- DL manuals

- Bunn

- Coffee Grinder

- JDF-4

- Installation And Operating Manual

Bunn JDF-4 Installation And Operating Manual

JDF-4

S/N 0005473 & UP

!

WA

RNIN

G

Re

frige

rat

ion

Compress

or and

Cond

enso

r Fan

Mot

or only

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the manual or to obtain the illustrated parts catalog, please visit the Bunn-O-Matic website,

at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. Contact Bunn-O-

Matic Corporation at 1-800-286-6070 to obtain a paper copy of the required Illustrated Parts Catalog mailed via U.S. Postal Service.

38218.0001D 02/08 ©2006 Bunn-O-Matic Corporation

www.bunn.com

DISCONTINUED VERSION

The information in this manual

is no longer current.

Summary of JDF-4

Page 1

Jdf-4 s/n 0005473 & up ! Wa rnin g re frige rat ion compress or and cond enso r fan mot or only installation & operating manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the manua...

Page 2

2 38218.1 020608 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compres...

Page 3

3 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 27442.0000 00986.0002 33461.0000 charge type r134a, amount 10 oz (283 gm) design ...

Page 4

4 initial set-up caution: the dispenser is very heavy! Use care when lifting or moving it. Use at least two people to lift or move the dispenser. Place the dispenser on a sturdy counter or shelf able to support at least 230 lbs. (104.3 kg). The jdf-4 is designed for indoor use only. Set the dispense...

Page 5

5 plumbing requirements this dispenser must be connected to a cold water system with operating pressure between 20 and 100 psi (138 and 690 kpa). This water source must be capable of producing a minimum flow rate of 3 fluid ounces (88.7 milliliters) per second. A shut off valve should be installed i...

Page 6

6 operating controls fig 2 refrigeration switch fig 3 sanitize switch & water valves a. Sanitize switch b. Water bath valve c. Main water valve (early models) c p2262.60 p2479 a b refrigeration switch the refrigeration switch is located on the top of the dispenser near the left rear corner. This swi...

Page 7

7 operating controls (cont.) fig 4 press and hold models a. Product dispense switch pressing and holding switch will initiate product flow from the respective nozzle; releasing the switch will stop the flow. B. Chilled water dispense switch pressing and holding switch will initiate chilled water flo...

Page 8

8 initial fill caution: the dispenser must be disconnected from the power source throughout the initial fill except when specified in the instructions. 1. Remove drip tray assembly and splash panel from the dispenser. Set the drip tray back into place. 2. Ensure that the main water valve (early mode...

Page 9

9 initial fill (cont) ambient concentrates (optional) 1. Install an ambient concentrate conversion kit (bunn-o-matic part number 33699.0000) per the instruc- tions provided in the kit. 2. Attach the concentrate product hose to the appropriate concentrate line located behind the dispenser’s splash pa...

Page 10

10 cleaning & preventive maintenance general cleaning and sanitizing procedures note: the bunn juice dispenser incorporates a rinse reminder feature which lights the rinse led on the front panel when it is time to rinse. See dip switch function list to activate this feature. Daily: rinse procedure t...

Page 11

11 cleaning (cont) 6. Select the dispense stations by pressing the “dispense switch” for that station. Use the “+/stop switch” for portion contol dispensers. The “refill” indicator will light and the beeper will sound for the dispense head selected. 7. Once the dispense heads have been selected, pre...

Page 12

12 monthly: clean condenser air filter 1. Remove the condenser air filter located on the rear of the dispenser. 2. Using a water spray, clean the air filter. Annually: replace pump tubing cleaning (cont) 38218.1 012207 note: high volume applications may require tubing changes every 6 months. 1. Open...

Page 13

13 adjustment & optional settings total dispense ratio set up procedure 1. Adjust water flow as described in water flow testing and adjustment. Record water output setting for later reference on each dispense head. 2. Enter program mode by simultaneously pressing both hidden switches. 3. Press and h...

Page 14

14 4. At the end of the 5 second period, the selected position will dispense water (no concentrate) for only 3 sec- onds. 5. Measure the water dispensed. 6. Adjust the water flow rate fig 7, (clockwise to increase flow rate; counterclockwise to decrease flow rate) to the corresponding product mix ra...

Page 15

15 3. To decrease the pump speed, press and hold the left-hand “hidden switch” (half-filled circle) and then mo- mentarily press the “product dispense switch (“+/stop switch” for portion control dispensers). Each time the “product dispense” (“+/stop”) switch is pressed, the motor speed is decreased ...

Page 16

16 1. Enter the “pump speed programming” mode by simultaneously pressing both “hidden switches”. Note that the beeper sounds twice and that the “program” indicator begins flashing. 2. Enter a “lockout” password as follows: a) press and hold the left hand “hidden switch” (half filled circle) for mode...

Page 17

17 adjustment & optional settings (cont) password protection the programming modes and service lockout function may be password protected to prevent accidental or unauthorized access to these features. The dispenser is shipped from the factory with a password of “0” (no password.) 1. Enter the “pump...

