- DL manuals

- BIRO

- Cutter

- 44

- Operating And Service Manual

BIRO 44 Operating And Service Manual

Summary of 44

Page 1

+ important notice + this manual contains important safety instructions which must be strictly followed when using this equipment. Ptct md 44 105-9-05-18 ptct md 44 105-9-05-18 105-7-13-24.

Page 2

..

Page 3: Table of Contents

Notice to owners and operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 safety tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 installation . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

..

Page 5: – Note –

Biro’s products are designed to process food products safely and efficiently. Unless the oper- ator is properly trained and supervised, there is the possibility of a serious injury. It is the responsi- bility of the owner to assure that this machine is used properly and safely, strictly following th...

Page 6: Safety Tips

Safety tips sharp moving band type saw blade to avoid serious personal injury never touch this machine without training and authorization by your supervisor. Always read operation and service manual before operating, cleaning or servicing. Always keep hands clear of sharp band type saw blade and oth...

Page 7: Installation

Installation to avoid serious personal injury properly install equipment in adequate work area always use qualified technician and electrician for installation. Always install equipment in work area with adequate light and space. Only operate on a solid, level, non-skid surface. Never operate with s...

Page 8

6. Place removable finger lift with saw guard assembly (part no. A18211) on the saw guide bar (part no. 116-27) and fasten in place with finger lift fastener knob (part no. 211a-291q). 7. Placing blade on cutter: hang upper wheel assembly (part no. A18003u335) on the hinge bracket (part no. 71-2). L...

Page 9: For Biro Power Cutters

12. Make sure saw guide bar with saw guard is in its lowest position. Close head and base doors. 13. Push start button and check for proper phasing of motor. Blade should be travelling down through saw guide. 14. Watch for proper tracking of blade. Back of blade should be centered in hole in saw gui...

Page 10

6.

Page 11

2. Make sure all doors are closed and locked. 3. Ajdust meat gauge plate forward to desired thickness of cut. 4. Push start button and watch blade for proper tracking. 5. Standing in front of the power cutter, place product on the meat carriage. Pay attention to position of your hands. Keep hands cl...

Page 12: Cleaning

Cleaning sharp moving band type saw blade to avoid serious personal injury always turn off, unplug from power source and perform lockout/tagout procedure to this machine before cleaning or servicing. Only use recommended cleaning equipment, materials and procedures. Never spray water or other liquid...

Page 13: Maintenance

Maintenance sharp moving band type saw blade to avoid serious personal injury always turn off, unplug from power source and perform lockout/tag out procedure to this machine before cleaning or servicing. Never touch this machine without training and authorization by your supervisor. Always keep hand...

Page 14

E. Stationary bar assembly: check condition of nylon filler (part no. 177), change every four (4) weeks. Check condition of saw guide (part no. 119a), check tracking of blade through guide, back of blade should be centered in hole, replace every six (6) months. Check condition of lower blade back-up...

Page 15

C. Saw guide bar and saw guard the factory recommends that when service is performed on any biro saw the servicing agency be sure that the biro saw is equipped with the most current safety features available. Model 44 saw guide bars and saw guards production of the biro model 44 began march 1956. Al...

Page 16

12.

Page 17

13.

Page 18

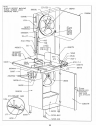

Item no. Description a16112 head door latch assembly as18005 head & door assembly, ss as18006 head door assembly, ss a71-2 upper wheel hinge bracket assembly hhs058s hex head screw, 5 16 -18 ´ 7 8 ss hhs060s hex head screw, 5 16 -18 ´ 1 ss lw15s lock washer, 5 16 ss sss15 set screw, 5 16 -18 ´ 5 16 ...

Page 19

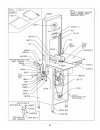

Item no. Description a18227 bearing cup/cone assembly a18360 lower bearing housing assembly hn25s hex nut, 3 8 -16, ss lw25s lock washer, 3 8 , ss sss20 set screw, 3 8 -16 ´ 3 8 , cup point s360cb-1 carriage bolt, 3 8 -16 ´ 1¼, ss 18003 lower wheel, 18" 18231dl lower shaft seal, double lip 18251al u...

Page 20

Item no. Description a18273-275 not sold as assembly a18273 meat gauge bracket assembly a18275 meat gauge plate assembly a262 meat gauge release assembly fw10s flat washer, 5 16 ss hhs035s hex head screw ¼-20 ´ 5 8 ss hhs040s hex head screw, ¼-20 ´ ¾, ss hhs049nl hex screw – nylon 5 16 -18 ´ ½ lg. H...

Page 21

Hhs070s 17.

Page 22

Item no. Description a415d stationary bar assembly as415d ss stationary bar assembly hhs035s hex head screw, 1 4 -20 ´ 5 8 , ss hn15s hex nut, 1 4 -20, ss lw10s lock washer, 1 4 , ss s286 stationary bar headless screw s415d stainless stationary bar 119a saw guide in stationary bar 119fsc saw guide i...

Page 23

(dns) s18115 5aez s18155ez-r raw top s18155ez-1 meat carriage top only w/weld studs not sold separately s18155ez without weld studs 19.

Page 24

20

Page 25: - Operators Notes -

- operators notes - 21.

Page 26

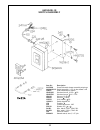

A609aaw-18 switch assembly item no. Description a16226a green/red switch button assembly w/springs a609aaw-16 switch assembly, 1 & 3 ph less heater coils h462a guard assembly for switch hhs010s hex head screw, 10-32 ´ 3 8 ss hhs070s hex head screw, 3 8 -16 ´ 1 ss hn10s hex nut, 10-32 ss hn20s hex nu...

Page 27: 609Aaw

609aaw 21 23.

Page 28

Watertight magnetic switch assemblies (aeg) includes mounting bracket and wires 22 item no. Description a16226a-sg green/red switch button assembly h462a guard assembly for switch hhs070s hex head screw, 3 8 -16 ´ 1 ss hn05s hex nut, 8-32 ss lw03s lock washer, #8 ss lw25s lock washer, 3 8 heavy ss r...

Page 29

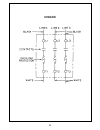

Model 44 schematic using 3ph aeg w.T. Switch for 220/380/440 volts, three phase, 60 cycle baldor motor 25.

Page 30

26.

Page 31

Model 44 parts numbers and descriptions send in model no. And serial no. When ordering parts motor section item no. Description m79-g56111-u motor, 3hp, 208/220/440-50/60-3 open m88-g56215-u motor, 5hp, 220/440-60-3 moisture resistant m89-g56214-u motor, 5hp, 575-60-3 moisture resistant item no. Des...

Page 32

Item no. Description as1120ez channle assembly, ez flow, ss as18005 head & door assembly, ss as18006 head door assembly, ss as290 cleaning unit stamping assembly as290-1 not sold as assembly as415d ss stationary bar assembly a112 head door handle assembly, to #4511 a116-27 saw guide bar assembly, 27...

Page 33

Warning label locations on machine 29.

Page 34

30

Page 35: Warning

Operator’s signature page warning read and understand this entire manual before signing below my signature attests that i have completely read and understand this manual. I realize that this machine, if operated carelessly, can cause serious injury to myself and others. Name (print) signature superv...

Page 36

Limited warranty: warranty: the biro manufacturing company warrants that model 44 will be free from defects in material and workmanship under normal use and with recommended service. Biro will replace defective parts, which are covered by this limited warranty, provided that the defective parts are ...