- DL manuals

- Bunn

- Kitchen Appliances

- TU3

- Operating & Service Manual

Bunn TU3 Operating & Service Manual

Summary of TU3

Page 1

Tu3 h o t l i q u i d ! Caution operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com 10225.0000n 03/04 ©1987 bunn-o-matic corporation.

Page 2

Page 2 contents introduction ..................................................................... 2 warranty .......................................................................... 2 user notices .................................................................... 3 electrical & plumbing require...

Page 3: Warning

Page 3 10225 031804 00831.0000f 3/98 ©1988 bunn-o-matic corporation read the entire operating manual before buying or using this product this appliance is heated whenever connected to a power source failure to comply risks equipment damage, fire, or shock hazard fill water tank before turning -on th...

Page 4

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. 120v model brewers require 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. "a" model brewers require 2-wire, grounded service rated 240 volts ac...

Page 5

Page 5 initial set-up caution - the brewer must be disconnected from the power source throughout the initial set-up, except when specified in the instructions. 1. Remove the top lid from the brewer. 2. Rotate the control thermostat knob fully counterclockwise to the "off" position and replace the to...

Page 6

Page 6 initial set-up (cont.) 29. If not, unplug the brewer and remove the top lid. 30. Adjust the delay knob of the timer on the right side of the hood as required. Replace the top lid and plug in the brewer. 31. Repeat steps 27-30 until the proper dilution timing is achieved. Adjusting brew volume...

Page 7

Page 7 10225 031804 auto sweetener set-up (cont.) 5. Plug brewer into the power source. 6. Place an empty reservoir under the dilution nozzle of the brewer. 7. Close the adjustment valve on the rear of the brewer fully (clockwise), then open (counterclockwise) 1/2 turn. 8. Set the selector switch to...

Page 8

Page 8 10225 031804 cleaning (cont.) 2. Place the on/off switch in the "off" position. Remove and thoroughly rinse the sprayhead. The holes must be open and clear of any mineral deposits. Wipe the sprayhead panel clean with a damp cloth. 3. Insert the deliming spring into the sprayhead fitting until...

Page 9

Page 9 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 10

Page 10 troubleshooting (cont.) problem probable cause remedy brew cycle will not start (cont.) water is not hot dilution cycle will not start 4. On/off switch 5. Start switch 6. Brew timer 7. Brew solenoid valve 8. Internal flow control (.195 gpm) 1. Limit thermostat caution - do not eliminate or b...

Page 11

Page 11 troubleshooting (cont.) problem probable cause remedy dilution cycle will not start (cont.) inconsistent beverage level in dis- penser consistently high or low beverage level in the dispenser 4. Dilution solenoid valve 1. Internal flow control (.195 gpm) 2. Syphon system 3. Lime build-up cau...

Page 12

Page 12 troubleshooting (cont.) problem spitting or excessive steaming drip-out time too long dripping from sprayhead water flows into tank continuously (on/off switch "on") water flows into tank continuously (on/off switch "off") probable cause 1. Lime build-up caution - tank and tank compo- nents ...

Page 13

Page 13 troubleshooting (cont.) problem beverage overflows dispenser weak beverage probable cause 1. Dispenser 2. Brew timer 3. Brew solenoid valve 4. Dilution timer 5. Dilution solenoid valve 1. Filter type 2. Tea 3. Sprayhead 4. Funnel loading 5. Water temperature remedy the dispenser must be comp...

Page 14

Page 14 remedy the bunn ® paper filter must be centered in the funnel and the bed of grounds leveled by gently shak- ing. The nut on the solenoid(s) must be tight or it will vibrate during opera- tion. Plumbing lines should not be rest- ing on the counter top. (a) the brewer must be connected to a c...

Page 15

Page 15 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 16

Page 16 service (cont.) brew solenoid valve fig. 2 brew solenoid valve p1277.40 location: viewing the brewer from the rear the brew sole- noid valve is mounted on the left side of the mounting bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white/violet an...

Page 17

Page 17 service (cont.) brew timer (early models) fig. 4 brew timer p1276.40 location: the brew timer is located in the hood. It consists of the left dial plate and circuit board. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the wires from terminals tl3, tl4, & tl5 of th...

Page 18

Page 18 10225 071500 service (cont.) digital brew timer (late models) fig. 6 digital brew timer p2202.40 location: the timer is located in the hood, on the left side. Test procedure:. Note: do not remove or install wires while timer board is installed. Pressure applied to one side may cause damage t...

Page 19

Page 19 10225 103000 to increase a brew volume, place the on/off switch in the "on" position, press and hold the start switch until three clicks are heard. Release the switch and press it again one or more times. (failure to re- lease the switch within two seconds after the third click causes the vo...

Page 20

Page 20 service (cont.) control thermostat fig. 8 control thermostat p1276.40 location: the control thermostat is located inside hood on the right side just behind the dilution timer. Test procedures: 1. Disconnect the brewer from the power source. 2. Locate the blue/black wire on the control thermo...

Page 21

Page 21 service (cont.) dilution solenoid valve fig. 10 dilution solenoid valve p1277.40 location: viewing the brewer from the rear the dilution so- lenoid is mounted on the center of the solenoid mount- ing bracket which is secured to the trunk base. Test procedure: 1. Disconnect the brewer from th...

Page 22

Page 22 service (cont.) dilution timer fig. 12 dilution timer p1276.40 location: the dilution timer is located inside the hood on the right side. It consists of the dial plate with two dials and circuit board. Test procedure: 1. Disconnect the brewer from the power source and remove the wires from t...

Page 23

Page 23 service (cont.) limit thermostat fig. 14 limit thermostat p1276.40 location: the limit thermostat is located inside the hood on the tank lid. Test procedure: 1. Disconnect the brewer from the power source and remove the black wire from the limit thermostat. 2. With a voltmeter, check the vol...

Page 24

Page 24 qu ick br ew service (cont.) on/off switch (selector switch - optional) fig. 16 on/off switch p1187.40 location: the on/off switch is located in the front of the hood, above and to the left of the brew funnel. Test procedure: brewers w/out half batch option 1. Disconnect the brewer from the ...

Page 25

Page 25 removal and replacement: 1. Remove the wires from the switch terminals. 2. Compress the clips inside the hood and gently push the switch through the opening. 3. Push the new switch into the opening and spread the clips to hold the switch captive in the hood. 4. Refer to fig. 17 when reconnec...

Page 26

Page 26 start switch h o t l i q u i d ! Caution fig. 18 start switch p1187.40 location: the start switch is located in the front of the hood, above and to the right of the brew funnel. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the wires from all four terminals. 3. Ch...

Page 27

Page 27 service (cont.) 10225 031804 location: viewing the brewer from the rear the sweetener solenoid is mounted on the right side of the solenoid mounting bracket which is secured to the trunk base. Test procedure: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check the volt...

Page 28

Page 28 service (cont.) tank heater fig. 23 tank heater terminals p1284 fig. 22 tank heater location: the tank heater is located inside the tank and se- cured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the voltage across the black and...

Page 29

Page 29 10225 071500

Page 30

Page 30 10225 071500

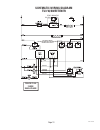

Page 31: Schematic Wiring Diagram

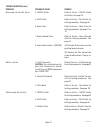

Page 31 10225 021804 27432.0000d 02/04 © 1996 bunn-o-matic corporation brn/whi whi/blu whi/vio whi whi whi/blu whi/yel whi/orn schematic wiring diagram tu3 w/sweetener 120 volts ac 2 wire single phase ready indicator blu/blk blk selector switch unsweet/off/sweet.

Page 32

Page 32 10225 071500