- DL manuals

- Bunn

- Beverage Dispenser

- FCD-4

- Installation And Operating Manual

Bunn FCD-4 Installation And Operating Manual

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

33496.0000C 08/01 ©2000 Bunn-O-Matic Corporation

www.bunnomatic.com

BUNN

®

INSTALLATION & OPERATING MANUAL

FCD-4

DISCONTINUED VERSION

The information in this manual

is no longer current.

Summary of FCD-4

Page 1

Bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 33496.0000c 08/01 ©2000 bunn-o-matic corporation www.Bunnomatic.Com bunn ® installation & operating manual fcd-4 discontinued version the information in this manual is no longer c...

Page 2

2 warranty bunn-o-matic corp. (“bunn”) warrants the equipment manufactured by it to be commercially free from defects in material and workmanship existing at the time of manufacture and appearing within one year from the date of installation. In addition: 1.) bunn warrants electronic circuit and/or ...

Page 3: Warning

3 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 27442.0000 00986.0002 33461.0000 ! Warning do not overload circuit. Always electr...

Page 4

4 initial set-up caution: the dispenser is very heavy! Use care when lifting or moving it. Use at least two people to lift or move the dispenser. Place the dispenser on a sturdy counter or shelf able to support at least 250 lbs. (113.4 kg). The fcd-4 is designed for indoor use only. 1. Set the dispe...

Page 5

5 plumbing requirements this dispenser must be connected to a cold water system with operating pressure between 20 and 100 psi (138 and 690 kpa). This water source must be capable of producing a minimum flow rate of 3 fluid ounces (88.7 milliliters) per second. A shut off valve should be installed i...

Page 6

6 operating controls refrigeration switch the refrigeration switch is located on the top of the dispenser near the left rear corner. This switch controls power to the compressor and the condenser fan motor. Sanitize switch the sanitize switch is located behind the drip tray in the lower left corner ...

Page 7

7 operating controls (cont.) fig 5 press and hold models a. Product dispense switch pressing and holding switch will initiate product flow from the respective nozzle; releasing the switch will stop the flow. B. Chilled water dispense switch pressing and holding switch will initiate chilled water flo...

Page 8

8 initial fill caution: the dispenser must be disconnected from the power source throughout the initial fill except when specified in the instructions. 1. Remove drip tray assembly and splash panel from the dispenser. 2. Pull the overflow tube from its retaining clip and place the end into an empty ...

Page 9

9 initial fill (cont) ambient concentrates (optional) 1. Install an ambient concentrate conversion kit (bunn-o-matic part number 33699.0000) per the instructions provided in the kit. 2. Attach the concentrate product hose to the appropriate concentrate line located behind the dispenser’s splash pane...

Page 10

10 dispenser use press and hold models (refer to fig 5) 1. Place a cup on the drip tray beneath the desired dispensing nozzle. 2. Press and hold the “product dispense” or “chilled water” switch until the beverage/water reaches the desired level, then release. Portion control models (refer to fig 6) ...

Page 11

11 cleaning & preventive maintenance general cleaning and sanitizing procedures note: the bunn juice dispenser incorporates a rinse reminder feature which lights the rinse led on the front panel when it is time to rinse. See dip switch function list to activate this feature. Daily: rinse procedure t...

Page 12

12 cleaning (cont) portion contol dispensers. The “refill” indicator will light and the beeper will sound for the dispense head selected. 7. Once the dispense heads have been selected, press and hold the “sanitize switch” for 5 seconds again to initiate the automatic cycle. (when the cycle is initia...

Page 13

13 monthly: clean condenser air filter 1. Remove the condenser air filter located on the rear of the dispenser. 2. Using a water spray, clean the air filter. Annually: replace pump tubing 1. Open dispenser door. 2. Remove all product containers and place them in a refrigerated (35-40 degrees f [1.6-...

Page 14

14 adjustment & optional settings setting the mix ratio/brix ratio cup method 1. Adjust the water flow as described in water flow testing and adjustment. 2. Remove the dispense nozzle from the appropriate dispense position. 3. Assemble, lubricate, and install the flow separator assembly (bunn-o-mati...

Page 15

15 water flow testing and adjustment 1. Enter the “pump speed programming” mode by simultaneously press- ing both “hidden switches” fig 5 or fig 6. Note that the beeper sounds twice and that the “program” indicator begins flashing. 2. Place a graduated measuring cup or the large chamber of the empty...

Page 16

16 that each step is confirmed by a single flash of the appropriate “refill” indicator and a single tone from the beeper. 4. Repeat as necessary at the remaining dispense stations. 5. Exit the “pump speed programming” mode by simultaneously pressing both “hidden switches”. Note that the beeper sound...

Page 17

17 b) in a 5 second period, press and release the “chilled water switch” the number of times that you want the password set to (maximum of 10.) for example: if you want the password set to 3, press and release the “chilled water switch” 3 times in the 5 second period. C) release the “hidden switch”....

Page 18

18 password protection the programming modes and service lockout function may be password protected to prevent accidental or unauthorized access to these features. The dispenser is shipped from the factory with a password of “0” (no password.) 1. Enter the “pump speed programming” mode by simultaneo...

Page 19

19 dispense fault list “refill” indicator beeper fault 2 flashes 2 beeps dispense station locked out. 3 flashes 3 beeps dispense/rinse sensing fault. 4 flashes 4 beeps dispense/rinse knob mis-positioned. 5 flashes 5 beeps pump motor stalled/speed sensor inoperative. All “refill” 3 beeps dispenser lo...

Page 20

20 dip switch function list dip switch controls off on 1 “refill” indicator when “concentrate out” is detected. Inactive active 2 lockout dispense components when “concentrate out” is detected. Inactive active (note) 3 number of positions that can dispense/rinse simultaneously. 3 2 4 rinse timer off...

Page 21

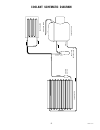

21 coolant schematic diagram condenser suction a ccumula t o r compressor ev apora t o r pr ocess tube 33464.0000a 09/00 ©2000 bunn-o-matic cor por ation fil ter dr yer 33496 011101.

Page 22: Schematic Wiring Diagram

22 j3-1 j3-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d j1-18 j7-1 j7-5 j7-10 j7-16 j8-1 j8-8 j6-1 j6-6 j6-12 right lamp assy. Left lamp assy. Grn grn grn n l1 blu brn/blk red/blk red/blk gry whi blk limit thermostat k comp. K compressor assembly + – rect transformer whi/blu whi whi whi whi/red whi...