- DL manuals

- Bunn

- Coffee Maker

- Single TF

- Operating & Service Manual

Bunn Single TF Operating & Service Manual

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

27124.0000 6/00 ©1996 Bunn-O-Matic Corporation

BUNN

®

DUAL

™

TF

1.75 GALLON

B

U

N

N

MA

NU

FA

CT

UR

ED

B

Y

BU

NN

-O

-M

AT

IC

C

OR

PO

RA

TIO

N

S

PR

IN

GF

IE

LD

, IL

LIN

OI

S,

U

.S

.A

.

MO

DE

L

S/

N

VO

LT

S

A

.C

.

A

MP

W

AT

TS

PH

AS

E

W

IR

E

HE

RT

Z

CO

VE

RE

D

UN

DE

R

ON

E

OR

M

OR

EO

F T

HE

FO

LL

OW

IN

G

PA

TE

NT

S

:

ON

E

OR

M

OR

E

OT

HE

R

PA

TE

NT

S

MA

Y

BE

P

EN

DI

NG

OP

ER

AT

IN

G P

RO

CE

DU

RE

S

1.

Chec

k Ser

ve

r siz

e if

Bre

wer refuses to bre

w.

2.

McDonald's Bre

w

Te

mper

ature:

200

°

F

±

5

°

(3-18-96)

CAUTION

DI

SC

AR

D D

EC

AN

TE

R

IF:

. C

RA

CK

ED

. S

CR

AT

CH

ED

. B

OIL

ED DR

Y

. H

EA

TE

D W

HE

N EM

PT

Y

. U

SE

D O

N H

IG

H FL

AM

E

. O

R E

XP

OS

ED

EL

EC

TRIC

E

LE

MEN

TS

FA

ILU

RE

TO

C

OM

PL

Y

RI

SK

S

IN

JU

RY

PN

: 6

58

19

85

B

UN

N-

O-

MA

TIC

C

OR

PO

RA

TIO

N

FU

NN

EL

C

ON

TE

NT

S

A

RE

H

OT

!

CAUTION

!

H O T

L I Q U I D

CAUTION

!

H O T

L I Q U I D

!

CAUTION

HOT WATER

DISCONNECT FROM

POWER SOURCE

BEFORE REM

OVAL OF ANY PANEL OR

REPLACEMENT OF ANY COMPONENT!

W

AR

NI

NG

!

Summary of Single TF

Page 1

Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 27124.0000 6/00 ©1996 bunn-o-matic corporation bunn ® dual ™ tf 1.75 gallon b u n n ma nu fa ct ur ed b y bu nn -o -m at ic c or po ra tio n s pr in gf ...

Page 2

Page 2 introduction this equipment will brew two half-gallon, gallon, or gallon and three forths batches of coffee into awaiting servers at the push of a button. The brewer is also equipped with a hot water faucet for allied beverage use and is designed to interface with a bunn ® grinder. The brewer...

Page 3

Page 3 requires 2-wire, grounded service rated 200 to 240 volts ac, 30 amp, single phase 50 or 60 hz. Requires 3-wire, grounded ser- vice rated 120/208 or 120/240 volts ac, 30 amp, single phase, 60 hz. 120v a.C. 120v a.C. 120v a.C. 208 or 240v a.C. L2 red l2 red white neutral l1 black l1 black 200 o...

Page 4

Page 4 electrical hook-up caution – improper electrical installation will damage electronic components. 1. An electrician must provide electrical service as specified. 2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source. 3. Remove the front panel benea...

Page 5

Page 5 initial set-up (cont.) 4. Wait approximately twenty minutes for the water in the tank to heat to the proper temperature. 5. Place an empty server beneath either of the brew stations. Place its associated selector switch in the desired position, the on/off switch in the upper position and init...

Page 6

Page 6 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 7

Page 7 remedy (a) direction of flow arrow must be pointing towards brewer. (b) remove the strainer/flow con- trol and check for obstructions. Clear or replace. Refer to service - on/off switch for testing procedures. See page 28 refer to service - start switch for testing procedures. See page 34 ref...

