- DL manuals

- Bunn

- Coffee Grinder

- CDS-2

- Operating & Service Manual

Bunn CDS-2 Operating & Service Manual

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

www.bunnomatic.com

29793.0000D 02/07 ©1999 Bunn-O-Matic Corporation

POWDER

AUTO FILL

™

For CDS-2 & 3

To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE,

and the quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper

copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

DISCONTINUED VERSION

The information in this manual

is no longer current.

Summary of CDS-2

Page 1

Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com 29793.0000d 02/07 ©1999 bunn-o-matic corporation powder auto fill ™ for cds-2 & 3 to obtain the illustrated parts catalog, visit the ...

Page 2

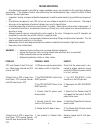

2 introduction this equipment supplies a liquid mix to the hoppers on the cds-2 or 3 dispensers. It is for indoor use only on a sturdy counter or shelf. Bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than ...

Page 3

3 00656.0000 00986.0000 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protection. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 29793 080102 10. Slowly feed the door support arms through th...

Page 4

4 operating instructions 1. On the cds control panel, make the following switch settings: a) power- “on” b) day/night- “day” 2. Pull the powder auto-fill fully forward on its sup- port rails and open the door. 3. Fill the powder auto-fill product hopper as fol- lows: a) pull the slide gate closed on...

Page 5

5 adjustments when using the powder auto-fill with a new powdered granita mix, follow the procedure outlined below to adjust the powder auto-fill to produce the correct recipe. 1. Determine the mix ratio of powdered granita mix. Convert the recipe so that it is expressed in terms of weight units [gr...

Page 6

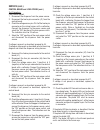

6 ejector elbow auger auger drive shaft auger drive bracket retaining clip retaining ring wiper blade shaft wiper blade wiper drive gear hopper base slide gate mixing chamber whipper chamber frother dispense tip whipper chamber receptacle o-ring cleaning recommended daily cleaning and maintenance ti...

Page 7

7 fault list door lamp fault on normal operation - powder auto-fill ready to dispense flashes on/off at 50% duty cycle low product level in powder auto-fill hopper two flashes about every 2 seconds cds/powder auto-fill probe circuit open three flashes about every 2 seconds powder auto-fill hopper no...

Page 8

8 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elect...

Page 9

9 troubleshooting (cont.) probable cause remedy problem product level in cds is lower than level probe - cds running; powder auto-fill door lamp flashes two times product level in cds is lower than level probe - cds running; powder auto-fill door lamp flashes three times product level in cds is lowe...

Page 10

10 troubleshooting (cont.) probable cause remedy problem powder auto-fill will not dispense product dripping from dispense tip water flows continuously 1. No water 2. No power or incorrect voltage to the dispenser. 3. Dispense solenoid valve 4. Control board and probe 5. Auger drive 6. Transformer 7...

Page 11

11 troubleshooting (cont.) probable cause remedy problem product overflows cds hopper weak product dispenser is making unusual nois- es display not lit 1. Control board and probe 2. Dispense solenoid valve 1. Whipper motor 2. Frother 3. Dispense solenoid valve 4. Auger drive 5. Auger spring 6. Auger...

Page 12

12 service this section provides procedures for testing and replacing various major components used in this dispenser should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electrical equipment sh...

Page 13

13 service (cont.) fig. 2 auger drive components location the auger drive components are located in the bottom of the hopper assembly. Removal, cleaning and replacement 1. Open the dispenser door. 2. Lift the hopper assembly over the retainer plates (16) on hopper support plate (12) and slide hopper...

Page 14

14 fig. 4 auger motor p1922 auger drive motor location: the auger motor is located on the right rear of the motor assembly mounting panel. Test procedures: 1. Disconnect the dispenser from the power source. 2. Check the voltage across the positive (red wire) terminal and the negative (black wire) te...

Page 15

15 frother and mixing/whipper chamber fig. 6 frother and mixing/whipper chamber p1923 location: the frother is located behind the dispenser door, mounted on the front panel and inside the whipper chamber. Removal, cleaning and replacement: 1. Disconnect the dispenser from the power source. 2. Open t...

Page 16

16 service (cont.) whipper motor fig. 8 whipper motor p1924 location: the whipper motor is located on the back side of the whipper motor mounting panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the white/red and white/brown wires of the main wiring harness fro...

Page 17

17 service (cont.) when reconnecting wires. 13. Slide the slinger onto the motor shaft flush against the front panel. 14. Wash whipper chamber components in a mild solution of dish detergent using a bristle brush. 15. Rinse thoroughly and allow to dry before reinstalling in the dispenser. 16. Slide ...

