- DL manuals

- Bunn

- Coffee Maker

- BrewWise DBC

- Service Manual

Bunn BrewWise DBC Service Manual

Summary of BrewWise DBC

Page 1

With smart funnel ® service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 41746.0000d 04/10 ©2008 bunn-o-matic corporation brewwise ® dbc ® brewers.

Page 2

Page 2 41746 041410 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) comp...

Page 3

Page 3 table of contents warranty .....................................................................................................................................2 table of contents ....................................................................................................................

Page 4

Page 4 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 5

Page 5 troubleshooting (cont.) screen displayed possible cause troubleshooting procedures no funnel present temperature too low 1. Smart funnel not fully inserted into the funnel rails. 2. Not using a smart funnel, and the funnel detect function is activated (on). 1. Water temperature in the tank do...

Page 6

Page 6 troubleshooting (cont.) troubleshooting procedures possible cause screen displayed to cancel press on/off to finish: press brew brew stopped! Server removed? 1. Soft heat server was moved out of position after the brew cycle was started. 1. On/off switch was pressed after the brew cycle was s...

Page 7

Page 7 troubleshooting (cont.) troubleshooting procedures possible cause screen displayed check water supply fill time too long 1. Water shut off to brewer 2. Inlet solenoid valve failure 3. Control board failure 1. Temperature sensor probe wire(s) broken or not making connection. 1. Temperature sen...

Page 8

Page 8 equipment will not operate. Brew cycle will not start. Automatic refill will not operate or display shows fill time too long 1. No power or incorrect voltage. 1. No water 2. On/off switch 3. Brew switch 4. Brew valve 5. Electronic control board 1. No water 2. Water strainer/flow control (.750...

Page 9

Page 9 troubleshooting procedure troubleshooting (cont.) problem possible cause automatic refill will not operate or display shows fill time too long (cont.) water flows into tank continuously with power removed from brewer. 3. Refill probe or sensitivity set- ting 4. Refill valve 5. Overflow protec...

Page 10

Page 10 troubleshooting (cont.) possible cause troubleshooting procedures check the sensitivity setting. Refer to refill function. If the left three digit number is less than the right number, the machine “thinks” it is full and the refill valve should be off. If the left number is larger than the r...

Page 11

Page 11 troubleshooting (cont.) problem possible cause troubleshooting procedures remove power from the brewer. Connect a voltmeter across one of the tank heaters. Reapply power to the brewer and refer to testing individual components. If the full supply voltage is measured when the tank heater is t...

Page 12

Page 12 troubleshooting (cont.) problem possible cause troubleshooting procedures 3. Electronic control board 1. Strainer/flow control (.750 gpm) 2. Improper water pressure 3. Brew valve 4. Bypass valve 5. Lime buildup perform the previous procedure for testing triacs. If the voltage measured is ver...

Page 13

Page 13 troubleshooting (cont.) problem possible cause troubleshooting procedures adjust the brew volume as required to achieve the recommended volume for each brew cycle. Repair or replace leaky valve. Bunn paper filters should be used for proper extraction. Check sprayhead the brew cycle should be...

Page 14

Page 14 troubleshooting (cont.) problem possible cause troubleshooting procedures weak beverage (cont.) brewer is making unusual noises. 6. Incorrect recipe 1. Solenoid (inlet) 2. Plumbing lines 3. Water supply 4. Tank heaters. Consider adjusting bypass percent- age, preinfusion, or pulse brew. Cont...

Page 15

Page 15 service tools this function allows the testing of individual com- ponents and the ability to check switches for proper function. This function also tests the soft heat server's status on the brewer (in place or removed), and the funnel sensor coil's frequency (diagnostic tool for troubleshoo...

Page 16

Page 16 test outputs? No yes service tools? No yes left brew valve on next off left bypass on next off left funnel lock on next off right brew valve on next off right bypass on next off right funel lock on next off refill valve on next off tank heatrs on next off heater contactor on next off brew va...

Page 17

Page 17 service tools (cont.) note: the tank heater will automatically turn off if left on too long. 26. After testing the tank heater, press next to advance to the next test. 27. The heater contactor is used only on certain models. Check the machine schematic to see if the contactor is present. Con...

Page 18

Page 18 service tools (cont.) 3. Press and hold the upper right hidden switch until the display reads units. Release the switch. Continue pressing and releasing the upper right hidden switch until service tools appears. 4. Pressing no will exit this function and advance to the next function screen. ...

Page 19

Page 19 component access this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal...

Page 20

Page 20 location: the membrane switch (fig 2) is located on the front of the hood with a ribbon cable extending through the hood and connected to the control board. Test procedures: there are two methods for testing the membrane switch. The easiest method is to use the built in test mode. Refer to t...

Page 21

Page 21 location: the dispense and bypass valve(s) (fig 3) are located inside the hood under the top cover. Test procedures: 1. Refer to the trouble shooting section for service tools/test outputs/dispense/bypass valve. 2. Be sure brew funnel & server are in place before activating valve. 3. Check t...

