- DL manuals

- Bunn

- Coffee Maker

- AutoPOD My Cafe AP

- Service & Repair Manual

Bunn AutoPOD My Cafe AP Service & Repair Manual

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

41169.0000A 06/12 ©2012 Bunn-O-Matic Corporation

My Café

®

AP

Summary of AutoPOD My Cafe AP

Page 1

Service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating manual, or to view the illustrated parts catalog, programming manual, or service manual, please vis...

Page 2

Page 2 41169 030912 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) airpots, thermal carafes, decanters, gpr servers, iced tea/coffee dispensers, mcp/mca pod brewers thermal servers and thermofresh servers (mechanical and digi...

Page 3

Page 3 41169 120711 contents warranty............................................................................................... 2 contents .............................................................................................. 3 troubleshooting ..............................................

Page 4

Page 4 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 5

Page 5 "fill time too long" refill does not shut off power "on" refill does not shut off power "off" probable cause remedy problem 1. Water shut off 2. Debris blocking inlet. 3. Water pressure below 20psi. 4. No voltage to solenoid valve. 5. Solenoid valve defective. 1. Lime build up on probe. 2. Wa...

Page 6

Page 6 heating circuit 1. Cba senses open or short circuit. 1. Limit thermostat or tco open. 2. Tank heater defective. 3. No voltage to tank heater. 1. Lime build up on temperature probe, tank or tank heater 2. Temperature probe 3. Control board 1. Plumbing lines 2. Water supply 3. Lime build up che...

Page 7

Page 7 troubleshooting (cont.) problem probable cause remedy brewing circuit brew cycle will not start consistently low beverage level in the dispenser or beverage overflows dispenser. Brew volume incorrect or incon- sistent. "no flow counts during brew" no pulses from flow meter. 1. Displays error ...

Page 8

Page 8 41169 120711 "water pump fault check water pump" water does not drop below level probe for 90 seconds during brew cycle. Weak beverage troubleshooting (cont.) problem probable cause remedy brewing circuit (cont.) 1. Sprayhead blockage. 2. Tubing between tank and spray- head blocked/limed up. ...

Page 9

Page 9 41169 120711 troubleshooting (cont.) problem probable cause remedy miscellaneous "index motor fault" cba has sensed that motor as- sembly has not rotated timing disk within 15 seconds. "replace seal soon/now!!!" counter set for 25000 brews. Early models were set at 5000. "path clear? Any swit...

Page 10

Page 10 component access this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal...

Page 11

Page 11 location: the control board is located inside the back cover. Test procedures: the test procedures for the control board will vary depending upon the problem. Refer to the troubleshooting section which is divided into three sections, refill circuit, heating circuit, and brewing circuit. Chec...

Page 12

Page 12 fig. 12-3 inlet valve - autopod fig. 12-4 inlet valve - mycafé ap location: the inlet valve is located inside the back cover. Test procedures: 1. Refer to the programing section for service tools/ test outputs/inlet valve. 2. Be sure container is placed on drip tray before activating valve. ...

Page 13

Page 13 fig. 13-1 limit thermostat - mycafé ap location: the tanks are located inside the back access panel. Note: autopod tanks are not serviceable. Tank heaters test procedures: 1. With a voltmeter, check voltage across the white wire (120v models) or red wire (120/208-240v models) from the termin...

Page 14

Page 14 location: the temperature probe is inserted through the tank lid assembly. Test procedures: 1. Disconnect the brewer from the power source. 2. With a dc voltmeter, check voltage across the two wires at j9 on control board (black probe to black wire, red probe to white wire. Refer to fig 18-2...

Page 15

Page 15 location: the vent valve is located inside the back access panel. Function: the vent valve closes (activates) only during hot water dispense to pressurize tank. Test procedures: 1. With a voltmeter, check voltage across the termi- nals of the vent valve. Activate valve in the "test outputs" ...

Page 16

Page 16 location: the air pumps are located inside the back access panel. Function: a: blows moisture out of pod after brewing, before being ejected. B: pressurizes tank during hot water dispense in conjunction with air vent valve. Test procedures: 1. Disconnect the brewer from the power source. 2. ...

