- DL manuals

- Bunn

- Coffee Maker

- OT

- Operating & Service Manual

Bunn OT Operating & Service Manual

OT & RT

10021.0000G 7/00 © 1989 BUNN-O-MATIC CORPORATION

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

BUNN

®

OPERATING & SERVICE MANUAL

WA

RN

IN

G

!

HIGH HEA

T W

ARMER

DO

N

OT

B

OIL

D

EC

AN

TE

R D

RY

KE

EP

C

OM

BU

ST

IB

LE

S A

WA

Y

FA

ILURE

TO

COMPL

Y RISKS

GLASS F

AILURE/HO

T LIQ

UID

BU

RNS AND FIRE H

AZARD

CAUTION

DIS

CA

RD

DE

CA

NT

ER

IF:

. C

RA

CK

ED

. S

CR

AT

CH

ED

. B

OIL

ED

DR

Y

. H

EA

TE

D W

HE

N E

MP

TY

. U

SE

D O

N H

IGH

FL

AM

E

. O

R E

XP

OS

ED

EL

EC

TR

IC

E

LE

ME

NT

S

FA

ILU

RE

TO

CO

MP

LY

RI

SK

S I

NJ

UR

Y

PN

: 6

58

19

85

BU

NN-O

-M

AT

IC C

OR

PO

RA

TIO

N

FU

NN

EL

CO

NT

EN

TS

AR

E H

OT

!

CAUTION

DIS

CA

RD

DE

CA

NT

ER

IF:

. C

RA

CK

ED

. S

CR

AT

CH

ED

. B

OIL

ED

DR

Y

. H

EA

TE

D W

HE

N E

MP

TY

. U

SE

D O

N H

IGH

FL

AM

E

. O

R E

XP

OS

ED

EL

EC

TR

IC

E

LE

ME

NT

S

FA

ILU

RE

TO

CO

MP

LY

RI

SK

S I

NJ

UR

Y

PN

: 6

58

19

85

BU

NN

-O

-M

AT

IC C

OR

PO

RA

TIO

N

FU

NN

EL

CO

NT

EN

TS

AR

E H

OT

!

Summary of OT

Page 1

Ot & rt 10021.0000g 7/00 © 1989 bunn-o-matic corporation bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 bunn ® operating & service manual wa rn in g ! High hea t w armer do n ot b oil d ec an te r d ry ke ep c om bu st ib le s...

Page 2

Page 2 contents introduction ............................................................... 2 user notices .............................................................. 3 electrical requirements ............................................. 4 plumbing requirements ....................................

Page 3: Warning

Page 3 00656.0000 00688.0000 warning ! High heat warmer do not boil decanter dry keep combustibles away failure to comply risks glass failure/hot liquid burns and fire hazard 00831.0000 00658.0000 user notices carefully read and follow all notices on the equipment and in this manual. They were writt...

Page 4

Page 4 models ot15 & 20 require 2- wire, grounded service rated 120 volts ac, 15 or 20 amp re- spectively, single phase, 60 hz. Model 15 has an attached cordset. Neutral white l1 black 208 or 240v.A.C. 120v.A.C. 120v.A.C. L2 red models ot35 & rt35 require 3-wire, grounded service rated 120/208 or 12...

Page 5

Page 5 plumbing requirements (cont.) plumbing hook-up model ot15 has an attached water strainer, proceed to step 2. Models ot20, ot35, & rt35, proceed as follows: 1. Remove the rear panel and bottom pan. Run the long piece of tubing from the strainer (supplied) under the brewer and attach it to the ...

Page 6

Page 6 model rt ca ut ion dis ca rd de ca nt er if: . C ra ck ed . S cr at ch ed . B oil ed dr y . H ea te d w he n e mp ty . U se d o n h igh fl am e . O r e xp os ed el ec tr ic e le me nt s fa ilu re to co mp ly ris ks in ju ry pn : 6 58 19 85 bu nn -o -m at ic co rp or at ion fu nn el co nt en t...

Page 7

Page 7 models ot & rt a. On/off brew station warmer switch placing the switch in the upper position supplies power to the brew station warmer and enables brew- ing. Placing the switch in the lower position cuts power to the brew station warmer and stops brewing. Stopping a brew cycle after it has be...

Page 8

Page 8 problem equipment will not operate. Brew cycle will not start. Probable cause 1. No power or incorrect voltage 1. No water 2. Water strainer 3. Flow control remedy (a) connect the brewer to the power source. (b) check the terminal block for the proper voltages. (c) check circuit breaker/fuse....