Page 22

Page 22 fig 6 refill valve (dual tf dbc early models) component access (cont) refill valve fig 7 refill valve (dual tf dbc late models) fig 4 refill valve (dual sh dbc models) fig 5 refill valve (single sh dbc models) 41746 112008.

Page 23

Page 23 location: dual sh dbc models: single tf dbc late models: dual tf dbc late models: the refill valve is located inside the front of the brewer behind the front access panel. Single sh dbc models: single gpr dbc models: single tf dbc early models: dual gpr dbc models: dual tf dbc early models: ...

Page 24

Page 24 component access (cont) tank heaters location: the tank heaters (fig 9) are located inside the tank, secured to the tank lid. Test procedures: 1. With a voltmeter, check voltage across the white wire (120v models) or red wire (120/208 and 120/240v models) and blue wire on the top of the tank...

Page 25

Page 25 component access (cont) temperature probe location: the limit thermostats (fig 11) are located under the top cover on the tank lid assembly. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the wires from the limit thermostat. 3. With an ohmmeter, check for cont...

Page 26

Page 26 fig 13 master power switch location: the main power switch (fig 13) is located un- der the brewer in the base just behind the right front leg on sh and gpr models and behind the front support leg on tf models. Test procedure: 1. Disconnect the brewer from the power source. 2. Disconnect the ...

Page 27

Page 27 component access (cont) master power switch (cont) 41746 040210 sh server timer setting timer may be set to the off position as shown on tag (fig 15) to prevent the led on the front of the server from flashing, or one of nine various set- tings to flash the led after timer has expired. For i...

Page 28

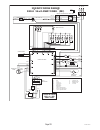

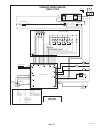

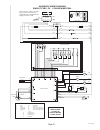

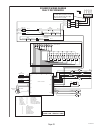

Page 28 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi whi whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – whi blk blu/blk blk blu/blk red 120/208 or 120/240 volt a.C. + gnd single ph...

Page 29

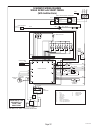

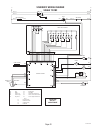

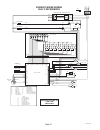

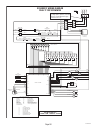

Page 29 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – blk blu/blk blk blu/blk red 230 volt ac 2 wire single phase 50hz 32043.0001b 07/05 © 200...

Page 30

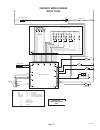

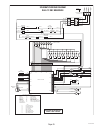

Page 30 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – blk blu/blk blk blu/blk red 200 volt ac 2 wire single phase 50/60hz 32043.0002b 07/05 © ...

Page 31

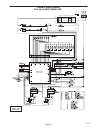

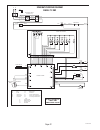

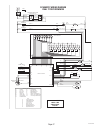

Page 31 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi-14 whi whi whi whi w h i l1 n mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – whi blk blu/blk blk blu/blk red 120 volt a.C. 2 - wire sin...

Page 32

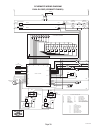

Page 32 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi whi whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – whi blk blu/blk blk blu/blk red 32043.0005b 02/07 ©2006 bunn-o-matic corpora...

Page 33

Page 33 limit thermostat triac tank heater sol sol sol sol brew bypass refill whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) + – ac ac rectifier 4 amp 24vdc + – blk blu/blk blk blu/blk red 200 volt ac 2 wire + gnd single phase 50/60hz 32043.0006c 06...

Page 34

Page 34 white strip-tac plus black ink finished size: 8.5" x 11.0" ~77% reduction 29876.0000d 01/07 © 2001 bunn-o-matic corporation 120/208 or 120/240 volt a.C. + gnd single phase grn n l1 blk-14 red-14 red-14 red-14 red-14 red-14 blk-14 blk-14 models with main on/off switch only whi whi l2 red blk ...

Page 35

Page 35 red red red red 29876.0001a 08/02 © 2002 bunn-o-matic corporation 230 volts ac 2 wire single phase 50hz thermal safety fuse thermal safety fuse thermal safety fuse thermal safety fuse red red resettable fuse schematic wiring diagram dual sh dbc (w/smart funnel) right tank heater left tank he...

Page 36

Page 36 red red red red 29876.0003a 06/04 © 2004 bunn-o-matic corporation thermal safety fuse thermal safety fuse thermal safety fuse thermal safety fuse red red resettable fuse schematic wiring diagram dual sh dbc (w/smart funnel) right tank heater left tank heater triac triac temp probe blk blk bl...

Page 37

Page 37 limit thermostat triac tank heater #1 sol sol sol sol brew bypass refill whi whi whi whi mt 1 blu -14 blk-14 blk-14 red n.C. Red overflow protection switch funnel lock (optional) 120 volt a.C. + gnd or 120/208-240 volt a.C. + gnd single phase 32043.0003c 01/07 © 2004 bunn-o-matic corporation...

Page 38

Page 38 schematic wiring diagram dual gpr with smart funnel (dbc) grn blk pnk whi temp probe j2-1 j9-1 j11-1 j11-5 j11-10 j11-18 j9-5 j2-10 j2-5 control pc board j4-1 j4-5 j4-10 j4-15 j4-19 29876.0004b 01/07 © 2004 bunn-o-matic corporation 120/208 or 120/240 volt a.C. + gnd single phase whi/vio whi/...

