- DL manuals

- Bunn

- Coffee Maker

- ICB-TWIN

- Installation And Operating Manual

Bunn ICB-TWIN Installation And Operating Manual

INSTALLATION & OPERATING MANUAL

ICB-TWIN

Infusion Series

®

with Smart Funnel

®

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the

quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper copy of the

required Illustrated Parts Catalog mailed via U.S. Postal Service

38112.0001E 03/08 ©2005 Bunn-O-Matic Corporation

www.bunn.com

Summary of ICB-TWIN

Page 1

Installation & operating manual icb-twin infusion series ® with smart funnel ® bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to obtain the illustrated parts catalog, visit the bunn-o-matic website, at www.Bunn.Com. This is ab...

Page 2

Page 2 38112.1 020608 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) co...

Page 3

Page 3 introduction this equipment will brew coffee into an awaiting server or airpot. The brewer may have an auxillary hot water faucet. It is only for indoor use on a sturdy and level counter or shelf. Please install in an area where there are no water jet devices. The infusion series, similar to ...

Page 4

Page 4 #03408.0000 #03409.0000 #00656.0000 #00986.0000 user notices carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should be kept in good condition. Replace any unreadable or damaged labels. #37881.0000 #00658.0000 risk of fire. Use a ul listed...

Page 5

Page 5 electrical requirements warning - if the power cord is ever damaged, it must be replaced by the manufacturer or its service agent with a special cord available from the manufacturer or its service agent in order to avoid a hazard. Refer to data plate on the brewer, and local/national electric...

Page 6

Page 6 plumbing hook up 1. Remove the shipping cap from the fitting on the rear of the brewer. 2. Attach the flare elbow fitting (supplied separately with the brewer) to the fitting. 3. Flush the water line and securely attach it to the flare elbow fitting. 4. Turn on the water supply. Plumbing requ...

Page 7

Page 7 enable on / off enable on / off brew brew operating controls a. On/off switch pressing the "on/off" pad will alternately turn the selected brewing side on and off. Pressing this pad during the brew cycle will interrupt the brew cycle, stopping the flow of water. Pressing this pad during progr...

Page 8

Page 8 initial set-up viewing assigned recipes & asset number 1. Make sure the on/off switch is off on the right side (led will not be lit). 2. Press and hold brew a on the right side. The display will show the name of the recipe assigned to brew a along with switch not on. This is to indicate that ...

Page 9

Page 9 coffee brewing without a smart funnel and mhg or dbc grinder: 1. Begin each brew cycle with a clean empty brew funnel. 2. Insert a bunn filter into the funnel. 3. Pour the fresh coffee into the filter and level the bed of grounds by gently shaking. 4. Slide the funnel into the funnel rails of...

Page 10

Page 10 cleaning 1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all surfaces on bunn-o-matic equipment. Do not clean this equipment with a water jet device. 2. Check and clean each sprayhead. The sprayhead holes must always remain open. Note:...

Page 11

Page 11 glossary ad card: an assembly consisting of computer chips and an instruction label. Used for loading advertising messages into the brewer. Auto pulse brew setup: the setting of a pulse brew routine by entering in the total desired water delivery time. The brewer will then calculate and perf...

Page 12

Page 12 recipe: set of brewing parameters stored in the brewer. The parameters are unique for each coffee name. Coffee recipes include brew ounces, bypass percentages, pulse brew or pre-infusion and drip time. Recipe card: an assembly consisting of a computer chip and an instruction label. Used for ...

Page 13

Page 13 programming using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify various brewing parameters such as brew temperatures, brew volumes, bypass percentages, pulse brew, etc. This allows for the precise brewing of various flavors of coffee. Pro...

Page 14

Page 14 main screen this screen will be shown when the brewer is ready for use. The screen displays the water temperature in the tank. When the water in the tank reaches the correct set temperature, the display will change from heating to ready to brew. Programming lockout switch (located on the mem...

Page 15

Page 15 programming the brewer (cont.) units metric done eng programming functions - level i programming functions - flow chart programming functions - level 2 set language? No yes review recipes no yes assign recipe no yes set temp 200° (-) done (+) ready degree 5° (-) done (+) enable ads? No done ...

Page 16

Page 16 programming functions - level i brew lockout this function allows the operator to prevent or allow brewing if the water temperature is less than the set ready temperature. Procedure for setting brew lockout: 1. To access this function screen press and hold the right hidden button. Release wh...

Page 17

Page 17 this function allows the operator to select the language used for the display. Procedure for setting language: 1. Press and hold the right hidden button until the display reads set language? And release. 2. Press yes to proceed. The display should now read english. Using (-) and (+), scroll ...

