- DL manuals

- Bunn

- Dispenser

- IMIX

- Service & Repair Manual

Bunn IMIX Service & Repair Manual

Summary of IMIX

Page 1

Service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 42032.0000a 06/09 ©2009 bunn-o-matic corporation imix ® & imix ® -s+.

Page 2

2 42032 012609 bunn-o-matic commercial product warranty (excluding regular maintenance items) bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: par...

Page 3

3 user notices all notices on this equipment are written for your protection. All notices are to be kept in good condition. Replace any unreadable or damaged labels. Contents warranty .......................................................................................................................

Page 4

4 cleaning the use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all sur- faces on bunn-o-matic equipment. Do not clean this equipment with a water jet device. 1 x 24h 37254.0000a 07/04 © 2004 bunn-o-matic corporation notice the cleaning instructions ...

Page 5

5 required regular maintenance: when performing daily-weekly cleaning procedures, inspect o-rings, seals, and bushings for signs of wear or damage and replace immediately. Rinse once or twice daily or as required. On models imix-3, 4, 5, 3s+, & 5s+ a rinse reminder can be set using the rinse alarm. ...

Page 6

6 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encoun- tered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ele...

Page 7

7 troubleshooting (cont.) problem probable cause remedy water is not hot spitting or excessive steaming dripping from dispense tip water flows into tank continuously product overflows mixing chamber 1. Limit thermostat 2. Control thermostat 3. Triac 4. Tank heater 1. Lime build up 2. Control thermos...

Page 8

8 troubleshooting (cont.) problem probable cause remedy place an empty container beneath the dispense tip. Initiate a dispense cycle and check water temperature immediately below the dispense tip with a thermometer. Repeat until maximum temperature is reached. Reading should be 185 – 190°f. Adjust t...

Page 9

9 troubleshooting (cont.) problem probable cause remedy (a) test inlet solenoid valve, see “test refil ?” under “diagnostic ?” menu (b) check that unit is connected to water supply, and water supply is turned on. See “water is not hot” in problem section above. (a) empty overflow cup of water (b) ch...

Page 10

10 42032 060109 notes.

Page 11

11 service this section provides procedures for testing and replacing various major components used in this dispenser should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electrical equipment sh...

Page 12

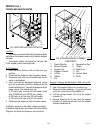

12 service(cont.) access panels location: all access panels are similar through the whole imix family (imix-5 shown). Before removing panels, make sure power is off to the machine and water is disconnected accept where indicated in testing procedures. Retain all screws and other attaching hardware f...

Page 13

13 location: the beeper is located on the back side of the component bracket assembly. Test procedures: 1. Enter programming to verify the “audible alarm” is activated. It will always beep when pressing switches during program modes. If activated, verify it is plugged correctly into j8 on the contro...

Page 14

14 service (cont.) auger drive components fig. 4 auger drive components p1341 location: the auger components are located inside the bottom part of the hopper except for the auger drive bracket, washer and locknut, which are located on the outside bottom rear of the hopper. The auger motors are locat...

Page 15

15 p2210.30 1. Hopper lid 2. Agitator disk assy 3. Auger drive shaft bushing 4. Mixing blade 5. Auger drive shaft 6. Auger shaft coupling 7. Locknut 8. Hopper 9. Auger wire 10. Ejector elbow 11. Auger motor mount- ing panel 12. Auger drive coupling 13. Auger motor 14. Dust seal 15. Shoulder screw 16...

Page 16

16 service (cont.) auger motor proximity rpm sensor (imix-3, 4 & 5 only) fig. 7 auger motor proximity sensor magnet proximity sensor nut & lockwasher fig. 8 proximity sensor terminals blk - common grn - signal red - +5vdc location: the proximity sensor and magnet are located on the back side of the ...

Page 17

17 service (cont.) ballast fig. 9 ballast location: the front door lamp ballasts are located behind the front access panel and may be on either side of the component bracket assembly. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the two black leads on the ballast ...

Page 18

18 service (cont.) control board (imix-3, 4 & 5 only) fig. 11 control board p3250.25 location: the control board is located behind the lower front access cover mounted on the component bracket. Test procedure: power supply circuitry: 1. Disconnect the dispenser from the power source. 2. With a voltm...

Page 19

19 service (cont.) control board (cont.) fig. 12 control board connectors p1640 removal and replacement: 1. Loosen the two #8-32 screws securing the com- ponent mounting bracket to the dispenser base. 2. Carefully pull the entire component bracket forward and rotate to gain access to the control boa...

Page 20

20 service (cont.) control board (imix-3s+ & 5s+ only) fig. 13 control board p3250.25 location: the control board is located behind the lower front access cover mounted on the component bracket. Test procedure: liquid level control circuitry: 1. Disconnect the dispenser from the power source. 2. Wit...

Page 21

21 service (cont.) 42032 060109 fig. 14 control board connectors removal and replacement: 1. Disconnect the three plugs on the main wiring har- ness from the connectors on the control board. 2. Remove the four #6-32 keps nuts securing the control board to the component bracket. 3. Remove control boa...