Page 18

18 service (cont.) control board and level probe fig. 11 control board p1925 location: the control board is located behind the rear panel, mounted on the back side of the hopper motor mount- ing panel. Test procedure: liquid level control 1. Disconnect the dispenser from the power source. 2. Disconn...

Page 19

19 service (cont.) control board and level probe (cont.) test procedure: low product detect 1. Disconnect the dispenser from the power source. 2. Disconnect the twelve pin connector (j1) from the control board. 3. Check the voltage across pins 2 & 3 of the twelve pin connector on the wiring harness ...

Page 20

20 service (cont.) control board and level probe (cont.) removal and replacement: 1. Disconnect the dispenser from the power source. 2. Remove the two plugs (j1 and j7) from the main wiring harness, the potentiometer plug (j3), the photo transistor plug (j6), and the photo led plug (j2) from the con...

Page 21

21 service (cont.) test/service switch fig. 13 test/service switch p1923 location: the test/service switch is located on the left front of the whipper motor mounting panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the wires from the switch terminals. 3. Check ...

Page 22

22 service (cont.) fig. 15 main power on/off switch main power on/off switch p1923 location: the main power switch is located inside the dis- penser on the right of the whipper motor mounting panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the black wires from...

Page 23

23 service (cont.) lamp cord assembly fig. 17 lamp cord assy p1891 location: the lamp cord assembly is located in the top of the dispenser. Test procedures: 1. Disconnect the dispenser from the power source. 2. Unplug the lamp cord assembly from lamp cord connector assembly. 3. Check for continuity ...

Page 24

24 service (cont.) lamp cord connector if continuity is present as described, the lamp cord connector is operating properly. If continuity is not present as described, replace the lamp cord connector. Removal and replacement: 1. Disconnect the lamp cord assembly from the lamp cord connector. 2. Remo...

Page 25

25 service (cont.) if continuity is present as described, the lamp is op- erating properly. If continuity is not present as described, replace the lamp. Removal and replacement: 1. Disconnect the lamp cord assembly from the lamp cord connector assembly in the top of the dispenser. 2. Remove the disp...

Page 26

26 service (cont.) transformer fig. 23 transformer p1930 location: the transformer is located under the hopper support panel mounted to the left of the whipper motor. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the four pin connector from the main wiring harness...

Page 27

27 service (cont.) potentiometer fig. 24 potentiometer p1931 location: the potentiometer is located under the hopper sup- port panel mounted to the left of the whipper motor and mounted on a bracket. Adjustments can be made by removing the 0.50” plug located on the whipper motor mounting panel. Test...

Page 28

28 service (cont.) hopper level indicator fig. 25 hopper level indicator p1932 location: the photo transistor and led are located on the hopper side panels mounted just below the hopper guide rails. Test procedures: refer to the section control board and level probe for test procedures. Removal and ...

Page 29

29 service (cont.) hopper switch fig. 26 hopper switch p1933 location: the hopper switch is located under the hopper support panel. Test procedures: 1. Disconnect the dispenser from the power source. 2. Open the dispenser door and remove the hopper. 3. Manually engage and release the hopper switch a...

Page 30

30 service (cont.) door switch fig. 28 door switch p1934 location: the door switch is located on the right side panel under the housing top cover. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the twelve pin connector (j1) from the control board. 3. Check continui...

Page 31

31 service (cont.) pressure regulator and needle valve fig. 30 pressure regulator and needle valve p1935 location: the pressure regulator and needle valve are located inside the rear panel at the bottom of the dispenser. Adjustments: the water pressure regulator is preset at the factory to produce 1...

Page 32

32 service (cont.) fig. 31 dispense solenoid valve p1935 dispense solenoid valve location: the dispense solenoid valve is located on the left side of the dispenser base inside of the rear cover. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the white/red and white...

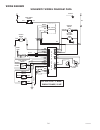

Page 33

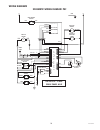

33 wiring diagrams 29793 022007 120 volts ac - 2 wire single phase, 60 hz m blk red whi/brn blk vio j7 j1 j6 pnk c o n t r o l p c b o a r d whi/red whi grn grn orn orn whi blk whi/blk whi/grn blu/blk blu/blk red/blk red/blk gry red whi/orn whi/orn j2 whi blk 1 4 1 1 4 1 5 10 j3 blk red grn m sol wh...

Page 34

34 29793 022007 wiring diagrams 230 volts ac - 2 wire single phase, 50 hz m blk red whi/brn blk vio j7 j1 j6 pnk c o n t r o l p c b o a r d whi/red whi grn grn orn orn whi blk whi/blk whi/grn blu/blk blu/blk red/blk red/blk gry red whi/orn whi/orn j2 whi blk 1 4 1 1 4 1 5 10 j3 blk red grn m sol wh...