Page 17

Page 17 location: the vent valve is located inside the back access panel. Function: the water pump (boost)on autopod pressurizes the brew tank during brew cycle. The water pump on my- cafe ap pressurizes the sprayhead during brew cycle. Test procedures: 1. With a voltmeter, check voltage across the ...

Page 18

Page 18 fig. 18-1 flow meter - mycafé ap flow meter fig. 18-2 flow meter - autopod location: mycafe-ap: below main cba. Autopod: behind main cba. Function: a: monitors incoming water flow rate (counts pulses). Test procedures: 1. Place container under brew chamber. 2. In "service tools" select "test...

Page 19

Page 19 location: the index motor & sensor are located on the ejector assembly. Fig 18-1. Function: a: motor drives the pod holder from brew position to open position to dump position. B: photosensor detects position of pod holder by reading slots in motor disk. Test procedures: 1. Go to "test index...

Page 20

Page 20 fig 19-2b home position index b motor dump next load 19-3b dump position index d motor dump next load fig 19-2a unblocked fig 19-3ablocked ejector assembly index l motor dump next load fig 19-1b load position fig 19-1a unblocked continued 41169 120711.

Page 21

Page 21 ejector assembly: removal and replacement: autopod & mycafé-ap 1. Unplug brewer. 2. Remove drip tray and bin assemblies. 3. Remove top cover and rear panel. 4. Pull out on bottom of door bezel. Slide bezel up and off of door. Fig 20-1. 5. Remove 2 clamps and hoses from sprayhead as- sembly. ...

Page 22

Page 22 ejector assembly index motor assembly: removal and replacement: mycafé-ap only 1. Press "open/close" button to open pod door. If you can not operate motor assembly, then manu- ally move pod holder assembly out to the load position. 2. Unplug brewer. 3. Remove top cover. 4. Loosen top allen s...

Page 23

Page 23 installation: 1. Connect motor and sensor harness to the new motor assembly. 2. Connect brewer to power source. Press "open/ close" button to open pod door. (or use the "test outputs" to move it to "load position"). 3. Unplug brewer. 4. Verify motor assembly is in the open/load po- sition. F...

Page 24

Page 24 check valve replacement: all models 1. Connect brewer to power source. Use the “test outputs/test index motor” to move it to “dump position”. 2. Unplug brewer. 3. Remove sprayhead/seal assembly: autopod: unscrew sprayhead/seal assembly. My café ap: remove top cover. Remove thumb- screw. Fig ...

Page 25

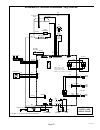

Page 25 schematic wiring diagram - my café ap grn chassis ground earth ground blk wht blk wht power cord brew pump fill solenoid flow meter yel blk red whi/gry whi/orn whi/vio (sig) (gnd) (+12v) (sig) (gnd) (+12v) red brn yel yel whi blu/blk heater j7 j4 index sensor j3 j11 j1 1 1 j2 1 1 4 j6 3 2 1 ...

Page 26

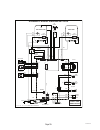

Page 26 schematic wiring diagram autopod grn chassis ground earth ground blk wht blk wht power cord hw brew flow meter yel blk red whi/gry whi/orn whi/vio (sig) (gnd) (+12v) (sig) (gnd) (+12v) vio vio red brn whi blu/blk heater j7 j4 index sensor pressure sw nc no c j3 j11 j1 1 1 j2 1 1 4 j6 3 2 1 4...

Page 27

Page 27 schematic wiring diagram autopod grn/yel chassis ground brn blu hw brew flow meter yel blk red whi/gry whi/orn whi/vio (sig) (gnd) (+12v) (sig) (gnd) (+12v) vio vio red brn whi blu/blk heater j7 j4 index sensor pressure sw nc no c j3 j11 j1 1 1 j2 1 1 4 j6 3 2 1 4 3 2 1 grn blk whi red displ...