neck 4 compressor block 5 intake filter 6 final pressure safety valve 7 condensate tank 8 hinged motor plate 9 condensate separator 10 automatic condensate drain unit 11 filter...

Page 10: Instruction Manual

Instruction manual breathing air compressors 4 1 3 9 5 10 13 2 4 8 6 15 11 7 12 14 1 rope starter 2 engine intake filter 3 fueltank 4 filling valves 5 compressor intake filter 6 filter system p41 7 final pressure safety valve 8 handle 9 battery 10 compressor control 11 hinged motor plate 12 condensa...

Page 11: Instruction Manual

Instruction manual breathing air compressors 5 1 3 9 5 10 12 2 4 8 6 13 11 7 1 rope starter 2 engine intake filter 3 fueltank 4 filling valves 5 compressor intake filter 6 final pressure safety valve 7 filter system p31 8 handle 9 condensate tank 10 hinged motor plate 11 condensate separator 12 auto...

Page 12: Instruction Manual

Instruction manual breathing air compressors 6 compressor block ik12.14 the compressor block ik12.14 is used to compress air in the high pressure range up to 420 bar (5,000 psi). The compressor block is of a four stage, three cylinder design. The cylinders are arranged in a w form, the 1st/2nd stage...

Page 13: Instruction Manual

Instruction manual breathing air compressors 7 air flow diagram see abb. 10. The air is drawn in through intake filter -5, com pressed to final pressure in cylinders -1, -2, -3, and -4, and re cooled by inter-coolers -6, -7 and -8, and after-cooler -9. The safety valves -13, -14, -15 and -16 prote...

Page 14: Instruction Manual

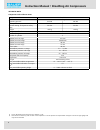

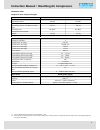

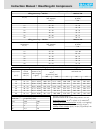

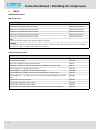

Instruction manual breathing air compressors 8 technical data compressor units without motor compressor unit mariner 320- 1 medium breathing air operating pressure pn 200 pn 300 delivery a) 320 l/min. 320 l/min. Pressure setting, final pressure safety valve 225 bar 330 bar weight 109 kg 109 kg compr...

Page 15: Instruction Manual

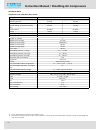

Instruction manual breathing air compressors 9 technical data compressor units with petrol engine compressor unit mariner 320-b medium breathing air operating pressure pn 200 pn 300 delivery a) 320 l/min. 320 l/min. Operating pressure, final pressure safety valve 225 bar 330 bar sound pressure 83 db...

Page 16: Instruction Manual

Instruction manual breathing air compressors 10 technical data compressor unit with three phase motor compressor unit mariner 320-e medium breathing air operating pressure pn 200 pn 300 delivery a) 320 l/min. 320 l/min. Pressure setting, final pressure safety valve 225 bar 330 bar sound pressure 83 ...

Page 17: Instruction Manual

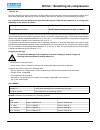

Mv3 − a/10/06 warning instruction manual breathing air compressors 11 2. Safety measures 2.1. Notes and warning signs notes and warning signs displayed on compressors accord ing to model, application or equipment. Warning hot surfaces, do not touch! Danger of burning by touching cylinders, cylinder...

Page 18: Instruction Manual

Instruction manual breathing air compressors 12 underway it is too late. This is particularly relevant for temporary personnel, e.G. Maintenance personnel. • at the very least, supervise temporary personnel's work in accordance with the instruction manual, taking into ac count safety and danger fac...

Page 19: Instruction Manual

Instruction manual breathing air compressors 13 • for assembly work above body height, use appropriate safety approved equipment, e.G. Ladders and platforms. Do not climb on machine parts. For maintenance work at high levels, wear a safety harness. • clean oil, fuel or care products from the machine...

Page 20: Instruction Manual

Instruction manual breathing air compressors 14 • always exchange damaged pressure vessels completely. Individual parts that are subject to pressure loads cannot be purchased as spare parts, since the vessels are tested as a complete part and the documentation considers them as a whole (see pressure...

Page 21: Instruction Manual

Instruction manual breathing air compressors 15 permission is according to trg 730, guidelines for permission to set up and operate filling stations. The test certificates and documents delivered with the compressor are important and may be requested during the procedure for obtaining per mission. ...

