- DL manuals

- Bunn

- Coffee Maker

- CDBC-DV

- Operating & Service Manual

Bunn CDBC-DV Operating & Service Manual

OPERATING & SERVICE MANUAL

CDBC-DV, CDBCF-DV

CDBC-DV, CDBCF APS-DV

CDBCF LPTC-DV

CDBC-MV, CDBCF-MV

CDBC-MV, CDBCF APS-MV

B

U

N

N

MA

NU

FA

CT

UR

ED

B

Y

BU

NN

-O

-M

AT

IC

C

OR

PO

RA

TIO

N

S

PR

IN

GF

IE

LD

, IL

LIN

OI

S,

U

.S

.A

.

MO

DE

L

S/

N

VO

LT

S

A

.C

.

A

MP

W

AT

TS

PH

AS

E

W

IR

E

HE

RT

Z

CO

VE

RE

D

UN

DE

R

ON

E

OR

M

OR

EO

F T

HE

FO

LL

OW

IN

G

PA

TE

NT

S

:

ON

E

OR

M

OR

E

OT

HE

R

PA

TE

NT

S

MA

Y

BE

P

EN

DI

NG

CA

UT

IO

N :

W

ARM

ER

S AN

D S

UR

FA

CE

S A

RE H

OT

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

29707.0000G 08/03 ©1999 Bunn-O-Matic Corporation

www.bunnomatic.com

Summary of CDBC-DV

Page 1

Operating & service manual cdbc-dv, cdbcf-dv cdbc-dv, cdbcf aps-dv cdbcf lptc-dv cdbc-mv, cdbcf-mv cdbc-mv, cdbcf aps-mv b u n n ma nu fa ct ur ed b y bu nn -o -m at ic c or po ra tio n s pr in gf ie ld , il lin oi s, u .S .A . Mo de l s/ n vo lt s a .C . A mp w at ts ph as e w ir e he rt z co ve re...

Page 2

Page 2 introduction this equipment will brew a half-gallon batch of coffee into an awaiting dispenser. It can be easily configured for 120v 15 amp, 120v 20 amp (mv models only), 120/208v 20 amp or 120/240v 20 amp. The brewer may have a hot water faucet for allied beverage use. It is only for indoor ...

Page 3

Page 3 #00658.0000 #00831.0000 #29710.0000 (mv models only) three warmer brewers optional field wiring 120 v, 17.0 a, 2050 w 1ph, 2-wire, 60hz or 120/208-240 v, 13.6-15.3 a, 2640-3430 w 1ph, 3-wire, 60hz #29710.0002 (mv models only) two warmer brewers optional field wiring 120 v, 18.0 a, 2150 w 1ph,...

Page 4

Page 4 user notices (cont.) #29710.0005 (dv models only) cdbcf-dv brewers optional field wiring 120 v, 15.0 a, 1800 w 1ph, 2-wire, 60hz optional field wiring 120/208-240 v, 15.6-17.5 a, 2980-3850 w 1ph, 3-wire, 60hz optional field wiring 120/208-240 v, 13.0-15.0 a, 2680-3550 w 1ph, 3-wire, 60hz #297...

Page 5

Page 5 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Requires 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. 1425w version 3180w version requires 3-wire, grounded service rated 120/240 volts ac, 2...

Page 6

Page 6 29707 112801 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Requires 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. Requires 2-wire, grounded service rated 120 volts ac, 20 amp, single phase...

Page 7

Page 7 initial set-up 1. Insert an empty funnel into the funnel rails. 2. Place a decanter with a small amount of water under the funnel. 3. Connect the brewer to the power source. 4. Press the "on/off" switch (indicator glowing). 5. Water will flow into the tank and stop when the tank is filled to ...

Page 8

Page 8 operating controls on/off switch pressing the "on/off" switch (indicator glowing) supplies power to the brew station warmer, enables the brew circuit, and energizes the tank refill circuit. Pressing the switch again (indicator not glowing) stops tank refilling and brewing and de-energizes the...

Page 9

Page 9 adjustments & optional settings hidden switch setting brew temperature the brewer is factory set to brew at 200 ° f (95 ° c). To change this setting, press and hold the "hidden" switch beneath the "®". The word "temp" above the "on/off" switch will glow to correspond with the temporary functi...