Page 18

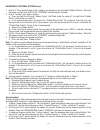

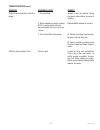

18 dispense fault list “refill” indicator beeper fault 2 flashes 2 beeps dispense station locked out. 3 flashes 3 beeps dispense/rinse sensing fault. 4 flashes 4 beeps dispense/rinse knob mis-positioned. 5 flashes 5 beeps pump motor stalled/speed sensor inoperative. All “refill” 3 beeps dispenser lo...

Page 19

19 dip switch function list dip switch controls off on 1 “refill” indicator when “concentrate out” is detected. Inactive active 2 lockout dispense components when “concentrate out” is detected. Inactive active (note) 3 number of positions that can dispense/rinse simultaneously. 3 2 4 rinse timer off...

Page 20

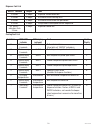

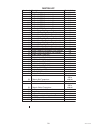

20 function # 0 1 2 3 4 101 102 103 104 7 8 9 10 11 12 13 14 15 16 17 18 27 28 29 30 31 32 33 34 50 51 52 53 54 55 75 76 77 78 99 100 description enter password set pump 1 rpm (concentrate a) set pump 2 rpm (concentrate a) set pump 3 rpm (concentrate a) set pump 4 rpm (concentrate a) set pump 1 rpm ...

Page 21

21 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elec...

Page 22

22 troubleshooting (cont.) check for "on" position or no con- tinuity - replace switch. Clean or replace condenser filter. Replace fan motor or check fan blades for obstructions. Check compressor relay coil for 120vac. Note: always check power with coil attached. If no 120vac - replace board. If yes...

Page 23

23 troubleshooting (cont.) dispense station not working "refill" led and beep code. A) 3-beep - dispense/rinse sens- ing fault. B) 4-beep - dispense/rinse knob mis-positioned. Refill led not extinguishing all stations dispense concentrate only 1. Bottle adapter switch mem- brane a) dispense/rinse sw...

Page 24

24 troubleshooting (cont.) dispense station concentrate only dispense station water only dispense starts then stops or "refill" flashes and beeps 5 times. Replace solenoid (24vdc) or check wire connection between water valve and main control board. Rotate knob to dispense position. Check for variabl...

Page 25

25 troubleshooting (cont.) water leak filling drip tray or around dispense deck area water leaking beneath machine erratic spray during dispense dispense nozzle dripping water can't access programming 1. Initial fill/setup 2. Dispense deck 3. Water pressure greater than 100psi 1. Bath tank overflow....

Page 26

26 troubleshooting (cont.) unit is not working and no beep/light fault codes difficulty brixing and/or weak bev- erage 1. Step-down transformer. 2. Main control board. 1. Product viscosity or too cold. 2. Low water pressure. 3. High water pressure. 4. Dispense valve adjustment set- ting. 5. Brix rat...

Page 27

27 difficulty brixing and/or weak bev- erage difficulty brixing bag-in-box 1. Pump tubing. 2. Bottle adapter assembly leaking note: leaking water into con- centrate bottle during rinse of any station. 3. Use of portable water pump. Vacuum leak inspect, clean, or replace tubing and pump rotor/rollers...

Page 28

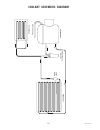

28 coolant schematic diagram condenser suction accumula to r compressor ev apora to r process tube fil ter dr yer 38218.1 030306.

Page 29: Schematic Wiring Diagram

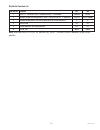

29 j3-1 j3-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d j1-18 j7-1 j7-5 j7-10 j7-16 j8-1 j8-8 j6-1 j6-6 j6-12 right lamp assy. Left lamp assy. Grn grn grn blu brn/blk red/blk red/blk gr y wh i blk limit thermostat k2 k2 comp. Compressor assembly + – rect transformer whi/blu whi whi whi whi/red whi/...

Page 30

30 j3-1 j3-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d j1-18 j7-1 j7-5 j7-10 j7-16 j8-1 j8-8 j6-1 j6-6 j6-12 sol sol #4 dispense sol ice water dispense tan red/blk red/blk red/blk whi/yel whi/blu sol #2 dispense #3 dispense red/blk whi/orn sol #1 dispense #4 rinse & dispense limit #2 rinse & dispe...

Page 31

31 j3-1 j3-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d j1-18 j7-1 j7-5 j7-10 j7-16 j8-1 j8-8 j6-1 j6-6 j6-12 j5-1 j5-5 j5-1 0 j5-1 5 j5-1 9 j4-1 j4-5 j4-10 j4-1 4 j9-1 j9-6 red whi grn/whi grn/blk orn/blk whi/blk blu/whi blk/whi red/blk red/whi orn grn blu blu/blk blk red whi grn/whi grn/blk orn/b...

Page 32

32 j3-1 j3-2 j1-1 j1-5 j1-10 c o n t r o l p c b o a r d j1-18 j7-1 j7-5 j7-10 j7-16 j8-1 j8-8 j6-1 j6-6 j6-12 right lamp assy. Left lamp assy. Grn 120v models grn grn n a b a b a b l1 blu brn/blk red/blk red/blk red/bl k gr y whi blk limit thermostat k2 k2 comp. Compressor assembly + – rect transfo...