- DL manuals

- Bumham

- Boiler

- RSA

- Installation, Operating And Service Instructions

Bumham RSA Installation, Operating And Service Instructions

1

Price - $3.00

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

RSA BOILERS

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide

Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number

Boiler Serial Number

Installation Date

_RSA _ _ _ _ _ _ _ _

6 _ _ _ _ _ _ _

Heating Contractor

Phone Number

Address

8143508R3-10/99

Summary of RSA

Page 1

1 price - $3.00 installation, operating and service instructions for rsa boilers for service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide boiler model number and serial number as shown on rating label. Boiler model number boiler serial number instal...

Page 2: Danger

2 the following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to important information concerning product life. Danger indicates an imminently ha zardous situation w hi ch, if not avoided, wil l re sult in death, serious inj ury or sub...

Page 3: Danger

3 danger do n ot store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. Warning improper installation, adjustment, alteration, servic e or mainte na nce can cause property damage, personal injury or loss of life. Failure to follow all instructions ...

Page 4: Warning

4 warning appliance materials of construction, products of combustion and the fuel contain alumina, silica, he av y me tals, carb on mon oxide, nit roge n oxides , a lde hyd es a nd/or oth er tox ic or harm ful substances which can cause death or serious injury and which are known to the state of ca...

Page 5

5 tables of contents i. Pre-installation ..................................... 7 ii. Knockdown boiler assembly ............... 9 iii. Water piping and trim ...................... 12 iv. Venting ............................................... 18 v. Electrical and sequence of operation 20 figure 1: rs...

Page 6

6 figure 1a: rsa packaged boiler (rsa170 / rsa285) boiler model num ber b are boiler a ssem bly m inim um chimney sizes water capacity gallons approx. S hi pping weight in. X in. X f t. (height) in. (dia.) x ft. (height) rs a170 wv-29-10 8 x 8 x 20 7" x 20' 42.6 600 lb. Rs a195 wv-29-13a 8 x 8 x 20 ...

Page 7

7 a . Inspect shipment carefully for any signs of damage. 1. All equipment is carefully manufactured, inspected and packed. Our responsibility ceases upon delivery of the crated boiler to the carrier in good condition. 2. Any claims for damage or shortage of shipment must filed immediately against t...

Page 8

8 c. Provide air supply and ventilation to accommodate proper combustion. If natural ventila- tion is inadequate, provide a screened opening or duct from the boiler room to the outside. The opening or duct must be sized so the boiler input will not exceed 4,000 btuh/sq. In. Of free area. If other ai...

Page 9

9 ii. Knock-down boiler assembly h. Installing the jacket 1. Before jacket can be secured to boiler assembly tankless heater coil or blank plate must be attached. Using rubber gasket and bolts provided secure heater coil or blank plate to boiler extension by inserting the bolts from the backside of ...

Page 10

10 figure 5: burner mounting 2. Bend jacket according to figure 6. Starting from the front, wrap the jacket around the boiler. Make sure that return pipe, observation port and shell extension fit proper into there corresponding clearance holes. Continue bending jacket around until front panels meet....

Page 11

11 figure 6: rsa jacket assembly.

Page 12: Warning

12 iii. Water piping and trim a. Design a piping system and install boiler which will prevent oxygen contamination of boiler water and frequent water additions. 1. There are many possible causes of oxygen contami- nation such as: a. Addition of excessive make-up water as a result of system leaks. B....

Page 13

13 figure 7: recommended piping for combination heating and cooling (refrigeration) system b . Install pressure relief valve. See figures 8 and 9. Pressure relief valve must be installed with spindle in the vertical position. Installation of the relief valve must be consistent with ansi/asme boiler ...

Page 14

14 figure 8: recommended boiler piping for circulator zoned heating systems.

Page 15

15 figure 9: boiler piping for zone valve zoned heating systems.