Page 18

Page 18 programming the brewer (cont.) programming functions - level 2 (cont.) units this function allows the operator to select if numeric settings are displayed in english or metric units. Procedure for setting the units: 1. Press and hold the right hidden button until the display reads set langua...

Page 19

Page 19 don't yes no know programming the brewer (cont.) programming functions - level 2 (cont.) review recipes (modify recipe, set up standard recipes) this function has three parts: 1. It allows the operator to view the brew settings for the various coffee recipes stored into the brewer. 2. It all...

Page 20

Page 20 programming the brewer (cont.) programming functions - level 2 (cont.) assign recipe this function allows the operator to assign recipes to the six brew buttons (three each side). Standard recipes and any saved recipes from a smart funnel or recipe card can be assigned to a brew button. Only...

Page 21

Page 21 programming the brewer (cont.) programming functions - level 2 (cont.) set new recipe (to set a new coffee recipe using a smart funnel or recipe card) using a smart funnel and a g9-2t dbc or mhg grinder: this function allows the operator to set brew vol- umes, bypass percentage, pulse brew t...

Page 22

Page 22 programming the brewer (cont.) programming functions - level 2 (cont.) tion of brew oz function). 8. Using (-) and (+), set the amount of brew water to be dispensed for that batch size. 9. When finished, press the other batch size and repeat step #8. 10. When finished setting both batch size...

Page 23

Page 23 27 for description of %bypass function). 13. Using (-) and (+), set the amount of bypass water (percentage) to be dispensed around the grounds. 14. When finished, press the other batch size and repeat step #13. 15. When finished setting both batch sizes, press and release done. The display s...

Page 24

Page 24 set new recipe using a recipe card to load coffee names and brew settings the g9-2t dbc or mhg grinder’s memory contains certain coffee names. If the operator uses a coffee name that is not already stored in the grinder’s memory, a recipe card can be obtained from the factory. The recipe car...

Page 25

Page 25 programming the brewer (cont.) programming functions - level 2 (cont.) set new recipe if not using a smart funnel and/or a g9-2t dbc or mgh grinder and/or a recipe card it is possible to operate the brewer without using a smart funnel and/or g9-2t dbc or mhg grinder. If a standard funnel or ...

Page 26

Page 26 programming the brewer (cont.) programming functions - level 2 (cont.) procedure for modifying coffee recipes: coffee recipes: brew oz: range: off, 10.0 oz to 224.0 oz (.3 - 6.6 l) for both batch sizes. This function allows adjustment of the brew volumes for each batch. 1. Press and hold the...

Page 27

Page 27 programming the brewer (cont.) programming functions - level 2 (cont.) coffee recipes: %bypass: range: 0 to 90% for both batch sizes this function allows adjustment of the amount of water that bypasses the grounds. The number signifies the percentage of the brew volume which does not flow ov...

Page 28

Page 28 programming the brewer (cont.) programming functions - level 2 (cont.) coffee recipes: set pulse brew/preinfusion this function allows the operator to program the brewer to “pulse” the sprayhead flow on and off during a brew cycle (start and stop the flow of water out of the spray- head). Th...

Page 29

Page 29 programming the brewer (cont.) programming functions - level 2 (cont.) setting pulse brew – easy pulse brew note: if the brewer is already on the set pulse brew screen, skip steps 1 through 6, and proceed directly to step 9. 1. Press and hold the right hidden button until the dis- play reads...

Page 30

Page 30 programming the brewer (cont.) programming functions - level 2 (cont.) setting pulsebrew/preinfusion – manual pulse brew note: if the brewer is already on the set pulse brew screen, skip steps 1 through 6, and proceed directly to step 9. 1. Press and hold the right hidden button until the di...

Page 31

Page 31 programming the brewer (cont.) programming functions - level 2 (cont.) review recipes? No yes no name coffee modify show next pressing no will advance to next function screen advance to the recipe to be modified (recipe name) modify show next set pulse brew no yes select method easy next man...

Page 32

Page 32 after a 5 second delay, display will advance to next recipe in brewer memory. If no other coffee names are present, the display will read; programming the brewer (cont.) programming functions - level 2 (cont.) coffee recipes: drip time this function allows the operator to adjust the drip tim...

Page 33

Page 33 programming the brewer (cont.) programming functions - level 2 (cont.) set temp this function allows the operator to adjust the brew water temperature in the tank. This also sets the hot water faucet dispense temperature. Procedure for setting the set temp range: 185° to 205° f (85° - 96° c)...

