- DL manuals

- Bunn

- Grinder

- FPG

- Service & Repair Manual

Bunn FPG Service & Repair Manual

GRINDERS

Includes: MHG, FPG,

FPG-2, LPG-2, G1, G2, G3,

G2 trifecta™, G9, G9WD,

G9-2 & G9-2T DBC

SERVICE & REPAIR MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

41545.0000C 11/11 ©2009 Bunn-O-Matic Corporation

Summary of FPG

Page 1

Grinders includes: mhg, fpg, fpg-2, lpg-2, g1, g2, g3, g2 trifecta™, g9, g9wd, g9-2 & g9-2t dbc service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating man...

Page 2

2 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compressors on refrige...

Page 3

3 contents warranty and trademark .................................................................................................3 introduction ....................................................................................................................4 recommended daily cleaning ............

Page 4

4 introduction the grinder will store various amounts of whole bean coffee and grind it to a preset grind and amount into an awaiting funnel and filter or french press from most commercial drip coffee brewers. The equipment is only for indoor use on a sturdy counter or shelf. Adequate space must be ...

Page 5: Warning

5 41545 111711 figure 1 step 1 - remove & discard tape holding funnel arm in place. (figure 1) step 2 - remove & discard two silicon tubes between funnel guide & housing. (figure 2) step 3 - remove four screws in front housing panel. (figure 3) step 4 - remove & discard shim under transducer. (figur...

Page 6

6 model g9-2 off/on/start switch off - (upper position) switching to this position stops all operation of the grinder. On - (middle position) the switch will return to this position after a grind cycle has begun and will remain in this position after grinding has ceased. Start - (lower, momentary po...

Page 7

7 urn o f f s t a r t on carafe p1300 batch selector switch (optional) urn - switching to this position allows the correct amount of beans to be dispensed when grinding a large batch. Carafe - switching to this position allows the correct amount of beans to be dispensed when grinding a small batch. ...

Page 8

8 model g9-2t dbc grind pad (a) pressing initiates a timed grind cycle. Stop pad (b) pressing ends the operation of the grinder. ® pad (c) pressing the ® pad allows programming access. Operating controls (continued) pantone red 032 cv pantone 430 cvc pantone 432 cvc pantone 354 cvc pantone black c d...

Page 9

9 operating controls (continued) p2947 p2947 model fpg off/on/start switch off - (upper position) switching to this position stops all operation of the grinder. On - (middle position) the switch will return to this position after a grind cycle has begun and will remain in this position after grindin...

Page 10

10 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elec...

Page 11

11 troubleshooting (cont.) problem probable cause remedy each motor is equipped with a temperature and current overload protection feature which will im- mediately shut off the motor when an overload has occurred. Check the grinder for obstructions. Refer to service - motor for testing pro- cedures....

Page 12

12 begin each grind cycle by visually inspecting the hopper(s) for ample supplies of whole bean coffee. Foreign materials must not block the openings at the bottom of the hopper(s). Refer to service - solenoids for test- ing procedures. Refer to service - timer for testing procedures. Refer to servi...

Page 13

13 problem probable cause remedy troubleshooting (cont.) incorrect coffee grind dispensed. Excessive chaff grinder only dispenses from one hopper timer will not display or displays incorrectly. Incorrect weight of coffee dis- pensed 1. Burr adjustment 1. Dechaffer 1. Hopper selector switch (model lp...

Page 14

14 service this section provides procedures for testing and replacing various major components used in this grinder should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipment sh...

Page 15

15 service (cont.) fig. 1 bag sensor switch p1704 location: the bag sensor switch is located inside the lower front of the grinder housing behind the coffee dispens- ing chute. Test procedure: 1. Disconnect the grinder and place a coffee bag behind the dispense chute. 2. Remove the white/violet wire...

Page 16

16 service (cont.) ac motor and grind chamber fig. 3 ac motor and grind chamber p1704 location: the motor is located inside the upper part of the grinder housing. Test procedure: 1. Remove the plug located on the right side of the housing. Press the red “reset” button visible through the opening. Li...

Page 17

17 service (cont.) whi/blu to relay n.O.(k4) whi to cordset (120v) red/blk to cordset (230v) grn to ground (120v) grn/yel to ground (230v) p1310 fig. 4 ac motor terminals 11. Clean all grinding burrs and mounting surfaces before reassembly. 12. Install the four .250”-20 cage nuts on the new motor. 1...

