- DL manuals

- Bunn

- Beverage Dispenser

- LCR-3 HV

- Installation & Operating Manual

Bunn LCR-3 HV Installation & Operating Manual

LCR-3 HV

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

41129.0000H 06/11 ©2008 Bunn-O-Matic Corporation

Summary of LCR-3 HV

Page 1

Lcr-3 hv installation & operating guide bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating manual, or to view the illustrated parts catalog, programming manual, or service ma...

Page 2

2 41129 050511 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

Page 3

3 introduction always follow the concentrate manufacturer’s for recommendations for proper storage and shelf life. The product flavor profile is extended by the refrigerated cabinet featured in the lcr-3. This dispenser is designed to operate at ambient temperatures from 32°f (0°c) minimum to 104°f ...

Page 4

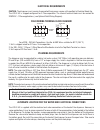

4 optional field wiring 120/208 v, 37.6 a, 7820 w 1ph, 3-wire + gnd, 60hz 120/240 v, 43.2 a, 10400 w 1ph, 3-wire + gnd, 60hz for use on individual branch circuit only 120/208y v, 32.8 a, 12000 w 3ph, 4-wire + gnd, 60hz 28181.0004 37947.0002 user notices carefully read and follow all notices on the e...

Page 5

5 electrical requirements caution: the dispenser must remain disconnected from power source until specified in electrical hook-up. The lcr-3 hv is shipped configured for 3 phase operation. The internal terminal block must be rewired for 208/240v – 1phase applications, (see optional field wiring diag...

Page 6

6 electrical hook-up caution: improper electrical installation will damage electronic components. 1. An electrician must provide electrical service as specified in conformance with all local, state and federal electrical codes. 2. Using a voltmeter, check the voltage and color-coding of each conduct...

Page 7

7 installing the pump tubing (refer to the tubing installation instructions in side the cabinet door for details.) 1. Loosen the thumbscrew securing the tubing retainer plate to the pump housing. Set the retainer plate aside. 2. Depress the tension screw and remove it from the notch in the pump body...

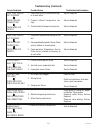

Page 8

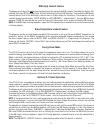

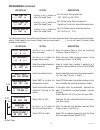

8 operating controls and interface 1. Master on/off switch: disconnects ac power to the dispenser. 2. Hot water handle: pull and hold to dispense hot water manually. 3. Door interlock switch: unit will not dispense product if the door is open. 4. Lcd display: displays status, programming menus and f...

Page 9

9 initial fill & heat 1. Confirm the water supply is on. 2. Connect the dispenser to the power source. 3. Turn the master on/off switch on and select run on the function selector switch. The lcd will display “tank filling – please wait!” and water will begin flowing into the tank. 4. Once the tank i...

Page 10

10 rinse alarm feature periodic rinsing of the mix chambers and dispense tips is essential for proper maintenance and optimum performance of the dispenser. The automated rinse alarm feature has three levels of operation; see programming the dispenser to select the desired alarm mode. Alarm level ala...

Page 11

11 bib empty lockout feature the dispenser can be set to not dispense product when the concentrate bib is empty. To enable this feature, first calibrate the empty bib threshold (refer to field calibrating the empty bib warning). Then enable the bib empty lockout feature (refer to the bib empty locko...

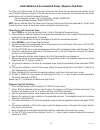

Page 12

12 programming the dispenser press the right hidden switch for 5 sec. To enter the programming menu. Use the left and right hidden switches to scroll through the menu screens. Select exit to leave the programming function and return to normal operations. Note 1: flashing menu items indicate which se...

Page 13

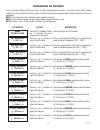

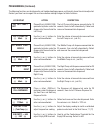

13 enter password (-) 0 (+) set password ? (-) 0 (+) 2 or 3 products? (2) exit (3) select units eng exit metric refrigeration ? On exit off deice cycle time (-) 120 min (+) rinse alarm ? No exit yes rinse time ? (-) 12 hrs (+) rinse lockout ? No exit yes the following functions can be password prote...