Page 22: Instruction Manual

Instruction manual breathing air compressors 16 3. Installation, operation, filling procedure 3.1. Installation of the compressor unit the compressor frame is equipped with anti-vibration mounts and thus a machine base or special means of secur ing the compressor are not necessary. The compressor u...

Page 23: Instruction Manual

Warning instruction manual breathing air compressors 17 3.3. Operation preparation for operation the compressors described in this manual are not suitable for com pression of oxygen. Explosion oc curs if an oil lubricated compressor is operated with pure oxygen or gases with an oxygen content of m...

Page 24: Instruction Manual

Warning warning warning instruction manual breathing air compressors 18 - press on button (2). Abb. 14 compressor control unit 1 2 3 units with petrol engine: open condensate drain valves on the filters to release pres sure, so that motor starts without load. Set choke to position start. Start engi...

Page 25: Instruction Manual

Instruction manual breathing air compressors 19 on models of 300 bar rated filling pressure do not attach bottles unless rated for this pressure (note pressure stamped on tank neck). Abb. 15 connecting air bottle - air bottles with international filling connector can be connected with filling adapto...

Page 26: Instruction Manual

Instruction manual breathing air compressors 20 abb. 19 change-over device 1 2 3.7. Shut-down procedure units with electric engine without compressor control system: the motor is switched off manually by pressing the stop but ton (1, abb. 20). Units with electric engine with compressor control sys...

Page 27: Instruction Manual

Abb. 22 b-timer abb. 23 display 1 2 3 4 5 6 7 1 key symbol (maintenance due) 2 letter symbol (maintenance type) 3 low battery symbol 4 cartridge saturation indicator 5 operating hours or cartridge number 6 mode select key 7 enter key instruction manual breathing air compressors 21 3.8. B-timer intro...

Page 28: Instruction Manual

Abb. 24 abb. 25 battery abb. 26 abb. 27 instruction manual breathing air compressors 22 • indication of compressor maintenance due by means of letter symbols and operating hours. A = 500 hours or 1 year b = 1000 hours or 1 year c = 2000 hours or 2 years • battery symbol indicating that the lithium b...

Page 29: Instruction Manual

Abb. 28 abb. 29 abb. 30 abb. 31 abb. 32 instruction manual breathing air compressors 23 press key again. Remaining operating hours to service inter val a (500 hours or annually) are shown (abb. 28). Press key again. Remaining operating hours to service inter val b (1000 hours or annually) are show...

Page 30: Instruction Manual

Abb. 33 abb. 34 abb. 35 instruction manual breathing air compressors 24 setup to enter the setup for the different functions of the b-timer press the and keys on the display simultaneously for more than 5 seconds from the cartridge number display (abb. 33). Filter symbol starts flashing (abb. 31) in...

Page 31: Instruction Manual

Warning warning instruction manual breathing air compressors 25 4. Maintenance 4.1. Maintenance record we recommend that all maintenance work is recorded in the service book delivered with every compressor unit, showing the date and details of the work carried out. This will help to avoid expensive ...

Page 32: Instruction Manual

Instruction manual breathing air compressors 26 for operation under less severe conditions we can also rec ommend mineral compressor oils which are suitable for oper ation under ambient temperatures between +5 °c (41 °f) and +35 °c (95 °f). Here also, pre-heating is required for lower temperatures...

Page 33: Instruction Manual

Instruction manual breathing air compressors 27 - fill compressor with the new oil. - after approx. 100 operating hours check lubricating oil for degree of contamination, and change oil again if necessary. - perform subsequent oil changes according to chapter oil change. - refill compressor with sam...

Page 34: Instruction Manual

Warning warning instruction manual breathing air compressors 28 4.5.1. Intake filter description a dry micronic filter is used to filter intake air, see abb. 41. Abb. 41 intake filter 1 maintenance the filter cartridge must be cleanded or changed at regular intervals according to maintenance schedul...

Page 35: Instruction Manual

Warning instruction manual breathing air compressors 29 lifetime the filter system is subject to dy namic load. It is designed for a cer tain number of load cycles, which originate from an abrupt pressure loss at condensate drain (1 load cycle i.E. Condensate drain = 1 depressu rization, 1 pressu...