Page 18

18 service (cont.) fig. 5 grind chamber components p1708 20 7 6 4 5 16 18 1 19 17 11 10 9 8 3 2 1 13 7 12 14 15 ac motor and grind chamber (cont.) removal and replacement - grind chamber - fig. 5: 1. Loosen the two set screws (16) securing the grind selector knob to the grind selector dial plate (18...

Page 19

19 service (cont.) dc motor and grind chamber - g1md only fig. 6 dc motor and grind chamber p1706 location: the motor is located inside the upper part of the grinder housing. Test procedures: 1. Remove the rear panel. Press the red “reset” button visible on the rear of the motor. Listen care- fully ...

Page 20

20 service (cont.) dc motor and grind chamber - g1md only (cont.) blu to blu from rectifier blu to whi/blu from relay (3) red to rectifier (-) blk to rectifier (+) fig. 7 dc motor terminals p1710 10. Remove motor and bracket out the rear of the grinder housing. 11. Remove the two .250”-20 screws sec...

Page 21

21 service (cont.) dc motor and grind chamber - g1md only (cont.) fig. 8 motor and grind chamber removal p1711 5 7 6 16 18 1 19 17 9 8 11 10 3 4 2 1 7 13 12 14 15 22 21 20 23 11. Install burr (7) on burr auger rotor/spring assem- bly (6) securing with two .250”-20 screws (5). 12. Slide burr auger ro...

Page 22

22 service (cont.) p1022 location: the motor is located inside the hopper assembly. Test procedures: 1. Disconnect grinder from the power supply. 2. On model lpg-2e, disconnect the black wire and the white wire to the motor from the main wiring harness, the red wire to the circuit breaker and the re...

Page 23

23 service (cont.) 1. Retaining ring w/hopper gasket 2. Slide plate, solenoid plunger and spring 3. Spacer plate 4. Mounting ring, solenoid and solenoid mounting plate 5. Setscrew, #8-32 6. Motor and burr housing p1050 1 2 3 4 5 2 6 fig. 11 solenoid and gates 8. Remove spacer plate (3) and set aside...

Page 24

24 service (cont.) 20. Remove the two #8-32 flat head screws securing the motor cover (18) to the motor and housing assembly (17) and remove the cover. Set aside for reassembly. 21. Discard old motor and housing assembly. 22. Place new motor on it’s side and install motor cover (18) using two #8-32 ...

Page 25

25 service (cont.) dechaffer (models lpg & fpg) fig. 13 dechaffer p1062 location: the dechaffer spring plates are located in the burr housing cap. 1 fig. 14 dechaffer removal/replacement p1063 2 removal and replacement: refer to fig. 14 1. Remove coffee beans from hopper(s). 2. Lay grinder on it’s b...

Page 26

26 service (cont.) 2. The entire wiring harness must be fed into the bottom of the grinder housing through the hole in the motor mounting plate. 3. Remove both 6-32 screws beneath the upper front inspection panel. 4. Remove the six 10-32, hex head screws on top of the motor mounting plate. 5. Slowly...

Page 27

27 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1. Indicator adjustment cap & decal 2. Adjusting screw 3. Burr housing cap 4. Rotor cup 5. Shear plate 9 8 7 6 5 4 3 2 1 6. Rotor 7. Spring 8. Burr (rotating) 9. Burr (stationary) p1311 removal and replacement - grind chamber 1. Refer to the illustration abov...

Page 28

28 service (cont.) snubber (models g9, g9-2, mhg) co arse fi ne th or oug hly clea n g rind c ha mb er b e f o r e r e a s s e m b ly em pty h opper be fore re mo vi n g t h is c o v e r . N otic e co arse fi ne p611 grn to chasis ground yel to snubber p621 whi/ blu to snubber whi/blu to relay whi/b...

Page 29

29 calibration 1. Place empty funnel into funnel rails. 2. Press and hold the right hidden (copyright) button until the “machine type” menu appears. (see level 2 programming) 3. Press the middle button under the screen until the “calibrate scales?” menu appears. 4. Press the right button under “yes”...

Page 30

30 p1745 fig. 20 capacitor location: the capacitor is located inside the front panel of the hopper housing next to the off/on/start switch. Test procedure: 1. Disconnect grinder from the power source. 2. Visually inspect the capacitor for leakage. If leakage is visible, replace the capacitor. 3. Con...