Page 14

14 programming (continued) bibempty lockout no exit yes brew lockout ? No exit yes energy saver mode no exit yes e-saver idle time (-) 4 hrs (+) e-saver tank temp no exit 140 select (yes) to enable select (yes) to enable select (on) to enable use the (+) or (-) buttons to adjust the idle time select...

Page 15

15 lcd display action description the following functions are for diagnostic and troubleshooting purposes and typically do not have to be adjusted. Contact your local service agent for assistance before making changes to these functions. Programming (continued) cal left pump ? Left cal lf pump vol (...

Page 16

16 lcd display action description programming (continued) xxoverflow > 155 (-) exit (+) xx refill -> 155 (-) exit (+) wtr start delay (-) .15sec (+) wtr stop delay (-) .15sec (+) test switches ? Useswitchtotest test refill ? Exit yes test heater ? Exit yes enter asset # (-) 000000 (+) serial # lcr 0...

Page 17

17 loading the concentrate 1. Thoroughly mix concentrate by vigorously shaking the product bag-in-box (bib). 2. Pull the bib connector through the hole provided in the box. 3. Open the dispenser door and locate the appropriate left, middle or right bib adapter fitting. 4. Connect the adapter fitting...

Page 18

18 filling cambros or other large containers the dispenser is designed primarily for containers that will fit under the dispense tip. However, it may be used to fill larger containers (up to 5 gal) by use of an extension hose on the dispense tip. Care must be taken to insure that the mixed product f...

Page 19

19 cleaning & preventative maintenance general cleaning and sanitizing procedures note: the bunn® liquid coffee dispenser incorporates a “user selectable” rinse reminder feature and can be set to disable dispensing when it is time to rinse. See programming functions to activate this feature. Daily: ...

Page 20

20 replacing the pump tubing the pumps and tubing used in this dispenser are designed to give maximum performance and long life. However, the tubes are a wear item and must be replaced periodically. How long the tubes last is dependent on usage and properties of the concentrate. Excessive wear will ...

Page 21

21 draining the hot water tank caution: the dispenser must be disconnected from the power source throughout these steps. 1. Disconnect the dispenser from the power source. 2. Shut off and disconnect the incoming water supply. 3. Remove the lower right access panel. 4. Pull out drain tube to empty in...

Page 22

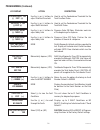

22 check pump & flow rate calibration, refer to field calibration procedures the calculated target rpm for the pump indicated is out of range ____ target rpm too high !! Replace bib, see loading the concentrate check bib connector fittings check tubing installation check empty bib threshhold, see fi...

Page 23

23 troubleshooting (continued) service required service required replace tubing 1. Pump motor failure 2. Rpm sensor failure 3. Tubing pinched in rollers ____ pump fault chk pump wiring chk rpm sensor chk tubing area check pump & flow rate calibration, refer to field calibration procedures the calcul...

Page 24

24 evap temp sensor out of range check for bad connections check wire for shorts cool temp sensor out of range check for bad connections check wire for shorts cooler fault! Evap temp too hi check evap fan chk evap sensor cooling time too long check air filter check cooling unit service required serv...

Page 25

25 field calibration of the concentrate pumps / dispenser flow rates the factory set default values for the pump & dispenser flow rates are very accurate and typically do not need to be field calibrated. However, if the mix ratio accuracy is ever in question, this procedure can be used to recalibrat...

Page 26

26 field calibrating the empty bib warning the dispenser will automatically display left, middle or right bib empty when the corresponding concentrate bib is empty. The refill message is triggered when the conductance sensor reading drops below the minimum setting. The factory set minimum is 600 and...

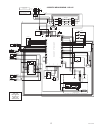

Page 27

27 41129 110608 41172.0000c 10/08 © 2008 bunn-o-matic corporation 208-240 volts ac 3 wire + gnd single phase 60hz or 208-240 volts ac 4 wire + gnd three phase 60hz j14-1 j14-7 j18-1 j18-9 j18-5 j18-7 j7-1 j7-5 j7-10 j2-1 j2 -8 j3-1 j3-6 j4-1 j4-5 j5-1 j5-3 j6-1 j6-5 j6-10 j6-15 j6-20 j1-1 j1-4 j15- ...