Page 22

22 fig. 16 touchpad connectors p1680 service (cont.) programming touchpad fig. 15 programming touchpad p1680 location: the touchpad is located on the front of the door below the display panel. Test procedure: enter programming and test switches. Removal and replacement: 1. Disconnect the dispenser f...

Page 23

23 service (cont.) programming - calibration & diagnostics 42032 060109 disable messages ? No exit yes tank temp xxx° ready temp xxx° (-) exit (+) strength adj. ? (-) exit (+) exit yes enter password (-) xxxx (+) calibration ? Exit yes locks/disables ? Exit yes audible alarm ? No exit yes enable ads...

Page 24

24 service (cont.) memory clock board (early models) (imix-3, 4 & 5 only) fig. 17 memory clock board p3250.25 location: the memory clock control board is located on the back side of the component bracket assembly. Test procedure: 1. Disconnect the dispenser from the power source. 2. Disconnect the w...

Page 25

25 temperature probe fig. 19 temperature probe p1665 service (cont.) fig. 20 temperature probe temp resistance voltage ready 190° f 891 Ω 1.5vdc 87.0° c room 70° f 11.9k Ω 4.5vdc 21.1° c location: the temperature probe is located on the top of the tank assembly. Test procedure: 1. Disconnect the dis...

Page 26

26 p1449 fig. 22 dispense switch terminals station #1 station #2 station #3 blk orn blk red blk tan dispense switches (imix-3s+ & 5s+ only) p3645 service (cont.) location: the dispense switches are located on the lower outside of the dispenser door. Test procedure: 1. Disconnect the dispenser from t...

Page 27

27 dispense switches service (cont.) p3243 fig.23 dispense switches location: the dispense buttons are located on the lower outside of the dispenser door and actuate switches on the dispense switch board located on the inside of the door. Test procedure: enter programming and test switches. Removal ...

Page 28

28 service (cont.) emi filter (230 volt imix-3, 4 & 5 only) fig. 25 emi filter p3250.25 location: the emi filter is located on the rear of the dispenser base near the terminal block on imix-3. The emi filter is located on the rear of the back side of the component bracket assembly on imix-4 & 5. Tes...

Page 29

29 vacuum fan fig. 27 fan p1436 location: the fan is located inside the dispenser housing on the right rear of the dispenser base plate. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the black and white wires from the fan terminals. 3. With a voltmeter, check the ...

Page 30

30 service (cont.) frother and whipper motor fig. 29 frother and whipper motor p1641.40 location: the frothers are located behind the dispenser door, mounted on the whipper motor shaft inside the whipper chamber. The whipper motors are located on the back side of the whipper motor mounting panel. Te...

Page 31

31 service (cont.) frother and whipper motor (cont.) 6. Pull the frother (6) off the motor shaft. Notice the flat side on the shaft and the matching flat inside the frother. It is important that these two flats are lined up when reassembling. 7. Slip the o-ring (5) off the whipper chamber recep- tac...

Page 32

32 service (cont.) lamp and lamp holder fig. 32 lamps & holders p1643.70 location: the lamps and lamp holders are located on the front of the upper panel behind the display panel. Test procedure: 1. Disconnect the dispenser from the power source. 2. Remove the outside window and display graphic. 3. ...

Page 33

33 fig. 35 limit thermostat terminals p1800 limit thermostat fig. 34 limit thermostat p1637 location: the limit thermostat is located in the center of the tank lid. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect both black wires from the limit thermo- stat. 3. Chec...

Page 34

34 on/off/night switch service (cont.) fig. 37 on/off/night switch terminals p1800 fig. 36 on/off/night switch p1637 location: the on/off/night switch is located inside the dispenser door on the lower right side of the whipper panel. Test procedures: 1. Disconnect the dispenser from the power source...

Page 35

35 normal/program/rinse switch service (cont.) fig. 39 normal/program/rinse switch terminals p1800 fig. 38 normal/program/rinse switch p1637 location: the normal/program/rinse switch is located inside the dispenser door on the upper right side of the whipper panel. Test procedures: 1. Disconnect the...

Page 36

36 service (cont.) overflow protection switch p1637 fig. 41 overflow protection switch leads p1212 fig. 40 overflow protection switch location: the overflow protection switch is located inside the copper overflow cup on the left side of the tank. Test procedures: 1. Disconnect the dispenser from the...

Page 37

37 service (cont.) solenoid valve (inlet) fig. 42 inlet solenoid valve p1445.40 location: the inlet solenoid is located inside on the rear of the dispenser base. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the two wires from the solenoid valve. 3. Check for cont...

Page 38

38 fig. 45 dispense solenoid valve terminals p1645 service (cont.) solenoid valves (dispense) fig. 44 dispense solenoid valves p1637.40 location: the dispense solenoids are located on the side of the tank. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the two wire...