Page 31

31 service (cont.) circuit breaker (models lpg, lpg-2e, fpg, fpg-2 dbc) p1036 fig. 22 circuit breaker p1037 fig. 23 circuit breaker terminals red from motor-lpg-2e blk from start switch-lpg blk from power cord removal and replacement: 1. Remove the wires from the circuit breaker. 2. Remove the face ...

Page 32

32 service (cont.) p1038 hopper selector switch (model lpg-2e only) p1029 location: the hopper selector switch is located in the lower left front of the hopper housing. Test procedure: 1. Disconnect grinder from the power supply. 2. Remove all wires from the switch terminals. 3. Check that the switc...

Page 33

33 service (cont.) hopper selector switch (model g9-2 only) fig. 26 hopper selector switch p594 location: the hopper selector switch is located in the center on the front of the hopper housing. Test procedure: 1. Disconnect the grinder from the power source. 2. Remove all wires from the switch termi...

Page 34

34 service (cont.) location: the off/on/start switch is located to the left side on the front of the housing above the upper front inspec- tion panel. Test procedure: 1. Unplug the grinder. 2. Remove the black wire from the switch. 3. Check for continuity across the black wire from the off/on/start ...

Page 35

35 service (cont.) urn o f f s t a r t on carafe p1300 location: the urn/carafe switch is located to the left side on the front of the housing above the upper inspection panel. Test procedure: 1. Disconnect the grinder from the power supply. 2. Remove the tan, yellow and green wires from the switch....

Page 36

36 service (cont.) fig 32 batch selector switch location: the batch selector switch is located on the left front of the hopper housing. Test procedure: 1. Disconnect the grinder from the power source. 2. Open hopper lid and loosen four screws inside the hopper and remove hopper. 3. The orn wire is c...

Page 37

37 small medium large p2946 service (cont.) fig 34 potentiometers location: the potentiometer switches are located on the top rear of the hopper housing. Test procedure: 1. Disconnect the grinder from the power source. 2. Open hopper lid and loosen four screws inside the hopper and remove hopper. 3....

Page 38

38 service (cont.) + a c a c removal and replacement: 1. Disconnect the wires from the rectifier. 2. Remove the #10-32 screw securing the rectifier to the motor mounting bracket. 3. Remove the rectifier and discard. 4. Install new rectifier on the rear of the motor mount- ing bracket and secure with...

Page 39

39 service (cont.) location: the relay is located on the timer bracket in the grinder base. The bracket can be removed by loosening the two 8-32 screws beneath the timer dial. Test procedure: 1. Disconnect the grinder from the power supply. 2. Check the voltage across the white/red and white/ green ...

Page 40

40 service (cont.) location: the relay is located on the grinder base inside the lower housing. Test procedure: 1. Disconnect the grinder from the power source and place a coffee bag behind the dispense chute. 2. Check the voltage across the white/orange and white or red/black wires on terminals a &...

Page 41

41 service (cont.) whi/blu from motor to relay k-4 whi/orn from bag sensor switch (a) fig. 41 relay terminals p1707 relay (cont.) whi to main harness 120v (b) red/blk to main harness 240v (b) whi/vio from switch to relay k-6 whi/red from switch to relay k-7 & k-9 removal and replacement (120 volt an...

Page 42

42 service (cont.) location: the relay is located either on the timer bracket or on the component mounting bracket in the grinder base. The bracket can be removed by loosening the two 8-32 screws beneath the timer dial. Test procedure: 1. Disconnect the grinder from the power supply. 2. Access the r...

Page 43

43 service (cont.) location: the slide plates are located on the solenoid mount- ing plate immediately beneath the hopper openings. The slide plates must always remain flat for proper operation. Test procedure: with the solenoid mounting plate attached to the hopper, push the solenoid plunger into t...

Page 44

44 service (cont.) location: the slide plates are located on the solenoid mount- ing plate immediately beneath the hopper openings. The slide plates must always remain flat for proper operation. Test procedure: with the solenoid mounting plate attached to the hopper, push the solenoid plunger into t...

Page 45

45 service (cont.) left right whi/orn to timer p4-4 red/blk to right solenoid red/blk to timer p4-7 whi/yel to timer p4-5 red/blk to left solenoid p612 location: the solenoids are located on the mounting plate immediately beneath the hoppers. Test procedure: 1. Unplug the grinder. 2. Connect a voltm...