Page 8

Page 8 4. Overflow protection switch 5. (a) level control board & level probe. (electro/mechanical con- trolled) (b) electronic controls 1. Brew selector switch 1. Solenoid valve 2. (a) level control board and level probe (electro/mechanical) (b) control assembly (electronic) 3. Overflow protection ...

Page 9

Page 9 troubleshooting (cont.) (b) control assembly (electronic) 3. Contactor (brewers with recov- ery booster) 4. Tank heaters 5. Triac assembly (electronic) 6. Relay (brewers with recovery booster) 1. (a) control thermostat (electro/ mechanical) (b) control assembly (electronic) 2. Triac assembly ...

Page 10

Page 10 troubleshooting (cont.) inconsistent beverage level in server. (cont.) consistently high or low beverage level in server. Dripping from sprayhead. Water overflows filter. Beverage overflows server 2. Improper water pressure 3. Dispense valve 4. Bypass valve 1. Timer adjustment 1. Dispense va...

Page 11

Page 11 troubleshooting (cont.) weak beverage brewer is making unusual noises. 1. Type of paper filters 2. Coffee 3. Sprayhead 4. Funnel loading 5. Water temperature 1. Solenoid (inlet) 2. Plumbing lines 3. Water supply 4. Tank heaters 5. Contactor bunn ® paper filters should be used for proper extr...

Page 12

Page 12 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 13

Page 13 service (cont.) bypass valve location: the bypass valves are located inside the right front and the center front of the hood. Test procedures: 1. Disconnect the brewer from the power source and place 1-3/4 gallon server under funnel. 2. Disconnect the white/green wire and the white/ violet w...

Page 14

Page 14 service (cont.) brew selector switch location: the brew selector switches are located in the front left and right side of the hood. Test procedure: timer: left or right 1. Disconnect the brewer from the power supply. 2. Separate the connector on the selector switch harness from the brew time...

Page 15

Page 15 service (cont.) brew selector switch (cont.) p991 tan gry pnk to left or right timer whi/vio to left or right by-pass valve whi/red to left or right dispense valve gry from left or right selector switch to gry lead on interface socket pnk from left selector switch to grinder switch (lower le...

Page 16

Page 16 service (cont.) contactor assembly location: the contactor assembly is located inside the hood just to the rear of the right dispense valve. Test procedures: mechanical thermostat (brewers with or without recovery booster) 1. Disconnect the brewer from the power source. 2. Disconnect the red...

Page 17

Page 17 service (cont.) contactor assembly (cont.) test procedures : electronic control (brewers w/recovery booster) 1. Disconnect the brewer from the power source. 2. Disconnect the gray wire from the black wire on the contactor coil and white /brown wire from the remaining black wire on the contac...

Page 18

Page 18 6. Gently remove the capillary bulb and grommet from the tank. 7. Check the voltage across the black wires of the control thermostat and the white insert on the three pole 120/208v, 120/240v terminal blocks and the red insert on two pole 200v, 240v terminal blocks with a voltmeter when the c...

Page 19

Page 19 service (cont.) control thermostat (cont.) blu to left & right ready lights blu to red lead from liquid level switch blk to blk lead of contactor coil blk toleft & right ready lights p780 dispense valve p975 location: dispense valves are located inside the hood in the center of each sprayhea...

Page 20

Page 20 service (cont.) dispense valve (cont.) electronic control assembly 10. Recovery booster relay 11. Contactor assembly 12. Bypass valve 13. Ready light 14. Solenoid valve 15. Led 16. Temperature adjust- ment 17. Triac assy 18. Server sensor 1. Electronic control 2. Terminal block 3. Timers 4. ...

Page 21

Page 21 service (cont.) problem: liquid level control system does not refill problem: liquid level control overflows retry no yes yes no yes replace control assembly (1) drain cup (4) overflow ? Overflow ? No overflow ? Replace solenoid valve (14) drain cup (4) disconnect wire solenoid valve (14) fr...

Page 22

Page 22 yes yes yes yes no no no no yes no no measure voltage at tank heater (5) voltage present replace tank heater (5) limit thermostat (6) ok ? Replace limit thermostat (6) replace control assembly (1) measure voltage at tank heater (5) voltage present replace triac (17) check for split tank heat...