Page 39

39 service (cont.) tank heater fig. 46 tank heater p1637.40 location: the tank heater is located inside the tank and se- cured to the tank lid. Test procedure: 1. Disconnect the dispenser from the power source. 2. With a voltmeter, check the voltage across the black and white wires 120 volt or 240 v...

Page 40

40 service (cont.) if voltage is present as described the transformer is operating properly. If voltage is not present as described, replace the transformer. Removal and replacement: 1. Loosen the two #8-32 screws securing the com- ponent bracket to the dispenser housing base. 2. Pull component brac...

Page 41

41 service (cont.) triac fig. 50 triac fig. 51 triac terminals location: the triac is mounted on the right side of the tank mounting bracket for models imix-3,4 & 5. Test procedure: 1. With the heater (load) connected and the triac is turned on, the voltage between the gate (tan wire) and either of ...

Page 42

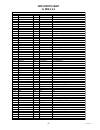

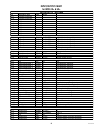

42 pin application imix type values j1-1 n/a n/a n/a n/a j1-2 heater output 120 vac triac signal j1-3 safety in input float switch imix and iced j1-4 neutral/l2 input n or 120vac self explanatory j1-5 l1 input 120 vac self explanatory j1-6 light output 120 vac turns on ballast j1-7 hot water output ...

Page 43

43 j6-1 auger 4 output 0 to 24 vdc adjustable to change dispense rate j6-2 rpm sensor input signal hall effect j6-3 rpm sensor output 5 vdc + power supply to hall effect j6-4 rpm sensor output negative power supply to hall effect j6-5 n/a n/a n/a n/a j6-6 dispense/whipper output n or l2 nuetral or s...

Page 44

44 j12-1 temp sensor input varistor j12-2 n/a n/a n/a n/a j12-3 level probe signal low ac monitors tank level j12-4 level probe grnd low ac monitors tank level j12-5 temp sensor input ? J12-6 n/a n/a n/a n/a j12-7 run position input ? Signals run position from rinse run switch j12-8 n/a n/a n/a n/a ...

Page 45

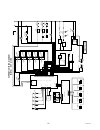

45 120 volts ac - 2 wire 120/208-240 volts ac - 3 wire single phase, 60hz schematic wiring diagram imix-3 grn l1 blk-16 blk blk blk blu-16 blk-16 tank heater limit thermostat whi whi whi whi n l2 blk fan j1-5 j1-8 j1-1 control circuit board #1 sol refill valve triac tan red whi blk blk gr y m j3-5 j...

Page 46

46 42032 060109.

Page 47

47 120 volts ac - 2 wire 120/208-240 volts ac - 3 wire single phase, 60hz schematic wiring diagram imix-4/imix-5 grn l1 blk-16 blk blk blk blk-16 blk-16 tank heater limit thermostat whi whi whi whi n l2 blk fan j1-5 j1-8 j1-1 c o n t r o l c i r c u i t b o a r d # 1 sol refill valve triac tan red w...

Page 48

48 42032 060109.

Page 49

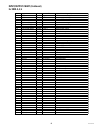

49 pin application imix type values j1-1 program connector j1-2 program connector j1-3 program connector j1-4 program connector j1-5 program connector j1-6 program connector j1-7 program connector j1-8 program connector j1-9 program connector j1-10 program connector j2-1 auger 1 output 0 to 24 vdc a...

Page 50

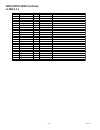

50 120 vo lt s ac - 2 wire single phase, 60hz schema tic wiring diagram imix-3s+ / imix-5s+ grn blk-16 blk-16 n.O. Com blk-16 limit thermost at c o n t r o l c i r c u i t b o a r d j4-5 j4-1 j4-10 j4-15 j4-20 j4-24 j5-5 j5-1 j2-6 j2-1 j3-4 j5-4 j3-1 j5-1 ballas t #1 bl k grn/bl k grn/wh i bl k 120v...

Page 51

51 230 vol ts ac - 2 wire single phase, 50hz schema tic wiring diagram imix-3s+a / imix-5s+a grn blk-16 blk-16 limit thermos ta t c o n t r o l c i r c u i t b o a r d j4-5 j4-1 j4-10 j4-15 j4-20 j4-24 j5-5 j5-1 j2-6 j2-1 j3-4 j5-4 j3-1 j5-1 ba ll as t #1 bl k gr n/ bl k gr n/ w hi bl k 240v : 24v a...

Page 52

52 42032 060109 120 vol ts ac - 2 wire single phase, 60hz schema tic wiring diagram imix5s+ - hot & iced grn blk-16 blk-16 limit thermost at c o n t r o l c i r c u i t b o a r d j4-5 j4-1 j4-10 j4-15 j4-20 j4-24 j5-5 j5-1 j2-6 j2-1 j3-4 j5-4 j3-1 j5-1 ba ll as t #1 bl k gr n/ bl k gr n/ w hi bl k 1...