- DL manuals

- Bunn

- Coffee Maker

- SRU

- Operating & Service Manual

Bunn SRU Operating & Service Manual

SRU

SRUA

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

10067.0000J 10/08 ©1981 Bunn-O-Matic Corporation

Summary of SRU

Page 1

Sru srua operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 to ensure you have the latest revision of the operating manual, or to view the illustrated parts catalog, programming manual, or service manual...

Page 2

Page 2 10067 100908 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) comp...

Page 3: Warning

Page 3 introduction this brewer will brew a three gallon batch of coffee into the reservoir, which has its own dispensing faucet. The brewer also has a hot water faucet for allied beverage use. It is only for indoor use on a sturdy counter where ambient temperature is in the range of 10-30°c (50-85°...

Page 4

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Sru model requires 3-wire, grounded service rated 120/208 or 120/240 volts ac, 30 amp, single phase, 60 hz. Proceed as follows: electrical installation instructions note:...

Page 5

Page 5 plumbing requirements these brewers must be connected to a cold water system with operating pressure between 20 and 90 psi (138 and 621 kpa) from a 1/2" or larger supply line. A shut-off valve should be installed in the line before the brewer. Install a regulator in the line when pressure is ...

Page 6

Page 6 initial setup caution - the brewer must be disconnected from the power source throughout the initial setup, except when specified in the instructions. Important: brewer must be level and installed on a sturdy structure. Electrician's and plumber's instructions are provided. These instructions...

Page 7

Page 7 adjusting brew volumes caution - disconnect the power source from the brewer prior to the removal of any panel for the replacement or adjustment of any component. Note: prior to setting or modifying batch sizes, check that the brewer is connected to water supply, the tank is properly filled, ...

Page 8

Page 8 cleaning note: tank and tank components should be delimed regularly based on local water conditions. Excessive mineral build up on stainless steel surfaces can initiate corrosion reactions resulting in serious leaks, 1. Remove funnel, funnel lid and support. Under hot water, rinse away all co...

Page 9

Page 9 problem brew cycle will not start probable cause 1. No water 2. No power or incorrect voltage to the brewer remedy water lines and valves to the brewer must be open. (a1) check the terminal block for 120 volts ac across the red and white terminals and the black and white terminal on three wir...

Page 10

Page 10 troubleshooting (cont.) problem brew cycle will not start (cont) tank not filling probable cause 3. Water level below pump housing. (water level in the hot water gauge glass should be approximately half full). 4. On/off switch 5. Start switch 6. Timer 7. Pump 8. Solenoid valve 9. Strainer 1....

Page 11

Page 11 troubleshooting (cont.) problem water running out of the overflow water is not hot probable cause 1. Brewer not level 2. Solenoid valve 3. Liquid level board 4. Probe 1. Limit thermostat caution - do not eliminate or bypass limit thermostat. Use only bunn-o-matic replacement part #29329.1000...

Page 12

Page 12 probable cause 1. Circuit breaker 2. On/off switch 3. Brew circuit 4. Refill circuit 1. Timer 2. Start switch 1. Timer 2. Solenoid valve 3. Lime build-up in swing spout and pump tubing. 1. Filters 2. Hole in bottom of funnel obstructed. 3. Pump - flow rate troubleshooting (cont.) problem cir...

Page 13

Page 13 troubleshooting (cont.) problem funnel overflows (cont.) coffee reservoir overflows brewer is making unusal noises probable cause remedy 4. Soft water 1. Coffee reservoir not completely empty before a brew cycle was started. 2. Timer 3. Pump - flow rate 1. Solenoid valve 2. Plumbing lines 3....

Page 14

Page 14 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 15

Page 15 service (cont.) circuit breaker (120/208v and 120/240v three wire models) location: the circuit breaker is located on the rear of the urn, behind the rear utility cover. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from the main harness from t...

Page 16

Page 16 service (cont.) location: the contactor is located inside the front lower ac- cess panel, left of center on the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2a. 120/208v and 120/240v three wire models disconnect the black wire from the contactor coil to...

Page 17

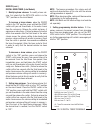

Page 17 red to terminal block(l2) blk thermal fuse to tank heater blk to tank heater (l1) service (cont.) contactor (cont.) blk to terminal block (l1) red to tank heater (l2) blk to limit thermostat whi from main harness (120/208v and 120/240v three wire models) red from main harness (208v, 240v two...

Page 18

Page 18 service (cont.) control thermostat fig. 6 control thermostat p2113.40 location: the control thermostat is mounted on the left front of the top component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Locate the thermostat and the voltage check points. Model 120/...

Page 19

Page 19 service (cont.) fuse and fuse holder (208v, 240v and 230v two wire models) location: the fuse and fuse holder are located on the rear of the urn behind the rear utility cover. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the cap and fuse from the fuse holder. 3....