Page 23

Page 23 service (cont.) electronic controls (cont.) problem: water boils yes no no no no replace control assembly (1) replace triac (17) check for split tank heater (5) drain cup (4) retry led (13)(15) on while boiling disconnect blue wire from control board pin #7 retry still boiling ? Replace cont...

Page 24

Page 24 service (cont.) electronic control assembly (cont.) o n caution ! Failure to comply voids warranty! Hot w ater system s – w ater tank w ill fill automatically w hen unit is connected to power! Coffee brewers – fill the water tank in accordance w ith the installation instructions! Do no t tur...

Page 25

Page 25 test procedure: 1. Disconnect the brewer from the power source. 2. Remove all wires from the switch terminals. 3. Place the selector switch in the left position. 4 check for continuity across the center and right terminals on the rear of the switch. 5. Continuity must not be present across t...

Page 26

Page 26 location: the level control board is located inside the front of the brewer just left of center on the component bracket test procedure: 1. Disconnect the brewer from the power source. 2. Remove the violet wire from terminal 1 & pink wire from terminal 4 of the circuit board. 3. Check the vo...

Page 27

Page 27 service (cont.) level control board and level probe (electro/mechanical only) (cont.) els and three wire 120/240 volt models. B.) 200 to 240 volts ac for two wire 200 or 240 volt models. 17. Disconnect the brewer from the power source. If voltage is present as described, reinstall the probe,...

Page 28

Page 28 service (cont.) location: the on/off switches are located on the front of the hood just to the left and right of the start switches. Test procedure: 1. Disconnect the brewer from the power source. 2. Viewing the switch from the back remove the white or red wire from the upper right terminal ...

Page 29

Page 29 . Mi nu te s bu nn -o -m at ic p/ n 26 20 - 12 0 v ac . Mi nu te s bu nn -o -m at ic p/ n 26 20 - 12 0 v ac 2 2 2 1.5 1.5 1 1 1 .5 .5 2.5 2.5 mi nu te s minutes mi nu te s minutes mi nu te s minutes p/ n 24 48 6-0 00 0 12 0 v ac p/n 24486-0000 120 vac bu nn -o -m at ic bunn-o-matic 3 3 3 4 4...

Page 30

Page 30 location: the overflow protection switch is located in- side the hood on the center of the tank inside the copper overflow cup. To test the overflow protection switch, access will also be needed to the level control board or electronic control assembly and terminal block. Test procedure: 1. ...

Page 31

Page 31 location: electro/mechanical controlled brewers the relays are located inside the hood, the right relay just to the right of the contactor in front of the tank and left relay is just left of the component bracket in front of the tank. Electronic controlled brewers the relay is located inside...

Page 32

Page 32 red blk to blk lead on contactor coil blk to blk lead on thermostat whi/red to left dispense valve whi/brn to left dispense valve whi/grn to right dispense valve blu to blu lead from thermostat blu to blu lead from liquid level board whi/vio to right dispense valve right left gry to blk lead...

Page 33

Page 33 service (cont.) solenoid valve (inlet) location: the solenoid valve is located inside the lower right front of the brewer. Test procedure: 1. Disconnect the brewer from the power source and draw 1/4 gallon of water from faucet. 2. Remove both wires from the solenoid valve coil terminals. 3. ...

Page 34

Page 34 service (cont.) solenoid valve (inlet) (cont.) p799 vio to level control board t1 (electro/mechanical) whi/blu to control assy #1 (electronic) whi to level control board t3 (120/208v or 120/240v electro/mechanical) whi to terminal block (120/208v or 120/240v electronic) red to level control ...

Page 35

Page 35 wires, the tank heaters are operating properly. If continuity is not present as described, replace the tank heater(s). Note - if the tank heater remains unable to heat, remove and inspect the heater for cracks in the sheath. Electronic control models: 1. Disconnect the brewer from the power ...

Page 36

Page 36 location: the timers are located inside the left front of the brewer on the upper part of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the wires from the timer terminals tl3, tl4 and tl5 and rotate the dial(s) fully counterclockwise. 3...