Page 36: Instruction Manual

Warning instruction manual breathing air compressors 30 general instructions for filter maintenance - depressurize system before starting any maintenance work. - dry inside of filter housing with a clean cloth before in stalling new cartridge and check for corrosion. Change if necessary. - lubricat...

Page 37: Instruction Manual

Instruction manual breathing air compressors 31 filling valve maintenance to protect filling valve against contamination a sintered metal filter is screwed in the filling valve body. - unscrew pressure gauge from filling valve body. - screw off sintered metal filter with a suitable screw driver. - t...

Page 38: Instruction Manual

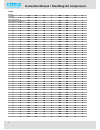

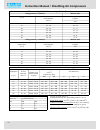

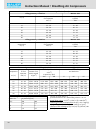

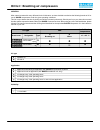

Instruction manual breathing air compressors 32 1. Filter cartridge 80100: filter cartridge lifetime [hours] filling pressure p = 200 bar mariner 320 ambient temperature tu [ °c] temperature of final separator tab [ °c] flow capacity q [l/min] 320 10 20 - 24 37 - 30 15 25 - 29 28 - 23 20 30 - 34 21 ...

Page 39: Instruction Manual

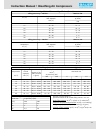

Instruction manual breathing air compressors 33 2. Filter cartridge 80114: filter cartridge lifetime [hours] filling pressure p = 200 bar mariner 320 ambient temperature tu [ °c] temperature of final separator tab [ °c] flow capacity q [l/min] 320 10 20 - 24 28 - 22 15 25 - 29 21 - 17 20 30 - 34 16 ...

Page 40: Instruction Manual

Instruction manual breathing air compressors 34 4.5.4. Filter system p41 (option) purpose and short description the mariner 320 compressor units can be fitted with filter system p41 as an optional extra instead of the standard filter system p31. The difference is a much higher filter cartridge life ...

Page 41: Instruction Manual

Warning instruction manual breathing air compressors 35 abb. 45 oil and water separator in out condensate out maintenance lifetime the oil and water separator is sub ject to dynamic load. It is designed for a certain number of load cycles, which originate from an abrupt pressure loss at con densat...

Page 42: Instruction Manual

Instruction manual breathing air compressors 36 - change cartridge before reactivating a compressor unit which has been out of service for more than 6 months. - leave cartridge in the filter as long as unit is out of ser vice. - keep all condensate drain valves and shut-off valves closed. Keep a mi...

Page 43: Instruction Manual

Instruction manual breathing air compressors 37 3. Filter cartridge 062565: filter cartridge lifetime [hours] filling pressure p = 200 bar mariner 320 ambient temperature tu [ °c] temperature of final separator tab [ °c] flow capacity q [l/min] 320 10 20 - 24 98 - 78 15 25 - 29 73 - 59 20 30 - 34 56...

Page 44: Instruction Manual

Instruction manual breathing air compressors 38 4. Filter cartridge 067224: filter cartridge lifetime [hours] filling pressure p = 200 bar mariner 320 ambient temperature tu [ °c] temperature of final separator tab [ °c] flow capacity q [l/min] 320 10 20 - 24 81 - 65 15 25 - 29 61 - 49 20 30 - 34 46...

Page 45: Instruction Manual

Instruction manual breathing air compressors 39 4.5.5. Pressure maintaining valve description a pressure maintaining valve is integrated in the p31 filter base (abb. 48), or mounted at the outlet of the filter system p41 (abb. 49). It ensures that pressure is built up in the filter even from the sta...

Page 46: Instruction Manual

Instruction manual breathing air compressors 40 this just ensures that the valve is functional and will release pressure in case of a malfunction. To check the blow-off pres sure value refer to ”blow-off pressure check”. Checking blow-off pressure check blow-off pressure of the final pressure safet...

Page 47: Instruction Manual

Instruction manual breathing air compressors 41 abb. 53 combined plate valve pressure side intake side top view valve change changing the valves should be performed by trained person nel, only. Valve change is described in the workshop manual which is available through the bauer technical service. ...

Page 48: Instruction Manual

Instruction manual breathing air compressors 42 stage every 15 minutes during operation. In addition, the au tomatic condensate drain is designed to drain these filters after shut-down of the compressor unit and to unload the compressor during the starting phase. The automatic condensate drain syst...