Page 9

Page 9 troubleshooting (cont.) problem brew cycle will not start. (cont.) water flows into tank continuously (on/off brew station warmer switch "off"). Water flows into tank continuously (on/off brew station warmer switch "on"). Water is not hot. Decanter warmer is not hot. Probable cause 4. On/off ...

Page 10

Page 10 troubleshooting (cont.) problem spitting or unusual steaming from sprayhead. Inconsistent beverage level in de- canter. Consistently high or low beverage level in decanter. Dripping from sprayhead. Probable cause 1. Control thermostat 2. Lime build-up caution: tank and tank compo- nents shou...

Page 11

Page 11 troubleshooting (cont.) problem beverage overflows decanter. Weak beverage. Brewer is making unusual noises. Probable cause 1. Beverage left in decanter 1. Type of paper filters 2. Coffee 3. Sprayhead 4. Funnel loading 5. Water temperature 1. Solenoid valve 2. Plumbing lines 3. Water supply ...

Page 12

Page 12 fig. 1 access panels service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Component access warning - disconnect the bre...

Page 13

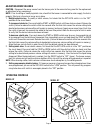

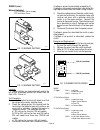

Page 13 fig. 2 brew timer fig. 3 brew timer wiring service (cont.) brew timer (early models) location: the brew timer is located behind the front panel to the right of the tank, fig. 2. Test procedure: 1. Disconnect the brewer from the power source and separate the polarized, three-pin connectors be...

Page 14

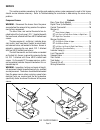

Page 14 tl 5 tl 4 tl 3 tl 2 tl 1 j2 set lock lo ck se t j1 digital brew timer (late models) p2201 fig. 4 digital brew timer location: the timers are located inside the front of the trunk on the upper right side of the component brackets. Test procedure. Note: do not remove or install wires while tim...

Page 15

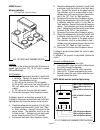

Page 15 3. Remove all wires from the timer. 4. Attach all wires to the replacement timer board prior to installation to the component mounting bracket. Refer to fig. 5 when reconnecting the wires. 5. Install new circuit board with spacers (as re- quired) to the component mounting bracket. 6. Adjust ...

Page 16

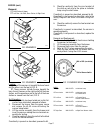

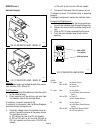

Page 16 fig. 6 control thermostat fig. 7 thermostat wiring service (cont.) control thermostat location: the control thermostat is located behind the front panel, fig. 6 to the left of the tank. To test the control thermostat, access will also be needed to the tank heater located in the top of the br...

Page 17

Page 17 fig. 8 warmers fig. 9 warmers fig. 10 warmer wiring service (cont.) warmer(s) ot: brew station & upper rt: left rear, left front, brew station, & right front location: ot: one of the warmers is beneath the brew funnel and the other is on the top lid, fig. 8. Rt: these warmers include the one...

Page 18

Page 18 fig. 11 three heat warmer fig. 12 three heat warmer wiring service (cont.) warmer rt: right rear three heat if continuity is present as described, proceed to #5. If continuity is not present as described, refer to the wiring diagrams and check the brewer wiring har- ness. 5. Check for contin...

Page 19

Page 19 fig. 13 warmer switches fig. 14 warmer switches fig. 15 warmer switch wiring service (cont.) warmer switch(es) ot: on/off brew station & upper rt: on/off brew station if voltage is present as described, proceed to #4. If voltage is not present as described, refer to the wir- ing diagrams and...

Page 20

Page 20 fig. 16 warmer switches fig. 17 warmer switch wiring service (cont.) warmer switch(es) rt: left rear, left front, & right front location: these warmer switches are the two at the left and the left most one on the right of the base as viewed from the front, fig. 16. Their knobs are marked off...

Page 21

Page 21 fig. 18 three heat warmer switch fig. 19 three heat warmer switch wiring service (cont.) warmer switch(es) rt: right rear three heat rotary 5. Check the voltage across terminals l1 and 2 with a voltmeter when the switch is in the "high" posi- tion. Connect the brewer to the power source. The...

Page 22

Page 22 fig. 22 indicator lamp wiring fig. 20 indicator lamp - model ot fig. 21 indicator lamp - model rt service (cont.) indicator lamp(s) c) 100 volts ac for two wire 100 volt models. 4. Disconnect the brewer from the power source. If voltage is present, the indicator lamp is operating properly. I...

Page 23

Page 23 fig. 23 limit thermostat fig. 24 limit thermostat wiring service (cont.) limit thermostat 4. Check for continuity across the limit thermostat terminals. If continuity is present as described, the limit thermo- stat is operating properly. If continuity is not present as described, replace the...

