- DL manuals

- Bunn

- Coffee Maker

- LCA-2 LCC-2

- Installation And Operating Manual

Bunn LCA-2 LCC-2 Installation And Operating Manual

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

www.bunnomatic.com

BUNN

®

34766.0000 12/02 ©2002 Bunn-O-Matic Corporation

LCA-2

LCC-2

! WARNING

HOT LIQUIDS

! A

VE

RT

ISS

EM

EN

T L

IQU

IDE

S C

HA

UD

S

PO

W

ER

RE

AD

Y

PO

RT

IO

N

RI

NS

E

RE

FI

LL

ST

OP

!

HO

T

W

AT

ER

Summary of LCA-2 LCC-2

Page 1

Installation & operating manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com bunn ® 34766.0000 12/02 ©2002 bunn-o-matic corporation lca-2 lcc-2 ! Warning hot liquids ! A ve rt iss em en t l iqu ide s c ha ...

Page 2

2 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compressors on refrige...

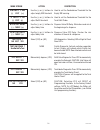

Page 3: Warning

3 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 00656.0000 00986.0002 11646.0002 ! Warning do not overload circuit. Always electr...

Page 4

4 electrical requirements caution: the dispenser must remain disconnected from the power source until specified in electrical hook-up. The lca-2 and lcc-2 dispensers are supplied with a 120-volt / 15 amp cord set and require a 2-wire, grounded, individual branch circuit rated for 120 volts ac, 15 am...

Page 5

5 initial set-up note: the lcc-2 (chilled unit) weighs approximately 80 lbs. (36.3 kg) and the lca-2 (ambient unit) weighs approximately 70 lbs. (31.8 kg). If necessary, use more than one person when lifting or moving the dispenser. 1. Locate and remove the information packets and tube kits from top...

Page 6

6 setting dispenser flow rate the dispenser comes from the factory with flow restrictors in the mix chambers. With the restrictors in place the dispense rate is about 1.8 oz./sec (53.2 ml/sec) and is used primarily for cup at a time dispensing. The flow restrictors can be removed to increase the dis...

Page 7

7 selecting the correct pump tubing there are two pump tube sizes available for use with this dispenser. To determine the correct tubing for you application, first determine the dispenser flow rate you intend to use, refer to setting dispenser flow rate . Then look up the recommended tube size for t...

Page 8

8 operating controls and interface 1. Dispense handles: pull and hold to dispense product. 2. Stop switch: momentary switch stops all dispense functions. 3. Hot water switch: push and hold switch to dispense hot water from the center dispense tip. 4. Portion control switch: momentarily pushed by use...

Page 9

9 initial fill & heat 1. Select normal on the function selector switch and run on the mode selector switch. 2. Confirm the water supply is on. 3. Connect the dispenser to the power source. The red power led will illuminate and water will begin flowing into the tank. The dispenser will automatically ...

Page 10

10 flavorgard™ feature flavorgard™ is a patented feed back control loop that monitors the mixed product and adjusts the concentrate delivery rate to maintain a consistent mix profile, i.E. Flavor profile. The system consists of a conductance probe mounted in the final stages of the mixing chamber, a...

Page 11

11 34766 112502 rinse alarm feature periodic rinsing of the mix chambers and dispense tips is essential for proper maintenance and optimum performance of the dispenser. The automated rinse alarm feature has three levels of operation, disabled, warning only and warning with brew lockout, see chart fo...

Page 12

12 programming the dispenser remove the lower splash guard assembly to access the digital programming module with lcd display. Press the down arrow key to inter the programming menu. Use the up and down arrow keys to scroll through the menu screens. Select exit to leave the programming function and ...

Page 13

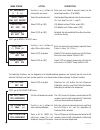

13 menu screen action description enter password (-) 0 (+) the following functions can be password protected if warranted. Lock flavor ? Exit yes flavors locked exit lf disp volume (-) 0.0oz (+) rt disp volume (-) 0.0oz (+) tank temp 180 (-) exit (+) ready temp 175 (-) exit (+) cabinet temp 65 (-) e...

Page 14

14 set password ? (-) 0 (+) select units eng exit metric chilled unit ? No exit yes rinse alarm ? No exit yes menu screen action description cal left pump ? Pull dispenser cal lf pump vol (-) 20ml (+) cal lf wtr flow pull dispenser if no - go to cal right side menu. Cal left side ? Exit yes the foll...