Page 46

46 service (cont.) timer (model lpg-2e) p1061 location: the timer is located inside the hopper housing just behind the left solenoid. Test procedure: 1. Disconnect grinder from the power source. 2. Insert the leads of a voltmeter set to read at least 120 volts ac, along side the red wire (terminal 8...

Page 47

47 service (cont.) timer (model lpg-2e) timer (models lpg, fpg) p1748 fig. 49 timer location: the timer is located inside the rear access panel. Adjustments can be made by removing the 2” hole plug. Test procedure: 1. Disconnect grinder from the power source. 2. Insert the leads of a voltmeter set t...

Page 48

48 service (cont.) location: the timer is located on the timer bracket in the grinder base. The bracket can be removed by loosening the two 8-32 screws beneath the timer dial(s). Test procedure: 1. Disconnect the grinder from the power supply. 2. Check the voltage across terminals tl1 & tl2 with a v...

Page 49

49 service (cont.) dis pen se tim e (s eco nds ) dis pla y incr eas e dec reas e rea dou t wi ll be dis play ed f or 5 m inut es. Tim er c an o nly b e ad just ed whi le re ado ut is disp laye d. + wa rn ing haz ard ous vo lta ge unp lug gr ind er bef or e r em ovi ng rig ht dis pen se time (se co n...

Page 50

50 service (cont.) control board (model mhg) location: the control board is located on the component mounting bracket mounted to the grinder base inside the front access panel. The bracket can be removed by loosening the two 8-32 screws securing the bracket to the grinder base. Test procedure: 1. Pr...

Page 51

51 service (cont.) control board (models fpg-2 & g9-2 dbc) location: the control board is located inside the hopper housing behind the membrane switch. Test procedure: 1. Check the continuity of the wiring between the component and the control board. 2. Test the individual components before replacin...

Page 52

52 service (cont.) membrane switches (model mhg only) location: the membrane switch is located on the front of the hopper housing. Test procedure: 1. Press and hold the right hidden button to enter programming. 2. Scroll through the menus to service tools and select yes. 3. Select yes at test output...

Page 53

53 pe rs on al in ju ry ha za rd . Kee p f inge rs an d fore ign ob je ct s ou t of h oppe r or ch ute open ing. Cau tio n service (cont.) membrane switches (models fpg-2 & g9-2 dbc) location: the membrane switch is located on the front of the hopper housing. Test procedures: note: before continuing...

Page 54

54 service (cont.) emi filter (models fpg & fpg-2) fig 60 emi filter fig 61 emi filter terminals location: the emi filter is located inside the rear cover of the grinder housing. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the two red wires and two white wires on...

Page 55

55 service (cont.) funnel sensing coil (models mhg & g9-2 dbc) location: the funnel sensing coil is located inside of the coil cover. Test procedure: 1. Disconnect the grinder from the power supply. 2. Remove the two 6-32 screws attaching the coil cover to the front of the grinder housing. 3. Pull s...

Page 56

56 service (cont.) memory clock board (model mhg) location: the memory clock board is located on the component mounting bracket mounted to the grinder base inside the front access panel. Test procedure: 1. Disconnect the grinder from the power supply. 2. Disconnect the wiring harness on the memory b...

Page 57

57 display board (model mhg) location: the display board is located inside the hopper housing behind the membrane switch. Test procedure: 1. Press and hold the upper right hidden button to enter the programming menus. 2. Scroll to service tools menu, and press the button under "yes". 3. Press "yes" ...

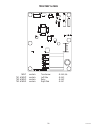

Page 58

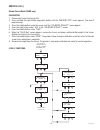

58 triac map for mhg mov1 controls transformer @ j5-4,5,6 th1 & mov2 controls left gate @ j5-3 th2 & mov3 controls relay @ j5-2 th3 & mov4 controls right gate @ j5-1 41545 122209.

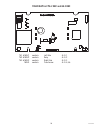

Page 59

59 triac map for fpg-2 dbc and g9-2 dbc th1 & mov1 controls left gate @ j1-1 th2 & mov2 controls relay @ j1-2 th3 & mov3 controls right gate @ j1-3 mov4 controls transformer @ j1-4,5,6 41545 122209.

