- DL manuals

- Bunn

- Coffee Maker

- LCA-1

- Installation & Operating Manual

Bunn LCA-1 Installation & Operating Manual

LCR-1

LCA-1

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

44806.0001A 08/11 ©2011 Bunn-O-Matic Corporation

Summary of LCA-1

Page 1

Lcr-1 lca-1 installation & operating guide bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating manual, or to view the illustrated parts catalog, programming manual, or service...

Page 2

2 44806.1 050511 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compres...

Page 3

3 warranty .................................................................................................................................................2 user notices ....................................................................................................................................

Page 4: Reminder!

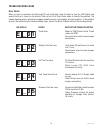

4 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 00656.0001 00986.0002 11646.0002 37881.0000 as directed in the international plum...

Page 5

5 electrical requirements refer to the data plate on the dispenser, and local/national electrical codes to determine circuit requirements. Warning - if the power cord is ever damaged, it must be replaced by the manufacturer or its service agent with a special cord available from the manufacturer or ...

Page 6

6 initial set-up note: the lca-1 weighs approximately 40 lbs. (18 kg) and the lcr-1 weighs approximately 55 lbs. (25 kg), when empty. If necessary, use more than one person when lifting or moving the dispenser. 1. Cut the plastic bands and remove the top box and other packing. 2. Locate and remove t...

Page 7

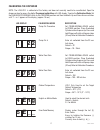

7 operating controls and interface (continued next page) 1. Dispense switch: push and hold to dispense product. 2. Hot water switch: push and hold to dispense hot water only. 3. Portion switch: momentarily pushed to select a portion dispense. 4. Power led: red - illuminates when ac power is applied ...

Page 8

8 selector switches: (located behind the splash guard panel) a. Down arrow: used to scroll to the next menu screen. B. (+): used to increase the displayed value. C. (exit): used to exit the programming menu. D. (-): used to decrease the displayed value. E. Up arrow: used to scroll to back to previou...

Page 9

9 installing pump tubing installing the pump tubing 1. Remove the bib and product shelf to access the pump assembly. 2. Loosen thumbscrew (fig 1) to remove the cover plate and set it aside. 3. Depress tension screw and remove it from notch in the pump body to release the tension on the pump band. (f...

Page 10

10 initial fill & heat 1. Select normal and run on the selector switches. 2. Confirm the water supply is on. 3. Connect the dispenser to the power source. 4. The red power led will illuminate and water will begin flowing into the tank. The dispenser will automatically stop filling when the tank is f...

Page 11

11 rinse alarm feature periodic rinsing of the dispense tip is essential for proper maintenance and optimum performance of the dispenser. The automated rinse alarm feature has two levels of operation, disabled and warning. Level selected alarm disabled none warning warning led will come on 4 hrs pri...

Page 12: 1 8 0

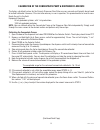

12 displays software version # - exits to home view after 3 seconds. Programming the dispenser two basic modes are available to the operator: display mode and program mode. Open the dispenser door to access the digital programming switches with led display. To enter the display mode, set the run/nig...

Page 13: 0 1 8 0

13 programming the dispenser (cont.) program mode : used to change or enter new set-up values. To enter the program mode, set the run/night/program switch to the program position, the unit will display “__ppp” to indicate it is in the program mode. Use the menu switch to scroll to the next display. ...

Page 14

14 operating the dispenser set the function selector switch to “normal” and the mode selector switch to “run.” 1a. Push and hold dispense mode (cup at a time). A. Place cup on the tray beneath the dispensing tip. B. Push and hold the dispense switch until the cup is nearly full. C. Remove the cup. 1...

Page 15

15 general cleaning and sanitizing procedures note: the bunn® lca-1 & lcr-1 dispensers incorporates a “user selectable” rinse reminder feature, which displays warning led on the front panel when it is time to rinse. See programming functions to activate this feature. Daily rinsing 1. Open dispenser ...

Page 16

16 replacing the pump tubing the pumps and tubing used in the dispenser are designed to give maximum performance and long life. However, the tubes are a wear item and must be replaced periodically. How long the tubes last is dependent on usage and properties of the concentrate. Excessive wear will r...

Page 17: 1 R U N

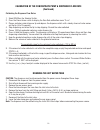

17 error code memory display cycles through the last (3) error codes. Erase by holding the decrease (-) switches for 10 sec. Currently have to hold (+) & (-) led display calibration mode description calibrating the dispenser pump cal. Procedure set prime-normal-rinse switch to prime position. Place ...

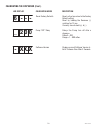

Page 18: 6 - - -

18 calibrating the dispenser (cont.) led display calibration mode description resets all set up values to the factory default setting. Reset by holding the decrease (-) switches for 10 sec. Currently have to hold (+) & (-) delays the pump turn off after a dispense. Default = 200 range = 1 - 999 msec...

Page 19: E _ 0

19 led display error description/troubleshooting troubleshooting guide error codes when an error has occurred, the warning led will be flashing. Open the door to view the led display and record the error # shown on the display. Refer to the list of error codes below to identify the problem. The trou...

Page 20: E _ 0

20 troubleshooting guide (cont.) error codes (continued) led display error description/troubleshooting cooling time too long cabinet sensor has not reached the set point in 4 hours. Check: air filter plugged or blocked. Cabinet door left open or faulty seal. Wiring for shorts or open connections. Ev...

Page 21

21 (continued next page) calibration of the concentrate pump & dispenser flow rate the factory set default values for the pump & dispenser flow rates are very accurate and typically do not need to be field calibrated. However, if the mix ratio accuracy is ever in question, this procedure can be used...

Page 22

22 calibration of the concentrate pump & dispenser flow rate (continued) calibrating the dispenser flow rates. 1. Select rinse on the selector switch. 2. Press the down arrow switch to display the flow rate calibration menu “2 run” 3. Place a container under dispense tip and depress the dispense swi...

Page 23

23 pnk pnk red/blk red/blk blu/blk blu/blk org org transformer m rpm sensor pump blk red blk red blk blk blk blk blk red blk blk whi/org whi/org tan tan blk whi whi whi whi whi whi whi whi whi yel yel yel blu grn org org red grn blk 1 secondary primary j2-4 j2-1 j1-1 j1-5 j1-6 j7-5 j7-1 limit therm....