Page 34

Page 34 ready degree this function allows the operator to set the minimum temperature allowable to start a brew cycle. The range can be from 2° to 20° f within the set temperature. The water must be at the ready temperature or higher for the display to indicate ready to brew. If brew lockout is enab...

Page 35

Page 35 programming the brewer (cont.) programming functions - level 2 (cont.) enable ads this function allows the operator to choose whether or not to display an advertising message. An ad can be saved to the brewer by either writing the ad using the programming commands, or by entering the ad into...

Page 36

Page 36 programming the brewer (cont.) programming functions - level 2 (cont.) enable ads (continued) procedure to read in a new ad: note: saving a new ad will erase any previously saved ad in the brewer’s memory. 1. From the new ad? Screen, press and release card. 2. The display will show insert ad...

Page 37

Page 37 programming the brewer (cont.) programming functions - level 2 (cont.) enabl sanitation this function allows the operator to enable the sanita- tion function and set the time before a cleaning alert will be displayed. Procedure for enabling sanitation: range: 0.0 to 72.0 hrs 1. Press and hol...

Page 38

Page 38 programming the brewer (cont.) programming functions - level 2 (cont.) enable energysavr this function allows the operator to enable the energy savings mode function and set the idle time. Once the set idle time has expired, the operator can choose to have the heaters either turn off, or red...

Page 39

Page 39 programming the brewer (cont.) programming functions - level 2 (cont.) enable fresh timer this function allows the operator to enable the freshness alert and set the expiration time. The expiration time is the amount of time the product is allowed to sit in the server/dispenser before a fres...

Page 40

Page 40 programming the brewer (cont.) programming functions - level 2 (cont.) refill range: 0 to 155 this function allows the operator to adjust the sensitiv- ity of the refill circuit. This is mainly a troubleshooting feature. Water in different geographical locations can have different conductivi...

Page 41

Page 41 programming the brewer (cont.) programming functions - level 2 (cont.) l/r spray oz/m this function allows the operator to view or to enter the actual flow rate coming out of the sprayhead for each side of the brewer. This is not used to control the actual flow rate, but to tell the internal...

Page 42

Page 42 programming the brewer (cont.) programming functions - level 2 (cont.) l/r bypass oz/m this function allows the operator to view or to enter the actual flow rate coming out of the bypass nozzle for each side of the brewer. This is not used to control the actual flow rate, but to tell the int...

Page 43

Page 43 programming the brewer (cont.) programming functions - level 2 (cont.) calibrate flow this function allows the operator to enter the actual flow rate of the sprayhead and the bypass for each side of the brewer by dispensing both separately for one minute. The volumes are then entered into th...

Page 44

Page 44 programming the brewer (cont.) programming functions - level 2 (cont.) calibrate flow (continued) procedure to calibrate the bypass flow rate: 1. Place a container, accurately graduated and with a minimum capacity of 60 ounces, beneath the fun- nel. 2. Press and hold the right hidden button ...

Page 45

Page 45 programming the brewer (cont.) programming functions - level 2 (cont.) brew counters this function allows the operator to track the total num- ber of brew cycles completed, as well as the number of batches brewed using each of the brew buttons. There are six resettable counters, and one life...

Page 46

Page 46 programming the brewer (cont.) programming functions - level 2 (cont.) asset number this function allows the operator to enter the machine's asset number. This can be useful for tracking the usage or service of an individual machine within a group. Procedure to enter the asset number: 1. Pre...

Page 47

Page 47 programming the brewer (cont.) programming functions - level 2 (cont.) service number this function allows the operator to enter in the tele- phone number to call if service is needed. The service number will be displayed anytime there is a fault mes- sage displayed (see troubleshooting on p...

Page 48

Page 48 programming the brewer (cont.) programming functions - level 2 (cont.) service tools this function allows the testing of individual components and the ability to check switches for proper function. This function also tests the funnel sensor coil’s frequency (diagnostic tool for troubleshooti...

Page 49

Page 49 programming the brewer (cont.) programming functions - level 2 (cont.) test outputs? No yes service tools? No yes on next off on next off on next off pressing no will advance to factory defaults brew valve -> -> on next off bypass valve -> -> on next off funnel lock -> -> on next off pressin...

Page 50

Page 50 programming the brewer (cont.) programming functions - level 2 (cont.) procedure to test switches: the following switches can be individually tested: full batch -> -> half batch -> -> power -> -> brew switch a -> -> brew switch b -> -> brew switch c -> -> left hidden done (-) (+) 1. Press an...