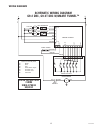

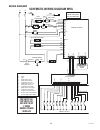

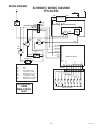

Page 60: Schematic Wiring Diagram

60 schematic wiring diagram g9-2 dbc, g9-2t dbc w/smart funnel™ n w h i b l k l1 left gate limit thermostat limit thermostat sol sol whi/ora whi/grn whi/yel blk whi red/blk j1-6 j1-6 j8-3 j8-1 j6-10 j6-5 j6-1 control pc board coil relay right gate 1 11 shield funnel sensor whi/grn whi/vio switch uni...

Page 61: Schematic Wiring Diagram

61 schematic wiring diagram g9-2 dbc, g9-2t dbc w/smart funnel™ n w h i b l k l1 left gate limit thermostat limit thermostat sol sol whi/ora whi/grn whi/yel blk whi red/blk j1-6 j1-6 j8-3 j8-1 j6-10 j6-5 j6-1 control pc board coil relay right gate 1 11 shield funnel sensor whi/grn whi/vio switch uni...

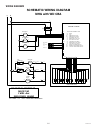

Page 62: Schematic Wiring Diagram

62 schematic wiring diagram g9-2tb dbc w/smart funnel™ n w h i b l k l1 left gate limit thermostat limit thermostat sol sol whi/ora whi/grn whi/yel blk whi red/blk j1-6 j1-6 j8-3 j8-1 j6-10 j6-5 j6-1 control pc board coil relay right gate 1 11 shield funnel sensor whi/grn whi/vio switch unit assy a3...

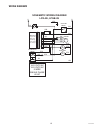

Page 63: Schematic Wiring Diagram Mhg

63 schematic wiring diagram mhg n b l k w h i l1 right gate left hopper sensor limit thermostat limit thermostat whi/yel whi/yel whi/grn whi/orn whi/orn yel orn yel orn blk whi whi whi whi j5-5 j5-1 j12-1 j9-10 j9-5 j9-1 control pc board display board relay left gate right hopper sensor 16 1 static ...

Page 64: Schematic Wiring Diagram

64 wiring diagrams 1 5 10 16 j19 4 j6 1 j12 5 1 j1 5 1 9 8 static shield switch unit assy right hopper coil left hopper coil funnel coil t1 load line vio vio org org yel yel k1 right gate relay left gate relay li n sol sol mtr limit thermostat limit thermostat k2 k3 right gate left gate wht k3 k2 k1...

Page 65

65 27103.0000d 04/07 ©1996 bunn-o-matic corporation schematic wiring diagram lpg-2e, lpgb-2e n l1 blk red whi 100 volts ac 120 volts ac 2 wire single phase 60 hz grn 3 amp 2 3 4 5 6 1 7 8 9 10 timer assy. (hopper slide gate timer dial wiring) right - brown left - orange yel whi blu yel whi/blk blk r...

Page 66

66 wiring diagrams 41545 122209.

Page 67

67 blk whi red red 10529.0000c 3/92 © 1990 bunn-o-matic corporation schematic wiring diagram lpg & lpg2 n l1 b l k p1 2 3 4 5 6 1 red whi/blk blk whi/blu whi/brn whi grn red whi/blk blk whi/blu whi/brn whi blk red whi/brn whi/blu 1 2 3 4 5 p2 blk red whi/brn whi/blu dc motor blk whi red red 4 1 2 3 ...

Page 68

68 blk whi red red 10529.0002e 8/01 © 1990 bunn-o-matic corporation schematic wiring diagram lpg-a l2 l1 b l k p1 2 3 4 5 6 1 red whi/blk blk whi/blu whi/brn whi grn red whi/blk blk whi/blu whi/brn whi blk red whi/brn whi/blu 1 2 3 4 5 p2 blk red whi/brn whi/blu dc motor blk whi red red 4 1 2 3 p3 g...

Page 69

69 blk whi red red 10529.0003e 10/98 © 1998 bunn-o-matic corporation schematic wiring diagram lpg w/capacitor l1 p1 2 3 4 5 6 1 1 2 red whi/blk blk whi/blu whi/brn whi grn red whi/blk blk blk whi/blu whi/brn whi blk blk blk red whi/brn whi/brn whi/brn whi/blu 1 2 3 4 5 p2 blk red whi/brn whi/blu dc ...

