- DL manuals

- Bunn

- Coffee Maker

- CWTF-APS-MV

- Operating & Service Manual

Bunn CWTF-APS-MV Operating & Service Manual

Summary of CWTF-APS-MV

Page 1

Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 28182.0000c 9/00 ©1997 bunn-o-matic corporation bunn ® cwtf-mv cwtf-aps-mv cwtf-ts-mv cwtf-tsr-mv.

Page 2

Page 2 introduction this equipment will brew a half-gallon batch of coffee into an awaiting dispenser. It can be easily configured for 120v 15 amp, 120v 20 amp, 120/208v 20 amp or 120/240v 20 amp. The brewer has a hot water faucet for allied beverage use. It is only for indoor use on a sturdy counte...

Page 3

Page 3 #00658.0000 #00656.0000 #00831.0000 #28181.0000 three warmer brewers #28181.0001 one warmer brewers #28181.0002 two warmer brewers also cwaps, cwts & cwtsr user notices (cont.) #02765.0000 28182 021500

Page 4

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Requires 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. Requires 2-wire, grounded service rated 120 volts ac, 20 amp, single phase, 60 hz. Elec...

Page 5

Page 5 1. Flush the water line and securely attach it to the tee. 2. Turn on the water supply. 3. Place an empty vessel beneath the faucet and lift the handle until water is dispensed. Plumbing requirements these brewers must be connected to a cold water system with operating pressure between 20 and...

Page 6

Page 6 initial set-up caution - the brewer must be disconnected from the power source throughout the initial set-up, except when specified in the instructions. 1. Insert an empty funnel into the funnel rails. 2. Place an empty dispenser under the funnel. 3. Place the heater switch at the rear of the...

Page 7

Page 7 28182 090100 2. Setting batch sizes. To set a batch volume, first check that the set/lock switch is in the "set" position on the circuit board. Press and hold the start or brew switch until three distinct clicks are heard, and then release the switch. (failure to release the switch within two...

Page 8

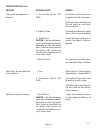

Page 8 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 9

Page 9 troubleshooting (cont.) problem brew cycle will not start (cont.) water is not hot probable cause remedy 5. Timer 6. Solenoid valve 7. Water strainer/flow control (.222 gpm) 1. Tank heater switch 2. Limit thermostat caution - do not eliminate or bypass limit thermostat. Use only replacement p...

Page 10

Page 10 troubleshooting (cont.) problem inconsistent beverage level in dispenser consistently low beverage level in the dispenser spitting or excessive steaming probable cause 1. Strainer/flow control (.222 gpm) 2. Syphon system 3. Lime build-up caution - tank and tank compo- nents should be delimed...

Page 11

Page 11 troubleshooting (cont.) problem spitting or excessive steaming (cont.) dripping from sprayhead water flows into tank continuously (on/off switch "on") water flows into tank continuously (on/off switch "off") beverage overflows dispenser probable cause 2. Control thermostat 1. Syphon system 2...

Page 12

Page 12 troubleshooting (cont.) problem weak beverage dry coffee grounds remain in the funnel brewer is making unusal noises probable cause 1. Filter type 2. Coffee grind 3. Sprayhead 4. Funnel loading 5. Water temperature 1. Funnel loading 1. Solenoid 2. Plumbing lines 3. Water supply remedy bunn ®...

Page 13

Page 13 troubleshooting (cont.) problem brewer is making unusal noises (cont.) low beverage serving tempera- ture (cwtf only) probable cause 4. Tank heater(s) 1. Warmer remedy remove and clean lime off the tank heater(s). See page 21 refer to service - warmer ele- ment for testing procedures. See pa...

Page 14

Page 14 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 15

Page 15 service (cont.) control thermostat location: the control thermostat is located inside the trunk on the upper left side of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Locate the blue wire on the control thermostat. 3. With a voltmeter, check the ...

Page 16

Page 16 service (cont.) fuse holder and fuse assembly fig. 4 fuse holder and fuse assembly location: the fuse holder and fuse assembly is located on the left rear side of the brewer. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the cap from the fuse holder and remove th...

Page 17

Page 17 limit thermostat location: the limit thermostat is located inside the rear of the hood on the center rear of the tank lid. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the blue and black wires from the limit thermostat. 3. With an ohmmeter, check for continu...

Page 18

Page 18 on/off switches service (cont.) fig. 7 on/off switches p1417 cwtf models cwtf-aps models 28182 090100 fig. 8 on/off switch terminals 6. Check for continuity across the center and lower terminal with the switch in the "on" (upper) posi- tion. Continuity must not be present when the switch is ...

Page 19

Page 19 location: the solenoid valve is located inside the trunk on the lower center part of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect both wires from the solenoid valve. Connect the brewer to the power source. With the lower warmer "on/off...

Page 20

Page 20 service (cont.) start switch fig.11 start switch p1417 location: the start switch is located on the front of the hood in the center of switch panel. Test procedure: 1. Disconnect the brewer from the power supply. 2. Disconnect the blue wire from the top switch terminal and the white/red wire...

Page 21

Page 21 tank heaters location: the tank heaters are located inside the tank and secured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the tank heater voltage across blue and white wires on 120 volt 15 amp version, black and white wires o...

Page 22

Page 22 service (cont.) tank heaters (cont.) 17. Refer to fig.14 when reconnecting the tank heater wires. Fig. 14 tank heater terminals p1420 28182 021500

Page 23

Page 23 service (cont.) tank heater switch location: the tank heater switch is located on the rear of the brewer on the upper left side of the trunk. Test procedure: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from the limit thermo- stat. 3. With a voltmeter, check t...

Page 24

Page 24 service (cont. Tank heater switch (cont.) 15. Reconnect the two black wires to the tank heater switch terminals. 16. Set tank assembly inside the hood on mounting brackets and secure with two #8-32 screws. 17. Reconnect the wires to the limit thermostat and tank heaters. Refer to limit therm...

Page 25

Page 25 thermal fuses fig. 17 thermal fuses p1415 location: the thermal fuses are located inside the rear of the hood connected to the left and right rear tank heater terminals. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal fuse from the right tank heater...

Page 26

Page 26 p1136 service (cont.) fig. 20 timer terminals location: the timer is located inside the front of the trunk on the upper right side of component bracket. Test procedure. 1. Disconnect the brewer from the power source. 2. Disconnect the polarized, three pin connector from the brewer wiring har...

Page 27

Page 27 service (cont.) digital timer (late models) fig. 21 digital timer p1415.40 late models 28182 090100 location: the timer is located inside the front of the trunk on the upper right side of the component bracket. Test procedure. Note: do not remove or install wires while timer board is install...

Page 28

Page 28 service (cont.) to increase a brew volume, place the on/off switch in the “on” position, press and hold the start switch until three clicks are heard. Release the switch and press it again one or more times. (failure to re- lease the switch within two seconds after the third click causes the...

Page 29

Page 29 service (cont.) warmer element(s)(cwtf models only) location: the warmer elements are located under the warmer plates. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check voltage across the white wire from the terminal block and the wire from the "on/o...

Page 30

Page 30 20 amp t1 t5 t3 t4 t2 28182 090100

Page 31

Page 31 schematic wiring diagram for cwt-aps mv, cwtf-aps mv, cwtf-ts mv, cwtf-tsr mv 28182 090100