- DL manuals

- Bunn

- Coffee Maker

- AXIOM 0/6 Twin

- Installation & Operating Manual

Bunn AXIOM 0/6 Twin Installation & Operating Manual

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

39130.0000C 05/07 ©2006 Bunn-O-Matic Corporation

www.bunn.com

To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE,

and the quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper

copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

Summary of AXIOM 0/6 Twin

Page 1

Installation & operating manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 39130.0000c 05/07 ©2006 bunn-o-matic corporation www.Bunn.Com to obtain the illustrated parts catalog, visit the bunn-o-matic website, at www.Bunn....

Page 2

Page 2 introduction this equipment will brew a 1 ⁄ 2 gallon batch of coffee into an awaiting decanter. The brewer may have a hot water faucet for allied beverage use. It is only for indoor use on a sturdy counter or shelf. Contents introduction & warranty ...............................................

Page 3

Page 3 #00658.0000 #37881.0000 39130 053107 #00986.0000 user notices carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be kept in good condition. Replace any unreadable or damaged labels. To reduce the risk of electric shock, do not remove ...

Page 4

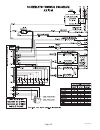

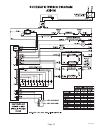

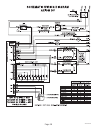

Page 4 electrical hook-up (all models) caution – improper electrical installation will damage electronic components. 1. An electrician must provide electrical service. 2. Determine the available on-site electrical service. 3. Select the desired unit voltage based on the available on-site electrical ...

Page 5

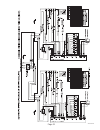

Page 5 39130 053107 electrical requirements 120v ac single phase models note: this electrical service re- quires 2 current carrying conduc- tors (neutral, and l1) and a separate conductor for earth ground. N l1 g l2 red l2 red white green green neutral l1 black white neutral l2 l1 black 120v. 120v. ...

Page 6

Page 6 -1000 213.8 101.0 200 93.3 -500 212.9 100.5 200 93.3 0 212.0 100.0 200 93.3 500 211.1 99.5 200 93.3 1000 210.2 99.0 200 93.3 1500 209.3 98.5 200 93.3 2000 208.4 98.0 200 93.3 2500 207.4 97.4 200 93.3 3000 206.5 96.9 199 92.8 3500 205.6 96.4 198 92.2 4000 204.7 95.9 197 91.7 4500 203.8 95.4 19...

Page 7

Page 7 operating controls (a) enable brew on/off switch pressing the "enable brew on/off" switch (indicator on) supplies power to the brew station warmer, enables the brew circuit, and energizes the tank refi ll circuit. Pressing the switch again (indicator off) stops tank refi lling and brewing and...

Page 8

Page 8 cleaning 1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all surfaces on bunn-o-matic equipment. 2. Check and clean the sprayhead. The sprayhead holes must always remain open. Insert the short end of the sprayhead cleaning tool into eac...

Page 9: Bunn

Page 9 rear front warmers bunn ® warmer ™ adjustments & optional settings p3633-2 39130 053006 ready to brew water temp: 200° 1 3 2 using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various brewing parameters such as brew lockout, brew volume, ...

Page 10

Page 10 39130 053107 adjustments & optional settings (cont.) brew meter 1 - + set ready: 195° (-) done (+) set temp: 200° (-) done (+) enter password 0 0 0 exiting brew wizard brew lockout ? No done yes programming functions - flow chart (cont.) brew wizard enter service #? No yes units metric done ...

Page 11

Page 11 enabl energysavr no done yes drip t i m e 0:30 (-) done (+) brew counters ? No yes calibrate flow ? No yes spray oz/m: 25.0 (-) done (+) enable brewlogic no done yes 0 refill 155 (-) done (+) enabl warmer off no done yes enablefreshtimer no done yes enable clean no done yes set pulse brew ? ...

Page 12: Brew Lockout?

Page 12 adjustments & optional settings (cont.) 39130 053107 main screen brew lockout this function allows the operator to prevent or allow brewing if the water temperature is less than the set ready temperature. To access this function screen press and hold the right hidden switch. Release when the...

