S l & s l & s l f s l f 10304.0000e 11/99 © 1988 bunn-o-matic corporation bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 bunn ® operating & service manual 10 04 3.0 00 0d 3 /97 © 1 98 8 bu nn -o -m at ic c or po ra tio n wh i ...

Page 2 contents introduction ............................................................... 2 user notices .............................................................. 3 electrical requirements ............................................. 4 plumbing requirements ....................................

Page 3 the buyer’s remedy against bunn for the breach of any obligation arising out of the sale of this equipment, whether derived from warranty or otherwise, shall be limited, as specified herein, to repair or, at bunn’s sole option, replacement or refund. In no event shall bunn be liable for any o...

Page 4 electrical requirements caution - do not connect the brewer to the power source until specified in initial set-up. Model 15 has an attached cordset, and requires 2-wire grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. Model 20 requires 2-wire, grounded service rated 120 volts...

Page 5 plumbing requirements this brewer must be connected to a cold water system with operating pressure greater than 10 psi from a 1/2” or larger supply line. A shut-off valve should be installed in the line before the brewer. Install a regulator in the line when pressure is greater than 90 psi to...

Page 6 19. Press the hot water switch to dispense exactly 20 ounces of hot water and immediately start a brew cycle into an empty graduated vessel. 20. Measure the brew water volume: if it is more than the amount measured in #16, remove the rear panel, turn the needle valve slightly clockwise, and r...

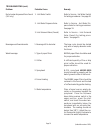

Page 7 problem equipment will not operate. Brew cycle will not start. Probable cause 1. No power or incorrect voltage 1. No water 2. Water strainer 3. Water level switch and overflow safety switch remedy (a) connect the brewer to the power source. (b) check the terminal block for the proper voltages...

Page 8 troubleshooting (cont.) problem brew cycle will not start. (cont.) water flows into fill basin continu- ously (on/lower brew station warmer switch "off"). Water flows into fill basin continu- ously (on/lower brew station warmer switch "on"). Water is not hot. Decanter warmer is not hot. Proba...

Page 9 troubleshooting (cont.) problem spitting or unusual steaming from sprayhead. Warmer plates too hot, solenoid coil smoking, or water in tank heats ex- cessively fast. Inconsistent beverage level in de- canter. Dripping from sprayhead. Probable cause 1. Control thermostat 2. Lime build-up cauti...

Page 10 troubleshooting (cont.) problem no hot water dispensed from faucet (slf only) probable cause 1. Hot water switch 2. Hot water dispense valve 3. Inlet solenoid valve (faucet) remedy refer to service - hot water switch for testing procedures. See page 24. Refer to service - hot water dis- pens...

Page 11 troubleshooting (cont.) problem brewer is making unusual noises. Probable cause 1. Solenoid valve 2. Plumbing lines 3. Water supply remedy the nut on top of the solenoid valve must be tight or it will vibrate dur- ing operation. Plumbing lines should not rest on the counter top. (a) the brew...

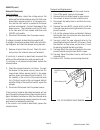

Page 12 fig. 1 access panels service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Component access warning - disconnect the bre...

Page 13 fig. 2 control thermostat service (cont.) control thermostat location: the control thermostat is located inside the front access panel, fig. 2. To test the control thermostat, access will also be needed to the tank heater located in the bottom of the tank assembly. Test procedure: 1. Disconn...

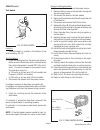

Page 14 fig. 4 warmers fig. 5 warmer wiring service (cont.) location: one of the warmers is beneath the brew funnel and the other is on the top lid, fig. 4. Test procedure: 1. Once the switch has been tested and switch fail- ure has been eliminated, proceed as follows. 2. Disconnect the brewer from ...

Page 15 fig. 6 warmer switches fig. 7 warmer switch wiring service (cont.) warmer switch(es) if voltage is present as described the switch is oper- ating properly. If voltage is not present as described, replace the switch. Removal and replacement: 1. Compress the clips inside the housing and gently...

Page 16 fig. 8 start switch fig. 9 start switch wiring service (cont.) start switch location: the start switch is located on the far right of the front switch panel , fig 8. Test procedure: 1. Disconnect the brewer from the power source and remove the wires from both terminals of the start switch. 2...

Page 17 p2014 fig. 10 limit thermostat fig. 11 limit thermostat wiring service (cont.) limit thermostat 2. Carefully slide the limit thermostat out from un- der the retaining clip. 3. Carefully slide the new limit thermostat into the retaining clip. 4. Refer to fig. 11 when reconnecting the wires. L...

Page 18 fig. 13 solenoid valve wiring service (cont.) solenoid valve(cont.) test procedure: 1. With a voltmeter check the voltage across the white and the white/red wires when the on/lower brew station warmer switch is in the upper posi- tion and the start switch is pressed to the lower position and...

Page 19 service (cont.) hot water dispense valve (optional) fig. 14 hot water dispense valve p2021 location: the hot water dispense valve is located under the top cover or top warmer housing and to the left of the switches, fig. 14. Test procedure: 1. With a voltmeter check the voltage across the wh...

Page 20 service (cont.) inlet solenoid valve (faucet - optional) fig. 16 inlet solenoid valve (faucet) p2021 location: the inlet solenoid valve (faucet) is located inside the rear access panel, fig. 16. Test procedures: 1. With a voltmeter check the voltage across the white and the white/violet wire...

Page 21 service (cont.) relay fig. 18 relay p2015 location: the relay is located inside the front access panel, near the top of the bracket, fig. 18. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the brown/black wire from the “a” ter- minal and the white wire from the “b”...

Page 22 fig. 20 tank heater service (cont.) tank heater removal and replacement: 1. Disconnect the brewer from the power source. 2. Remove the top cover or top warmer housing and the rear access panel. 3. Disconnect the wires to the tank heater. 4. Gently pull the thermostat bulb with grommet out of...

Page 23 service (cont.) water level and overflow safety switch fig. 22 water level and overflow safety switches p2016 location: the water level and overflow safety switches are located under the top cover or top warmer housing and inside and front of the tank fill basin, fig. 22. Test procedure: 1. ...

Page 24 service (cont.) hot water switch(optional) (added november 1999) 10 04 3.0 00 0d 3 /97 © 1 98 8 bu nn -o -m at ic co rp or at ion wh i bl u lim it th er mo st at sw . & th er mo st at ta nk he at er n bl k l1 bl k wh i p1 p3 p2 p1 , p 2, & p 3 a re pi ns of a p ol ar ize d t hr ee -pi n co n...

Page 25 replacement parts 05099.0000 ......... Airvent tube 01171.0001 ......... Check valve 13229.0000 ......... Decal, front end-cap switch 02769.0000 ......... Decal, surfaces are hot 01188.0000 ......... Deliming spring 12753.0001 ......... Dispense valve 13210.0000 ......... Fill basin anti-syp...

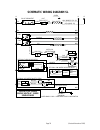

Page 26 blk sw4 whi/vio whi/vio whi whi optional hot water faucet system 120 volts ac 2 wire 120/240 volts ac 3 wire single phase 10305.0000m 11/99 © 1989 bunn-o-matic corporation whi blk auxiliary outlet whi/red blk "keep warm" heater whi blk green whi schematic wiring diagram sl tank heater l1 pro...