Re gu la r de ca fe re fil l re ad y po we r rin se ca raf e´ ho t w at er st op ! 2. P res s an d h old wh en in ma nu al m od e o r pre ss and re lea se wh en in p ort ion mo de 1. Pre ss for car afe´ an d cho ose pr od uct lcc-2 lp bunn chilled installation & operating guide bunn-o-matic corporat...

2 39288 050511 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

3 warranty .................................................................................................................................................2 user notices ....................................................................................................................................

4 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices are to be kept in good condition. Replace any unreadable or damaged labels. 00986.0002 11646.0002 37881.0000 39288 060711 40054.0000 reminder! Clean air filt...

5 electrical requirements refer to data plate on dispenser, and local/national electrical codes to determine circuit requirements. Warning - if the power cord is ever damaged, it must be replaced by the manufacturer or its service agent with a special cord available from the manufacturer or its serv...

6 initial set-up note: the lcc-2 lp weighs approximately 70 lbs. (32 kg). If necessary, use more than one person when lifting or moving the dispenser. 1. Cut the plastic bands and remove the top box. 2. Locate and remove the parts box from top of packaging and set aside. 3. Remove foam packing. 4. S...

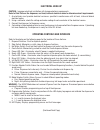

7 operating controls and interface refer to the photos on the following page for the location of these features. 1. Dispense switches: push to dispense product. 2. Stop switch: momentary switch stops all dispense functions. 3. Hot water switch: push and hold switch to dispense hot water from the cen...

8 14 11 12 13 2 4 1 3 7 8 5 6 9 10 39288 083106.

9 installing pump tubing installing the pump tubing refer to the tube replacement instruction inside the cabinet door. 1. Loosen the thumbscrew securing the tubing retainer plate to the pump body and set the retainer plate aside. 2. Depress the tension screw and remove it from the notch in the pump ...

10 initial fill & heat 1. Select normal on the function selector switch and run on the mode selector switch. 2. Confirm the water supply is on. 3. Connect the dispenser to the power source. The red power led will illuminate and water will begin flowing into the tank. The dispenser will automatically...

11 rinse alarm feature periodic rinsing of the mix chambers and dispense tips is essential for proper maintenance and optimum performance of the dispenser. The automated rinse alarm feature has two levels of operation, disabled and warning. Alarm level selected alarm mode disabled none warning rinse...

12 programming the dispenser open the dispenser door to access the digital programming module with led display. Two basic modes are available to the operator: display mode and program mode. To enter the display mode, set the run/night/program switch to the run position. To enter the program mode, se...

13 regular dispense total displays total regular coffee dispensed (xx.X gal) decaf dispense total displays total decaf coffee dispensed (xx.X gal) displays software version # - exits to home view after 3 seconds. Lcd display display mode description empty product threshold displays empty product thr...

14 programming the dispenser (cont.) program mode : used to change or enter new set-up values. To enter the program mode, set the run/night/program switch to the program position, the unit will display “__ppp” to indicate it is in the program mode. Use the menu switch to scroll to the next display. ...

15 right (decaf) dispense total lcd display program mode description programming the dispenser (cont.) program mode (continued) empty product threshold set conductance threshold default = 600 range = 100 min / 900 max to check conductance of hot water, view the display while rinsing. Set value to 10...

16 priming the concentrate lines 1. Open the dispenser door. 2. Select prime on the function selector switch and run on the mode selector switch. 3. Close the dispenser door. 4. Place a container under the dispense tip. 5. Activate the appropriate dispenser until concentrate flows from the dispense ...

17 operating the dispenser set the function selector switch to “normal” and the mode selector switch to “run.” 1a. Push and hold dispense mode (cup at a time). See programming functions to set this amount. A. Place cup on the tray beneath the dispensing tip. B. Push and hold the corresponding dispen...

18 cleaning & preventative maintenance general cleaning and sanitizing procedures note: the bunn ® lcc-2 lp dispenser incorporates a “user selectable” rinse reminder feature, which lights the rinse led on the front panel when it is time to rinse. See programming functions to activate this feature. D...

19 replacing the pump tubing the pumps and tubing used in the dispenser are designed to give maximum performance and long life. However, the tubes are a wear item and must be replaced periodically. How long the tubes last is dependent on usage and properties of the concentrate. Excessive wear will r...

20 right (decaf) water rate set prime-normal-rinse switch to rinse position. Press and hold decaf dispense switch until flow stops (20 sec.) refer to field calibration of the concentrate pumps. Lcd display calibration mode description calibrating the dispenser left (regular) pump cal. Set prime-norm...

21 calibrating the dispenser (cont.) lcd display calibration mode description right (decaf) water rate enter liters collected from the 20 sec. Test above. Default = 1.08 range = 0.95 - 1.12 liters cooler control temperature delays the pump turn off after a dispense. Default = 200 range = 1 - 999 mse...

22 led display error description/troubleshooting troubleshooting guide error codes when an error has occurred, all door led’s will be flashing. Open the door to access the led display and record the error code. Refer to the list of error codes below to identify the problem. A troubleshooting guide i...

23 troubleshooting guide (cont.) error codes (continued) led display error description/troubleshooting tank temp sensor failed sensor reading out of range (high or low). Faulty sensor wiring. Switch board failure unable to communicate with the switch board in the door. Faulty wiring between the door...

24 (continued next page) field calibration of the concentrate pumps & dispenser flow rates the factory set default values for the pump & dispenser flow rates are very accurate and typically do not need to be field calibrated. However, if the mix ratio accuracy is ever in question, this procedure can...

25 field calibration of the concentrate pumps & dispenser flow rates (continued) 5. Place a 1500 to 2000 ml graduated container under left dispense tip. 6. Press & hold the regular dispense switch. The dispenser will display a 20 second count down timer and then stop dispensing automatically. Releas...

26 39288 083106 blu/blk-16 red-22 wht/blk-22 wht/blu-22 wht/blu-22 wht/blk-22 tan-22 m board switch & led red/blk-18 rpm sensor right pump m rpm sensor left pump wht/red-18 brn/wht-18 brn/blk-18 grn red blk 1 red grn blk 1 j5-1 j5-3 wht/red-18 red-22 wht/blk-22 red/blk-18 brn/wht-18 brn/blk-18 tan-2...