Page 15

15 menu screen action description cal lf wtr vol (-) 36.0oz (+) cal left side ? Exit yes cal right side ? Exit yes cal right pump ? Pull dispenser cal rt pump vol (-) 20ml (+) cal rt wtr flow pull dispenser cal rt wtr vol (-) 36.0oz (+) cal right side ? Exit yes xxx cal -> xxx (-) tanktemp (+) xxx c...

Page 16

16 menu screen action description bib empty -> 400 (-) exit (+) 0 refill -> 155 (-) exit (+) wtr start delay (-) .15sec (+) wtr stop delay (-) .15sec (+) test led’s ? No exit yes test switches ? Useswitchtotest test refill ? Exit yes test heater ? Exit yes factory defaults no yes use the (+) or (-) ...

Page 17

17 loading the concentrate 1. Thoroughly mix concentrate by vigorously shaking the product bag-in-box (bib). 2. Pull the bib connector through the hole provided in the box and place it on the drip tray with the connector facing up. (see fig. 1) 3. Open the dispenser door and locate the appropriate l...

Page 18

18 operating the dispenser set the function selector switch to normal and the mode selector switch to run. 1. Pull and hold dispense mode (cup at a time) a. Place cup on the cup tray beneath the desired dispensing tip. For a large container, flip the cup tray up and place the container on top of the...

Page 19

19 cleaning & preventative maintenance general cleaning and sanitizing procedures note: the bunn ® liquid coffee dispenser incorporates a “user selectable” rinse reminder feature, which lights the rinse led on the front panel and disables dispensing when it is time to rinse. See programming function...

Page 20

20 replacing the pump tubing the pumps and tubing used in the dispenser are designed to give maximum performance and long life. However, the tubes are a wear item and must be replaced periodically. How long the tubes last is dependent on usage and properties of the concentrate. Excessive wear will r...

Page 21

21 draining the hot water tank caution: the dispenser must be disconnected from the power source throughout these steps. 1. Disconnect the dispenser from the power source. 2. Shut off and disconnect the incoming water supply. 3. Remove the front splash panel. 4. Pull out drain tube to empty into a s...

Page 22

22 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • only qualified service personnel should...

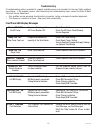

Page 23

23 overflow cup full. Empty cup heating time too long check heating circuit fill time too long check water supply tank temp sensor out of range check for bad connections cool temp sensor out of range check for bad connections 1. Refill valve stuck open 2. Faulty refill probe 3. Faulty overflow switc...

Page 24

24 screen displayed possible cause troubleshooting procedures service required service required check to confirm that wire(s) are not pinched between two surfaces or connected to each other. Service required service required service required service required service required remove blockage source m...

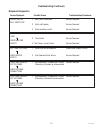

Page 25

25 field calibration of the concentrate pumps / dispenser flow rates the factory set default values for the pump & dispenser flow rates are very accurate and typically do not need to be field calibrated. However, if the mix ratio accuracy is ever in question, this procedure can be used to recalibrat...

Page 26

26 34766 112502 dispenser flow rate calibration 13. Press down arrow key to display the cal lf wtr flo menu screen. 14. Place a 64 oz (2000 ml) graduated container under left dispense tip and pull the left dispense handle momentarily. The dispenser will dispense water for 20 seconds and then shut of...

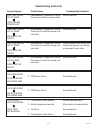

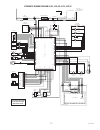

Page 27

27 34641.0000c 12/02 © 2002 bunn-o-matic corporation 120 volts ac 2 wire 120/208-240 volts ac 3 wire 208-240 volts ac 2 wire single phase 50/60hz j14-1 j14-7 j7-1 j7-5 j7-10 j2-1 j2 -8 j3-1 j3-6 j4-1 j4-5 j5-1 j5-3 j6-1 j6-5 j6-10 j6-15 j6-20 j1-1 j1-4 j15-1 j15-4 c o n t r o l p c b o a r d j8-1 j8...

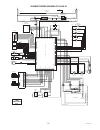

Page 28

28 34641.0001b 12/02 © 2002 bunn-o-matic corporation j14-1 j14-7 j7-1 j7-5 j7-10 j2-1 j2 -8 j3-1 j3-6 j4-1 j4-5 j5-1 j5-3 j6-1 j6-5 j6-10 j6-15 j6-20 j1-1 j1-4 j15-1 j15-4 c o n t r o l p c b o a r d j8-1 j8-3 j16-1 j16-5 j16-12 double pole limit thermostat orn blk blk blk blk whi whi tan tan blk gr...