Page 70

70 blk whi red red 10529.0001d 10/98 © 1990 bunn-o-matic corporation schematic wiring diagram lpg-b n l1 b l k p1 2 3 4 5 6 1 red whi/blk blk whi/blu whi/brn whi grn red whi/blk blk whi/blu whi/brn whi blk red whi/brn whi/blu 1 2 3 4 5 p2 blk red whi/brn whi/blu dc motor blk whi red red 4 1 2 3 p3 g...

Page 71

71 whi/vio whi/vio whi/blu whi/ora 1 or a grn or grn/yel 230v grn/yel l1 n sw1 blk whi/red sw2 k 0 or b m l1 l2 100 volt ac 120 volt ac 230 volt ac 240 volt ac 2 wire + grd single phase 50/60 hz whi whi l2 red/blk red/blk k-2 or k-7 k-8 or k-9 k-6 k-4 white strip-tac plus black ink finished size: 6"...

Page 72: Schematic Wiring Diagram G9

72 10173-0000f 4/91 © 1987 bunn-o-matic corporation whi/grn blk k1 whi/blu m l2 l1 120 volts ac 2 wire single phase 60 hz l1 n green k1 n.O. Schematic wiring diagram g9 timer whi/red whi/yel whi/ora whi whi whi/red whi/red optional key sw 5 4 3 2 1 w h i / o r a ora urn carafe whi/grn 1 blk k1 whi/b...

Page 73

73 10187-0000c 02/08© 1987 bunn-o-matic corporation whi/grn blk k1 whi/blu m l2 l1 230 volts ac 2 wire + gnd single phase 50 hz l1 l2 green k1 n.O. Schematic wiring diagram g9a hd timer whi/red whi/red whi/yel whi/ora red/blk red/blk red/blk whi/red whi/red 5 4 3 2 1 optional power indicator light w...

Page 74: Schematic Wiring Diagram G9

74 4 3 whi/grn 1 blk whi/blu l2 l1 120 volts ac 2 wire single phase 60 hz 10388-0000b 12/88 © 1988 bunn-o-matic corporation l1 n green k1 n.O. Schematic wiring diagram g9 timer 3 2 4 5 whi/red whi/yel whi/ora whi whi whi/red whi/red gry 1 2 optional multi-set sw optional brewer interface connector p...

Page 75

75 blu vio yel gry tan ora red/blk whi whi/grn whi/ora whi/yel red/blk blk whi/red whi/blu m l2 l1 whi/blu whi/blk yel 230 volts ac 2 wire single phase 50 hz 10768.0000e 05/03 © 1993 bunn-o-matic corporation l1 l2 k1 n.O. Schematicwiringdiagramg9-2a hd off/on/start sw hopper selector sw tan 1 8 time...

Page 76

76 wiring diagrams 41545 122209.

Page 77

77 wiring diagrams blk whi red red 36781.0000a 04/04 ©2004 bunn-o-matic corporation schematic wiring diagram fpg n l1 red whi/blk blk whi/blu whi/brn whi red whi/blk blk whi/blu whi/brn whi grn blk sm med lg red whi/brn whi/blu 1 2 3 4 5 p2 blk red whi/brn whi/blu dc motor blk whi red red 4 1 2 3 p3...

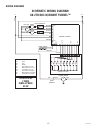

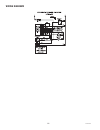

Page 78: Schematic Wiring Diagram

78 wiring diagrams schematic wiring diagram fpg-2 dbc, fpgb-2 dbc n w h i w h i / b l k b l k l1 left gate limit thermostat limit thermostat sol sol whi/ora whi/grn whi/yel red whi/blk whi/blk j1-6 j1-6 j6-10 j6-5 j6-1 control pc board coil relay right gate 1 11 shield switch unit assy b2 c4 c5 c6 a...

Page 79: Schematic Wiring Diagram

79 wiring diagrams n l1 left gate limit thermostat limit thermostat sol whi/ora whi/ora whi/grn whi/yel whi/yel red whi whi whi whi whi/blk whi whi whi whi grn grn whi whi j1-6 j1-1 j6-10 j6-5 j6-1 control pc board relay right gate 1 11 shield switch unit assy b2 c4 c5 c6 a2 a1 c3 c2 c1 whi red red ...