- DL manuals

- Bunn

- Kitchen Appliances

- TU3Q

- Operating & Service Manual

Bunn TU3Q Operating & Service Manual

Summary of TU3Q

Page 1

Tu3q qu ick br ew operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com 10288.0000n 03/04 ©1988 bunn-o-matic corporation.

Page 2

Page 2 contents user notices .................................................................... 3 electrical & plumbing requirements ............................... 4 initial set-up .................................................................... 5 auto sweetener set-up ..........................

Page 3: Warning

Page 3 00831.0000f 3/98 ©1988 bunn-o-matic corporation read the entire operating manual before buying or using this product this appliance is heated whenever connected to a power source failure to comply risks equipment damage, fire, or shock hazard fill water tank before turning -on thermostat or c...

Page 4

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. 120v model brewers require 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. "a" model brewers require 2-wire, grounded service rated 230 volts ac...

Page 5

Page 5 10288 031604 1. Remove the shipping cap from the bulkhead fitting on the rear of the brewer. 2. Attach the flare fitting from the short piece of tubing on the strainer/flow control (supplied) to the water inlet fitting at the rear of the brewer. 3. Flush the water line and securely attach it ...

Page 6

Page 6 auto sweetener set-up (cont.) product for at least 4 minutes without shutting off. Some pump systems shut off after a few minutes of continu- ous running. 4. Plug brewer into the power source. 5. Place an empty reservoir under the dilution nozzle of the brewer. 6. Close the adjustment valve o...

Page 7

Page 7 10288 031604 operating controls a. On/off switch on - placing the switch in the left position allows the start switch to activate a timed brew cycle for three gallons of tea. Off - placing the switch in the right position stops the brew cycle. Stopping a brew cycle after it has been started w...

Page 8

Page 8 tea brewing 1. Begin each brew cycle with a clean empty brew funnel and server. (be sure the server lid doesn’t interfere with the flow of dilution water.) 2. Insert a bunn® filter into the funnel. 3. Pour the packet of loose fresh tea leaves into the filter. Approximately three to five ounce...

Page 9

Page 9 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 10

Page 10 troubleshooting (cont.) problem probable cause remedy brew cycle will not start (cont.) water is not hot dilution cycle will not start inconsistent beverage level in dispenser 6. Brew timer 7. Brew solenoid valve 1. Limit thermostat caution - do not eliminate or by- pass limit thermostat or ...

Page 11

Page 11 troubleshooting (cont.) problem probable cause remedy consistently high or low beverage level in the dispenser spitting or excessive steaming drip-out time too long sweetener is not working 1. External strainer/flow control (.750 gpm) 1. Lime build-up caution - tank and tank compo- nents sho...

Page 12

Page 12 troubleshooting (cont.) problem dripping from sprayhead water flows into tank continuously (on/off switch "on") (unsweet/off/sweet switch in "unsweet" or "sweet" position) water flows into tank continuously (on/off switch "off") (unsweet/off/sweet switch in "unsweet" or "sweet" position. Bev...

Page 13

Page 13 troubleshooting (cont.) problem weak beverage (cont.) dry tea leaves remain in the funnel brewer is making unusual noises probable cause 4. Funnel loading 5. Water temperature 6. Low brew water volume 1. Funnel loading 1. Solenoid(s) 2. Plumbing lines 3. Water supply 4. Tank heater remedy th...

Page 14

Page 14 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 15

Page 15 service (cont.) brew solenoid valve fig. 2 brew solenoid valve p2087.40 location: viewing the brewer from the top, the brew sole- noid valve is mounted on the right side of the brewer. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white/violet and white/g...

Page 16

Page 16 service (cont.) brew timer (early models) fig. 4 brew timer p2088.50 location: the brew timer is located in the hood. It consists of the dial plate and circuit board. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the wires from terminals tl3, tl4, & tl5 of the tim...

Page 17

Page 17 service (cont.) digital brew timer (late models) fig. 6 digital brew timer p2200.50 location: the timer is located inside the hood, on the left side. Test procedure. Note: do not remove or install wires while timer board is installed. Pressure applied to one side may cause damage to the boar...

Page 18

Page 18 service (cont.) tl1 - whi to power cord (100v & 120v) or red to power connector (230v) and whi to on/off switch (100v & 120v) or red to on/off switch (230v) tl2 - whi/vio to brew solenoid and whi/vio to on/off switch tl3 - whi/orn to start switch tl4 - whi/grn to brew solenoid tl5 - whi/yel ...

Page 19

Page 19 service (cont.) control thermostat fig. 8 control thermostat p2200.50 location: the control thermostat is located inside hood on the right side. Test procedures: 1. Disconnect the brewer from the power source. 2. Locate the blue/black wire on the control thermo- stat. 3. With a voltmeter, ch...

Page 20

Page 20 service (cont.) limit thermostat fig. 10 limit thermostat p2200.50 location: the limit thermostat is located inside the hood on the tank lid. Test procedure: 1. Disconnect the brewer from the power source and remove the black wire from the limit thermostat. 2. With a voltmeter, check the vol...

Page 21

Page 21 service (cont.) on/off switch fig. 12 on/off switch p2092.40 location: the on/off switch is located in the front of the hood, above and to the left of the brew funnel. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove the black and white/violet wires from the switch t...

Page 22

Page 22 if continuity is present as described, reconnect the wires, the switch is operating properly. If continuity is not present as described, replace the switch. Removal and replacement: 1. Remove the wires from the switch terminals. 2. Compress the clips inside the hood and gently push the switc...

Page 23

Page 23 service (cont.) tank heater fig. 16 tank heater location: the tank heater is located inside the tank and se- cured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the voltage across the black and white wires on 100 volt and 120 vol...

Page 24

Page 24 service (cont.) 10288 031604 location: viewing the brewer from the front, the sweetener solenoid is mounted on the left side of the solenoid mounting bracket which is secured to the bottom base housing. Test procedure: 1. Disconnect the brewer from the power source. 2. With a voltmeter, chec...

Page 25

Page 25 10288 031604 service (cont.) off/selector switch (sweetener option) fig. 20 off/selector switch p2845.40 location: the off/selector switch is located in the front of the hood, above and to the left of the brew funnel. Test procedure: 1. Disconnect the brewer from the power source. 2. With a ...

Page 26

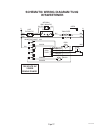

Page 26 10288 110503 schematic wiring diagram tu3q (optional) ready indicator blu/blk blk sw. & thermostat limit thermostat l1 blk blu/blk blk green tank heater n whi whi whi whi sw2 "keep warm heater" sw1 blk whi/vio whi/vio whi whi whi/ora whi/grn whi/yel sol 1 2 3 4 5 brew timer 10287.0000c 10/03...

Page 27: W/sweetener

Page 27 10288 031604 limit thermostat blu/blk tank heater "keep warm" heater start l1 n blk whi blk brew timer whi whi green whi/yel whi/ora blk whi/grn whi/vio whi brn/whi whi/vio whi whi schematic wiring diagram tu3q w/sweetener 120 volts ac 2 wire single phase thermostat sol 1 2 3 4 5 sol whi/grn...