Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunn.Com h10x wa rnin g ver y ho t w ater use w ith ca re! ! 10889.0000e 02/08 ©1995 bunn-o-matic corporation to ensure you have the latest revision...

2 10889 020608 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

3 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 12537.0000 10889 021408 12593.0000 00831.0000 37881.0000 00656.0000 this equipmen...

4 electrical requirements caution - the dispenser must be disconnected from the power source until specified in initial set-up. This dispenser requires 2-wire, grounded service rated 208 or 240 volts ac, 40 amp, single phase. (refer to the dispenser’s dataplate for exact voltage requirement.) electr...

5 initial set-up caution - the dispenser must be disconnected from the power source throughout the initial set-up, except when specified in the instructions. 1. Connect the dispenser to the power source and turn on the water supply. 2. The “heater” led will glow for approximately five seconds. Durin...

6 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elect...

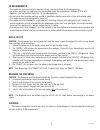

7 troubleshooting (cont.) problem automatic refill will not operate after drawing hot water. Water flows into the tank continu- ously. (dispenser disconnected from power source). Water flows into the tank con- tinuously (dispenser connected to power source). Water is cold. Probable cause 1. No water...

8 troubleshooting (cont.) problem water is cold (cont.) water boils continuously. Probable cause 3. Tank heater 4. Temperature control 5. Dry plug protection 1. Temperature control 2. Lime build-up remedy refer to service - tank heater for testing procedures. See page 19. Refer to service - electron...

9 service this section provides procedures for testing and replacing various major components used in this dispenser should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Component access warning - disconnect the dispenser from the power so...

10 service (cont.) electronic control assembly troubleshooting: check these items first • is circuit board popped out of bracket? • is circuit board wet due to misaligned overflow tube? • is water in overflow cup activating float switch? • is overflow cup not making good contact with tank? • is disp...

11 service (cont.) electronic controls (cont.) liquid level control test procedure 1. Disconnect the dispenser from the power source. 2. Check the voltage across terminals 3 & 4 of the electronic control assembly with a voltmeter. Connect the dispenser to the power source. The indication must be 200...

12 service (cont.) electronic controls (cont.) temperature control flow charts (cont.) temperature control test procedure 1. Disconnect the dispenser from the power source. 2. Check the voltage across terminals 3 & 4 of the electronic control circuit board with a voltmeter. Connect the dispenser to ...

13 service (cont.) electronic controls (cont.) 11. Disconnect the dispenser from the power source. If voltage was present as described, return the new triac assembly to bunn-o-matic for credit. The temperature control of the system is operating properly. If voltage was not present as described, rein...

14 triac assembly removal and replacement note - each triac installation requires the use of an approved silicone heat sink compound. Bunn-o-matic recommends the use of dow corning 340 compound or equivalent. It can be purchased direct from bunn- o-matic (p.N. M2522.1000) 1. Remove the existing tria...

15 service (cont.) limit thermostat p1993 fig. 5 limit thermostat test procedure: 1. Disconnect the dispenser from the power source. 2. There are two black wires on the limit thermostat terminals. One comes from the terminal block. The other goes directly to the tank heater terminal. Re- move the bl...

16 location: the overflow protection switch is located within the side of the dispenser inside the copper overflow cup. For testing or removal of the overflow protection switch, access may also be needed by removing the two screws attaching the electronic control assembly to its mounting bracket. Te...

17 solenoid valve location: the solenoid valve is located within the side of the dispenser on the right side near the bottom. To test the solenoid valve, access will also be needed to the electronic control assembly. Haz ardou s volt age disco nnec t fro m pow er so urce befo re re movin g! War ning...

18 whi/blu to electronic contol #1 red to terminal block red to electronic control #5 p1779 fig. 10 solenoid valve wiring 5. Lift out the solenoid valve. 6. Remove the two 10-32 slotted-head screws holding the solenoid valve to its mounting bracket. 7. Securely install the new solenoid valve to its ...

19 service (cont.) tank heater location: the tank heater is located in the tank lid. P1993 fig. 11 tank heater test procedure: 1. Disconnect the dispenser from the power source. 2. Check the voltage across the terminals of the tank heater with a voltmeter. Connect the dispenser to the power source. ...

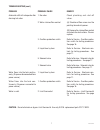

20 grn/yel blk red blu whi/vio blk triac tank heater blk red blu 200-240 volts ac 2 wire + gnd single phase 10888.0000c 01/07 © 1989 bunn-o-matic corporation sol schematic wiring diagram h10xa grn/yel refill probe pnk- 20 electronic control assy tan red whi/blu blk overflow protection switch blu 6 3...