Page 51

Page 51 programming the brewer (cont.) programming functions - level 2 (cont.) procedure to test coil frequency: 1. Press and hold the right hidden button until the dis- play reads set language. Press the right hidden button until the display reads service tools. 2. Press and release yes. The displa...

Page 52

Page 52 programming the brewer (cont.) programming functions - level 2 (cont.) factory defaults this function allows the operator to erase all of the previously entered recipes and ad messages. Factory-set default values will replace all previous settings. Procedure to set factory defaults: 1. Press...

Page 53

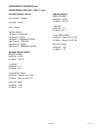

Page 53 programming the brewer (cont.) programming functions - level 2 (cont.) factory default values brew lockout - enabled language - english units - english switch recipe left brew a – regular left brew b – decaf left brew c – breakfast blend right brew a – regular right brew b – decaf right brew...

Page 54

Page 54 programming the brewer (cont.) programming functions - level 2 (cont.) factory default values (continued) hot tea recipe: brew volumes half batch – 64 oz full batch – 128 oz % bypass half batch – 0 % full batch – 0 % pulse brew times half batch – manual :30/:15/:15 full batch – manual :30/:1...

Page 55

Page 55 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of...

Page 56

Page 56 probable cause remedy problem troubleshooting (cont.) temperature too low heating time too long fill time too long temp sensor out of range, check for bad connections temp sensor out of range, check wire for shorts equipment will not operate 1. Water temperature in the tank does not meet the...

Page 57

Page 57 troubleshooting (cont.) probable cause remedy problem check plumbing and shut-off valves check for voltage across the termi- nals at the terminal block. Test the on/off switch. Refer to the test switch procedures on page 50. Test the brew switch. Refer to the test switch procedures on page 5...

Page 58

Page 58 troubleshooting (cont.) problem probable cause remedy check plumbing and shut-off valves remove the strainer and check for obstructions. Clear or replace. Check the sensitivity setting. Refer to the refill function on page 40. If the left three digit number is less than the right number, the...

Page 59

Page 59 troubleshooting (cont.) problem probable cause remedy refill valve – disconnect the brewer from the power source and remove wires from refill valve coil. Check for continuity across the terminals of the solenoid coil. If continuity is not present, replace the refill valve. If continuity is p...

Page 60

Page 60 troubleshooting (cont.) problem probable cause remedy water flows into tank continuously with power removed from brewer. 1. Refill valve 2. Refill probe or sensitivity set- ting 3. Control board foreign material lodged in valve, holding it in open state. Check the sensitivity setting. Refer ...

Page 61

Page 61 troubleshooting (cont.) problem probable cause remedy water will not heat or display shows heating time too long. 38112.1 042105 1. Limit thermostat 2. Temperature probe 3. Tank heaters 4. Control board remove power from the brewer. Check for continuity through the limit thermostat. Caution:...

Page 62

Page 62 no bypass water spitting or unusual steaming from sprayhead or air vent. 1. Bypass valve 2. Recipe settings 1. Lime buildup 2. Temperature probe 3. Control board test the bypass valve. Refer to the test outputs procedures on page 48. Check to make sure bypass % has been set for the current r...

Page 63

Page 63 troubleshooting (cont.) problem probable cause remedy inconsistent beverage level in server/dispenser check operating water pressure to the brewer. It must be between 20 and 90 psi (138 and 620 kpa). Test the brew valve. Refer to test outputs on page 48. Turn the valve on for 30 seconds and ...

Page 64

Page 64 troubleshooting (cont.) problem probable cause remedy dripping from sprayhead. Water overflows filter. Beverage overflows server. Brewer is making unusual noises. Repair or replace leaky valve bunn paper filters should be used for proper extraction check sprayhead the brew cycle should be st...

Page 65

Page 65 troubleshooting (cont.) problem probable cause remedy weak beverage. Bunn paper filters should be used for proper extraction for coffee, a sufficient quantity of fresh drip or regular grind should be used for proper extraction. Bunn-o-matic sprayhead should be used to properly wet the bed of...

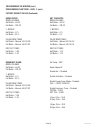

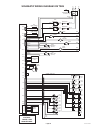

Page 66

Page 66 memory board schematic wiring diagram icb twin 37299.0001c 02/07 ©2005 bunn-o-matic corporation blu-14 blu-14 limit thermostat whi whi whi/red whi/yel whi whi refill right dispense j21-1 j21-3 j17-1 j17-5 j15-1 j15-5 j17-10 j17-14 c o n t r o l p c b o a r d com n.O. Yel blk-14 blu-14 whi/gr...