Cwt twin cwtf twin cwtf twin-aps ca ut ion ca ut io n di sc ar d de ca nt er di sc ar d de ca nt er if: if: . C ra ck ed . C ra ck ed . S cr at ch ed . S cr at ch ed . B oi led d ry . B oi le d dr y . H ea ted w hen empt y . H ea te d w he n em pt y . U sed o n hi gh fl am e . U se d on h ig h fl am...

Page 2 introduction this equipment will brew one or two half-gallon batches of coffee simultaneously into awaiting dispensers (with just the press of a button). One side may include a hot water faucet for allied beverage use. It is only for indoor use on a sturdy counter. Bunn-o-matic commercial pro...

Page 3 user notices carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be kept in good condition. Replace any unreadable or damaged labels. #12364.0000 #00658.0000 #00656.0000 #00831.0000 10737 081706 #37881.0000

Page 4 electrical hook-up caution – improper electrical installation will damage electronic components. 1. An electrician must provide electrical service as specifi ed. 2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source. 3. Place the heater switchs at...

Page 5 models cwt & cwtf plumbing requirements these brewers must be connected to a cold water system with operating pressure between 20 and 90 psi (138 and 620 kpa) from a 1 ⁄ 2 " or larger supply line. A shut-off valve should be installed in the line before the brewer. Install a regulator in the l...

Page 6 initial set-up caution - the brewer must be disconnected from the power source throughout the initial set-up, except when specifi ed in the instructions. 1. Insert an empty funnel into the funnel rails. 2. Place an empty dispenser under the funnel. 3. Place the heater switch at the rear of th...

Page 7 10737 100801 operating controls on/off switch placing the "on/off" switch in the "off" lower position stops brewing. Stopping a brew cycle after it has been started will not stop the fl ow of water into the funnel until the tank syphons down to its proper level. Plac- ing the switch in the "o...

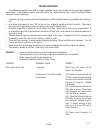

Page 8 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 9 troubleshooting (cont.) problem brew cycle will not start (cont.) water is not hot probable cause remedy 10737 120800 refer to service - on/off switch for testing. See page 16 refer to service - start switch for testing procedures. See page 20 refer to service - timer for testing procedures. ...

Page 10 troubleshooting (cont.) problem inconsistent beverage level in dispenser consistently low beverage level in the dispenser spitting or excessive steaming probable cause 1. Strainer/flow control (.222 gpm) 2. Syphon system 3. Lime build-up caution - tank and tank compo- nents should be delimed...

Page 11 troubleshooting (cont.) problem spitting or excessive steaming (cont.) dripping from sprayhead water fl ows into tank continuously (on/off switch "on") water fl ows into tank continuously (on/off switch "off") beverage overfl ows dispenser probable cause 2. Control thermostat 1. Syphon syste...

Page 12 troubleshooting (cont.) problem weak beverage dry coffee grounds remain in the funnel brewer is making unusal noises probable cause 1. Filter type 2. Coffee grind 3. Sprayhead 4. Funnel loading 5. Water temperature 1. Funnel loading 1. Solenoid 2. Plumbing lines 3. Water supply remedy bunn ®...

Page 13 troubleshooting (cont.) problem brewer is making unusal noises (cont.) low beverage serving tempera- ture probable cause 4. Tank heater 1. Warmer remedy remove and clean lime off the tank heater. See page 21 refer to service - warmer ele- ment for testing procedures. See page 27 10737 120800

Page 14 on on of f of f t a n k cau tio n : w ar m er s and s ur fa ce s ar e ho t ca ut io n ca ut io n di sc ar d de can te r di sc ar d de ca nt er if: if: . Cra cke d . C ra ck ed . S cra tc he d . S cr at ch ed . B oi le d dr y . B oi le d dr y . H ea te d w he n em pt y . H ea te d w he n em p...

Page 15 service (cont.) control thermostat location: the control thermostats are located inside the trunk on the left side of the component brackets. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check the voltage across the blue wire on the control thermostat...

Page 16 location: the on/off switchs are located on the front of the hood. On/off switches service (cont.) limit thermostat location: the limit thermostats are located inside the rear of the hood on the center rear of the tank lids. Test procedures: 1. Disconnect the brewer from the power source. 2....

Page 17 service (cont.) 10737 100801 on/off switches (cont.) test procedure: 1. Disconnect the brewer from the power source. 2. Viewing the switch from the back remove the white or red wire from the upper terminal and the black wire from the center terminal. 3. With a voltmeter, check the voltage ac...

Page 18 service (cont.) recovery booster relay (optional 2/2 & 0/6 only) fig. 8 recovery booster relay p2197 location the recovery boosters are located inside the trunk on the center of the component brackets just above the solenoid valve. Test procedures 1. Disconnect the brewer from the power sour...

Page 19 service (cont.) solenoid valves location: the solenoid valves are located inside the trunk on the lower center part of the component brackets. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white and black wires from the solenoid valve. Connect the brewer ...

Page 20 aps models start switches service (cont.) fig. 12 start switches p2489.20 location: the start switches are located on the front of the hood in the center of each switch panel. Test procedure: 1. Disconnect the brewer from the power supply. 2. Disconnect the blue wire from the top switch term...

Page 21 service (cont.) tank heater location: the tank heaters are located inside the tank and secured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the voltage across black and red wires on the tank heater. Connect the brewer to the pow...