Page 10

Page 10 3. Press and hold the brew start button until you hear the brew solenoid click on-and-off three times (approximately 5 seconds). Release the button. 4. Allow the cycle to continue until the desired amount of water is dispensed and then turn "off" the brewer. The brewer is now set to dispense...

Page 11

Page 11 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of...

Page 12

Page 12 will not fill or refill probable cause remedy problem 1. Power off to brewer 2. Water shut off 3. Display flashing 4. On/off switch 5. Lime build up on probe 6. Refill valve or control board press warmer switches on control panel to determine if power is on. Make sure water is on. Brewer has...

Page 13

Page 13 troubleshooting (cont.) fill or refill does not shut "off" (on/ off switch "on") fill or refill does not shut "off" (on/ off switch "off") probable cause remedy problem 1. Lime build up on probe 2. Water level probe sensing sys- tem 3. Refill valve or control board 1. Refill valve or control...

Page 14

Page 14 troubleshooting (cont.) problem probable cause remedy heating circuit 1. Display flashing 2. Water not touching temperature probe 3. Water level probe sensing sys- tem 4. Temperature probe 5. Limit thermostat brewer has shut down due to mal- function (see diagnostic chart in manual, page 20,...

Page 15

Page 15 troubleshooting (cont.) problem probable cause remedy water does not heat to proper tem- perature (cont.) important: make sure no tem- perature tests are taken before the ready light is "on". Tank tempera- ture must be stabilized before read- ings are taken. 6. Tank heater 7. Fuse holder & f...

Page 16

Page 16 troubleshooting (cont.) problem probable cause remedy spitting or excessive steaming (cont.) brewer is making unusual noises 1. Lime build up on temperature probe, tank or tank heater 2. Temperature probe 3. Control board 1. Plumbing lines 2. Water supply 3. Lime build up inspect probe and t...

Page 17

Page 17 troubleshooting (cont.) problem probable cause remedy brewing circuit brew cycle will not start 1. Display flashing 2. No water 3. No power or incorrect voltage to the brewer 4. On/off switch not in the "on" position 5. Low water temperature (brew lockout is enabled) 6. Water not touching re...

Page 18

Page 18 troubleshooting (cont.) problem probable cause remedy brewing circuit (cont.) if the switch panel is operating prop- erly, proceed as follows. Attach a voltmeter to the terminals of the dispense solenoid. Connect the brewer to the power source. Turn on the brewer and press the brew switch. V...

Page 19

Page 19 troubleshooting (cont.) problem probable cause remedy brewing circuit (cont.) dripping from sprayhead weak beverage 1. Lime build up 2. Dispense valve 1. Sprayhead 2. Water temperature 3. Filter type 4. Coffee grind 5. Funnel loading inspect the tank assembly for ex- cessive lime deposits. D...

Page 20

Page 20 troubleshooting (cont.) problem probable cause remedy brewing circuit (cont.) dry coffee grounds remain in the funnel low beverage serving temperature 1. Sprayhead 2. Funnel loading 1. Warmer make sure sprayhead is present and holes are clear and unobstructed. There should be six separate st...

Page 21

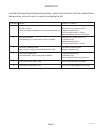

Page 21 intermittent flashing of the bank of temperature indicators, indicates that a fault exists. Count the number of flashes between pauses and use this chart as a guide to investigating the fault. Flashes cause things to check 1 dry plug - in fault - water pressure (is water shut "off"?) sheath ...

Page 22

Page 22 ca ut io n : w ar m er s an d su rf ac es a re h ot ca ut io n dis ca rd d ec an te r if: ! Bunn ma nu fa ct ur ed b y b un n- o- ma tic c or po ra tio n s pr in gf ie ld , il lin oi s, u .S .A . Mo de l s/n vo lt s a .C . A mp w at ts ph as e w ir e h er tz co ve re d un de r on e o r mo re...

Page 23

Page 23 service (cont.) control board location: the control board is located inside the top cover behind the front end cap. Test procedures: the test procedures for the control board will vary depending upon the problems experienced by the brewer. Refer to the troubleshooting guide beginning on page...