Page 39

Page 39 35726.0000b 02/07 © 2003 bunn-o-matic corporation 120/208 or 120/240 volt a.C. 3 wire + gnd single phase schematic wiring diagram single tf dbc funnel lock sol brew bypass refill whi whi whi vio gry whi/grn brn/whi brn/blk tan yel blk whi tank heater triac mt 1 blu-14 blk-14 blk-14 mt2 limit...

Page 40

Page 40 36883.0000a 05/04 © 2004 bunn-o-matic corporation 230 or 200 volt a.C. Single phase schematic wiring diagram single tf dbc funnel lock sol sol sol sol brew bypass refill red red red vio gry whi/grn brn/whi brn/blk tan yel blk red l2 tank heater triac mt 1 blu-14 red-14 blk-14 blk-14 red-14 b...

Page 41

Page 41 36883.0002a 11/04 © 2004 bunn-o-matic corporation 120 volt a.C. 2 wire single phase 60hz schematic wiring diagram single tf dbc funnel lock sol sol sol sol brew bypass refill whi whi whi vio gry whi/grn brn/whi brn/blk tan yel blk whi n tank heater triac mt 1 blu-14 whi-14 blk-14 blk-14 mt2 ...

Page 42

Page 42 36883.0001b 02/07 © 2004 bunn-o-matic corporation 200,208 or 240 volt a.C. 2 wire + gnd single phase 50/60hz schematic wiring diagram single tf dbc funnel lock sol brew bypass refill red red red vio gry whi/grn brn/whi brn/blk tan yel blk red tank heater triac mt 1 blu-14 red-14 blk-14 blk-1...

Page 43

Page 43 36883.0003a 02/07 © 2007 bunn-o-matic corporation funnel lock sol sol sol sol brew bypass refill red red red vio red/blk gry whi/grn brn/whi brn/blk yel blk red funnel sensor whi/vio vio whi pnk blk grn temp probe water level probe red red n.C. Overflow protection switch control pc board swi...

Page 44

Page 44 34916.0000b 02/07 © 2002 bunn-o-matic corporation 120/208 or 120/240 volt a.C. 3 wire + gnd single phase schematic wiring diagram dual tf dbc brewwise white strip-tac plus black ink finished size: 8.0" x 9.5" ≈76% reduction right tank heater left tank heater switch unit assy c5 c4 c6 whi ref...

Page 45

Page 45 blk-14 grn/yel l2 l1 blu-14 blu-14 blk-14 red-14 red-14 red-14 blu-14 main on/off switch (late models only) blk-14 blu l3 red blk 34916.0001e 06/09 © 2002 bunn-o-matic corporation 120/208 or 120/240 volt a.C. 4 wire + gnd 3-phase schematic wiring diagram dual tf dbc brewwise contactor whi wh...

Page 46

Page 46 34839.0000b 10/05 © 2003 bunn-o-matic corporation 200/230 volt a.C. 2 wire single phase schematic wiring diagram dual tf dbc brewwise right limit thermostat (1/2) left limit thermostat (1/2) right limit thermostat (1/2) left limit thermostat (1/2) red red-14 red-14 red red red red red red l2...

Page 47

Page 47 34839.0002d 02/07 © 2004 bunn-o-matic corporation 200,208 or 240 volt a.C. 2 wire + gnd single phase 50/60 hz schematic wiring diagram dual tf dbc brewwise limit thermostat limit thermostat red red red red red red-14 red-14 blk-14 blk-14 blk-14 blk-14 l2 l1 l4 l5 l6 l7 l8 l3 right mt1 blu-14...

Page 48

Page 48 34839.0003c 09/06 © 2005 bunn-o-matic corporation 400-415 volt a.C. Phase to phase, 230 volts ac phase to neutral 3 phase 50/60 hz red red red red red red red l2 l1 l4 l5 l6 l7 l8 l3 switch unit assy c6 c5 c4 a4 b2 a3 b1 a2 d3 a1 d2 c3 d1 c2 c1 shield 1 left funnel sensor right funnel sensor...

Page 49

Page 49 blk-14 grn/yel l2 l1 blu-14 blu-14 blk-14 red-14 red-14 red-14 blu-14 blk-14 blu l3 red blk 34916.0003a 02/10 © 2010 bunn-o-matic corporation 120/208 or 120/240 volt a.C. 4 wire + gnd 3-phase or 1-phase schematic wiring diagram dual tf dbc brewwise contactor whi whi whi whi whi whi k left li...

Page 50

Page 50 blk-14 grn/yel l2 l1 blu-14 blu-14 blk-14 red-14 red-14 red-14 blu-14 blk-14 blu l3 red blk 34916.0004b 03/10 © 2010 bunn-o-matic corporation 208 or 240 volt a.C. 3 wire + gnd 3-phase or 1-phase schematic wiring diagram dual tf dbc brewwise contactor whi whi whi whi whi whi k left limit ther...