Page 22 service (cont.) fig. 16 tank heater terminals p1239 location: the tank heater switches are located on the rear of the brewer on the upper left and right side of the trunk. Test procedure: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from the limit thermo- stat...

Page 23 service (cont.) 10737 120800 diagrams and check the brewer wiring harness. 5. Check for continuity between the black wire re- moved from the limit thermostat and the black insert on the terminal block. With the tank heater switch in the "on" upper position. Continuity should not be present i...

Page 24 on on of f of f t a n k use copper wire onl y for po wer suppl y connections use copper wire onl y for po wer suppl y connections 1 2 3 4 5 .5 minutes bu n n -o -m a t ic p/n 2235-120 v a c 1 2 3 4 5 .5 minutes b u nn-o-ma t ic p/n 2235-120 v a c b u n n c w se r ies r e a d y on /lo we r to...

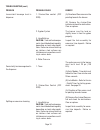

Page 25 service (cont.) 10737 120800 digital brew timer (late models) p2197 fig. 21 digital brew timer location: the timers are located inside the front of the trunk on the upper right side of the component brackets. Test procedure. Note: do not remove or install wires while timer board is installed...

Page 26 10737 120800 blu/blk wire from tl5 to p1 whi/grn wire from tl4 to (whi) solenoid whi/blu wire from tl3 to (blk) solenoid whi wire from tl2 to p2 blk wire from tl1 to p3 fig. 22 digital timer wiring p2037 digital brew timer (late models)(cont.) service (cont.) 1. Modifying brew volumes. To mo...

Page 27 on on off of f t a n k ca ut io n : w ar m er s an d su rf ac es a re h ot ca ut io n ca ut io n di scar d de ca nt er di sc ar d de ca nt er if: if: . C rac ke d . C ra ck ed . S cr at ch ed . S cr at ch ed . B oi le d dr y . B oi le d dr y . H ea te d w he n em pt y . H ea te d w he n em p...

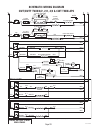

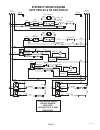

Page 28 whi/red (not available on cwt twin-aps) left lower warmer whi/red whi/grn p1-2 p1-3 p4-2 p4-3 schematic wiring diagram cwt/cwtf twin 0/2, 2/2, 4/2 & cwt twin-aps l1 green n l2 (faucet) thermal safety fuse blk right tank heater blk blk b lk red blu blk blk sw2 rt. Limit thermostat rt. Ready i...

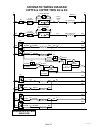

Page 29 p4-2 p4-3 schematic wiring diagram cwt twin 2/2 & 4/2 w/recovery booster l1 green n l2 red whi whi whi left top warmer right top warmer whi p4-1 yel yel whi/yel whi/yel whi whi red sw7 sw8 blk p5-3 p5-2 10867.0000e 12/00 © 1995 bunn-o-matic corporation 120/240 volts ac 3 wire single phase re...

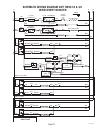

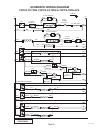

Page 30 gry pin l.E.D. L.E.D. Gry pin gry pin optional indicator timer whi/red whi/grn p1-2 p1-3 schematic wiring diagram cwtf twin 0/6 l1 green (faucet) blk blk right tank heater blk blu blk blk sw2 rt. Limit thermostat rt. Ready indicator rt. Sw. & thermostat blk red left brew warmer right brew wa...

Page 31 blk whi red blu tank heater blk limit thermostat limit thermostat sw1-l sw1-r (faucet side) "keep warm" heater schematic wiring diagram cwtf twin 4/2 & 0/6 two-circuit green green l2 n l1 left l2 n l1 right 10847.0000c 12/00 © 1994 bunn-o-matic corporation two individual branch circuits requ...

Page 32 whi/red whi/grn p1-2 p1-3 schematic wiring diagram cwtf twin 0/6 with recovery booster l1 green (faucet) thermal safety fuse blk blk right tank heater blk blu blk blk sw2 rt. Limit thermostat rt. Ready indicator rt. Sw. & thermostat blk red left brew warmer right brew warmer whi p1-1 whi/red...

Page 33 whi/red whi/grn p1-2 p1-3 p4-2 p4-3 schematic wiring diagram cwtfa twin 2/2, 4/2 & twin-aps l1 grn/yel l2 l3 right tank heater blk blu rt. Ready indicator rt. Sw. & thermostat red blk sw2 blu rt. Limit thermostat blu 10736.0001g 02/06 © 1993 bunn-o-matic corporation 230 volts ac 3 wire three...

Page 34 blk whi/red whi/grn p1-2 p1-3 p4-2 p4-3 schematic wiring diagram cwtfa & cwtfb twin 2/2 & 4/2 l1 grn/yel l2 (faucet) thermal fuse blk right tank heater blk red blu blk blk sw2 rt. Limit thermostat rt. Ready indicator rt. Sw. & thermostat blk red 10736.0002j 12/00 © 1993 bunn-o-matic corporat...

Page 35 blk whi/red whi/grn p1-2 p1-3 p4-2 p4-3 schematic wiring diagram cwtfa 2/2 twin, cwtfa 4/2 twin & cwtfa twin-aps l1 l2 10736.0004a 02/06 © 2006 bunn-o-matic corporation 230 volts ac 2 wire single phase red red red model 4/2 only not applicable to aps models not applicable to aps models blk s...