Page 20

Page 20 limit thermostat service (cont.) fig. 11 limit thermostat terminals fig. 10 limit thermostat p1732 location: the limit thermostat is located on the center rear of the component bracket behind the tank heater. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the ...

Page 21

Page 21 service (cont.) liquid level board and level probe 5. Reconnect the blue wire to t1 on the liquid level board. 6. Carefully connect a piece of insulated jumper wire to t4. Keep the other end of this wire away from any metal surface of the brewer. 7. Touching the free end of the jumper to the...

Page 22

Page 22 service (cont.) liquid level board and level probe (cont.) t1 blu to solenoid valve t2 blk to on/off switch (all models except 230v-ce models- red on ce models) t3 whi to main harness (120/208v and120/240v models) t3 red to main harness (208v, 240v single phase and three phase models) t3 blk...

Page 23

Page 23 10067 040100 on/off switch fig.14 on/off switch p2053.25 location: the on/off switch is located on the left side of the lower front panel. Test procedures: 1. Disconnect the brewer from the power source. 2. A)120/208v, 120/240v, 208v and 240v models remove the black wire on the on/off switch...

Page 24

Page 24 service (cont.) pump assembly fig.16 pump assembly p2113.40 location: the pump is located on the right of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from the black lead on the pump and the white wire from the black lea...

Page 25

Page 25 service (cont.) selector switch (half batch option) fig. 18 selector switch (half batch) p2053.25 location: the selector switch is located in the center of the front access panel at the base of the urn on all models except the 230v ce models. The selector switch is located to the right of th...

Page 26

Page 26 service (cont.) solenoid fig. 20 solenoid p2113.40 location: the solenoid is mounted on the upper left rear of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. A) for 120/208 volt and 120/240 volt 3-wire, single phase models, disconnect the black wir...

Page 27

Page 27 service (cont.) solenoid 10. Install water inlet tube to connector on the sole- noid. 11. Turn on the water supply to the brewer. 12. Refer to fig. 21 and reconnect the wires. 10067 081506 blu from liquid level board #1 whi from main harness (120/208v, 120/240v, 380v and 440v models) red fro...

Page 28

Page 28 start switch (brew) fig. 22 start switch (brew) p2053.25 location: the brew start switch is located on the lower right side of the front access panel at the base of the urn on all models except 230 volt ce. On 230 volt ce models, the start switch is located on the lower right of the front ac...

Page 29

Page 29 blk to contactor t1 (all models except 230v-ce models) blk (thermal fuse) to t1 (230v-ce models) red to contactor t2 (120/208v, 120/240 three wire single phase, 208v and 240v two wire, single phase) red (thermal fuse) to t2 (230v-ce models) service (cont.) tank heaters p1746 fig. 24 tank hea...

Page 30

Page 30 service (cont.) thermal fuses (230v-ce models only) fig. 26 thermal fuses p2121.40 location: the thermal fuses are mounted on the tank heater terminals. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal fuse from the tank heater terminal and the conta...

Page 31

Page 31 timer (early models) fig. 27 timer p2114.40 location: the timer is located behind the front access panel on the right side of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the polarized, three pin connector from the brewer main harness ...

Page 32

Page 32 service (cont.) timer (early models)(cont.) to three pin female connector on main harness blk to pump lead whi to pump lead three pin connector from half/full batch switch fig. 28 timer terminals p1751 10067 080200 removal and replacement: 1. Separate all connectors between the brewer wiring...

Page 33

Page 33 service (cont.) digital brew timer (late models) fig. 29 digital brew timer p2208.40 late models location: the timer is located inside the front of the trunk on the top of the component bracket. Test procedure. Note: do not remove or install wires while timer board is installed. Pressure app...

Page 34

Page 34 service (cont.) digital brew timer (late models) 1. Modifying brew volumes. To modify a brew vol- ume, first check that the set/lock switch is in the “set” position on the circuit board. To increase a brew volume, place the on/off switch in the “on” position, press and hold the start switch ...

Page 35

Page 35 10067 011608 master on/off switch (late models) fig. 31 master on/off switch p2053.25 all models except 230v - ce models service (cont.) fig. 32 master on/off switch wiring location: the master on/off switch is located in the base, at the left rear, fig. 31. Test procedure: 1. Disconnect the...

Page 36

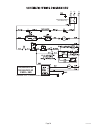

Page 36 10067 011608 120/208 volts ac 120/240 volts ac 3 wire + gnd 10490.0000e 01/07 © 1990 bunn-o-matic corporation n l1 l2 whi blk red main on/off switch (late models only) not a purchased schematic for reference only.

Page 37

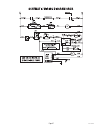

Page 37 10067 080200

Page 38

Page 38 10067 080200 g 8 /blk whi/grn whi/blu t1 t5 t3 t4 t2.