Page 49: Instruction Manual

Instruction manual breathing air compressors 43 removed and the condensate drain valve (6) drains as de scribed above. Control air condensate abb. 58 condensate drain 1 intermediate separator after 2nd stage 2 intermediate separator after 3rd stage 3 oil and water separator after 4th stage 4 soleno...

Page 50: Instruction Manual

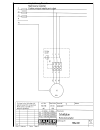

Instruction manual breathing air compressors 44 abb. 59 condensate separator 3 4 5 6 7 10 9 8 2 1 4.5.11. Electrical system this section describes the standard electric control system of the compressor unit. The amount of built-in components varies depending on order. For schematic diagrams, see ann...

Page 51: Instruction Manual

Instruction manual breathing air compressors 45 abb. 61 final pressure switch off max. = 350 bar a) off min. = 200 bar in case of readjustment becoming necessary, open cover (2, abb. 61). Adjust screw (1) to the required pressure using a 6 mm allen key. Service switch (optional) abb. 62 service swit...

Page 52: Instruction Manual

Instruction manual breathing air compressors 46 abb. 63 timer k10 (electric units) 1 2 3 adjusting the timer (units with petrol engine; power-flow timer) - adjust condensate drain period (in seconds) with control (1, abb. 64). - adjust condensate drain interval (in minutes) with control (2). Abb. 64...

Page 53: Instruction Manual

Instruction manual breathing air compressors 47 abb. 66 dip switch adjustment 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 a b on off on off preliminary setting final setting abb. 67 potentiometer setting funct units with petrol or diesel engine description of drive engine see instruction manual of honda petrol ...

Page 54: Instruction Manual

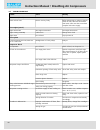

Instruction manual breathing air compressors 48 4.6. Trouble-shooting trouble cause remedy drive motor (electric) motor will not start electric circuitry faulty before attempting to make any repairs, check all fuses, terminal connections, wire leads, make sure that motor data complies with mains sup...

Page 55: Instruction Manual

Instruction manual breathing air compressors 49 remedy cause trouble automatic condensate drain (optional) drain valves do not close no control air check control air line drain valves leaking dismantle drain valve and clean drain valves do not open condensate drain valve piston jammed dismantle drai...

Page 56: Instruction Manual

Instruction manual breathing air compressors 50 5. Storage, preservation general if the compressor is put out of service for more than six months, the unit should be preserved in accordance with the following instructions: make sure the compressor is kept indoors in a dry, dust free room. Only cover...

Page 57: Instruction Manual

Instruction manual breathing air compressors 51 6. Repair instructions general preventive maintenance usually involves replacing the valves, gaskets and sealing rings as well as carrying out the mainten ance work. Repair work can be carried out on the compressor block to a certain extent but a cert...

Page 58: Instruction Manual

Instruction manual breathing air compressors 52 7. Tables maintenance parts maintenance kits: designation part no. Maintenance kit (500 hours) mariner electric mariner320-e-mu-a1 maintenance kit (500 hours) mariner petrol mariner320-b-mu-a1 maintenance kit (1000 hours) mariner electric mariner320-e-...

Page 59: Instruction Manual

* exception: mounting bolts of final pressure safety valve: 10 nm instruction manual breathing air compressors 53 tightening torque values unless otherwise specified in text, the fol lowing torque values apply. All valve head screws require torque wrench tightening! The indicated torque values are ...

Page 60: Instruction Manual

Instruction manual breathing air compressors 54.

Page 61: Instruction Manual

Instruction manual breathing air compressors 55 8. Annex • air flow diagram schematic diagrams lubricating oil list parts lists.

Page 62: Instruction Manual

Instruction manual breathing air compressors 56.

Page 71: Oil List

Oil list breathing air compressors general after extensive tests with many different kinds of lubricants, we have decided to authorize the following brands of oil for use in bauer compressors under the given operating conditions. This list is up to date at the time of printing and will be reviewed c...

Page 72: Oil List

Oil list breathing air compressors type of oil due to the thermal load on the compressor only high quality oil should be used. You are recommended to restrict oils to those which have been approved by us and are listed in the instruction manual or in the lubricating list on page 1. Our compressor un...