Page 24

Page 24 service (cont.) switch panel location: the switch panel is located in the front of the hood. Test procedures: the test procedures for the switch panel and the control board will vary depending upon the problems experienced by the brewer. Refer to the troubleshoot- ing guide beginning on page...

Page 25

Page 25 service (cont.) dispense valve location: the dispense valve is located inside the top cover behind the front end cap. Test procedures: 1. Disconnect the brewer from the power source. 2. Check the water level in the tank to confirm that it is within 1/2" from the top of the tank. 3. Connect t...

Page 26

Page 26 ca ut io n : w arme rs an d su rfaces are ho t limit thermostat location: the limit thermostat is located inside the front access panel on the front side of the tank. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the blue and black wires from the limit thermo...

Page 27

Page 27 all models removal and replacement: 1. Remove the top cover or top warmer housing and front access panel as previously described. 2. Disconnect the vent hose from the top of the tank by pulling the elbow fitting from the grommet in the top of the tank lid. 3. Drain water from the tank. 4. Di...

Page 28

Page 28 29707 012502 11. Disconnect the two white wires from the tank warmer blanket. 12. Disconnect the black, white and blue wires from the tank heater terminals. Dv models only, dis- connect the brown and red wires from tank heater terminals. 13. Remove the four #8-32 nuts securing the tank to th...

Page 29

Page 29 ca ut io n : warmers and surfaces are hot location: the voltage selector switch is located on the component mounting bracket behind the front access panel. Test procedure: 1. Disconnect the brewer from the power source. 2. With the voltage selector switch in the 120v posi- tion, connect a vo...

Page 30

Page 30 service (cont.) refill valve location: the refill valve is located inside the trunk on the lower center part of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white and white/blue wires from the refill valve. Set the "on/off" switch ...

Page 31

Page 31 ca ut io n di sc ar d de ca nt er if: ! Location: the warmer element(s) is located under the warmer plate. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check voltage across the two wires at the warmer element with the "on/off" switch in the "on" posit...

Page 32

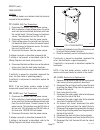

Page 32 ca ut io n : w armers and su rfaces are hot trm 2 j1 j2 j3 j4 j5 j6 j7 tr m1 service (cont.) fig. 15 fuse holder and fuse assembly location: the fuse holder and fuse assembly is located on the left rear side of the brewer. Test procedures: 1. Disconnect the brewer from the power source. 2. R...

Page 33

Page 33 tr m2 j1 j2 j3 j4 j5 j6 j7 tr m1 service (cont.) thermal fuses mv models only fig. 16 thermal fuses p1938 location: the thermal fuses are included with the wiring harness from the tank heater terminals to the terminal block located inside the top cover. Test procedures: 1. Disconnect the bre...

Page 34

Page 34 p1, p2, & p3 are pins of a polarized three-pin connector. Sol schematic wiring diagram cdbc dv 29685.0002d 05/02 ©2001 bunn-o-matic corporation p2 p1 p1 front warmer p3 brn/blk vio whi rear warmer l1 blu-14 blu-14 "keep warm" heater brew station warmer (controlled by on/off sw) limit thermos...

Page 35: Cdbcf Aps/tc/lptc-Dv

Page 35 sol schematic wiring diagram cdbc aps-dv cdbcf aps/tc/lptc-dv 29685.0003e 08/03 ©2001 bunn-o-matic corporation l1 blu-14 blu-14 "keep warm" heater limit thermostat whi whi whi whi whi sol refill dispense j1-1 j1-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d com n.O. Blk blk blk-14 blk-14 blk...

Page 36

Page 36 p1, p2, & p3 are pins of a polarized three-pin connector. Sol schematic wiring diagram cdbc mv 29685.0000a 4/99 ©1999 bunn-o-matic corporation p2 p1 p1 front warmer p3 brn/blk vio whi rear warmer l1 blu-14 blu-14 "keep warm" heater brew station warmer (controlled by on/off sw) limit thermost...

Page 37

Page 37 sol schematic wiring diagram cdbc - aps mv 29685.0001a 4/99 ©1999 bunn-o-matic corporation l1 grn blu-14 blu-14 "keep warm" heater whi whi whi limit thermostat whi whi whi sol refill dispense j1-1 j1-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d com n.O. Blk blk blk blk-14 blk whi/grn whi/gr...