Installation, operation and maintenance manual bisolid comfort 30.1.2013 г . 19:38 om-bscv00/08/2012/en manual for installation, operation and maintenance of hot water solid fuel boiler from series bisold comfort 03/04/05.

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 2 content page. 1. Important information about system operation 3 1.1. Safety instructions 3 1.2. Purpose of the boiler 4 1.3. Fuel 4 1.4. Boiler overall dimensions 5 1.5. Boilers technical data 5 2. Introduction 8 2...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 3 1. Important information about system operation dear bisolid comfort 03/04/05 hot water boiler owners, we would like to congratulate you for your new ecological boiler system. By purchasing this quality product fro...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 4 direction information marked with this symbol contains additional data. Works or activities for setting the appliance in proper technical working order warning repairs of constructional elements which functions are...

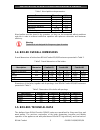

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 5 table 1. Wood pellets main parameters. Parameter dimension value diameter mm 6;8 length mm 3.5-40 water content % 10 ash content % 0.7 mechanical durability % 97.5 caloricity mj/kg 16.5 bulk density kg/m 3 600 wood...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 6 harmful emissions released into the atmosphere. The boilers are designed for heating one or two floor single-family houses or small company buildings, as well as for heating hot domestic water. Outer view of hot wa...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 7 table 4. Technical data of hot water boiler from series bisolid comfort03/04/05. Description dimension comfort 03 comfort 04 comfort 05 number of sections pcs. 3 3 4 4 5 5 fuel - wood pellets wood pellets wood pell...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 8 2. Introduction 2.1. Boiler general requirements the boiler and its accompanying equipment must be installed and used in accordance to the designed heating installation, all applicable legal norms, technical standa...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 9 at the end of the boiler’s life cycle, it should be packed together with its parts and disposed in an environmentally safe way. The manufacture company is not responsible for damage or harms caused by non-complianc...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 10 figure 2. Pressure losses in the combustion chamber..

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 11 3. Operation instructions 3.1. Overall characteristics of hot water boiler from bisolid comfort series the solid fuel boilers from bisolid comfort 03/04/05 series are designed for heating of domestic and industria...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 12 figure 3.Chimney (flue) flap for draught regulation. Another element for regulation of the boiler draught is the thermo-regulating valve (figure 4). The regulator is situated on the cast-iron body exit. It regulat...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 13 danger when installing the elements for safety and control please do not forget that all installation works must comply with the safety labor principles. If thermo- regulation valve or other safety element replace...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 14 figure 6. Termometer. Hydraulic scheme it is presumed that the hydraulic system is opened type and has to be built in accordance to the following scheme (figure 7). Figure 7. Schematic hydraulic diagram. 1. Safety...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 15 the expansion tank must be chosen properly, complying with the water volume changes resulting from its heating and cooling. The expansion tanks and their pipe connection lines must be protected against freezing. T...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 16 4. Boiler initialization to operation 4.1. Boiler check-ups before initialization for operation before initializing the boiler for operation the service technician must check: if the installation complies with the...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 17 5. Boiler operation and control with wood logs 5.1. Boiler firing before firing a hot water boiler from bisolid comfort 03/04/05 series check the manometer and wether there is enough water in the heating system. O...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 18 5.4. Boiler heating mode during the night this mode is used when you want to keep the fire in the boiler burning, for example during the night. First scrape all the ash from the combustion chamber, with completely...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 19 5.9. Boiler long-term switch off when switching the boiler off for long period of time (at the end of the heating season), it must be completely cleaned from all unburned accumulations (soot, ash and deposits). Ot...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 20 test and if necessary clean the water filter. Check expansion tank (buffer) and clean it if necessary. Test pressure sensor. Clean or replace it if necessary. Perform operation control check for safety of the hydr...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 21 table 5. Delivery kit of boiler bisolid comfort. Pos. Description pcs 1 hot water boiler bisolid comort 1 2 wood pellet burner bisolid gp 1 3 pellet auger bisolid 1 4 ash-tray 1 5 electrical control panel 1 6 trv ...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 22 6. Boiler operation and controls with wood pellets 6.1. Boiler firing before firing the boiler from series bisolid comfort 03/04/05 when utilizing wood logs please comply with the instructions in part 5.1, present...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 23 figure 8. Boiler protection grate. Warning when using a pellet burner from bisolid gp series, remove the protection grate by unscrewing its fixing bolts. Warning when using wood logs it is obligatory to install th...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 24 6.3. Boiler servicing when servicing hot water boilers from series comfort 03/04/05 operating with wood logs, please observe the instructions in part 5.10 from the current manual for operation. When operating with...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 25 figure 9. Electrical control panel of the boiler. Warning all works and activities over the electrical wiring of the burner or adjustments, where is necessary to remove its covers and other elements, that protect ...