Page 16: Warning

16 2. Tempering of hot water — installation of an automatic mixing valve will lengthen the delivery of the available hot water by mixing some cold water with the hot. This prevents the possibil- ity of scalding hot water at the fixtures. In addition, savings of hot water will be achieved since the u...

Page 17

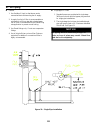

17 figure 11: schematic tankless heater piping table 1: tankless heater ratings boiler model std. #7524 opt. #7530 gpm psid gpm psid rsa170 3¾ 25½ 4 26½ rsa195, 240, & 285 4 29 4¼ 31 boiler model s350 s375 gpm psid gpm psid rsa(h)85 & 110 3 12 3½ 15 rsa110(h)125 & 135 3¼ 16 3¾ 25 rsa125 & 135 3½ 19.

Page 18

18 iv. Venting a . General guidelines. 1. Vent system installation must be in accordance with these instructions and applicable provisions of local building codes. Contact local building or fire officials about restrictions and installation inspec- tion in your area. 2. The rsa series is designed to...

Page 19

19 figure 12: recommended smokepipe arrangement and chimney requirements figure 13: draft regulator locations.

Page 20: Danger

20 a . General 1. Install wiring and electrically ground boiler in accordance with requirements of the authority having jurisdiction, or in absence of such require- ments the national electrical code, ansi/nfpa 70, and/or the csa c22.1 electric code. 2. A separate electrical circuit should be run fr...

Page 21

21 figure 14: “rsal” wiring less tankless, single circulator figure 15: “rsat” or “rsar” wiring with tankless, single circulator.

Page 22

22 figure 16: circulator zoned wiring for honeywell r8888.

Page 23

23 figure 17: zone valve zoned wiring for r8889.

Page 24: Notice

24 figure 18: different manufacturer’s zone valve connections to honeywell r8889 notice the h oneywell r888 9 control is ava ilable in two three (3) zone mode ls and two four (4) zone models. Burnha m recommends using m ode l r88 89a for three (3) zone sys tems and model r888 9b for four (4) z one s...

Page 25: Notice

25 notice the burnham ec50 00 control includes a water temperature sensor. Mount this sensor to the sys te m s uppl y piping. 8. Burnham ec5000 circulator zoned system – refer to figure 19 of this manual for the electrical diagram for this type of system. Wire the system as indicated in that diagram...

Page 26

26 figure 19: circulator zoning with ec5000 wiring schematic.

Page 27

27 figure 20: zone valve zoned with ec5000 wiring schematic.

Page 28: Notice

28 a . General. 1. Use flexible oil line(s) so that burner can be removed without disconnecting the oil supply. 2. A supply line fuel oil filter is recommended as a minimum for all firing rates but a pleated paper fuel oil filter is recommended for the lowest firing rate application to prevent nozzl...

Page 29

29 c . Two-pipe oil lines 1. For two-piped systems, where more lift is required, the two-stage fuel unit is recommended. Table 2 (single-stage) and table 3 (two-stage) show allowable lift and lengths of 3/8 inch and 1/2 inch od tubing for both suction and return lines. Refer to figure 22. Figure 22:...

Page 30

30 vii. System start-up a . Verify that the venting, water piping, oil piping, and electrical system are installed properly. Refer to installation instructions contained in this manual. B . Confirm all electrical, water and oil supplies are turned off at the source and that the vent is clear from ob...

Page 31

31 solid stream without air bubbles for approxi- mately 10 seconds. 3. Close vent fitting and burner flame should start immediately. 4. If the burner does not start immediately, check the manual overload switch on the motor, if so equipped, and the safety switch on the burner primary control. K. Adj...

Page 32

32 instrumentation to obtain a co 2 of 11.5 to 12.5% with draft of -.02” w.C. In fire box. These settings will assure a safe and efficient operating condition. If the flame appears stringy instead of a solid flame, try another nozzle of the same type. Flame should be solid and compact. After all adj...

Page 33: Notice

33 extreme case may become a fire hazard. D. Air leaks— any such leaks should be repaired, as they may cause erratic burning of the fuel and in extreme cases may become a fire hazard. There may be many possible causes of leaks in oil lines such as: i. Fitting leaks due to misflared tubing or damaged...