Page 13

Page 13 - + this function allows the operator to adjust the brew volume. Procedure: 1. Press and hold the right hidden switch until the display reads "brew wizard" and release. 2. The display will then read: "brew oz: xx.X" 3. Press (-) "digital" to decrease the amount, or (+) "control" to increase....

Page 14

Page 14 adjustments & optional settings (cont.) enable ads this function allows the operator to choose wheth- er or not to display an advertising message. An ad can be saved to the brewer by writing the ad using the programming commands. This message will be displayed when the brewer is idle. Proced...

Page 15

Page 15 new ad ? No yes write top line ? No yes 2 lines 16 chars available enable ads ? No done yes scrol thru alpha next next letter a scroll done next write btm line ? No yes save ? No edit yes advertisement setup complete adjustments & optional settings (cont.) enter service #? Enter service #? A...

Page 16

Page 16 service number this function allows the operator to enter in the telephone number to call if service is needed. The service number will be displayed anytime there is a fault message displayed. Procedure to enter the service number: 1. Press and hold the right hidden switch until the display ...

Page 17

Page 17 note: access to the remaining functions in level 2 is intended for trained service personnel only. More in depth information can be found in the axiom service manual 39132.0000 programming functions - level 2 (cont.) enter asset # ? No yes set ready: 195° (-) done (+) set temp: 200° (-) done...

Page 18

Page 18 "easy pulse brew" times: min: base brew time + 40 seconds max: base brew time + 3:00 minutes drip time 0:30 (-) done (+) 0 refill 155 (-) done (+) enable clean no done yes set pulse brew ? No yes programming functions - level 2 (cont.) adjustments & optional settings (cont.) this function al...

Page 19

Page 19 too hot-will cool tank now accuracy risk!!! Ok cal. Calibrate now? No yes place brewer in final location enable brewlogic no done yes programming functions - level 2 (cont.) adjustments & optional settings (cont.) the brewlogic system allows the brewer to be calibrated to high mineral locati...

Page 20

Page 20 39130 053107 spray oz/m: xx.X lp1-lp2 oz xx.X enter oz xx.X (-) done (+) waitingtilcycle 4 cycle x complete calibrate spray press brew start container ready? Quit yes programming functions - level 2 (cont.) when the dispensing fi nishes, empty the decanter/server and place back under brew fu...

Page 21

Page 21 factory defaults no yes service tools ? No yes brew counters ? No yes calibrate flow ? No yes spray oz/m: 25.0 (-) done (+) programming functions - level 2 (cont.) view or enter the actual fl ow rate coming out of the sprayhead. This is used to tell the internal controller how fast the water...

Page 22

Page 22 probable cause remedy problem troubleshooting temperature too low heating time too long fill time too long temp sensor out of range, check for bad connections temp sensor out of range, check wire for shorts equipment will not operate water fl ows into tank continu- ously with power removed f...

Page 23

Page 23 probable cause remedy problem troubleshooting (cont.) check plumbing and shut-off valves a) wait for the brewer to heat to the proper temperature b) disable the brew lock- out function. See page 12 for procedure turn on service required service required service required 1. No water 2. Water ...

Page 24

Page 24 probable cause remedy problem troubleshooting (cont.) weak beverage. Bunn paper fi lters should be used for proper extraction for coffee, a suffi cient quantity of fresh drip or regular grind should be used for proper ex- traction. A bunn sprayhead should be used to properly wet the bed of g...

Page 25

Page 25 probable cause remedy problem troubleshooting (cont.) brewer is making unusual noises. Service required plumbing lines should not be resting on the countertop. The brewer must be connected to a cold water line. Water pres- sure to the brewer must not be higher than 90 psi (620 kpa). Install ...

Page 26

Page 26 39130 053107.

Page 27

Page 27 39130 053107.

Page 28

Page 28 39130 053107.

Page 29

Page 29 39130 053107.

Page 30

Page 30 39130 053107.

Page 31

Page 31 39130 053107.