Page 24

Page 24 fig. 25 solenoid valve fig. 26 solenoid valve wiring service (cont.) solenoid valve 4. Check the solenoid valve for coil action. Con- nect the brewer to the power source, place the on/off brew station warmer switch in the upper position, press and release the start switch. Lis- ten carefully...

Page 25

Page 25 fig. 28 start switch - model rt fig. 27 start switch - model ot fig. 29 start switch wiring service (cont.) start switch location: the start switch is located in the base, below and to the right of the brew station, fig.S 27 & 28. Test procedure: 1. Disconnect the brewer from the power sourc...

Page 26

Page 26 fig. 30 tank heater fig. 31 tank heater wiring service (cont.) tank heater removal and replacement: 1. Remove the wires to the tank heater and limit thermostat terminals. 2. Gently pull the thermostat tube with grommet out of the tank lid. 3. Remove the sprayhead and sprayhead nut from the p...

Page 27

Page 27 thermal cut-off location: the thermal cut-off is located on the tank heater, fig. 32. Service (cont.) test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal cut-off from the tank heater terminal and the wiring harness. 3. Check for continuity across the th...

Page 28: Schematic Wiring Diagram Ot

Page 28 whi/grn whi/blu blk brew station warmer whi blu blu/blk whi whi brew timer blk blk p1 p3 p2 schematic wiring diagram ot blk blk blk whi p1, p2, & p3 are pins of a polarized three-pin connector. 10278.0000e 7/00© 1988 bunn-o-matic corporation 120 volts ac 2 wire 120/240 volts ac 3 wire single...

Page 29

Page 29 blk pnk gry blk blk blu limit thermostat n l1 blk brew station warmer 130w whi blu blu/blk whi whi blk blk p1 p3 p2 green schematic wiring diagram ot blk l2 blk blk whi p1, p2, & p3 are pins of a polarized three-pin connector. 10280.0000d 7/00 © 1988 bunn-o-matic corporation 120/240 volts ac...

Page 30

Page 30 blk blk blk blu limit thermostat sw. & thermostat l1 blk brew station warmer blu blu/blk blk blk p1 p3 p2 grn/yel schematic wiring diagram ota blk l2 blk blk p1, p2, & p3 are pins of a polarized three-pin connector 10282.0000b 7/00 © 1988 bunn-o-matic corporation 240 volts ac 2 wire single p...

Page 31

Page 31 blk blk brew station warmer blu blu/blk blk blk p1 p3 p2 schematic wiring diagram ot25b blk blk blk p1, p2, & p3 are pins of a polarized three-pin connector. 100 volts ac 2 wire single phase 50-60 hz blk upper warmer blk p3 p2 red red red red red blk red whi blk blu limit thermostat l1 blk g...

Page 32

Page 32 blk blk blk blu limit thermostat l1 blk brew station warmer blu blu/blk blk blk p1 p3 p2 grn/yel schematic wiring diagram ot35b blk l2 blk blk p1, p2, & p3 are pins of a polarized three-pin connector. 200 volts ac 2 wire single phase 50-60 hz red tank heater blk upper warmer blk p3 p2 red re...

Page 33: Schematic Wiring Diagram Rt

Page 33 blk warmer whi blk schematic wiring diagram rt blk whi "keep warm" heater whi 10277.0000d 7/00 © 1988 bunn-o-matic corporation 120/240 volts ac 3 wire single phase 60 hz whi blk blk whi blk blk whi blk blk left front warmer right front warmer left rear warmer right rear warmer 2 1 3 off low ...

Page 34: Schematic Wiring Diagram Rta

Page 34 blk blu limit thermostat sw. & thermostat tank heater blk l1 blk warmer blu blk blk p3 10283.0000c 7/00 © 1988 bunn-o-matic corporation grn/yel schematic wiring diagram rta blk l2 red blk blk p1, p2, & p3 are pins of a polarized three-pin connector. Blk blk blk blk blk blk left front warmer ...

Page 35

Page 35 blk warmer blu blk blk p3 schematic wiring diagram rt25b blk blk blk p1, p2, & p3 are pins of a polarized three-pin connector. Blk blk blk blk blk blk left front warmer right front warmer left rear warmer right rear warmer 2 1 3 off low med high n l 100 volts ac 2 wire single phase 50-60 hz ...

Page 36

Page 36 blk blu limit thermostat tank heater blk l1 blk warmer blu blk blk p3 grn/yel schematic wiring diagram rt35b blk l2 red blk blk p1, p2, & p3 are pins of a polarized three-pin connector. Blk blk blk blk blk blk left front warmer right front warmer left rear warmer right rear warmer 2 1 3 off ...