Page 37

Page 37 service (cont.) timers (early models)(cont.) p1070 2 2 2 1.5 1 1 1 .5 2.5 minutes minutes minutes p/n 24486-0000 120 vac bunn-o-matic 3 3 3 4 4 5 5 6 6 7 8 2 2 2 1.5 1.5 1 1 1 .5 .5 2.5 2.5 minutes minutes minutes minutes minutes minutes p/n 24486-0000 120 vac p/n 24486-0000 120 vac bunn-o-m...

Page 38

Page 38 service (cont.) timers (late models) p2194 location: the timers are located inside the left front of the brewer on the upper part of the component bracket. Test procedures: note: do not remove or install wires while timer board is installed. Pressure applied to one side may cause damage to t...

Page 39

Page 39 j1 j2 tl3 tl5 tl4 tl2 tl1 set lock set lock p2037 service (cont.) timers (late models)(cont.) left timer right timer yel whi/yel wire to tl5 whi/brn whi/grn wire to tl4 pnk pnk wire to tl3 whi whi wire to tl2 (120v two pole, 120/208v or 120/240v three pole terminal block) red red wire to tl2...

Page 40: & Two-Grinder Interface

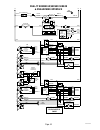

Page 40 27201.0001b 5/96 © 1996 bunn-o-matic corporation 120/208 volts ac or 120/240 volts ac 3 wire vio probe pin-20 1 4 3 2 liquid level board blk whi limit thermostat whi whi overflow protection sw red red sw. & thermostat ready indicators optional recovery booster blk blu k2 n.O. K3 n.O. Red dua...

Page 41: & Two-Grinder Interface

Page 41 27201.0002b 5/96 © 1996 bunn-o-matic corporation 200 or 240 volts ac 2 wire vio probe pin-20 1 4 3 2 liquid level board blk limit thermostat overflow protection sw red red sw. & thermostat ready indicators optional recovery booster blk blu k2 n.O. K3 n.O. Red dual-atf or btf brewer w/server ...

Page 42: & Two-Grinder Interface

Page 42 gry 27201.0003b 5/96 © 1996 bunn-o-matic corporation 120/208 volts ac or 120/240 volts ac 3 wire dual -tf brewer eca w/server sensor & two-grinder interface blk right sw. Gry tan pnk grinder interface connector yel fractional batches (connect as required) full batch (no connection) tan gry p...

Page 43: & Two-Grinder Interface

Page 43 gry 27201.0004b 5/96 © 1996 bunn-o-matic corporation 200 or 240 volts ac 2 wire dual -atf brewer eca w/server sensor & two-grinder interface blk right sw. Gry tan pnk grinder interface connector yel fractional batches (connect as required) full batch (no connection) tan gry pnk 1/4 batch 1/3...

Page 44: & One-Grinder Interface

Page 44 27201.0005b 5/96 © 1996 bunn-o-matic corporation 120/208 volts ac or 120/240 volts ac 3 wire vio probe pin-20 1 4 3 2 liquid level board blk whi limit thermostat whi whi overflow protection sw red red sw. & thermostat ready indicators optional recovery booster blk blu k2 n.O. K3 n.O. Red dua...

Page 45: & One-Grinder Interface

Page 45 gry 27201.0006b 5/96 © 1996 bunn-o-matic corporation 120/208 volts ac or 120/240 volts ac 3 wire dual -tf brewer eca w/server sensor & one-grinder interface blk right sw. Yel fractional batches (connect as required) full batch (no connection) tan gry pnk 1/4 batch 1/3 batch 1/2 batch 2/3 bat...

Page 46: & One-Grinder Interface

Page 46 27201.0007b 5/96 © 1996 bunn-o-matic corporation 200 or 240 volts ac 2 wire vio probe pin-20 1 4 3 2 liquid level board blk limit thermostat overflow protection sw red red sw. & thermostat ready indicators optional recovery booster blk blu k2 n.O. K3 n.O. Red dual-atf or btf brewer w/server ...

Page 47: & One-Grinder Interface

Page 47 gry 27201.0008b 5/96 © 1996 bunn-o-matic corporation 200 or 240 volts ac 2 wire dual -atf brewer eca w/server sensor & one-grinder interface blk right sw. Yel fractional batches (connect as required) full batch (no connection) tan gry pnk 1/4 batch 1/3 batch 1/2 batch 2/3 batch 3/4 batch bat...