Page 34

34 a. Simulate flame failure: • follow the starting procedure to turn on the burner. • close the hand valve in the oil supply line. • safety switch should lock out in approxi- mately 15 seconds. Ignition should stop and oil valve should close. Blower will stop after postpurge period. • push red rese...

Page 35

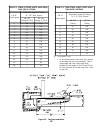

35 installation instructions for shield required for combustible floor this shield for combustible floors is intended for use only with the following burnham oil-fired boilers: use part number 6183504 for the following models: rsa(h)85 rsa(h)110 rsa(h)125 rsa(h)135 adds 4-3/16” to boiler height use ...

Page 36: Notice

36 viii. Service and cleaning a . General. Inspection service and cleaning should be conducted annually. Turn off electric power and close oil supply valve while conducting service or mainte- nance. B . Firetubes and combustion chamber. (see figure 25) notice b ur ner s h u td o wn : o p e n s e rv ...

Page 37

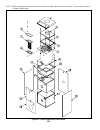

37 ix. Repair parts all rsa repair parts may be obtained through your local burnham wholesale distributor. Should you require assistance in locating a burnham distributor in your area, or have questions regarding the availability of burnham products or repair parts, please contact your burnham regio...

Page 38

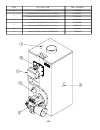

38 note: when ordering parts always give the serial number and model number shown on the boiler. Also provide the name of the part(s) shown below: figure 26: rsa85-135 bare boiler repair parts repair parts.

Page 39: 'A'

39 boiler model 'a' 'b' rsa85 12 603350112 rsa110 16 603350116 rsa125 12 603350212 rsa135 16 603350216 item no. Qty. Description part no. 1 2 wing nut, 1/4 - 20 80860910 2 10 washer, flat 1/4 (sae) 80860633 3 1 canopy assembly 6113509 4 2 1/2" thick x 1" x 12-3/8" cerafelt strip 9206005 5 2 1/2" thi...

Page 40

40 figure 27: rsa170-285 boiler repair parts note: when ordering parts always give the serial number and model number shown on the boiler. Also provide the name of the part(s) shown below:.

Page 41: 'A'

41 boiler model 'a' 'b' rsa170 10 6306332 rsa195 13 6306329 rsa240 16 6306309 rsa285 19 6306310 item no. Description part no. 1 jacket top panel assem bly 60435022 2 canopy assem bly 6113510 3 ½" thick x 1" x 23" c er afelt s trip 9206005 4 ½" thick x 1" x 17" c er afelt s trip 9206005 5 turbulator,...

Page 42

42 item description part number 1 jacket top panel 60435086 2 jacket wrap-a-round panel, rsa85/110 60435087 jacket wrap-a-round p anel, rsa125/135 60435088 3 temperature / p ressure g auge 8056169u 4 honeywel l l8148a1090 hi-limi t control 80160449u honeywell l8124c1102 limi t control 80160406 5 o b...

Page 43

43 service schedule date service performed.

Page 44

44 beckett burner parts list for rsa series steel boilers for replacement oil burner parts, contact your wholesaler or the burner manufacturer: r. W. Beckett corp. 38251 center ridge rd. P. O. Box 1289 elyria, ohio 44036 1-800-645-2876 note: when ordering parts always give the serial and model numbe...

Page 45

45 ordering information for quality replacement parts figure 29: beckett afg model burner.

Page 46

46 beckett burner parts list for rsa series steel boilers for replacement oil burner parts, contact your wholesaler or the burner manu- facturer: r. W. Beckett corp. 38251 center ridge rd. P. O. Box 1289 elyria, ohio 44036 1-800-645-2876 boiler model rsa170 rsa195 rsa240/285 burner model af af af ai...

Page 47

47 ordering information for quality replacement parts figure 30: beckett af and sf model burners.

Page 48

48.