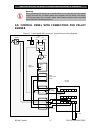

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 26 6.7. Boiler with pellet burner wiring diagram figure 10. Boiler with pellet burner – wiring diagram. Auger 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6 6 5 4 3 2 1 6 5 4 3 2 1 fresh air extactor fan - option pump ignition ...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/bg 27 warning when operating with wood logs or wood pellets do not interrupt the boiler power supply, because the circulation pump must operate until the boiler cools down. In all wiring types the circulation pump must ...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 28 warning connecting a room thermostat: before connecting the room thermostat to the connector (moving part) for room thermostat (positioned on the back of the boiler’s side cover panel), remove the factory installe...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 29 7. Boiler installation instructions 7.1. Boiler installation – overal information the hot water boilers from series bisolid comfort 03/04/05 must be initianted into operation by authorized servicing technicians. T...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 30 warning the filter, as well as the precipitant must be checked and cleaned regularly. 7.2. Boiler water requirements the boiler water requirements are presented in the european standards. If the sum of calcium and...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 31 7.4. Minimum distances figure 12. Minimum distances between the boiler and the fuel. 7.5. Positioning in the boiler room figure 13 presents the minimum distances which must be observed in order to guarantee safe o...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 32 figure 13. Minimum distances in the boiler room. Danger when the boiler operates do not touch any hot water pipe lines or flue pipes. 7.6. Installation procedure position the boiler over inflammable material surfa...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 33 7.7. Boiler spare parts the spare parts for hot water boilers from series bisolid comfort 03/04/05 are presented in figure 14 and figure 15. Figure 14. Spare parts of the boiler. Figure 15. Spare parts of the boil...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 34 table 6 presents the list of spare parts for cast iron boilers from series bisolid comfort 03/04/05. Table 6. Spare parts list. Comfort03 comfort04 comfort05 1 front section sn 060 sn 060 sn 060 2 middle section s...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 35 7.8. Boiler operation with accumulating tank in some cases the heat energy can be delivered to the consuming devices by accumulating tank. The formula for determining the minimum needed water quantity for accumula...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 36 7.10. Flue outlet pipeline installation figure 17 presents the correct connecting of the boiler flue pipeline to the chimney, by additional pipe connection. Please observe the following rules when installing the f...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 37 figure 17. Flue pipeline installation. 7.11. Chimneys and advices for connecting to chimneys it is enough to have a drawing for connecting the boiler flue outlet to the chimney, as main condition for the boiler co...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 38 have in mind that the boiler must be connected to the chimney system (to flue gasses) in accordance to the local legal conditions. When connecting the boiler to the chimney it is necessary to ask professional inst...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 39 8. Troubleshooting failure reason solution the fuel quality is low due to high water content. Try using fuel with higher caloricity and lower water content. Operation instructions are not observed. Check the chimn...

Installation, operation and maintenance manual bisolid comfort om-bscv00/08/2012/en 40 supplier: address: city. Str. Tel.: fax.: http:// reserved rights for technical changes!.